Week 5 Assignment: 3D Scanning + 3D Printing

Go back HOME

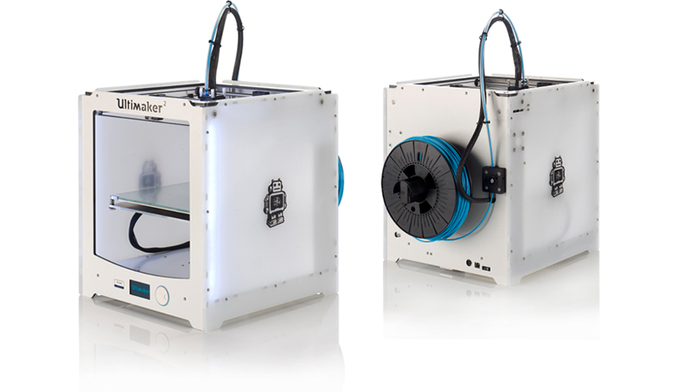

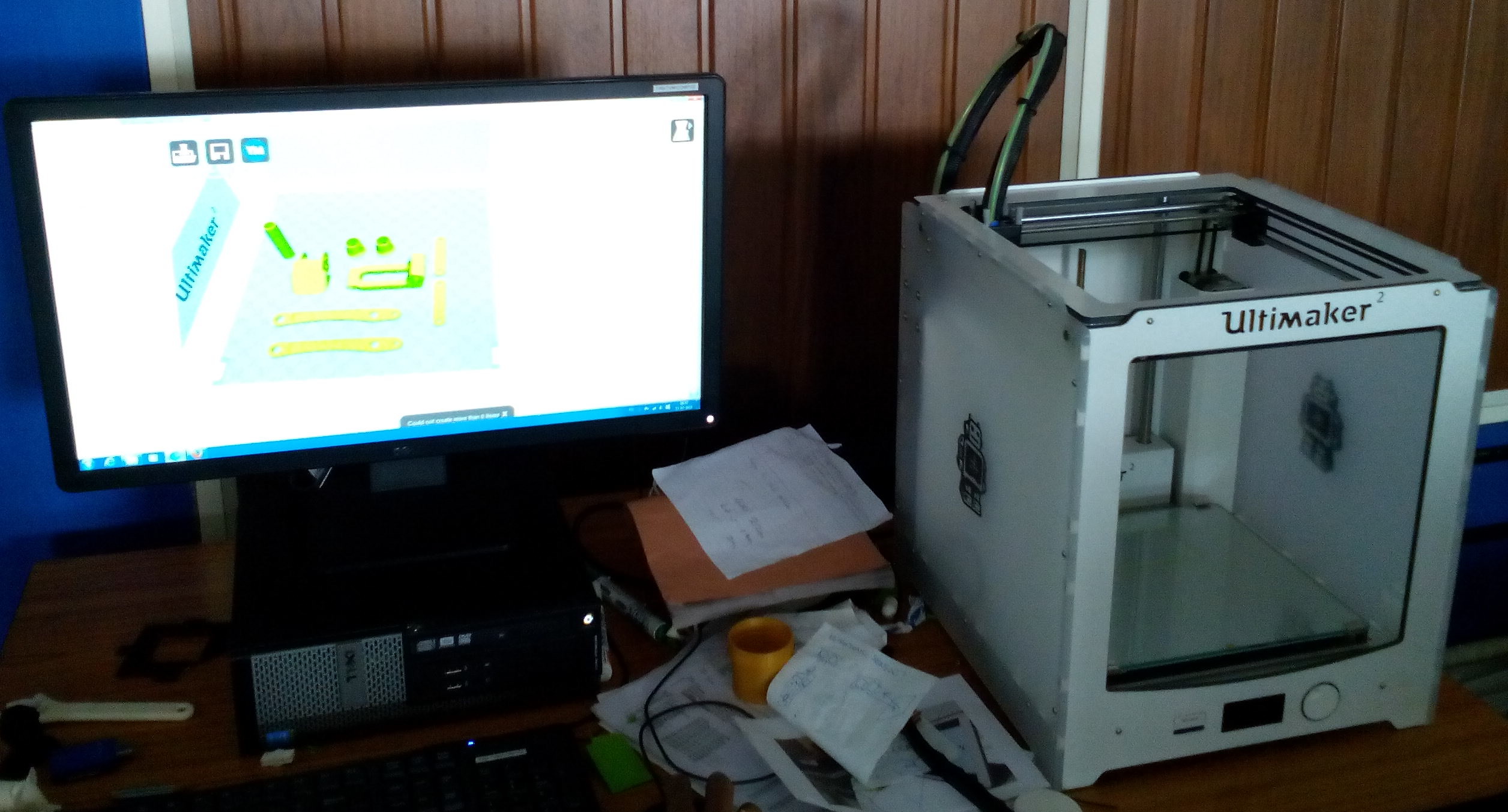

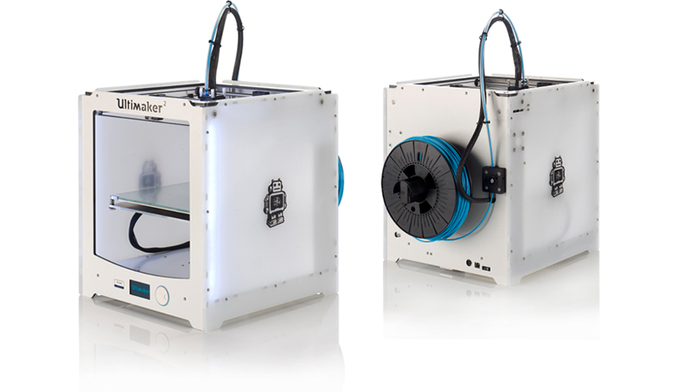

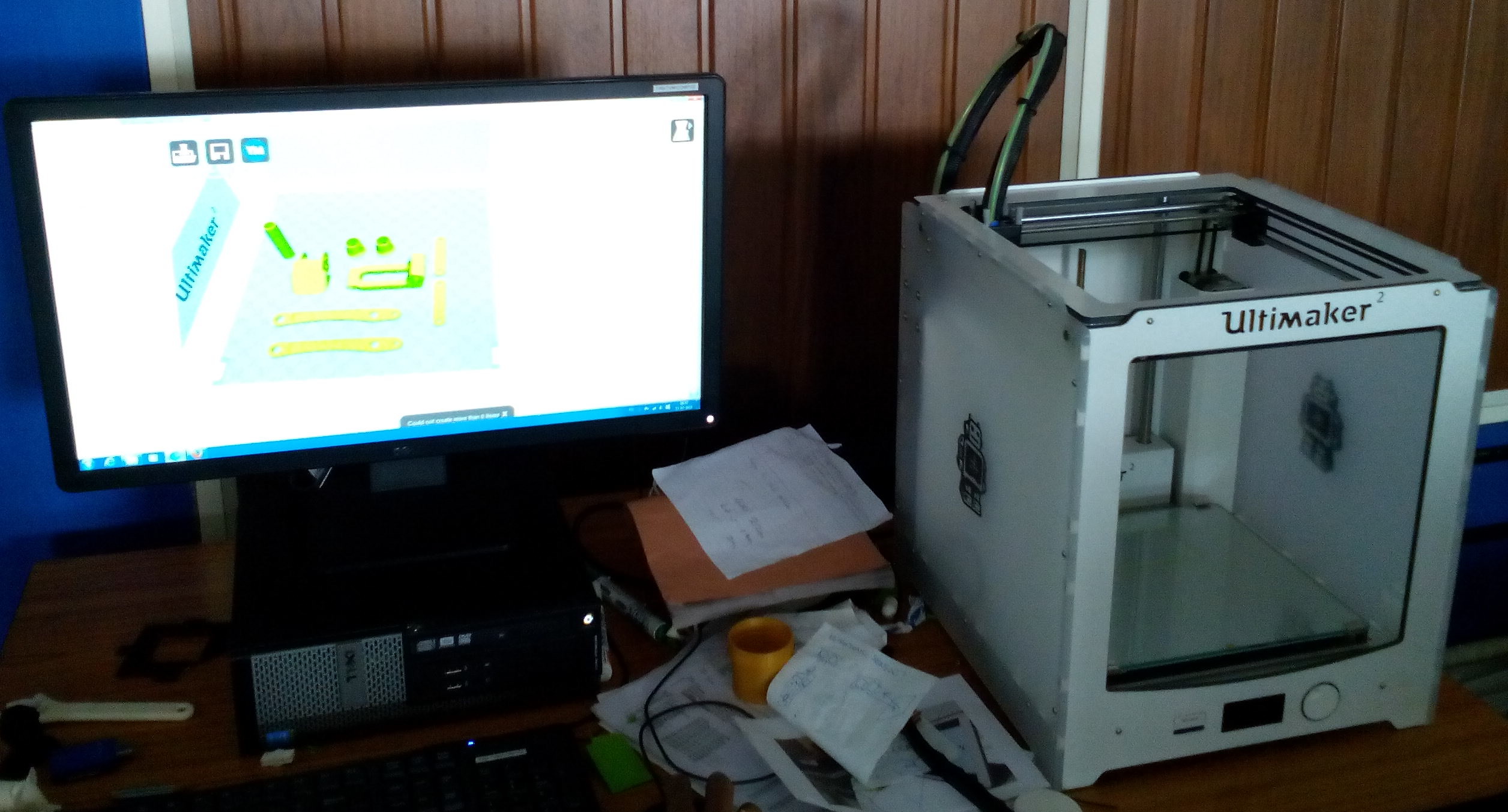

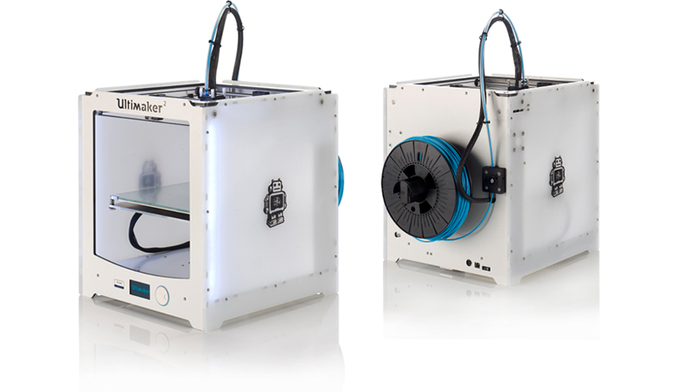

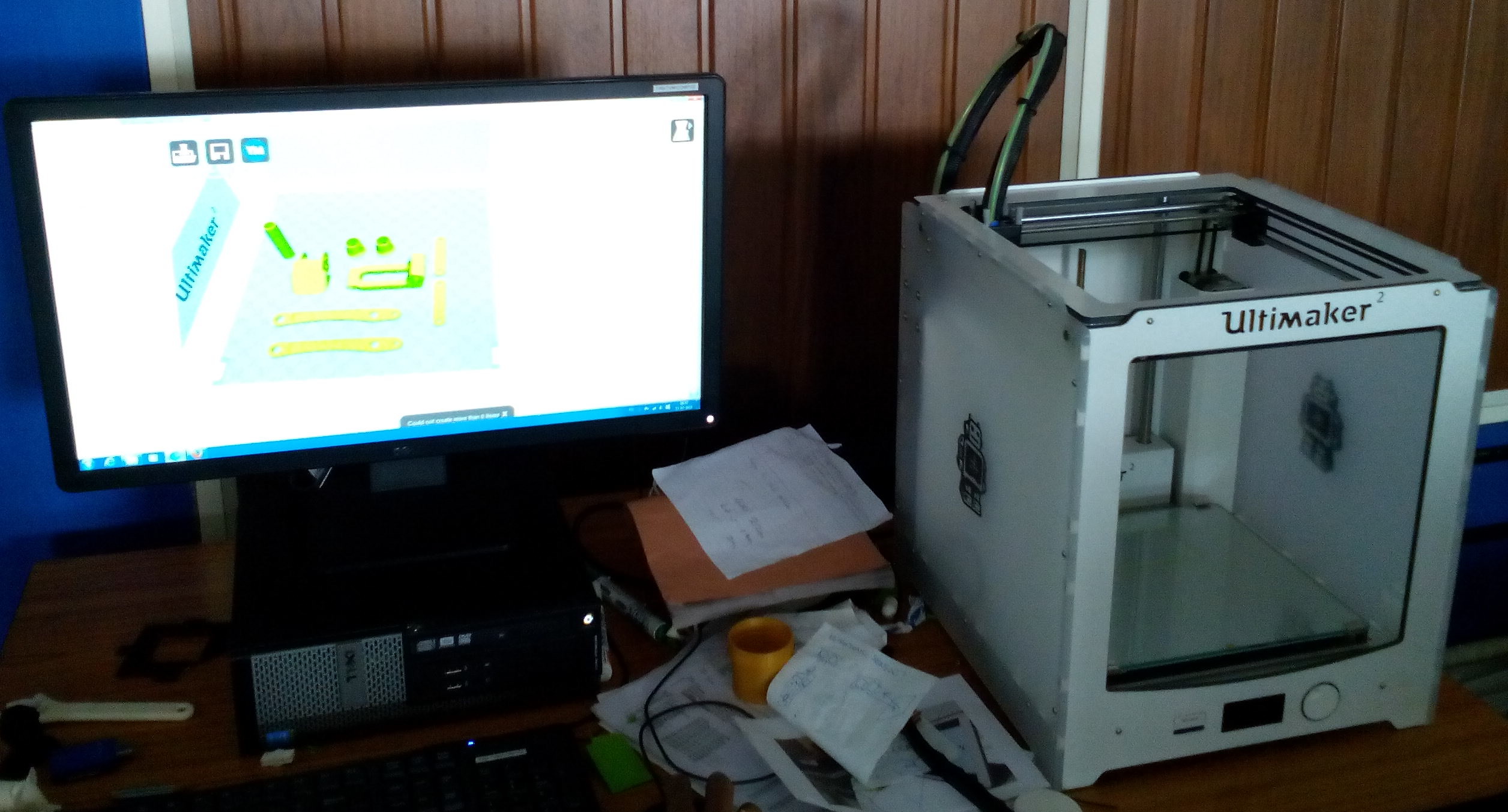

Week 5 of Fab Academy brought us up, close and personal with 3D Printing and 3D Scanning. At our Fab Lab in Kerala (Trivandrum) we have an UltiMaker2 - a widely used open source 3D Printer which is probably one of the most robust machines out there for 3D Printing.

Picture Source: Ultimaker2 (as profiled on Make:)

Task #1: Test the Design Rules for your 3D Printer [Group Project]

Along with a few of my classmates enrolled in Fab Academy 2016; we printed out a "print test" model to see how the 3D Printer would perform given certain constraints (as can be seen on the annotated diagram of our group print):

Please find the original .stl file from this object's page on Thingiverse: http://www.thingiverse.com/thing:1363023

