Desgning a Table

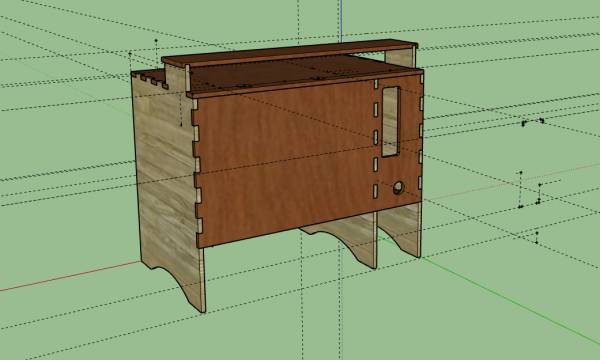

This week’s assignment was to make something big, using a CNC machine. So in fablab vestmannaeyjar we recently received few new computers and for a while now the tables we’ve been using for the computers are not up to standards.

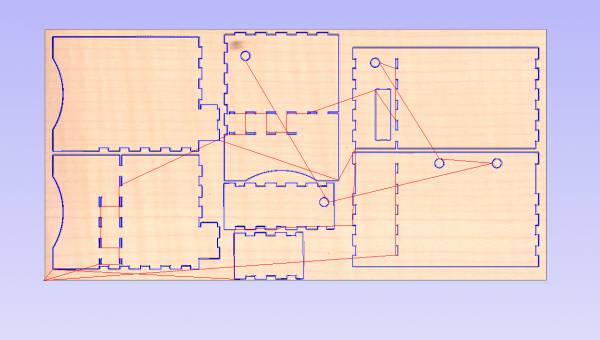

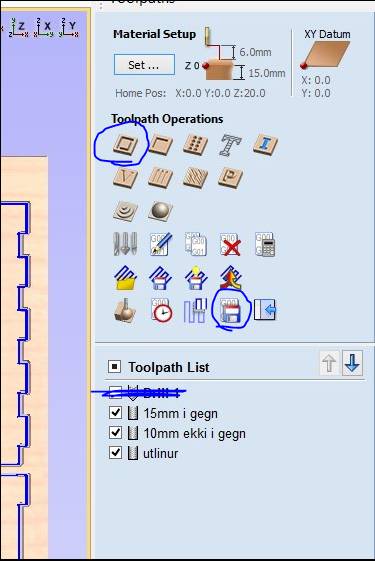

For the CNC machine we use Vcarve create the toolpaths. Knowing that, I decided to use sketchup for you can easily import your components into vcarve.

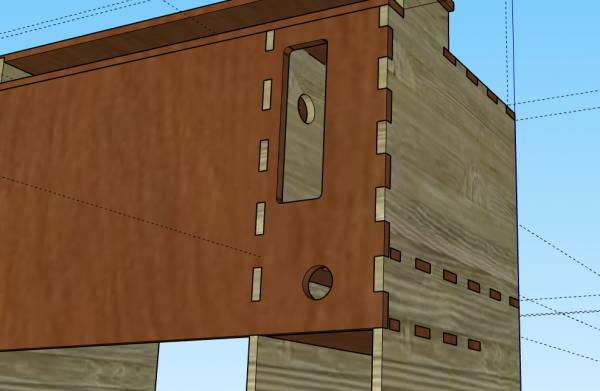

Knowing almost nothing in sketchup I followed a tutorial on Youtube on how to make box joints for cutting and that gave me a really good base to work with.

It was able to give a pretty good image of the table and then I made all of the parts a component (triple click the object and press G, then ENTER) I saved it as a .skp version 8 file