In this week there is an opportunity to make machine. So, the work is divided into the two weeks. Week 9 is to make the mechanical design and Week 10 is proposed for Mechanical design.

Goal

Goal for this week is to have the plan to make the design for machine and the test the availability of the problem. The as well as testing the existing options available for solving the problem statement.

Problem Statement

Make the machine to draw Rangoli, which is the traditional art form.

Plan

What I did this week?

This week is all about planning and procuring the things. While having the team discussion I decided to do following tasks.

- Project Co-ordination

- Sketching rough models for machine

- Material Procurement

- Electronics Design

- Finding proper firmware for the our RAMBO board

Project Co-ordination

Project coordination stages usually include creating an overall goal, planning essential tasks, plus executing and controlling the project. Project co-ordination is as important to keep the project alive and achieve the goals. This includes the communication between the teams to reach the short-term. Project should respect time frame, if not then it will be disastrous project will collapse and the resources will be wasted. To successfully crack reach the goal, it is necessary for the project coordinator have the knowledge of the expertise of every member in team and their skillets.

I made a WhatsApp group which will keep everyone updates with the process we till date. WhatsApp group

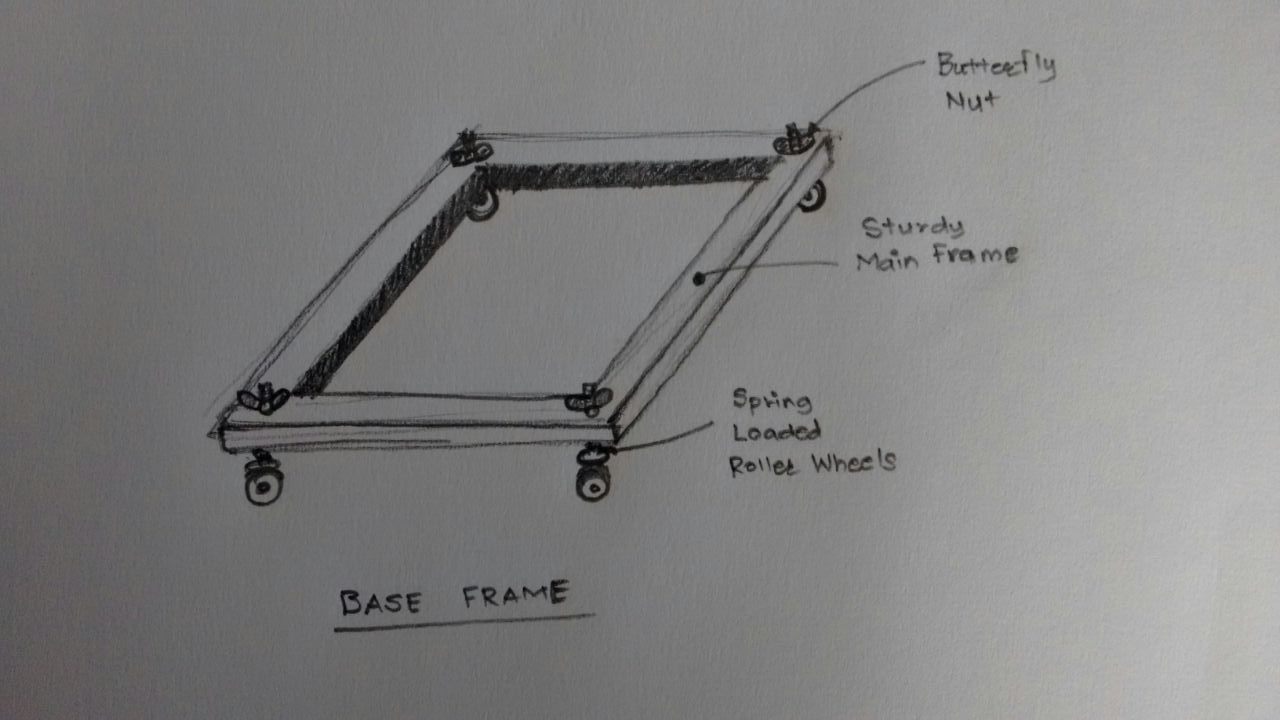

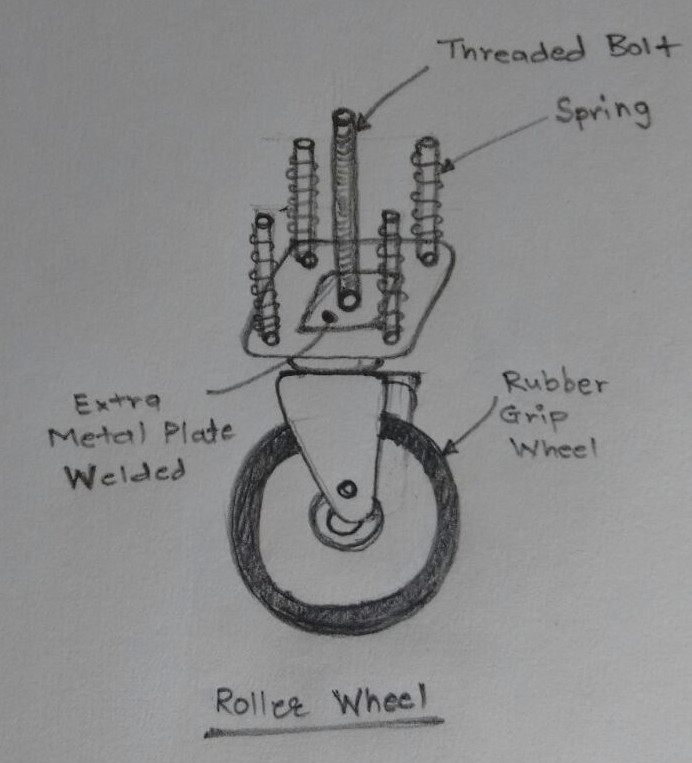

Sketching rough models for machine

Sketching the the thoughts is necessary to make others visualize what you want to do. As per our team discussion I made the above sketches which depicts the main chassis and the wheels to maneuverer the machine. As well as to have the level adjustments there's design for special wheels with the nut-bolts. Nut-bolts when tighten and loosen it helps to move particular point in the plane to go up and down.

Material Procurement

Procuring the material are also plays a major role in respecting the time frame. It is very important get the hold of the material right-on-time and right-in-quantity so the team can work and flow control will be uninterrupted.