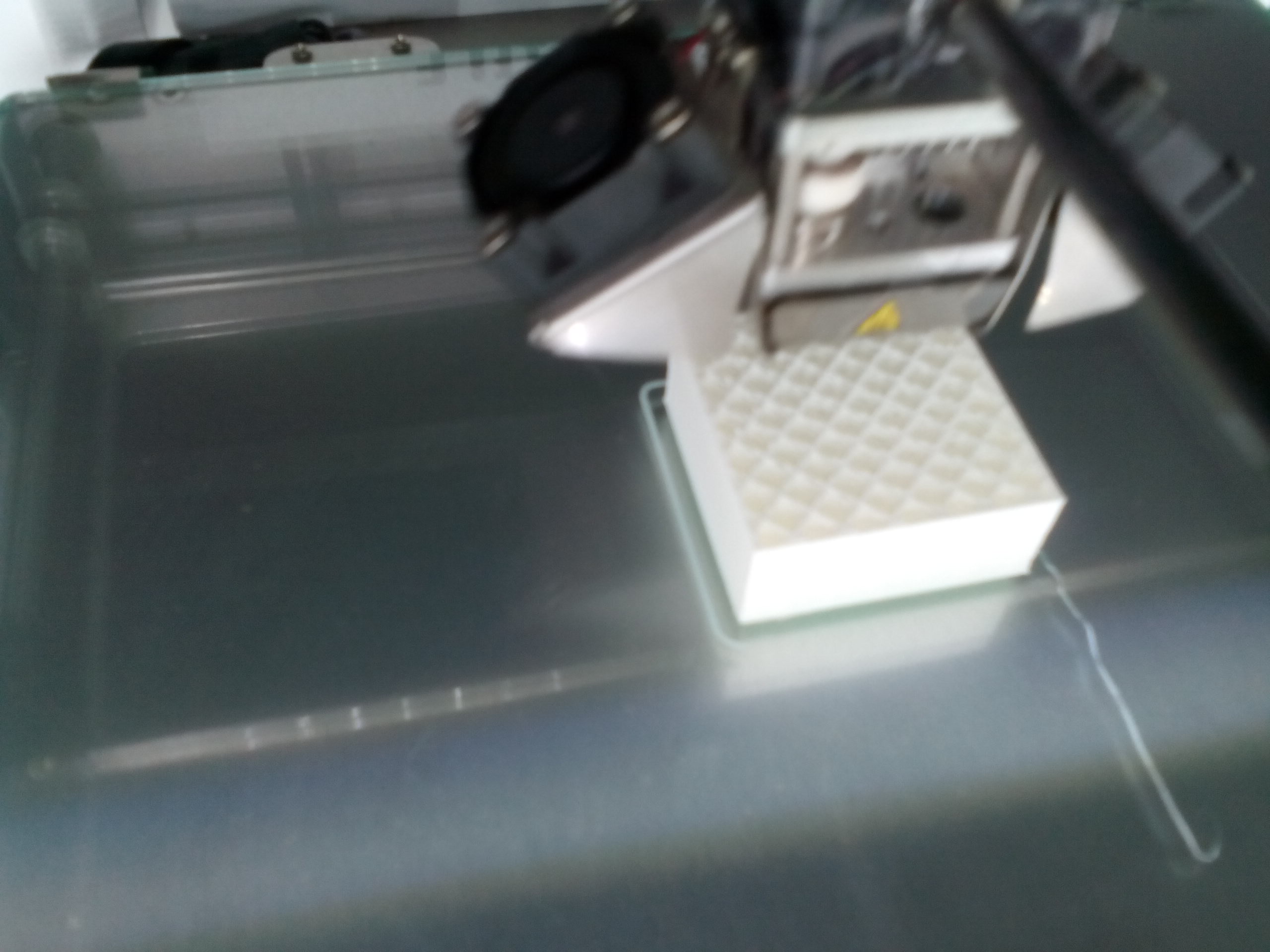

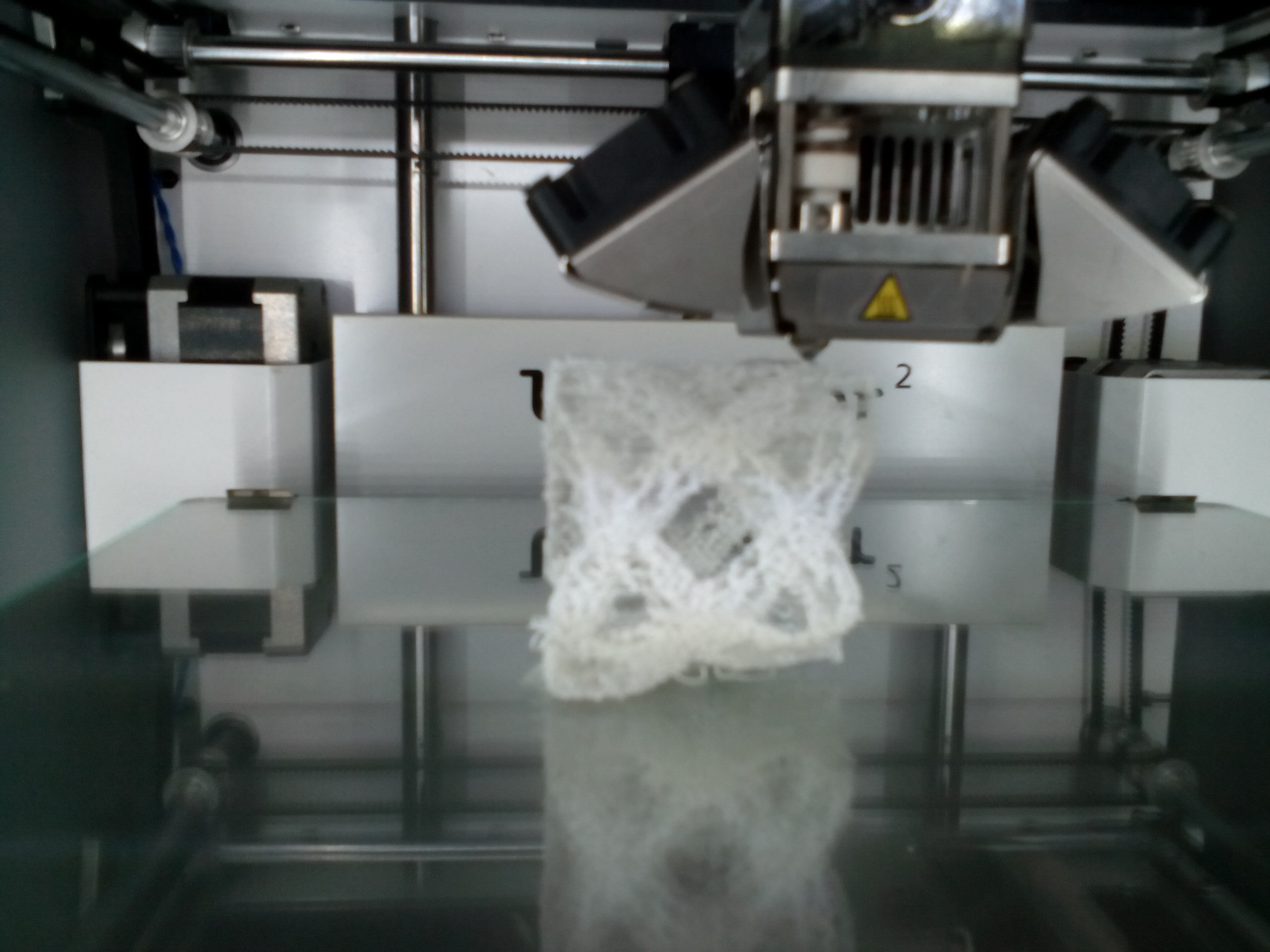

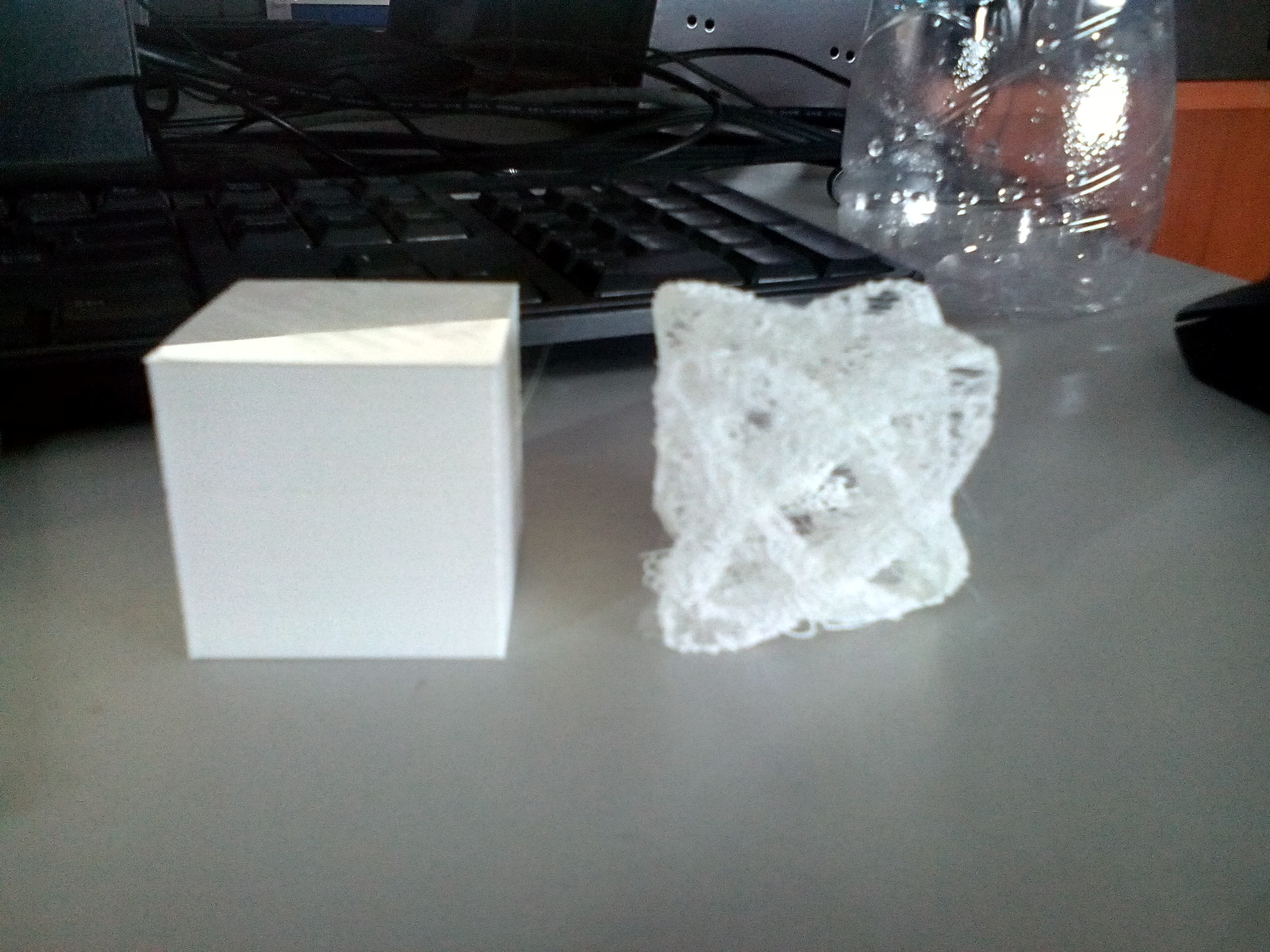

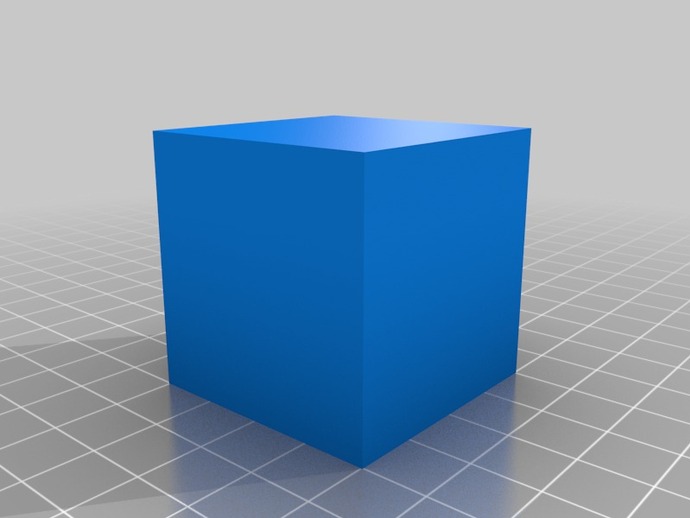

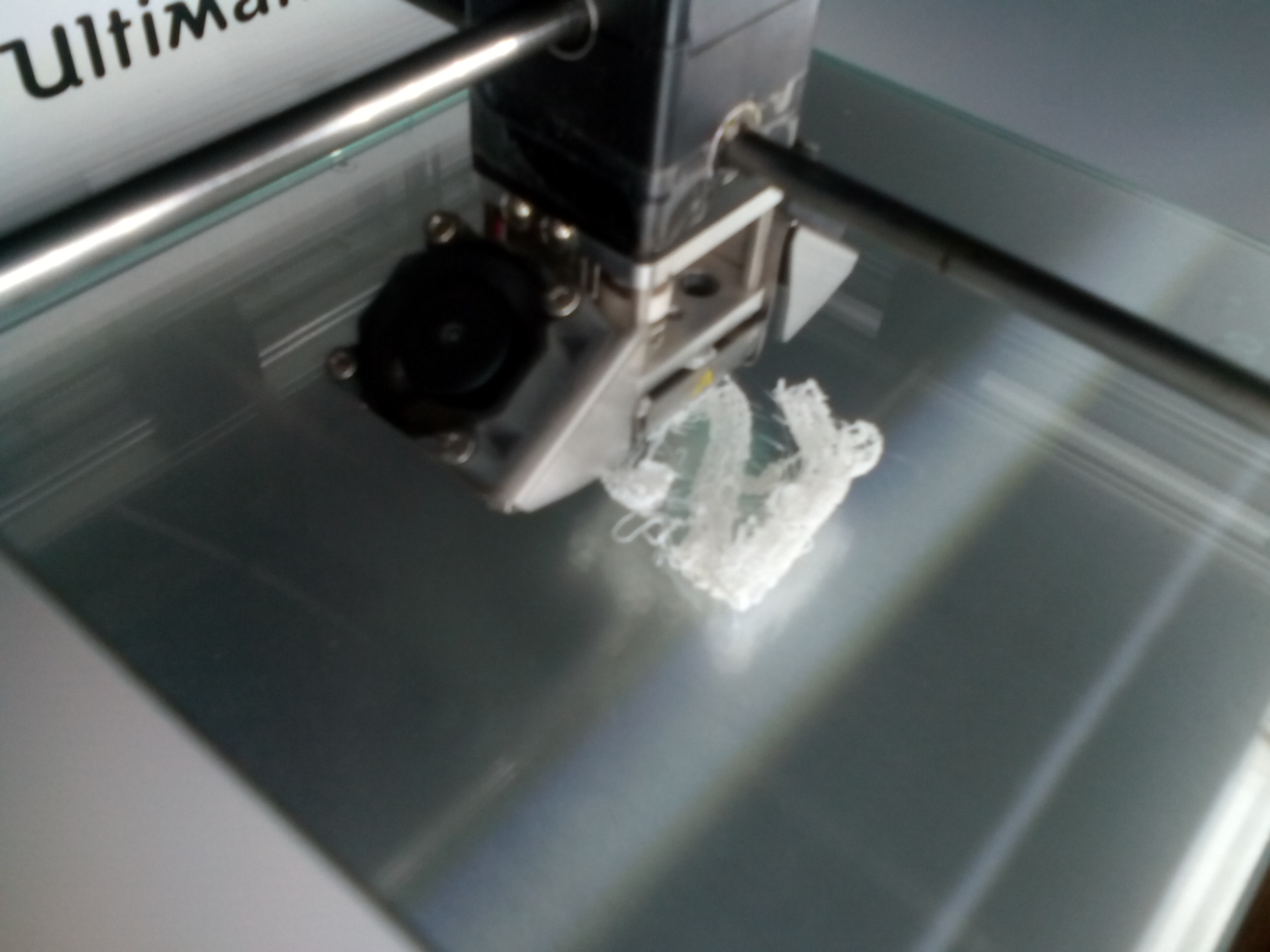

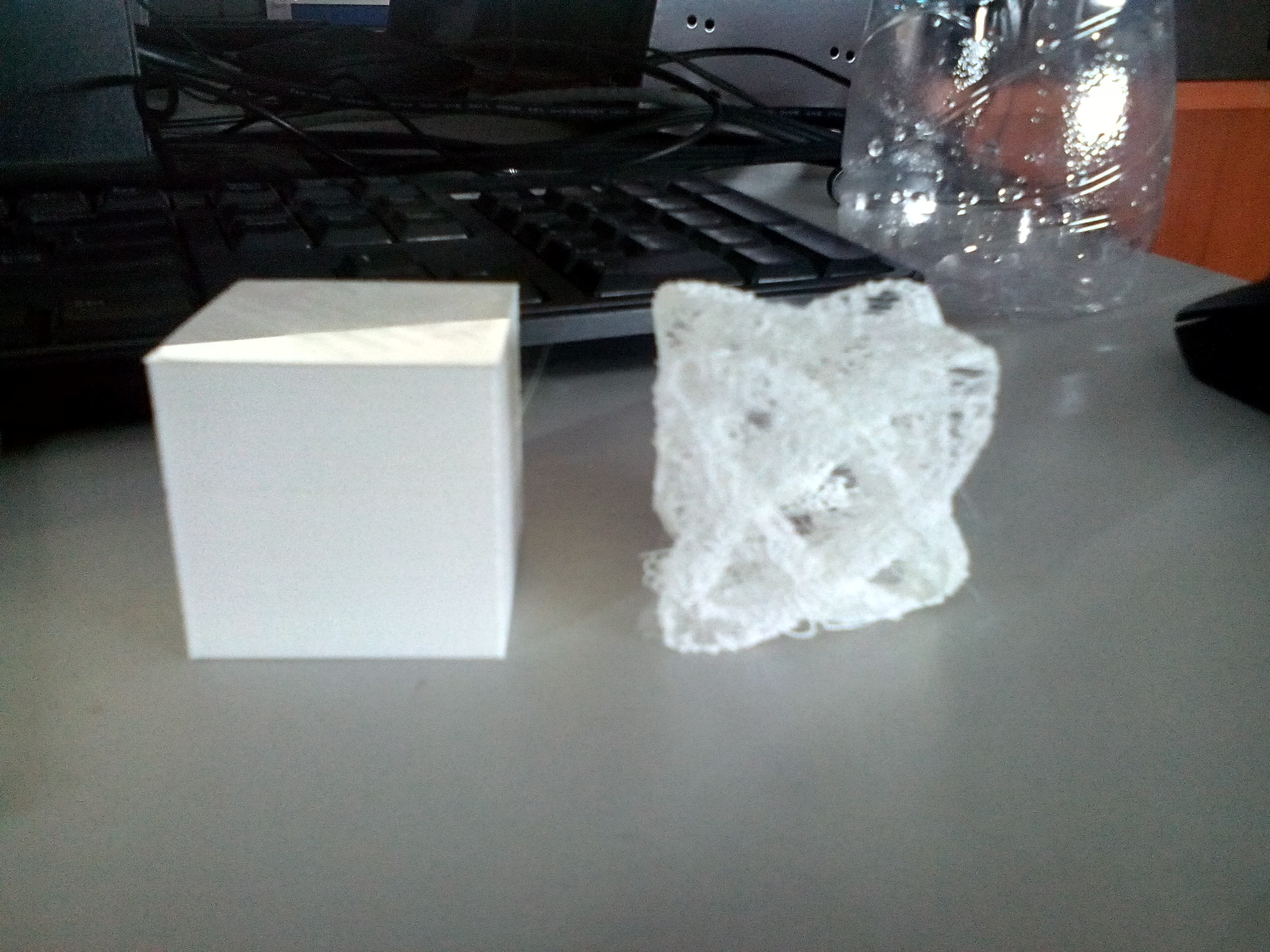

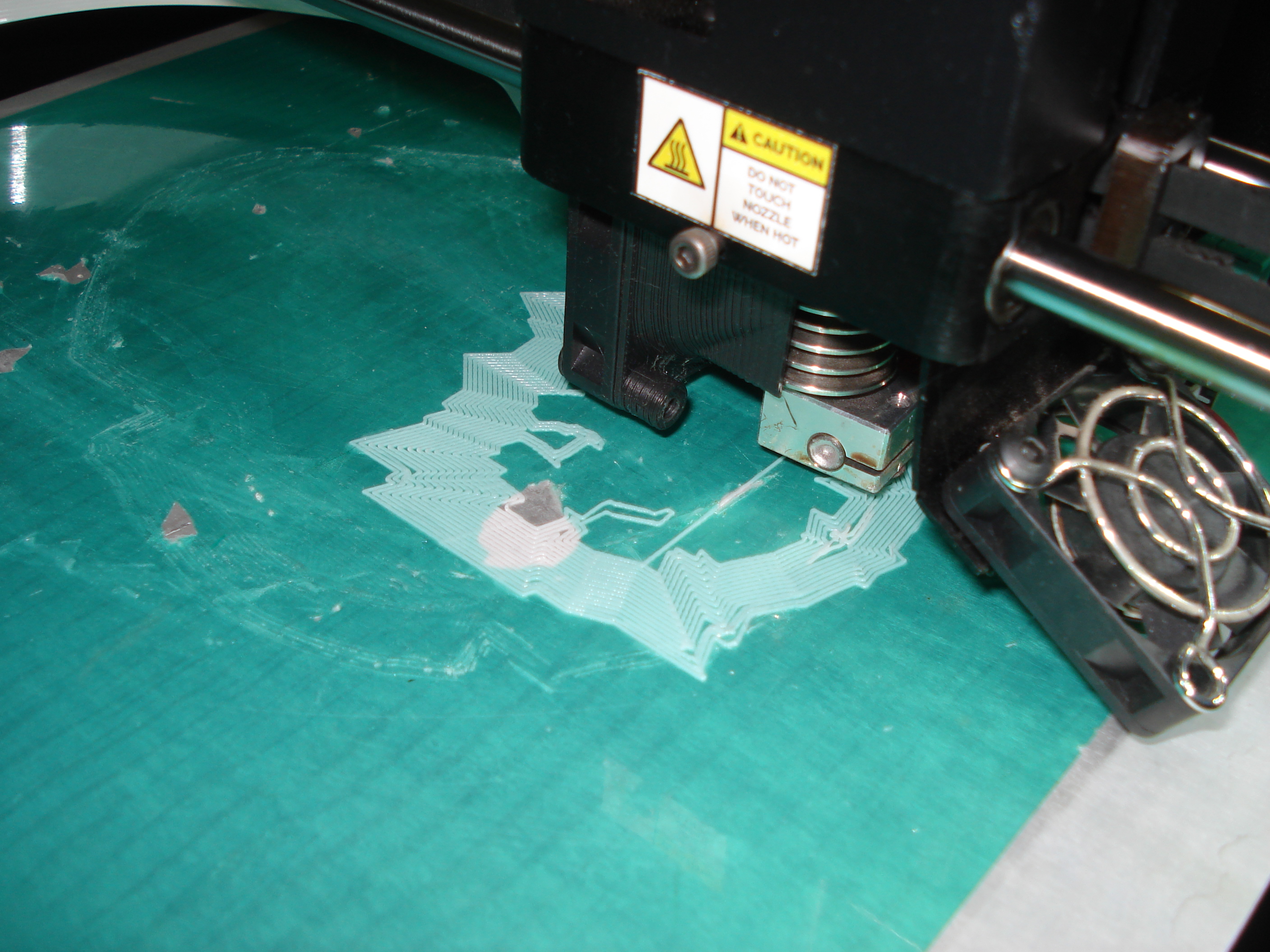

Just for the fun of it; As I was using our Lab's Ultimaker2 for the first time, I wanted to see how the ubiquitous "40mm Cube Test Object" would be printed, so I downloaded the .zip folder containing the .stl file for the "thing" and checked out how the print took place where I deliberately set the 3D Print Infill to only 18%:

Noticing the obvious "lattice-like" pattern that was being applied to the cube's print -- I could see how the image's g-codes were programmed (by the slicer software Cura) in such a way as to speed up the print time --> total print time was only 1.1 hours, as well as to reduce the overall amount of filament used on the print. If I had set the Infill to 100%; I'm sure the print would have taken a lot, lot longer to complete (probably around 4-5 hours I'm guessing)