I did all the material procurement part by going directly into the market which reduced the lead time and I got many options to choose from real-time. Walking directly into the markets fetched another advantages like I got plenty of contacts to get the materials even though the contacts generated are not useful for this project directly but which may help me and my team in next projects to source the material from.

Electronics Design

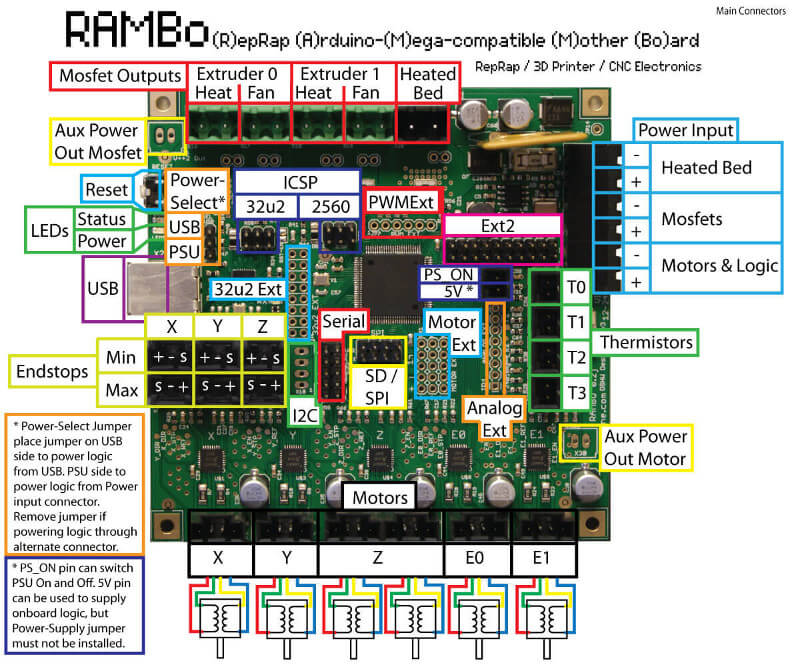

Previously we thought of having the machine brain as the controller board designed and the having nodes to communicates with each other to send signals here and there. Using nodes approach is really modular, means node can be added and omitted any point of time whenever is required, a very little change in code makes the system to go to next higher stage.

The terminology of 'stage' means one actuator which results into one more degree of freedom considered as a stage. In our case machine is of two stage. One stage which moves the access in X direction and other in Y direction. Multiple stages means more complex machine which can handle the very complex jobs.

To respect the time frame we have decided to go with the RAMBO board which is attached here. It is the board which has got the Atmega328 and the motor drivers on a single board which reduces the hardware complexity as well as time required for the troubleshooting the things.

Board includes all the connectors for the connecting motors, end effectors and difference sensors.

Finding proper firmware for the our RAMBO board

Every electronic thing you imagine there's always piece of code working on it's background which makes the machine intelligent and can handles the errors and respond them with debugging messages or the counter measures. RAMBO is the one-stop solution for all our needs so, I was sure about the software's availability to make the system work. Google is best buddy to start with, he helped me a lot to decide and say yes, RAMBO will be at the heart of the machine. It hosts the processing power and ports for required actuator actions.

When we decided to go for the RAMBO I've studied the board architecture and the capabilities and the availability of the firmware for running the machine. It is one of the most popular 3D printer controller board available in the market. There are plenty of the 3D printer firmwares available which can be easily altered to make our machine work.

In next week will be actually developing or tweaking the codes and burning it on micro-controllers and testing the actuators.