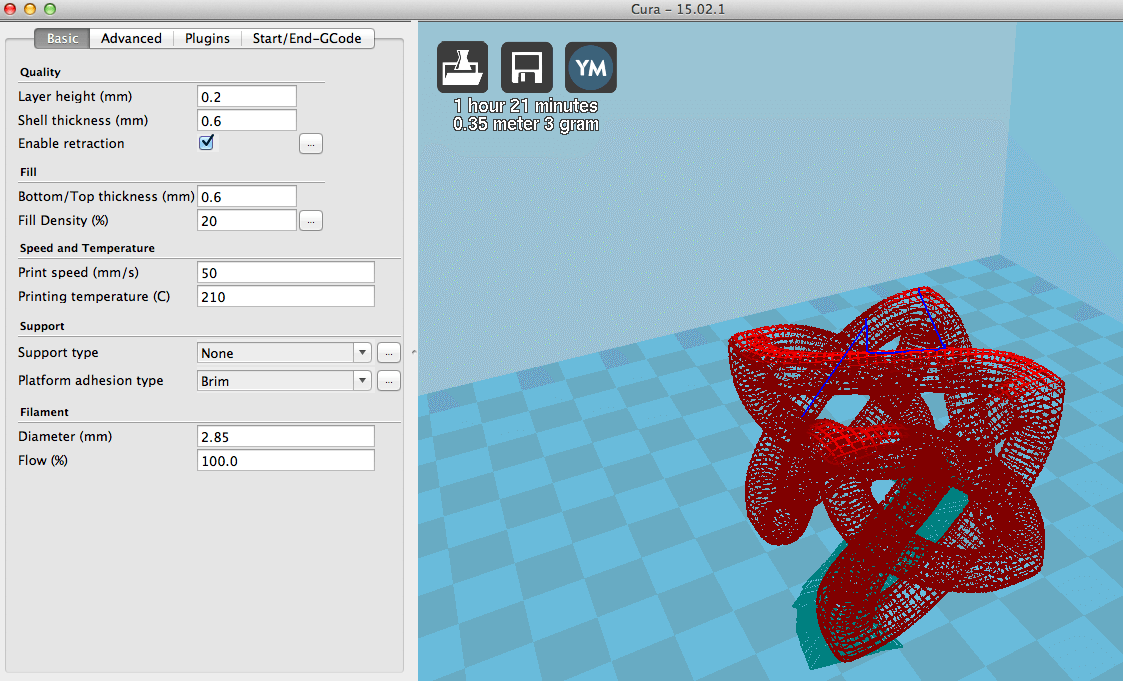

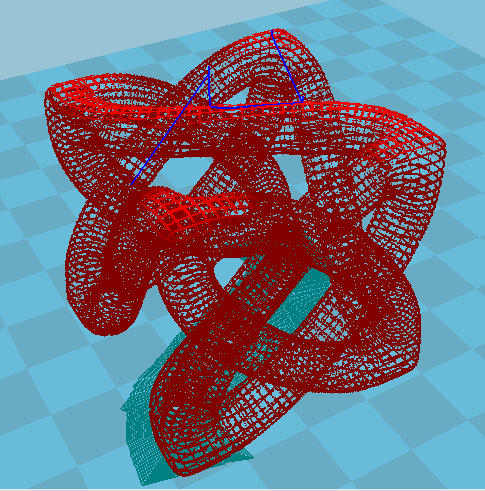

Preparation For Task #2: 3D Print something you could not make subtractively

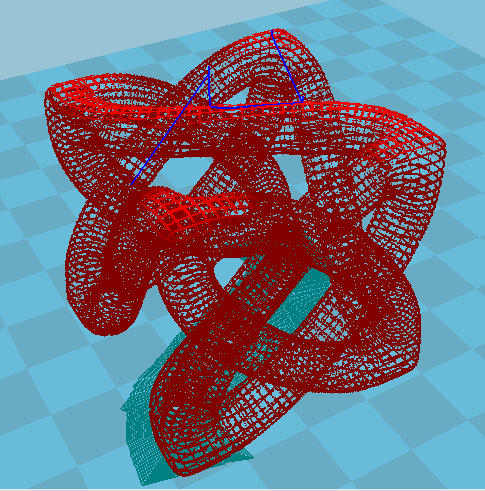

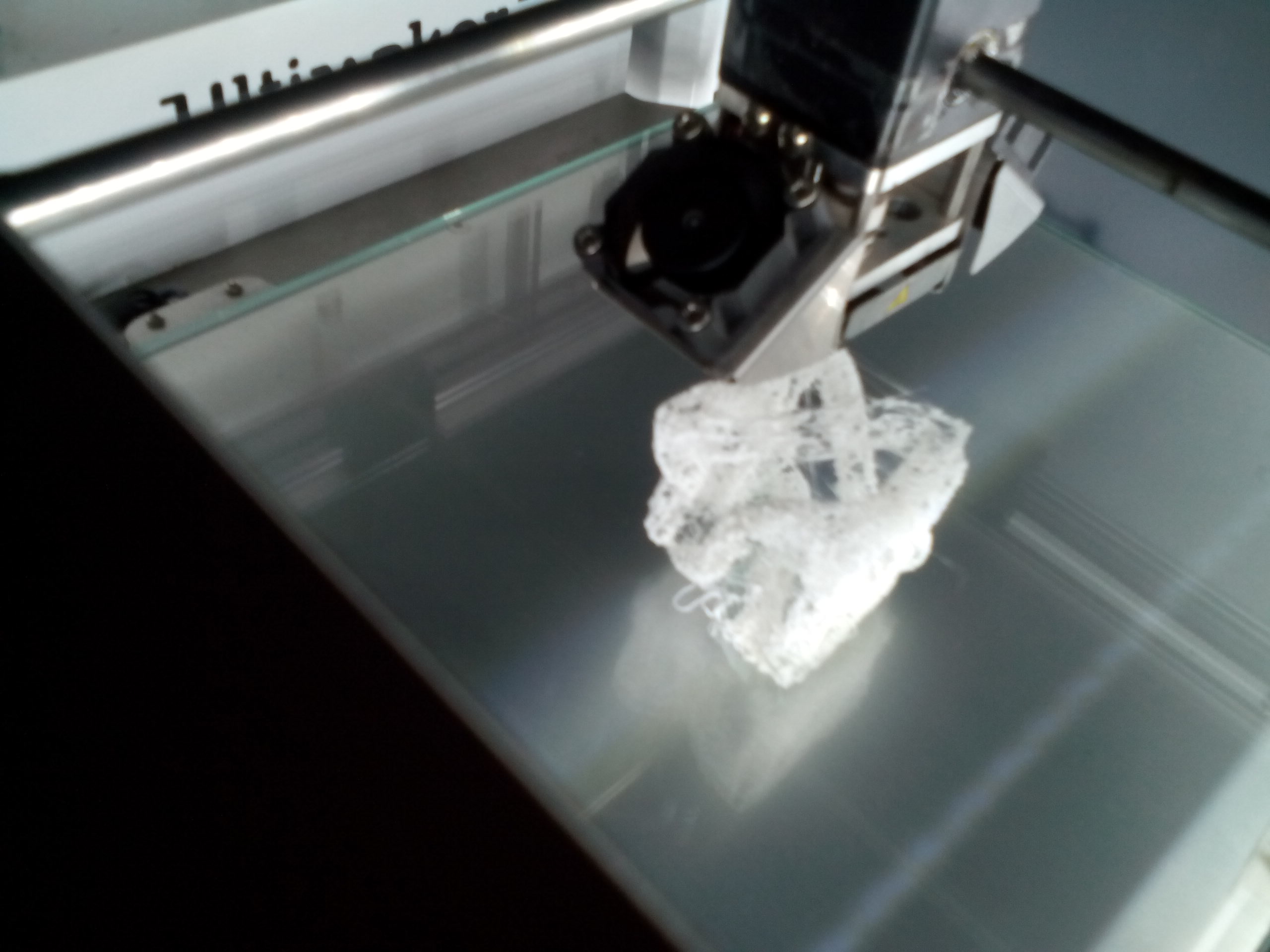

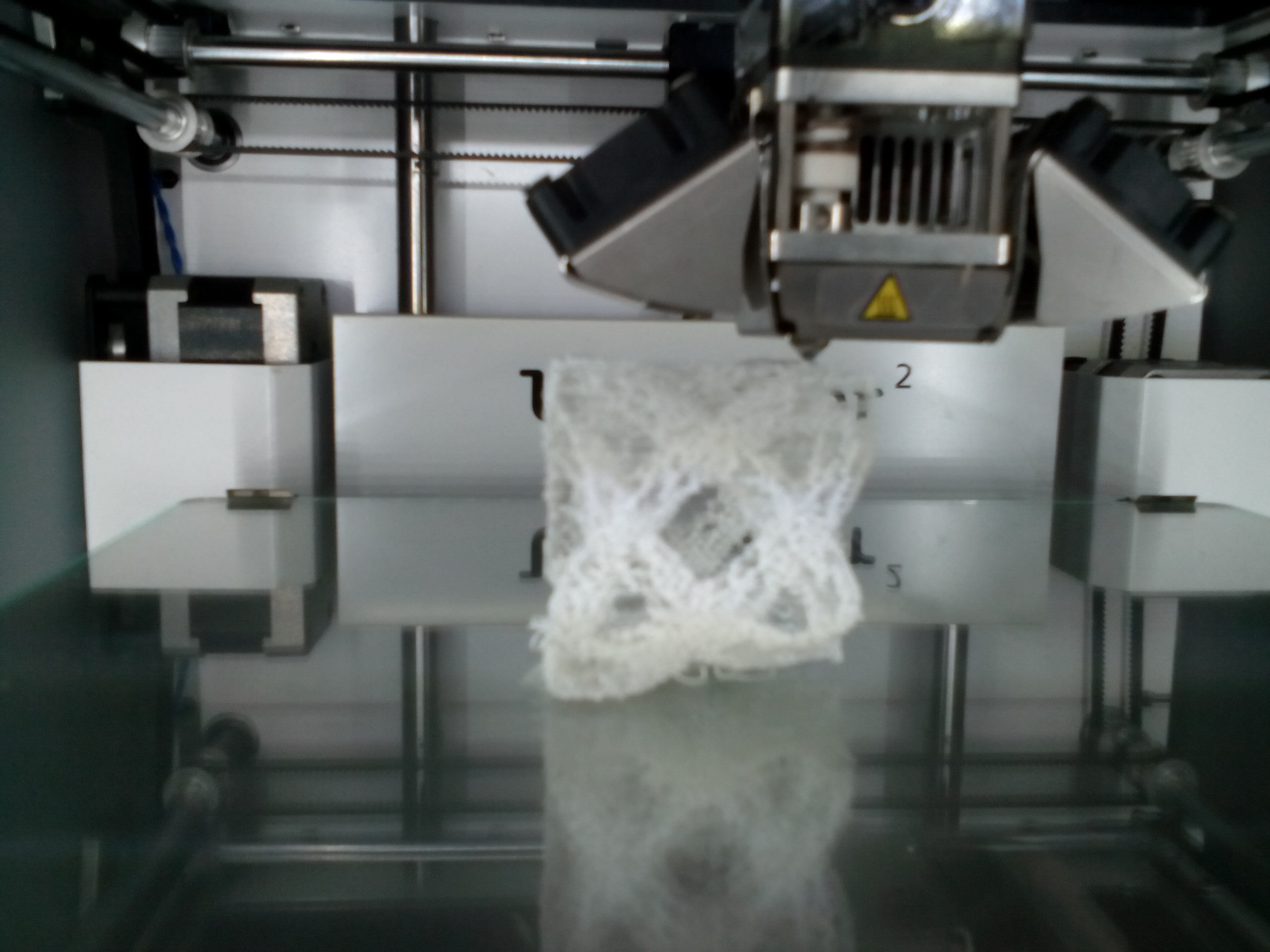

Going with the Cube series, I chose to 3D Print an interesting "Twisty Cube" I found on Thingiverse as my object that could not be created subtractively: http://www.thingiverse.com/thing:111950

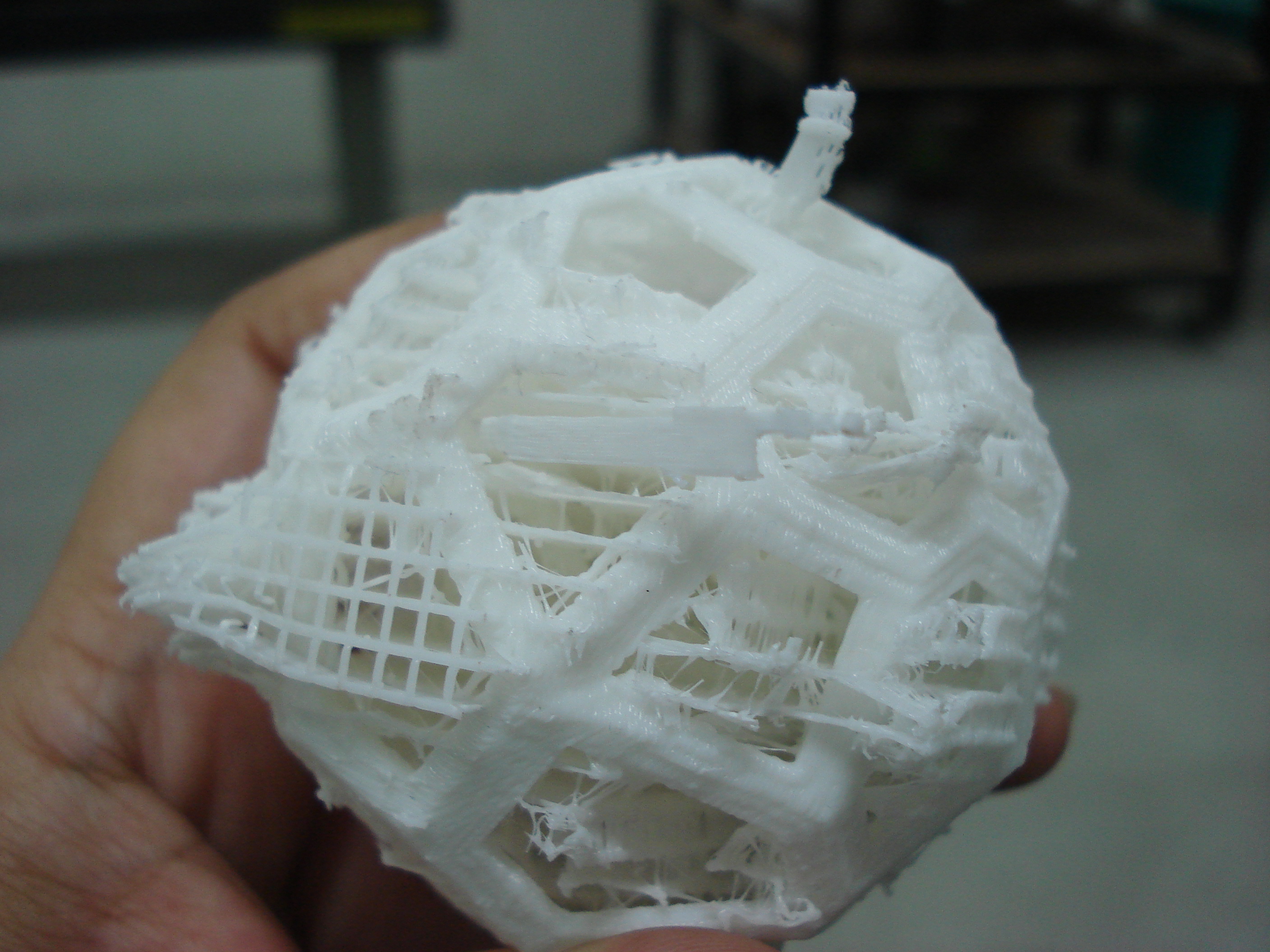

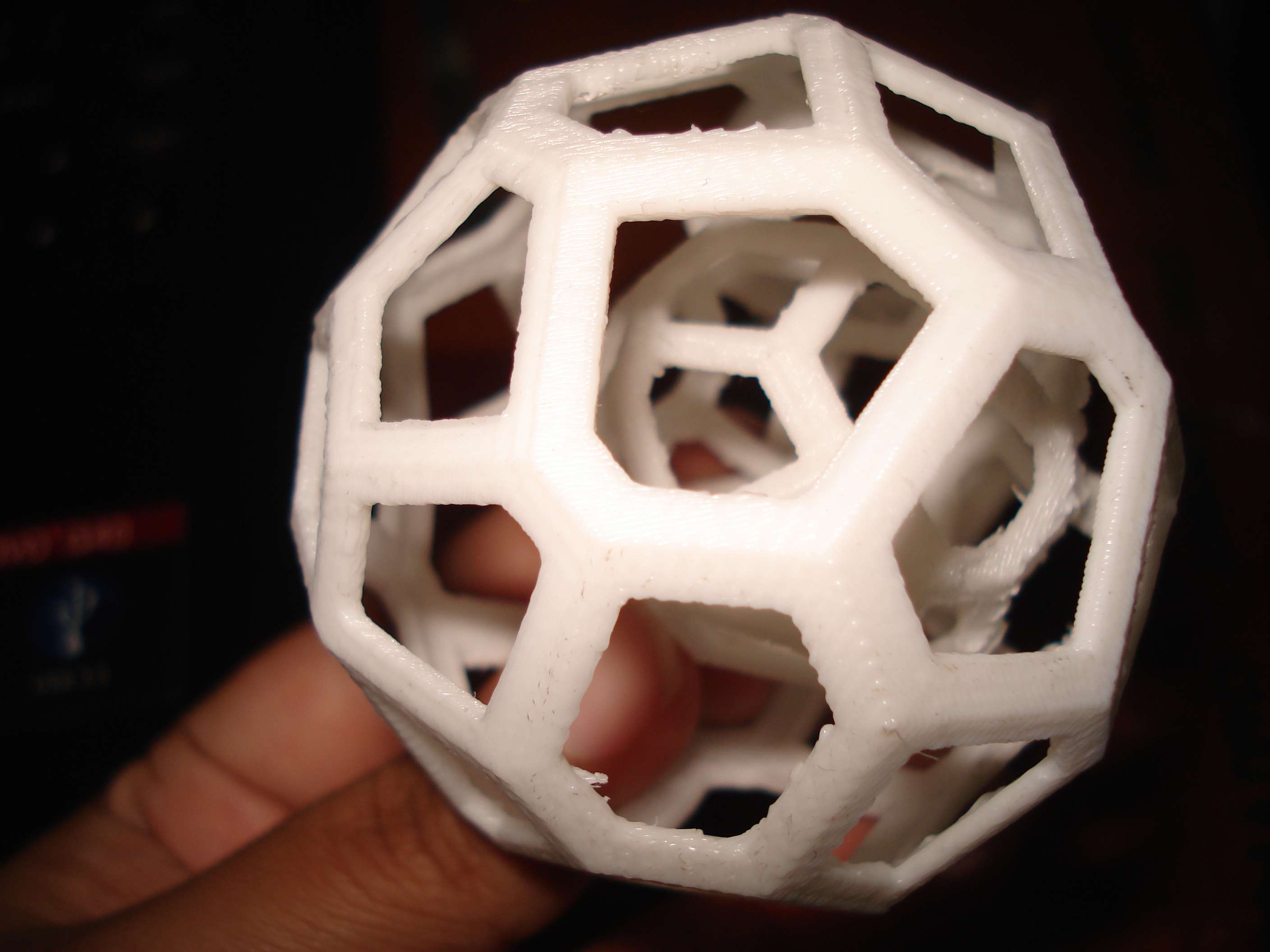

This cube was designed as a complex mesh structure -- upon closer examination, I realized that it would be almost impossible to manufacture this structure subtractively, unless each individual hole in the mesh could be "carved" out in such a way that wouldn't destroy the overall composition:

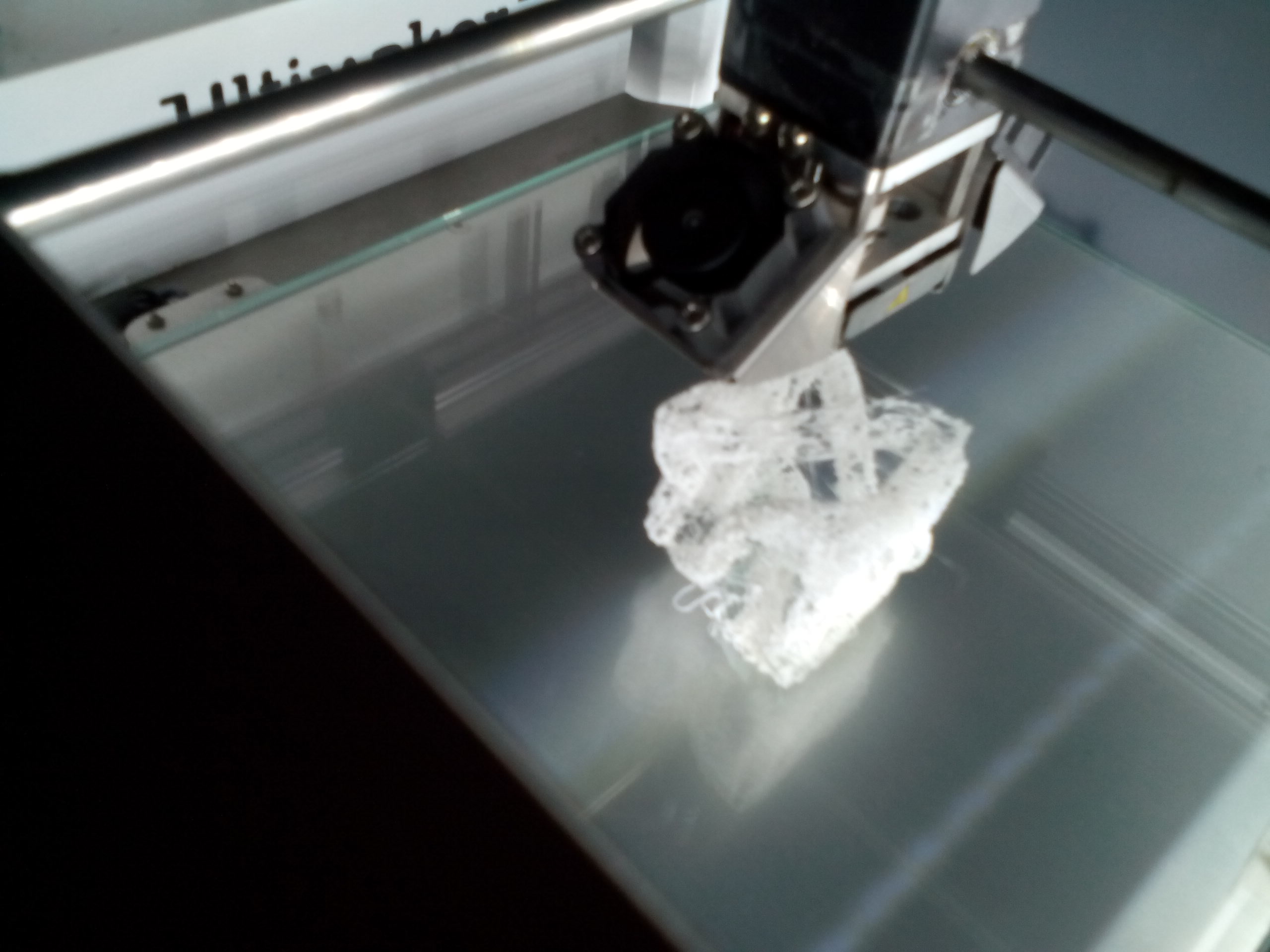

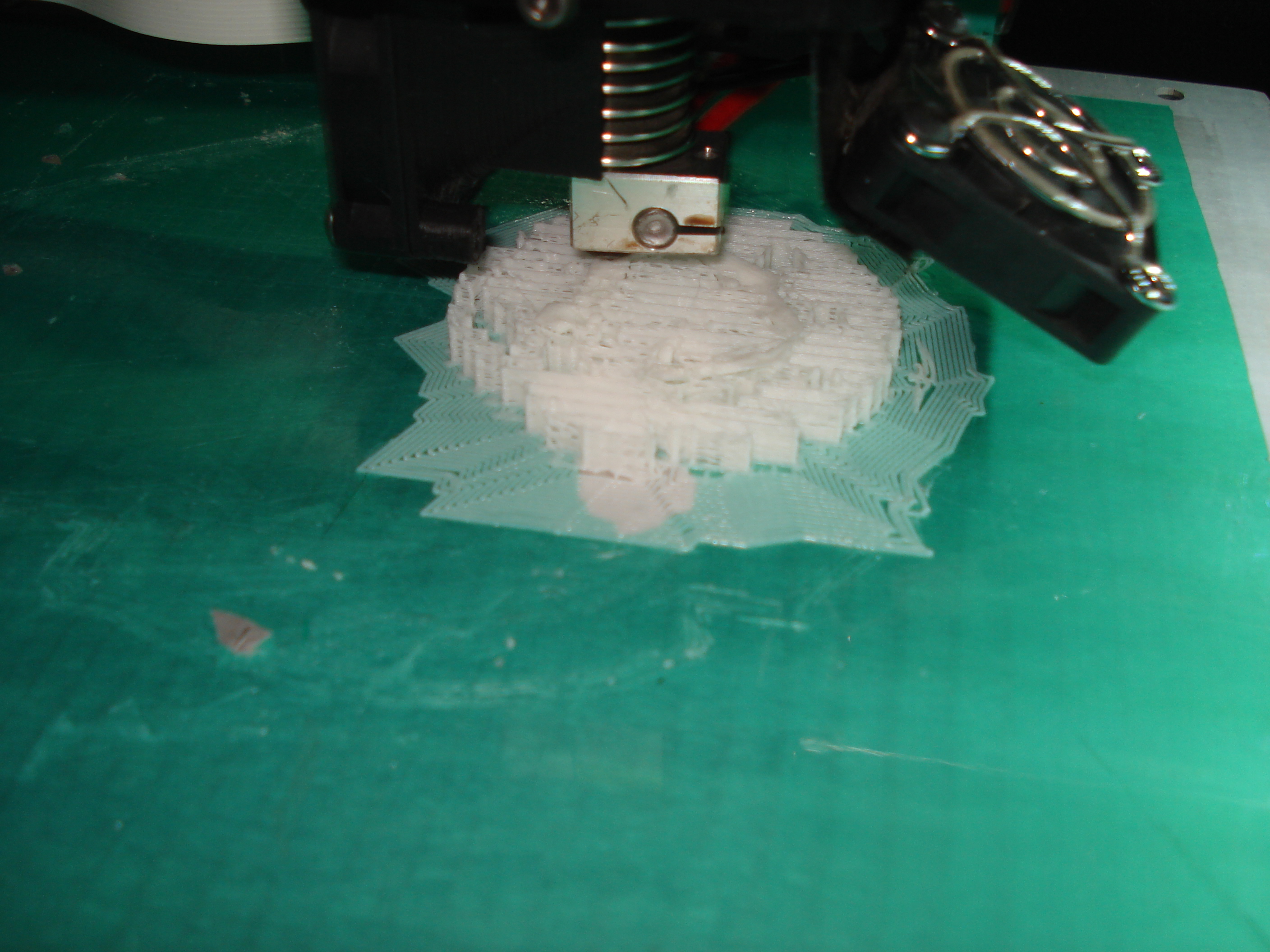

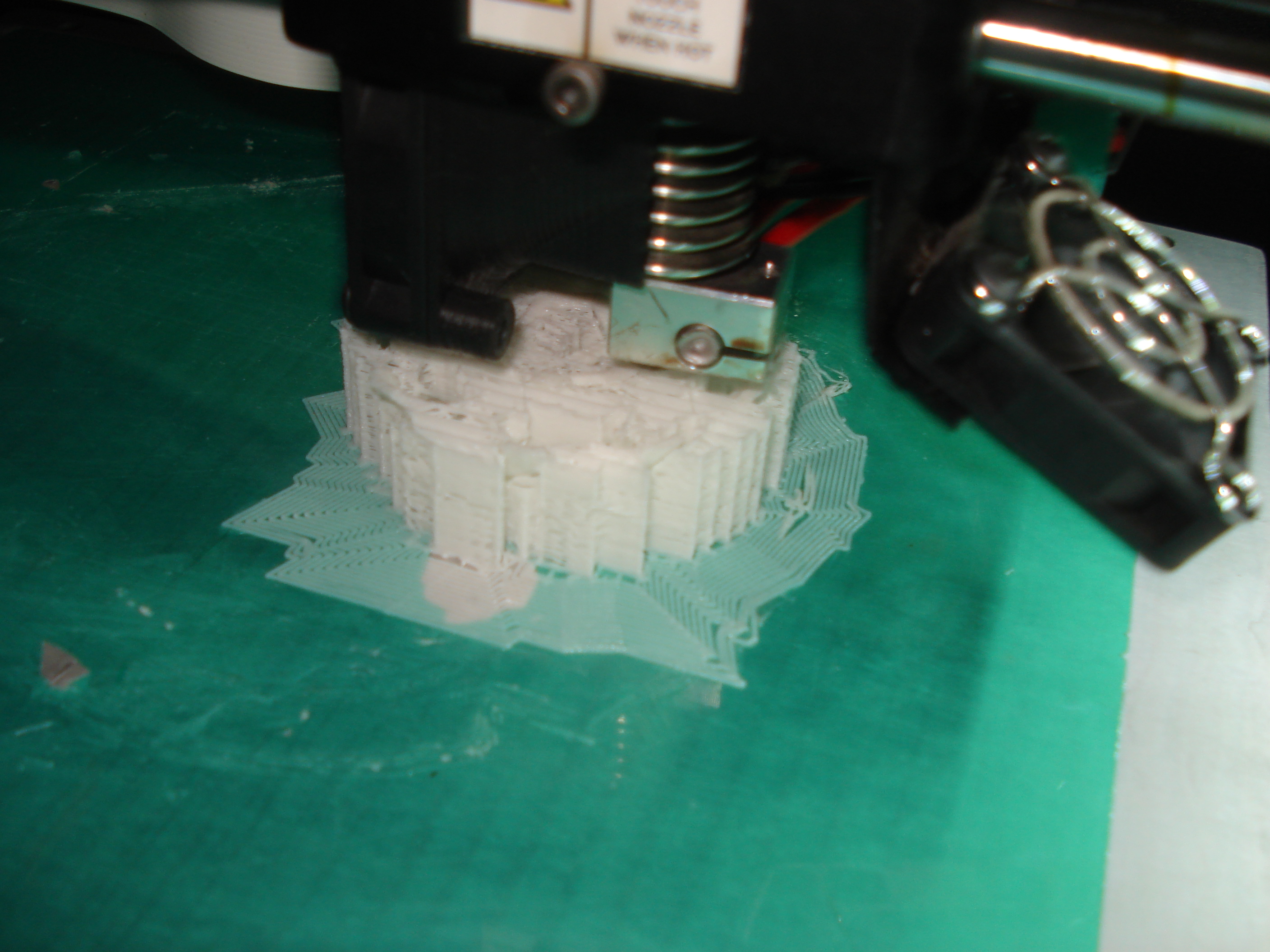

I checked the object during several stages of its print:

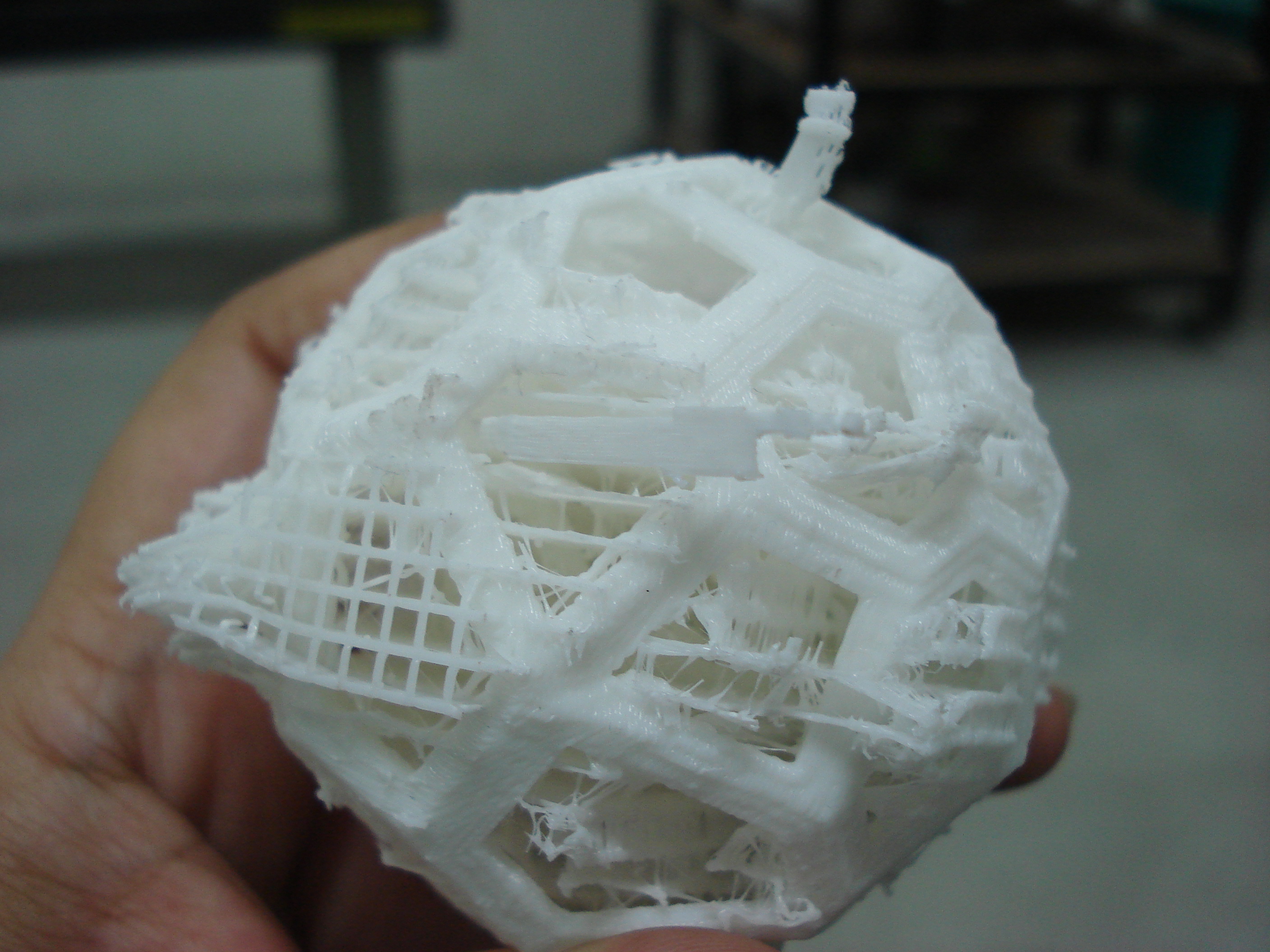

It seemed to come out okay, but I did notice that the mesh pattern wasn't completely smooth; and there was a lot of fraying in between the difference "mesh loops" of the object! Here is an attempted hero shot of the two cubes I printed:

Please find the relevant files I used to carry out this print job from the original link on Thingiverse:

http://www.thingiverse.com/thing:111950

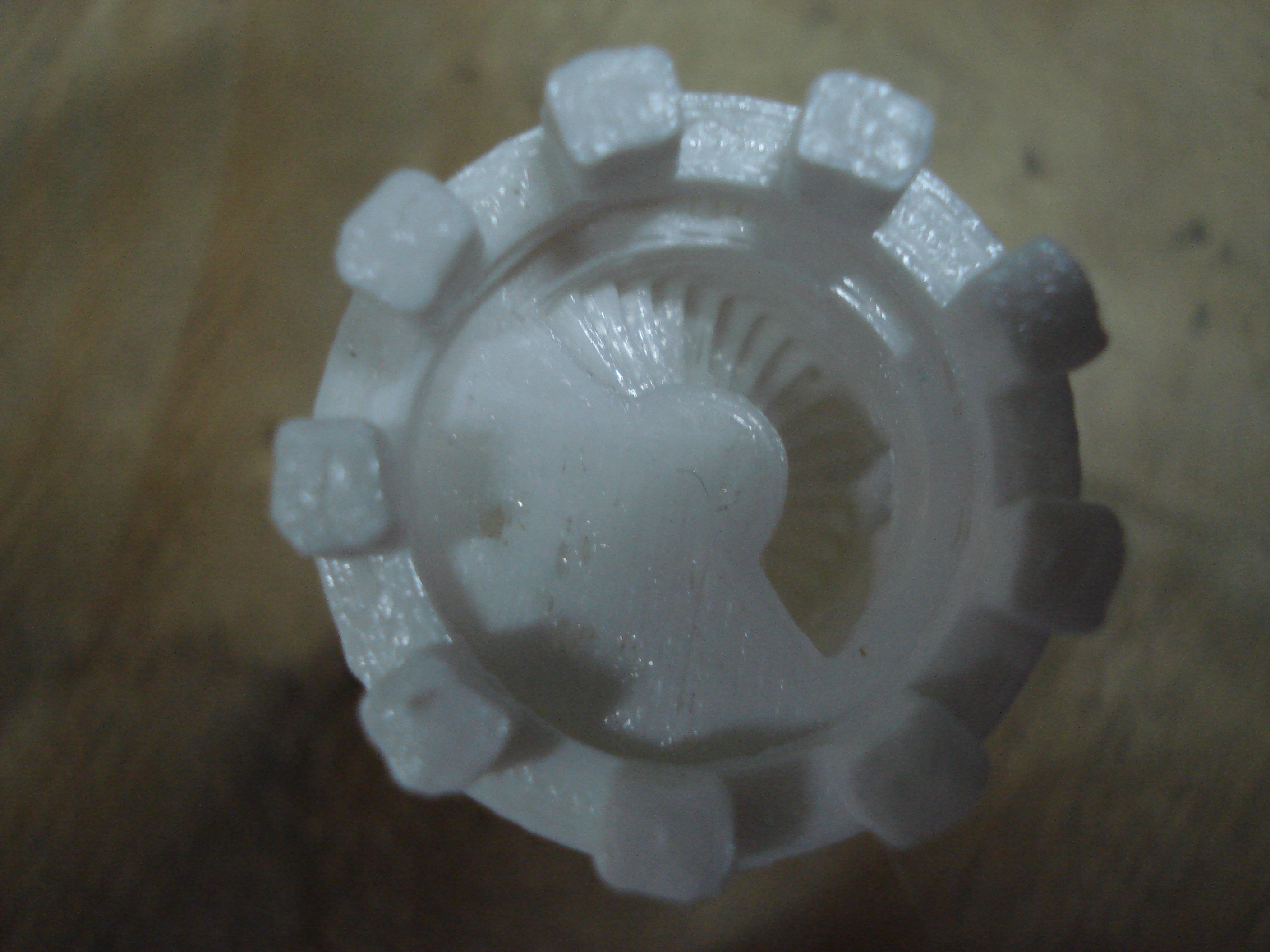

I tried another example of something that could not be manufactured subtractively: A Rook chess piece which had an intricate staircase designed on its inside:

Please find the relevant files I used to carry out this print job from the original link on Thingiverse:

https://www.thingiverse.com/thing:1005110

Task #2: 3D Print something you could not make subtractively

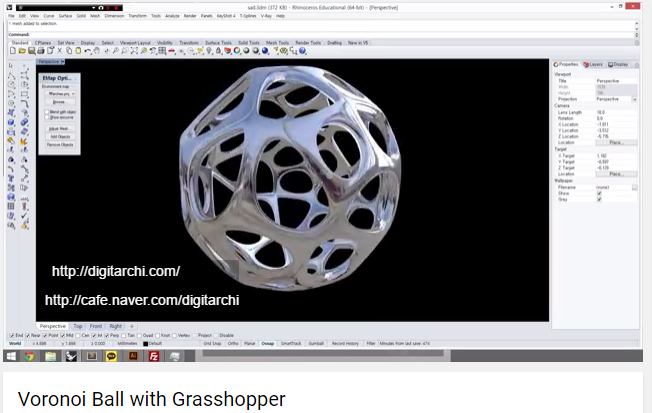

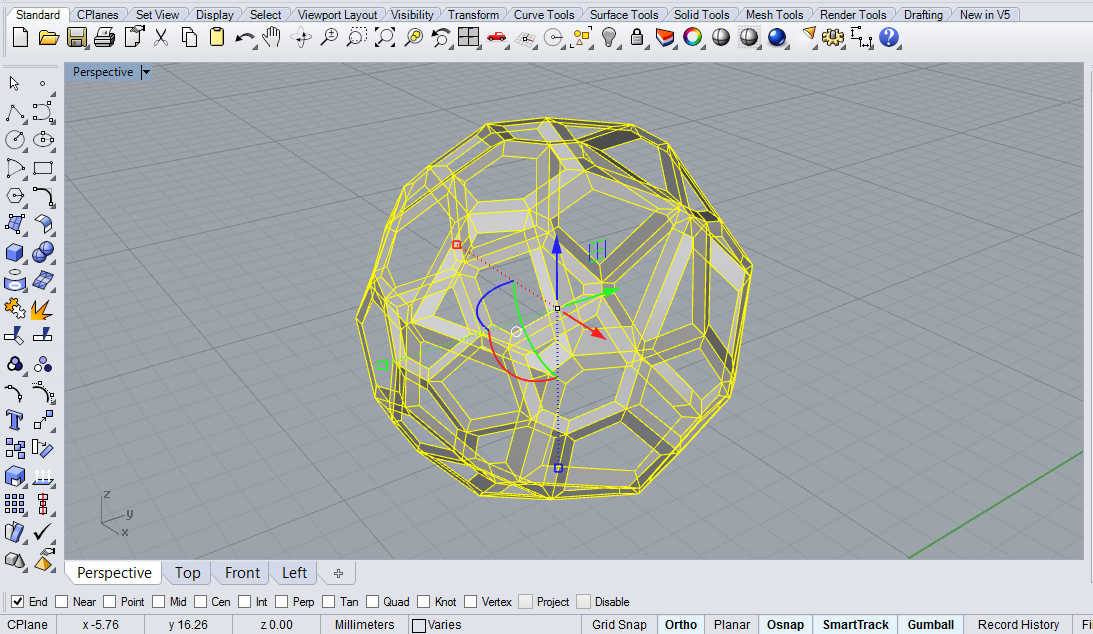

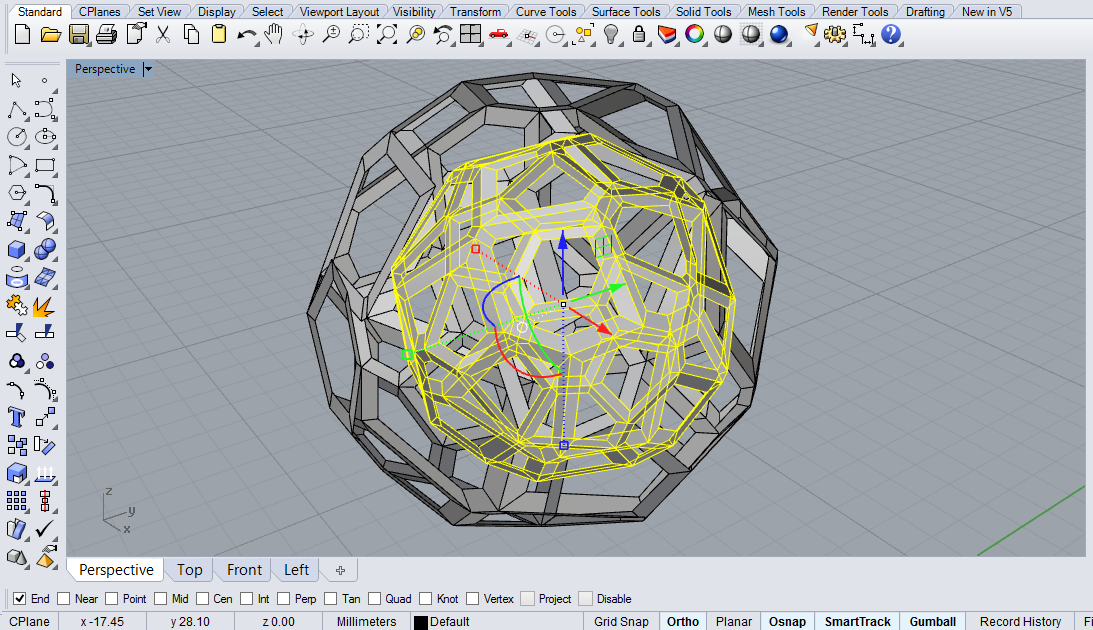

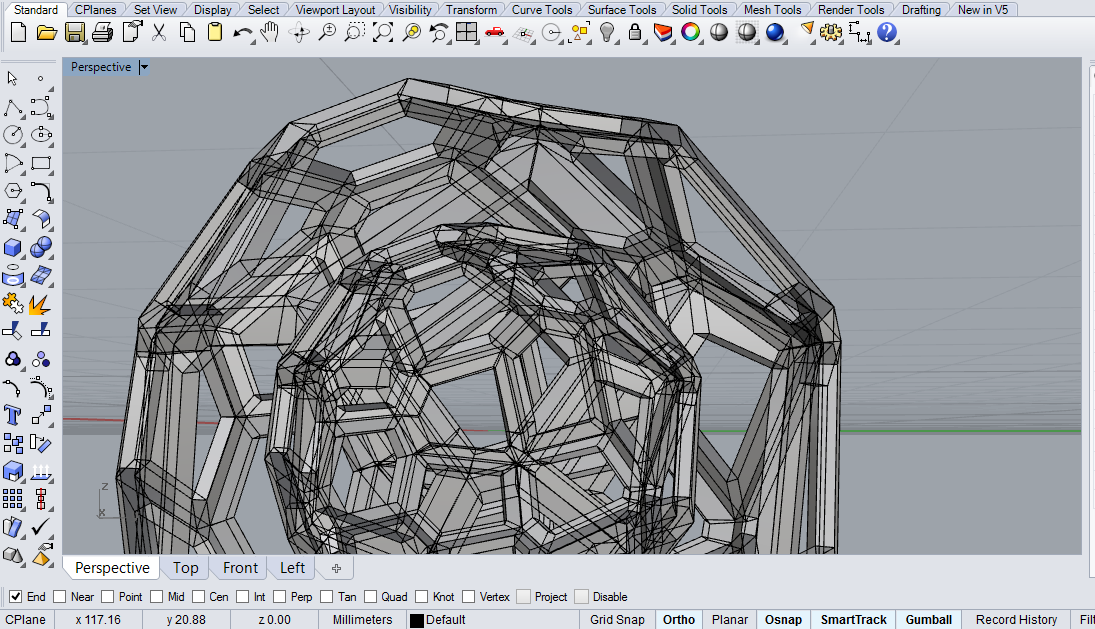

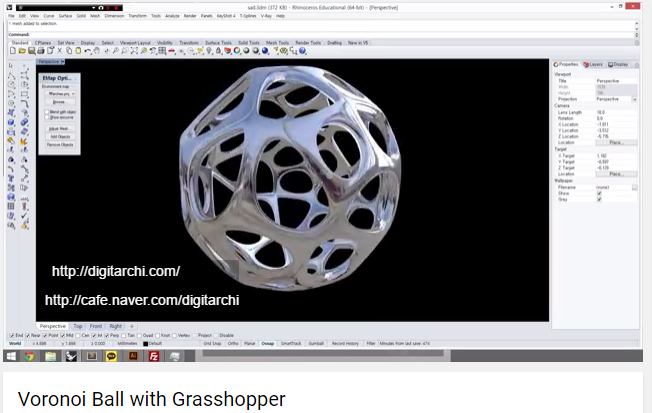

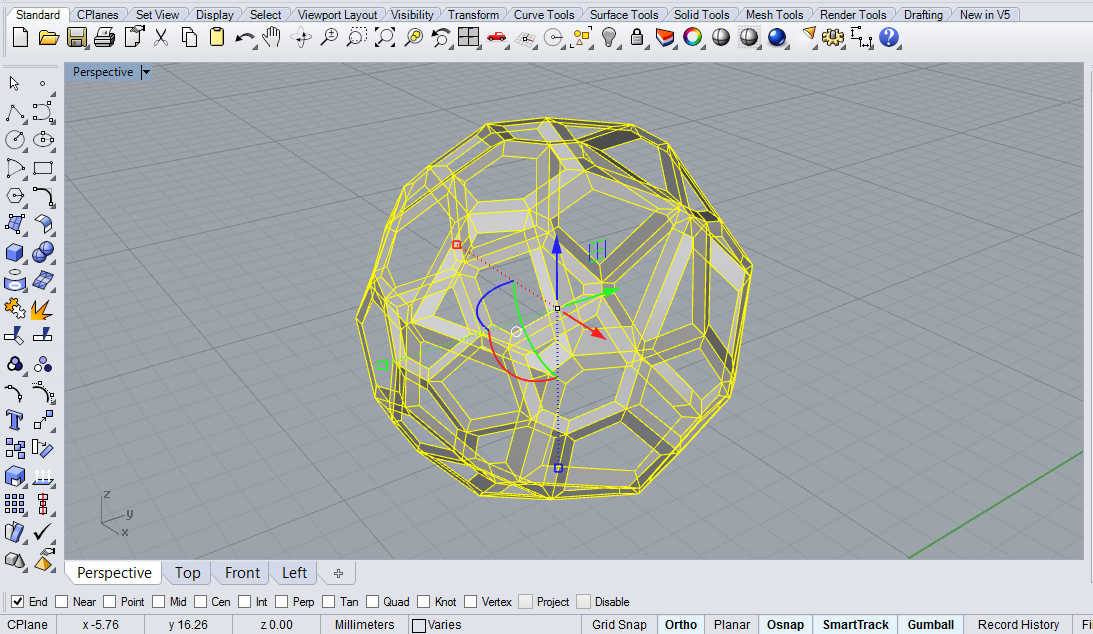

Since we needed to include an original design for this sub-task, I had no choice but to understand how to go about creating an object in a 3D modeling software program --> which I then needed to 3D Print. It was clear from the nature of the assignment that only a parametrically designed object would fit this criteria of "not being able to be made subtractively" so I went about researching various tutorials and finalized on using Rhinoceros with the Grasshopper plugin to go about my design.

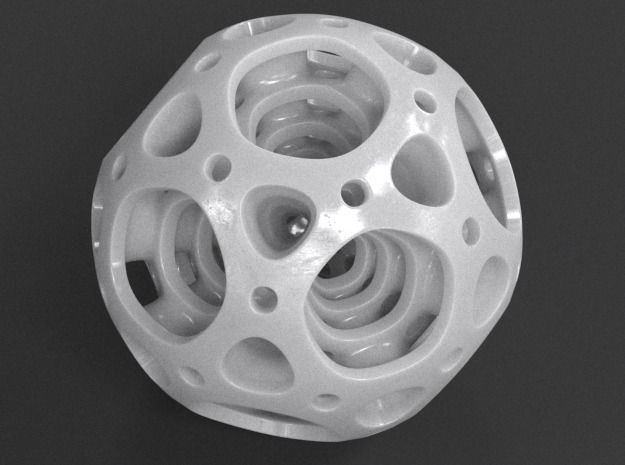

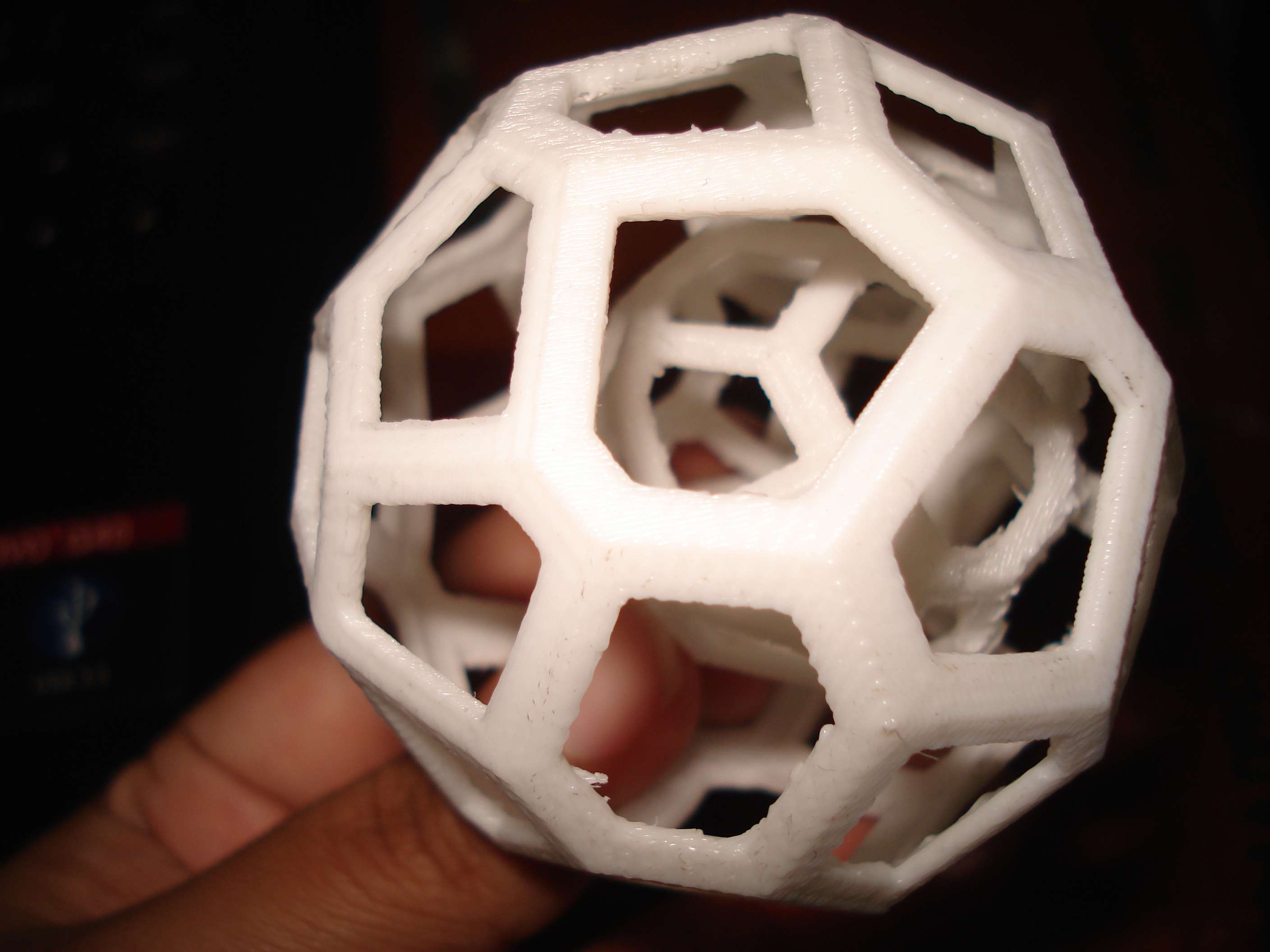

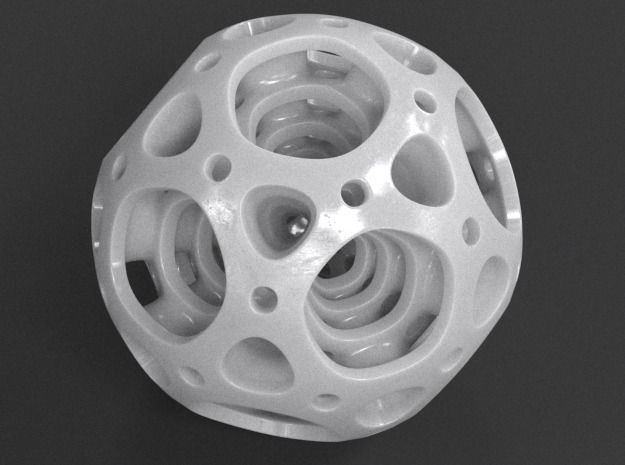

During my search for "non-subtractively manufactured objects" I came across a lovely example of a nested docahedron that would be an interesting choice to create my parametric model from:

Nested Docahedron [Image Source] Modeling a Voronoi Ball in Rhinoceros [Source]

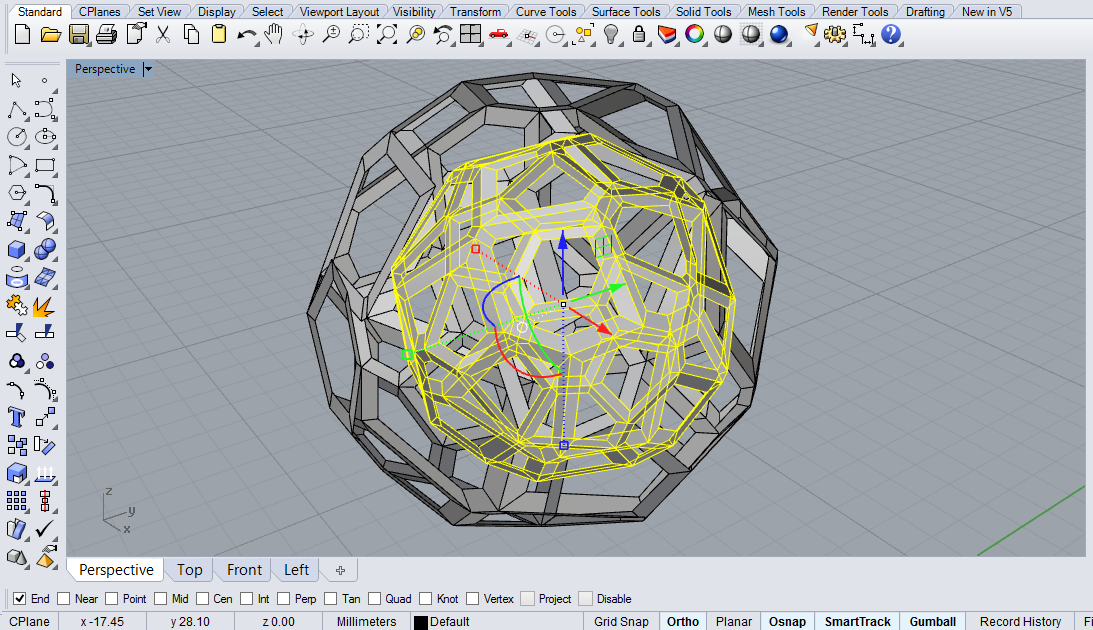

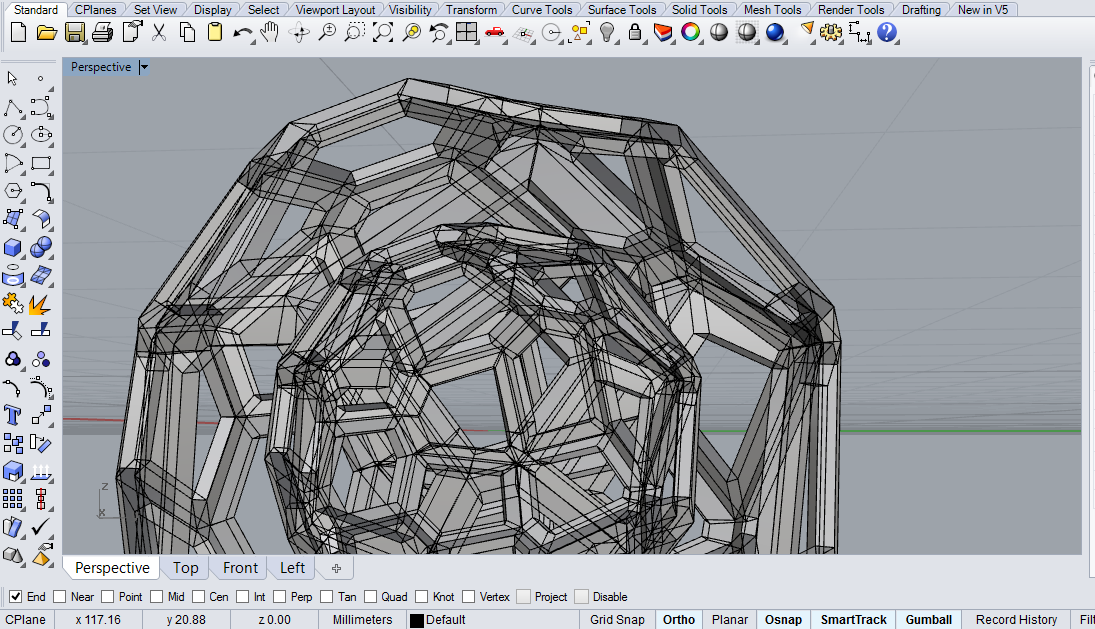

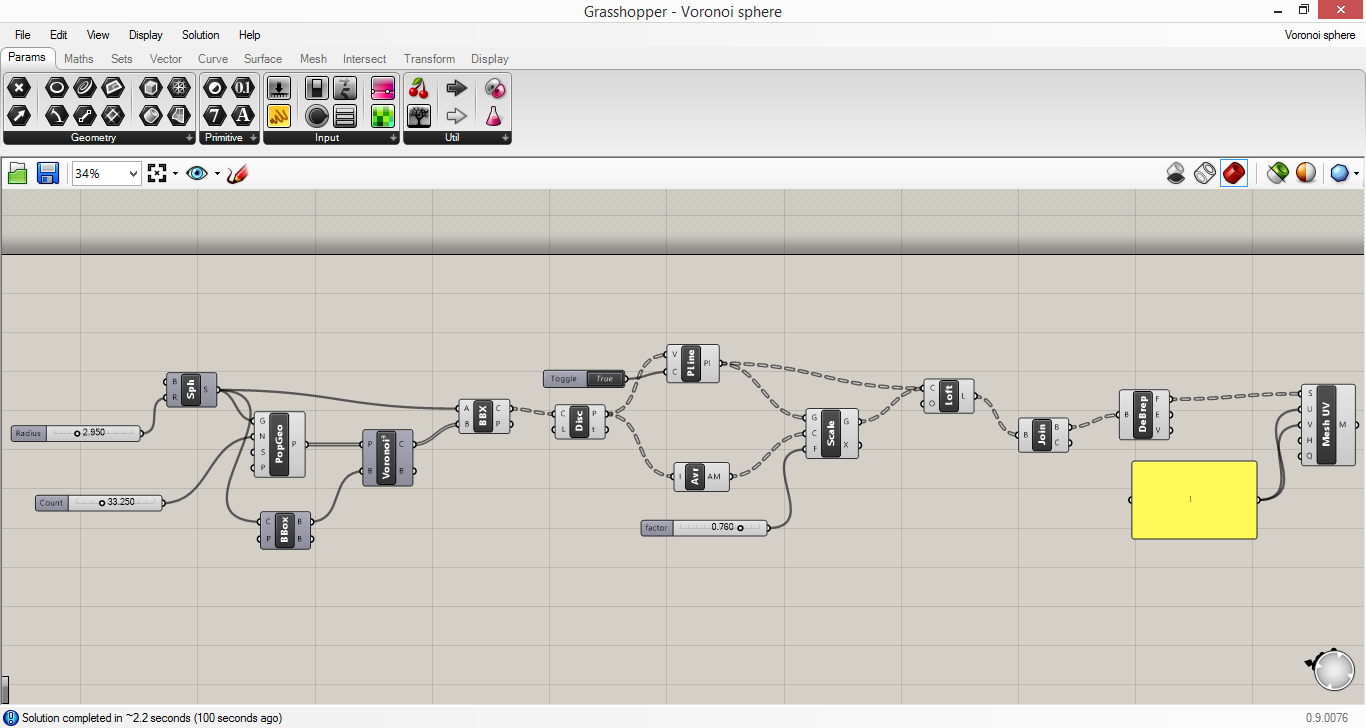

Upon searching for the kind of model or type of object this nested docahedron could be created, I came across some interesting tutorials and youtube videos on "Voronoi spheres". This led me to explore how I could create one on my own using Grasshopper as the scripting environment within the Rhino CAD modeling software. I followed several tutorials to get to the point where I could carefully replicate what I had taken inspiration from. This tutorial probably helped the most: https://www.youtube.com/watch?v=WiRXfHbw74g

Creating the first Voronoi ball Forming the second Voronoi ball

Smoothing out the edges of both voronoi balls

Joins from Point Cloud formed using Grasshopper

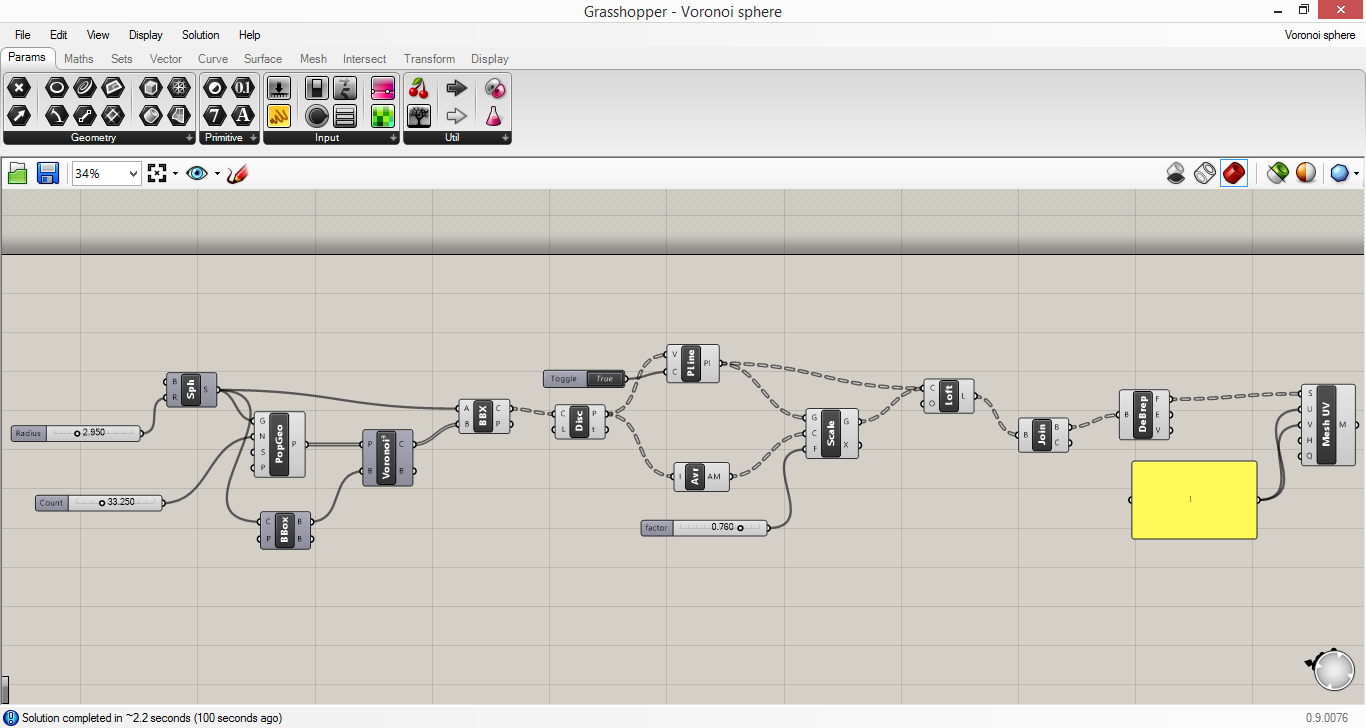

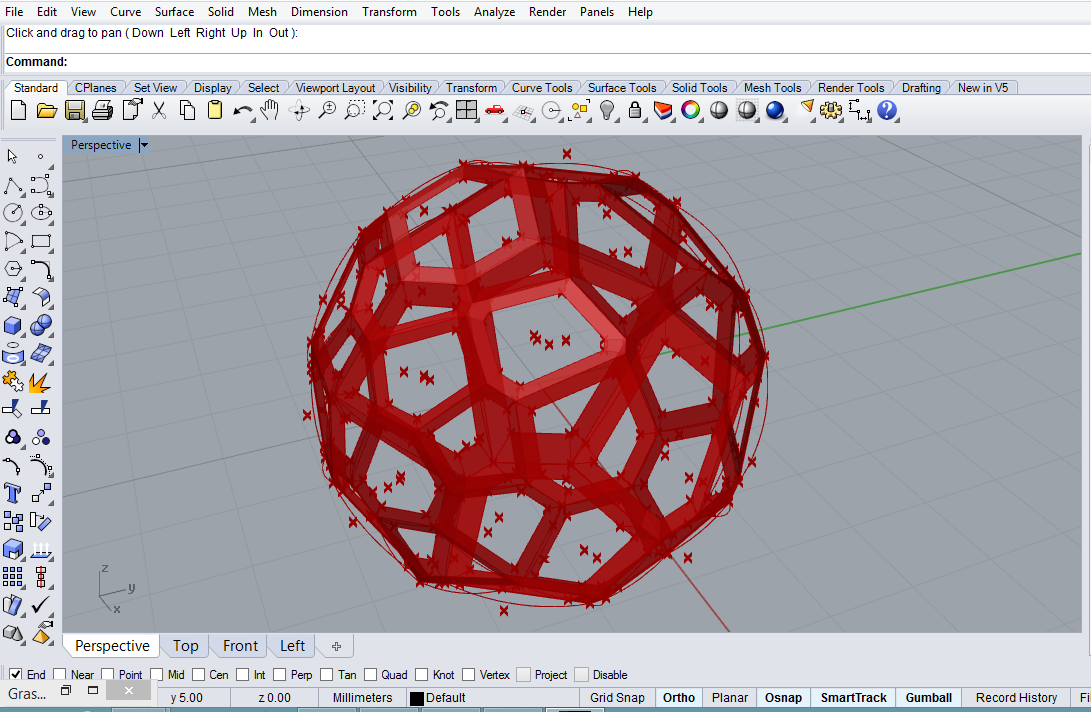

Grasshopper Script used to create final model

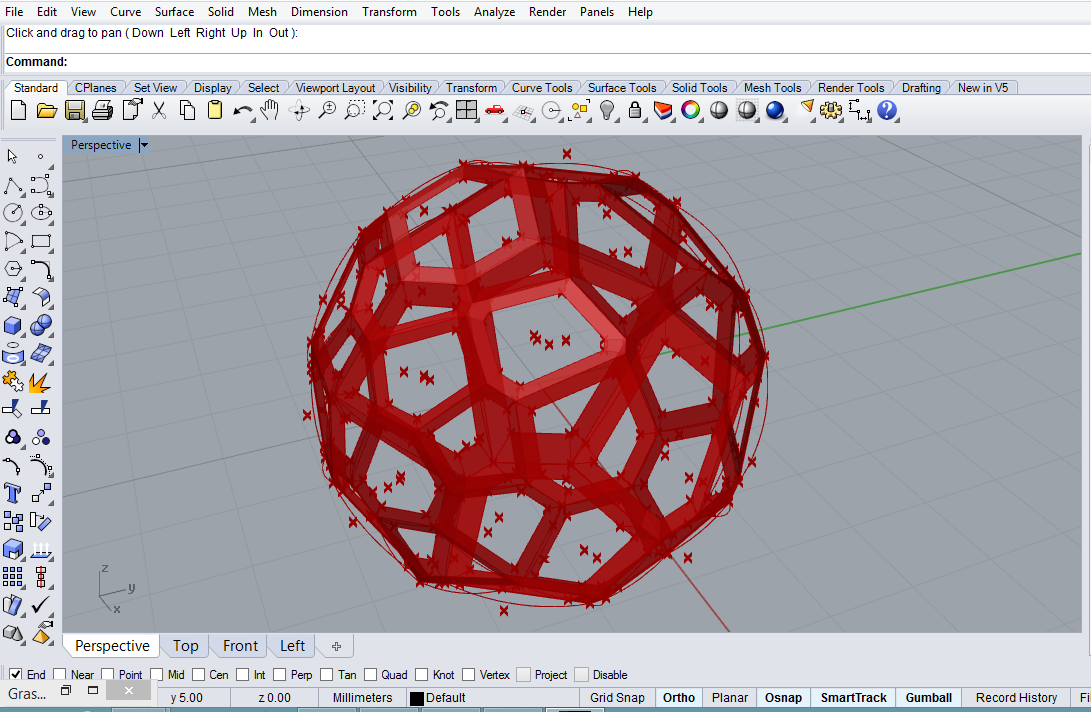

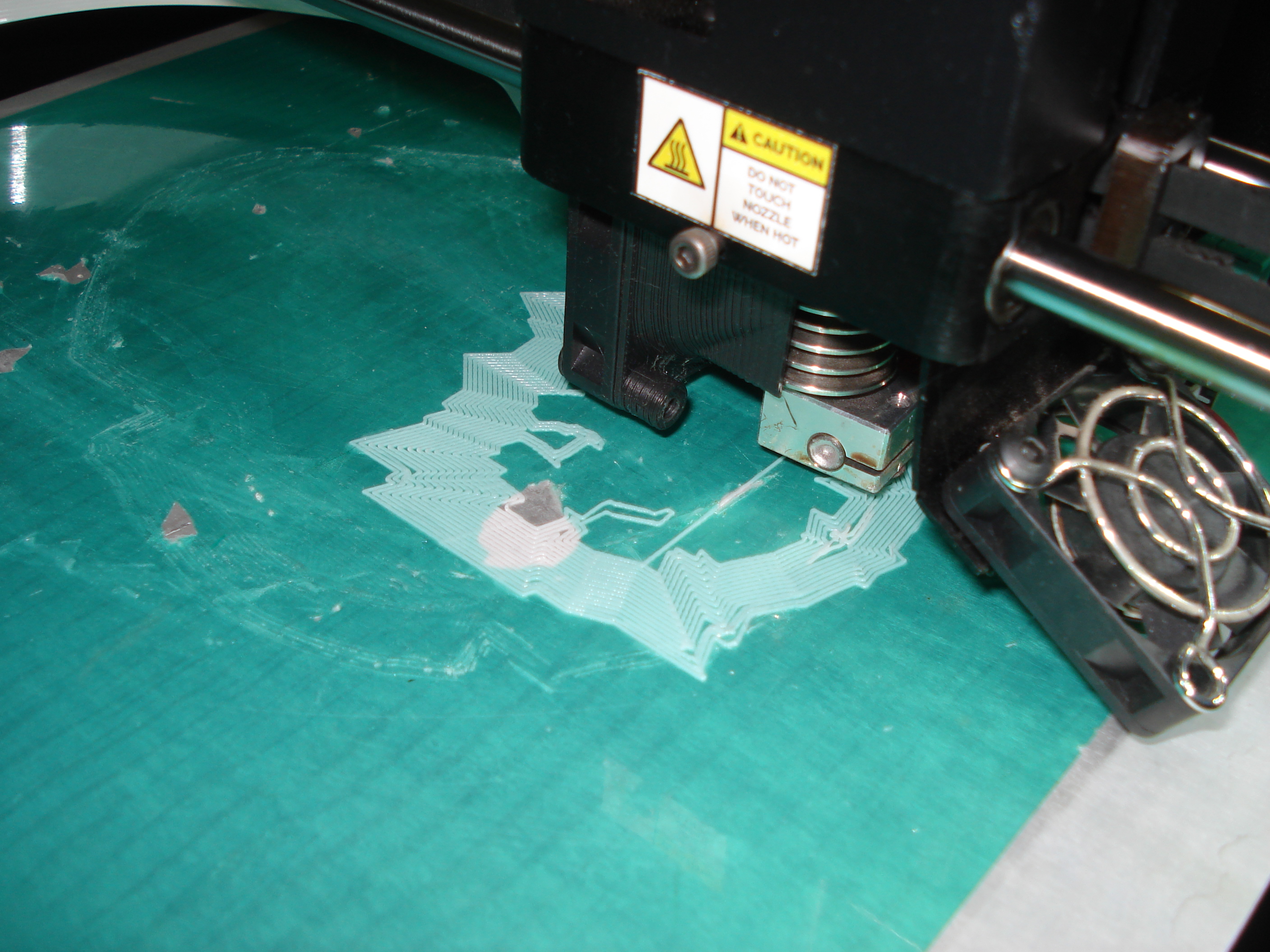

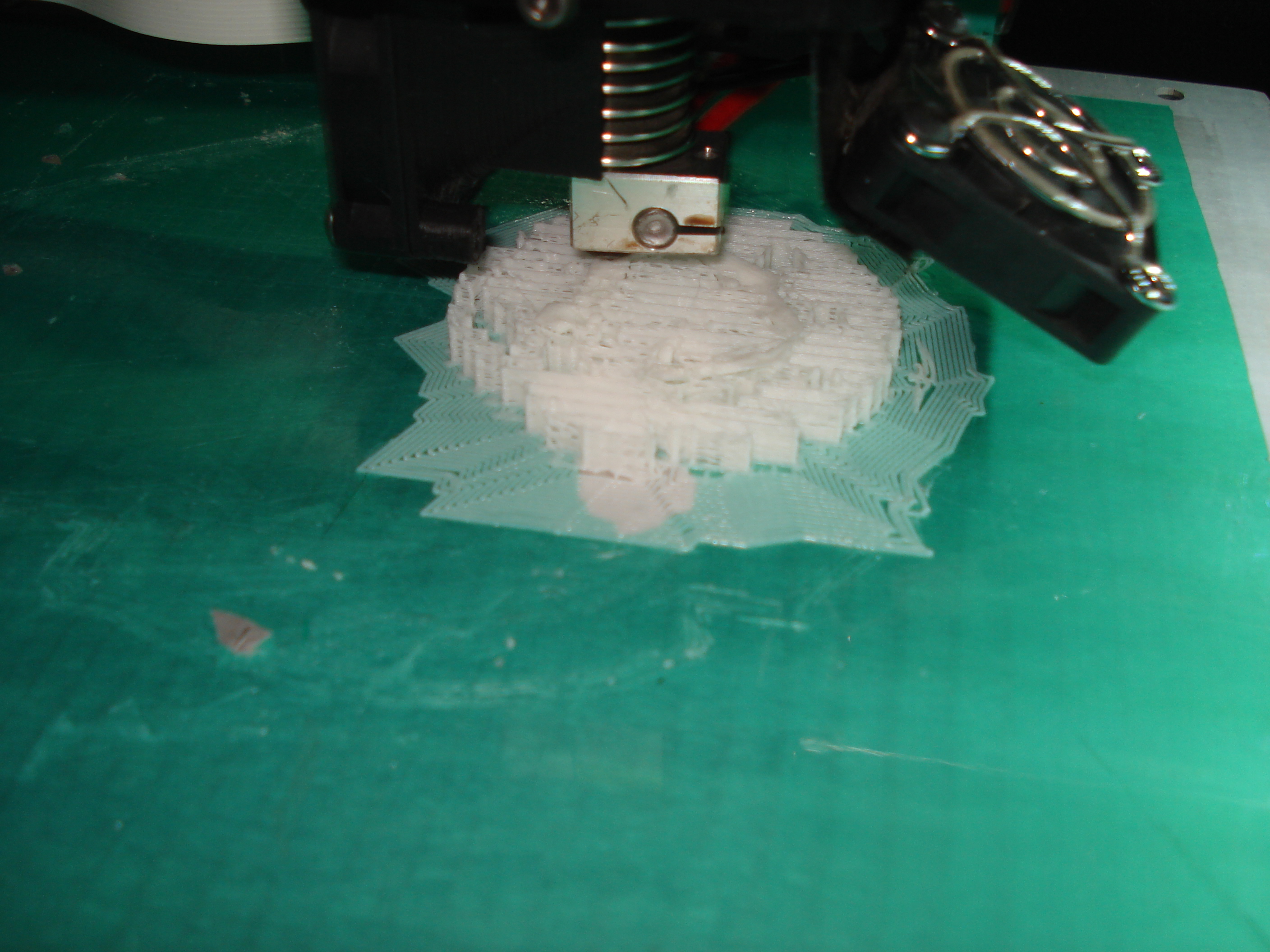

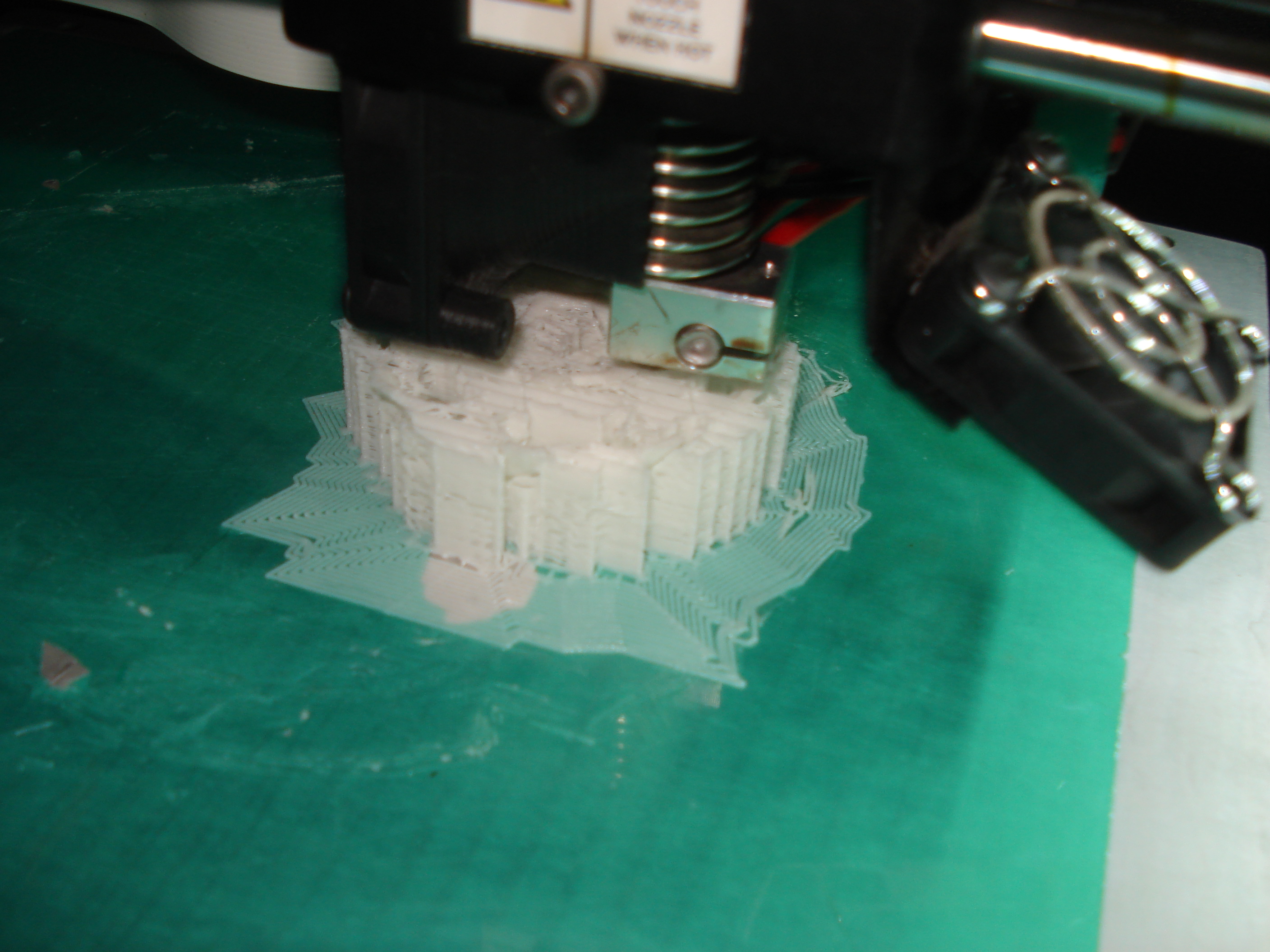

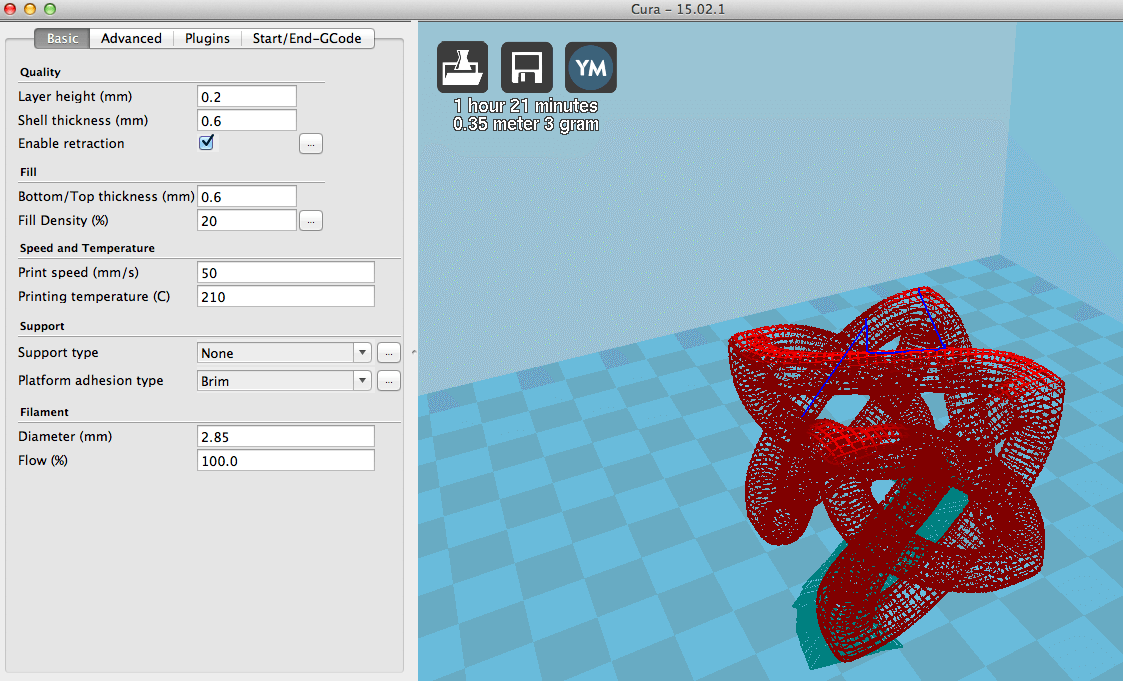

I used a Fracktal Works Julia+ FDM 3D Printer to print out my design using the following settings:

- Fill Density: 25%

- Print Speed: 45mm/s

- Extruder Travelling Speed: 150mm/s

- Supports and Rafts added to overall print (Automatically Enabled on Fracktal Works 3D Printers)

- Total Time for Printing: 3 hours 30 minutes

At the end of 3 hours 30 minutes, the resulting nested voronoi balls came out like the figure below! I've used a .gif image to depict how I removed all the support material (tirelessly!) away from both spheres, so that one could see how the actual object turned out:

Please find the files I used to create my 3D model for Task 2 of this assignment:

Rhino File for Nested Voronoi Spheres

Grasshopper Script

Task #3: 3D Scan an object

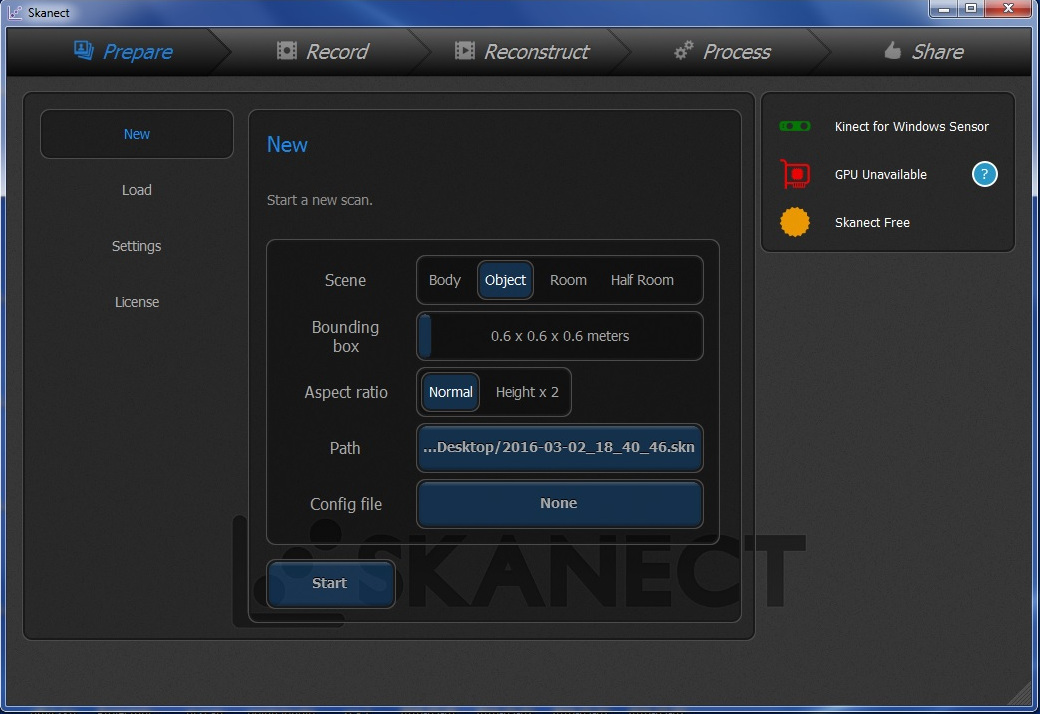

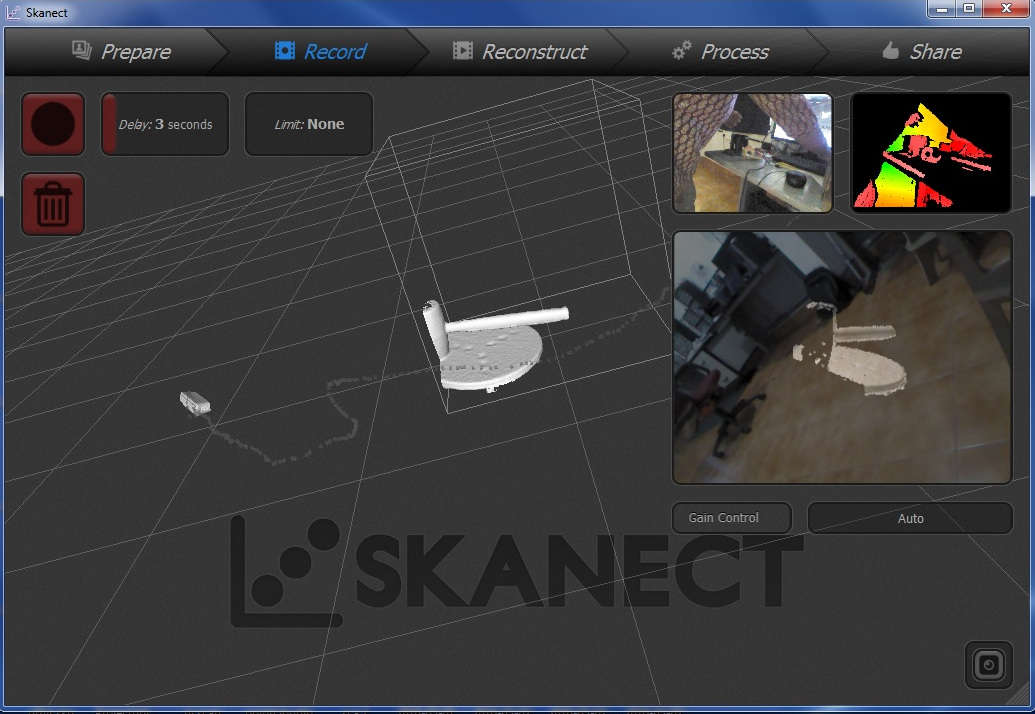

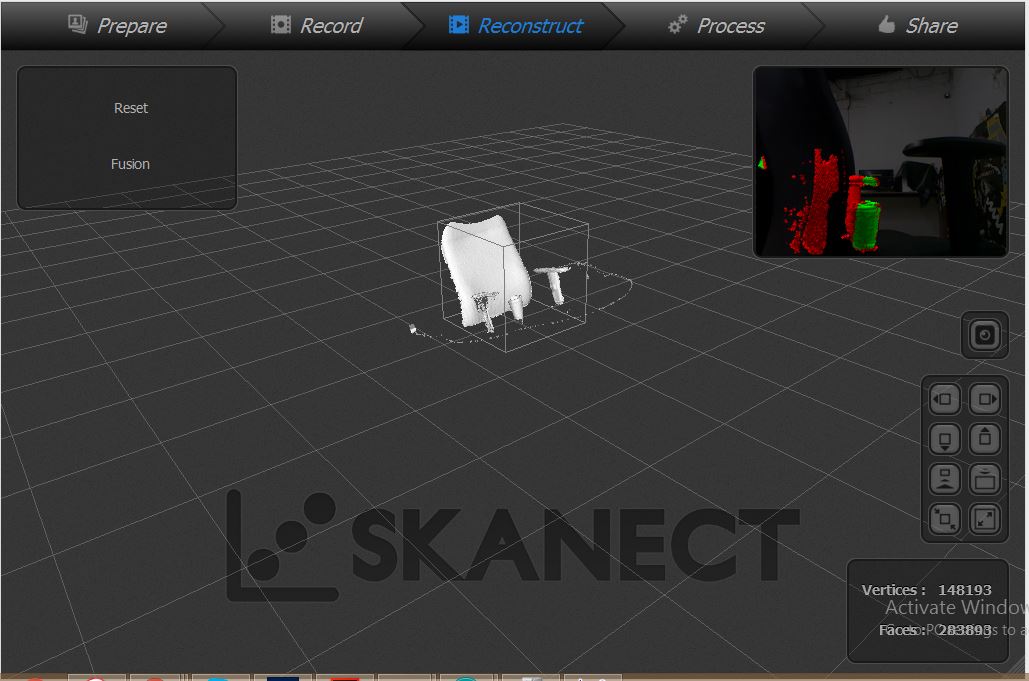

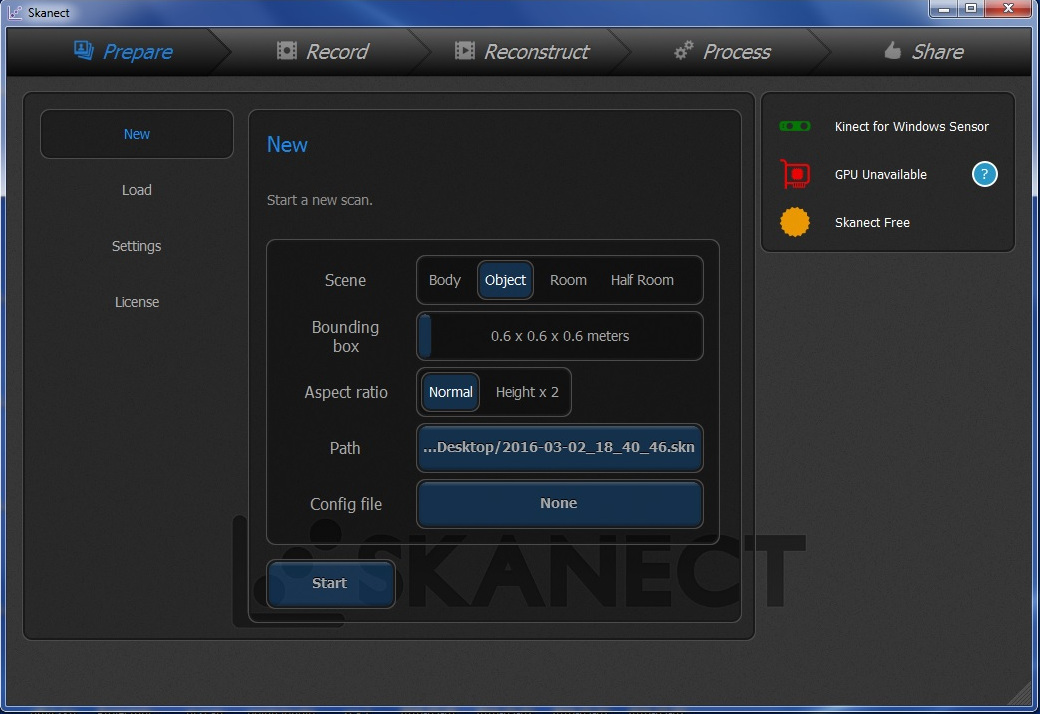

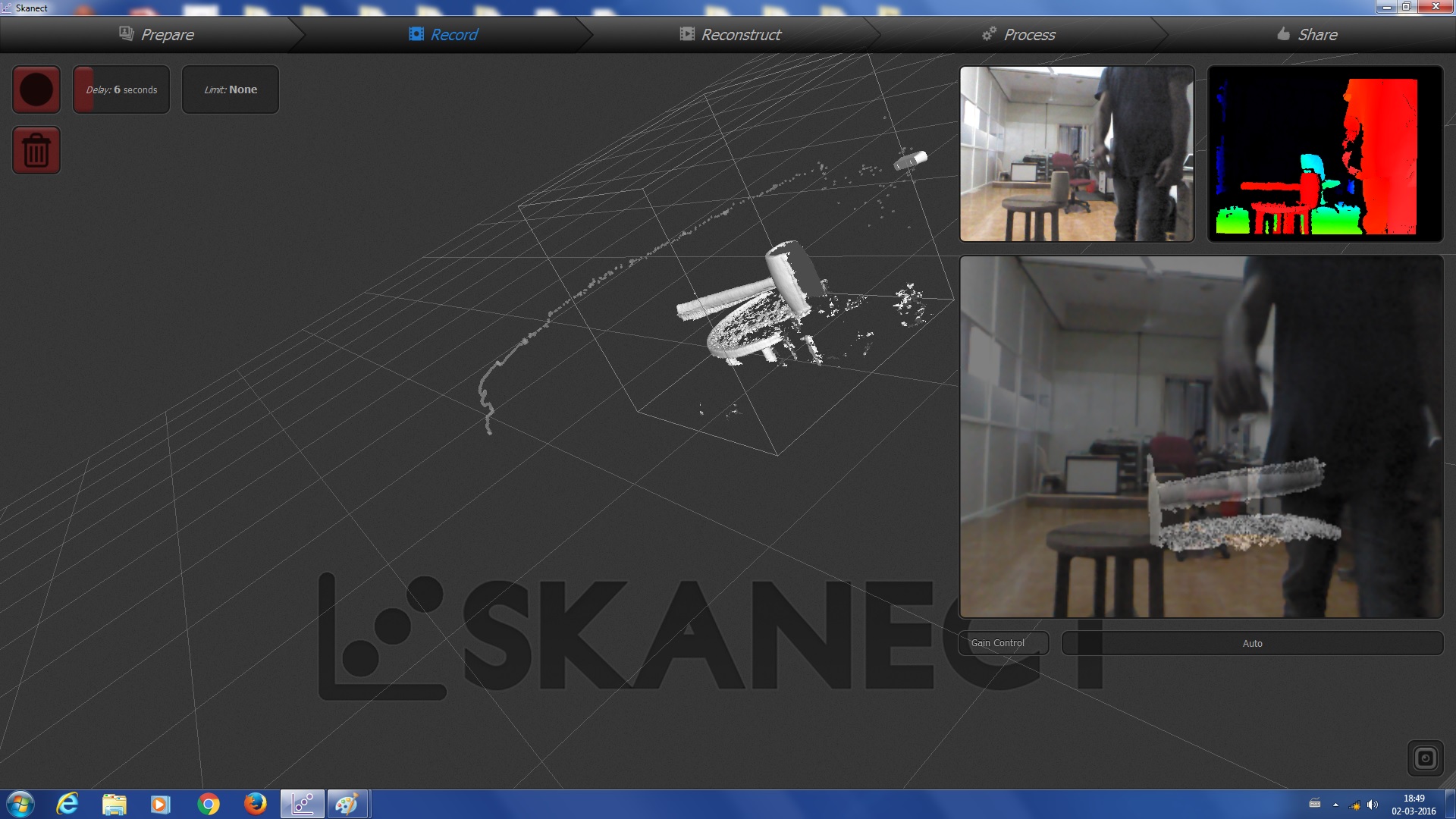

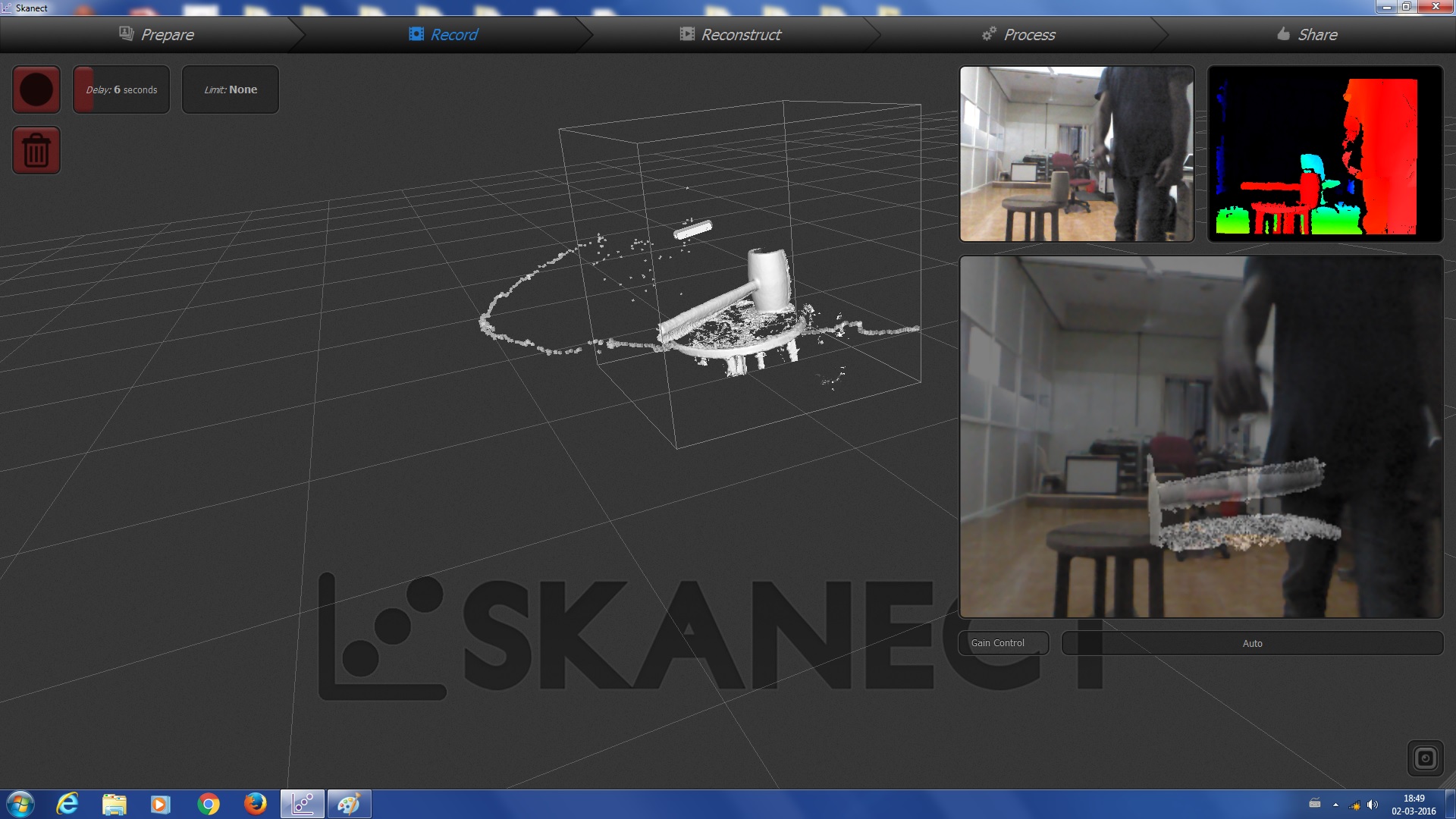

I used a Microsoft Kinect sensor unit connected to a Windows PC (in our Fab Lab) to 3D Scan a sample object:

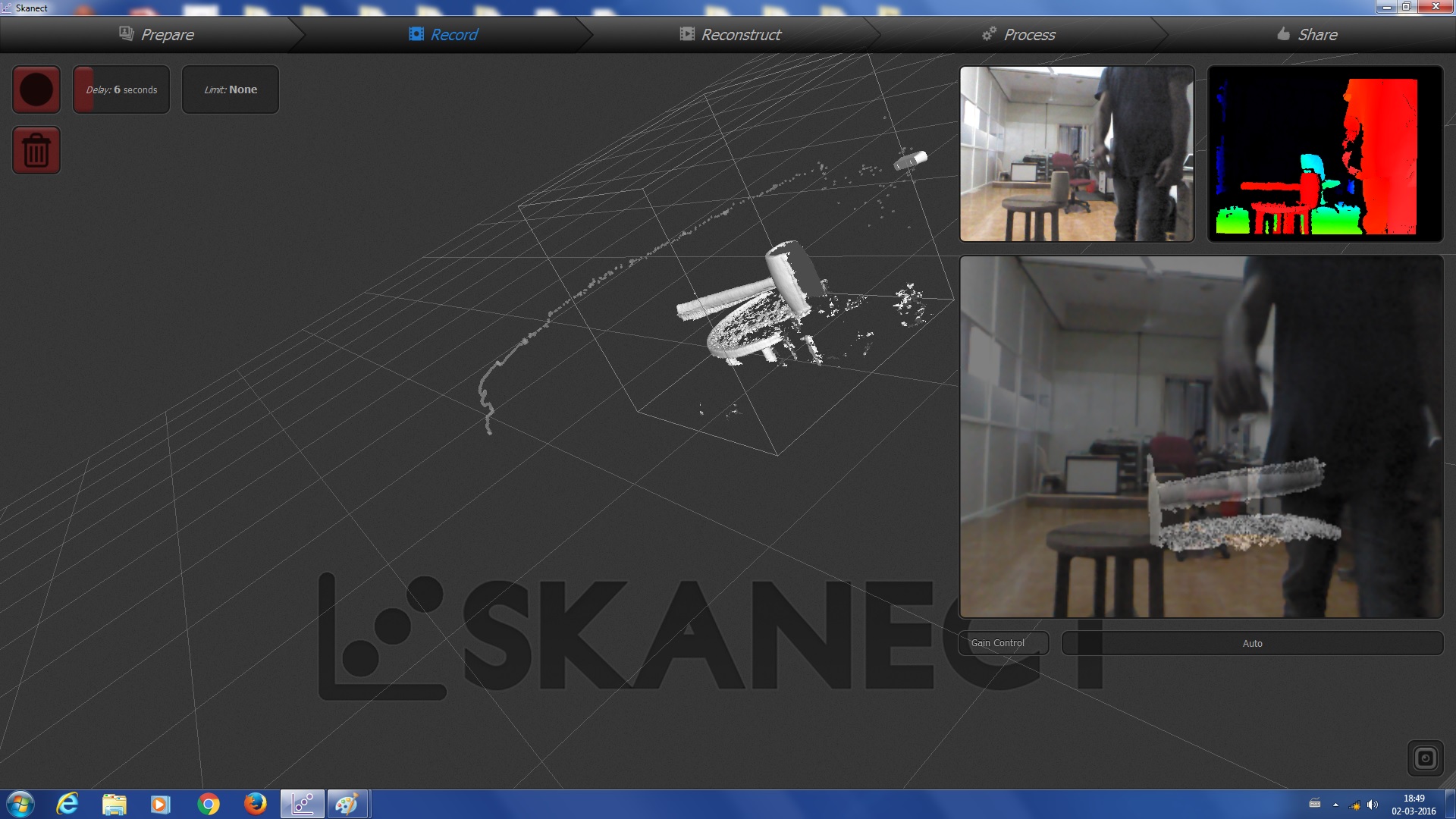

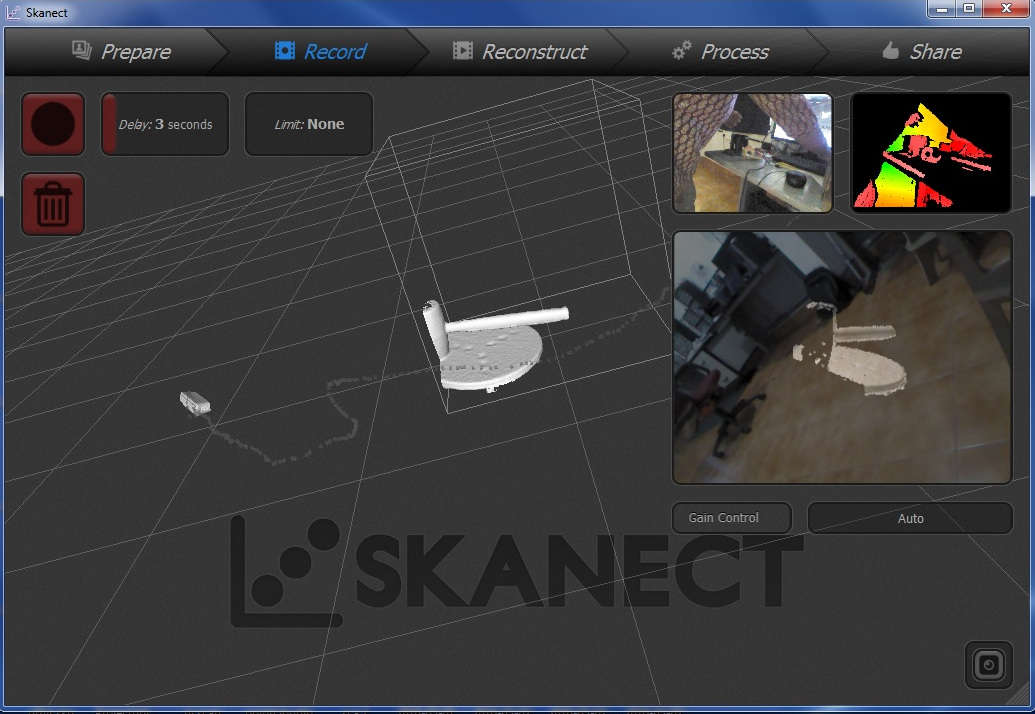

I used the pre-installed Kinect software with a Scanning Software called "Skanect" that interpreted the Kinect's image tracking. I was told I needed to take a 360 degree rotation of the object I was scanning (in my case a Mallet!) so that the 3D scan could form appropriately:

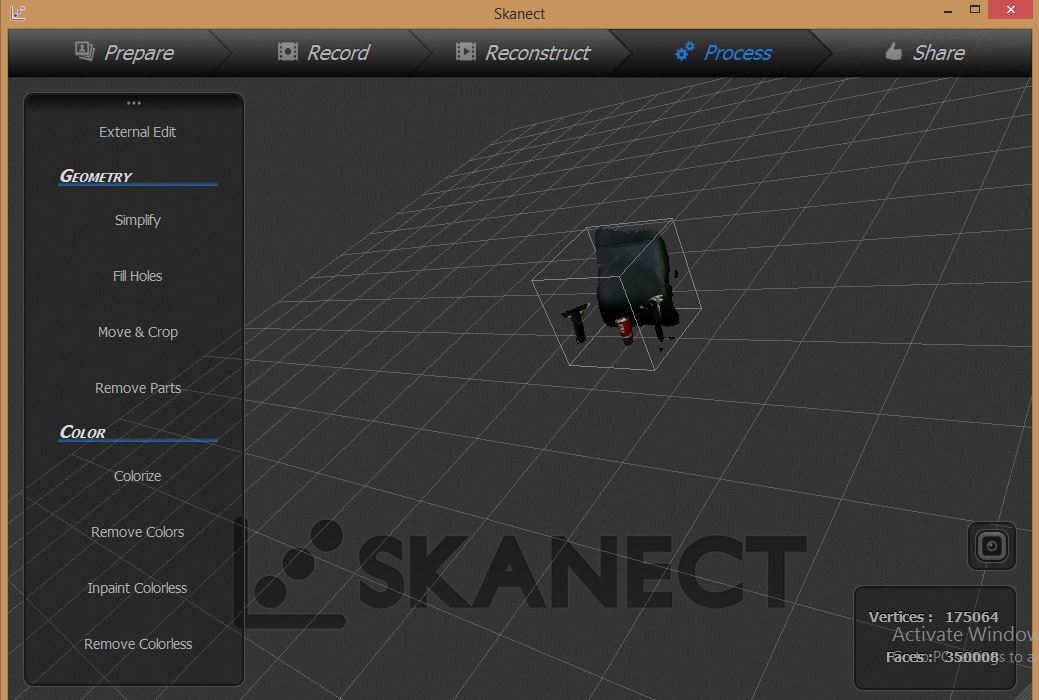

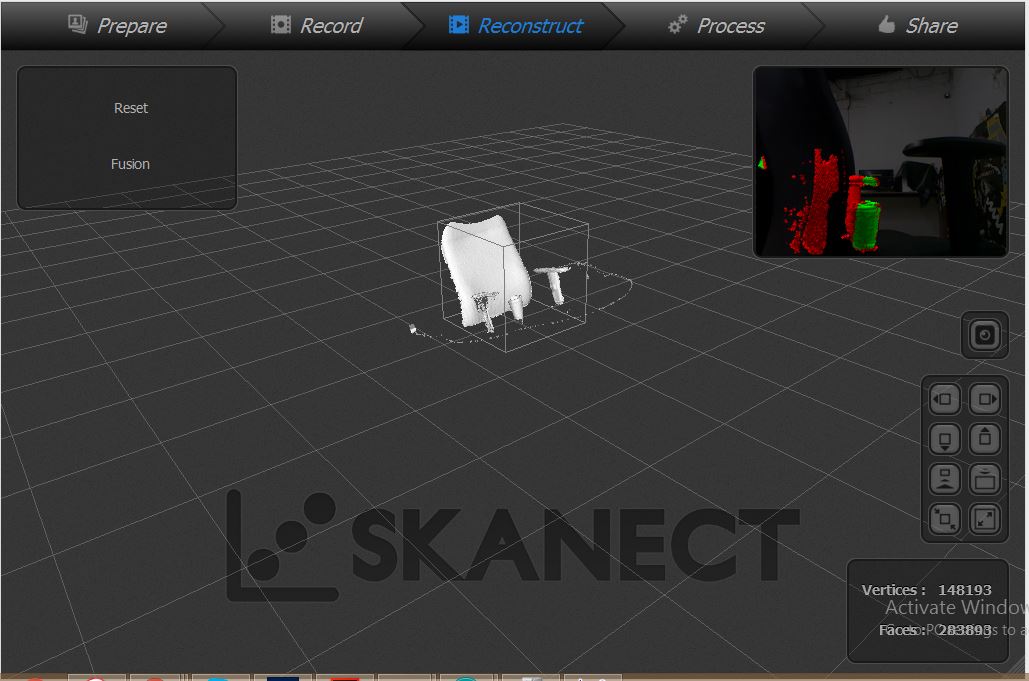

Update: Friday July 8th, 2016

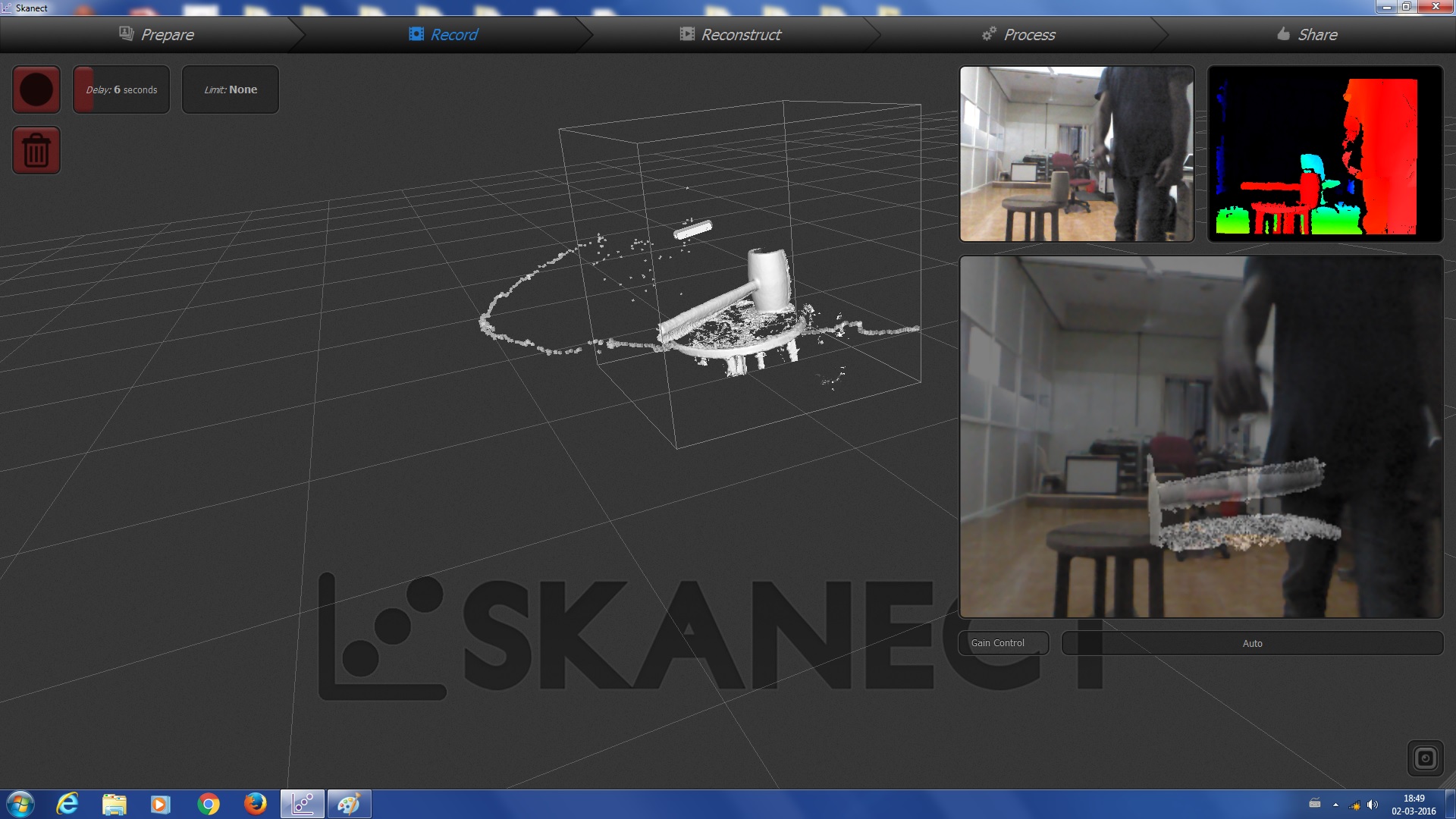

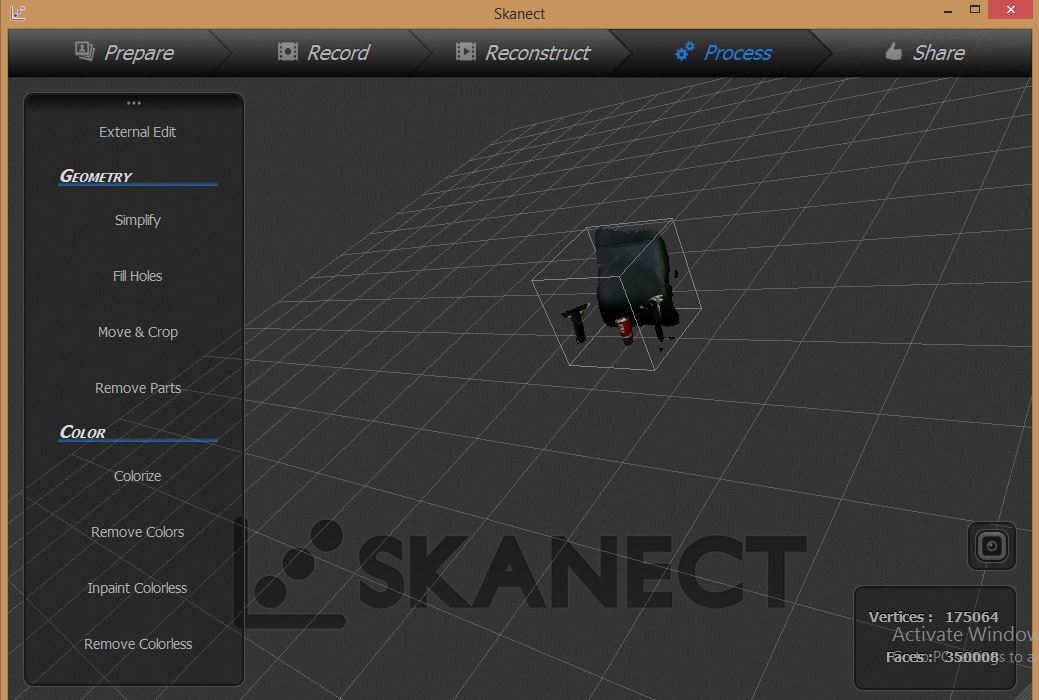

After getting frustrated time and time again with my inability to take a successful 3D Scan using a Microsoft Kinect sensor unit -- I finally decided to take a unique approach! Instead of moving the Kinect module around a stationary object, I decided to "move the stationary object" [in this case the red colored Coffee Cup] using a swivel chair such that I could get as much of a full 360 degree rotation as I could. Below are the results of this exercise:

This attempt yielded slightly better results:

Note: The above images could only me magnified to this resolution -- since the Kinect is by and large a "depth sensor" it needs to be separated at a certain distance from the object being scanned and because I was using the "free version of Skanect software" this was the only resolution the coffee cup could be captured.

Go back HOME