Notes Assignement

design and make a 3D mold (~ft2), and produce a fiber composite part in it

What i am going to do

I want to build a miniature version of Boat Hull using composite materials .

What is s Composite Material?

A composite material also called (Composition Material) is a material made from one or more materials with diffrent chemical or physical properties .

Concrete is the most common example of composite material.

Some Other Composite Materials I studied.

Carbon-fiber-reinforced polymer

Fiber Glass(fiber-reinforced plastic)

Benifits of Composites

-Non -Corrosive

-Non -Conductive

-Flexible

-Design Flexibility

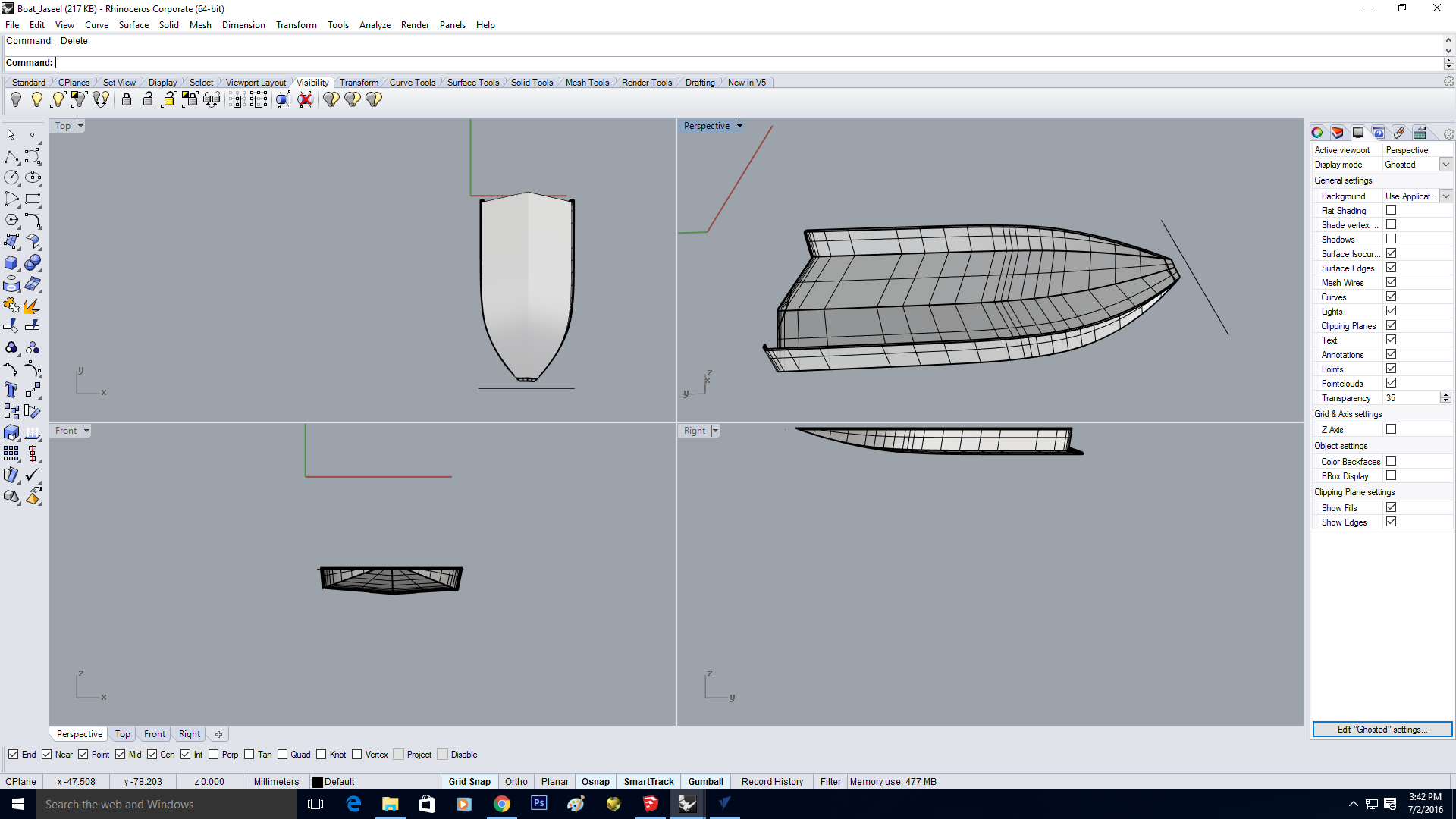

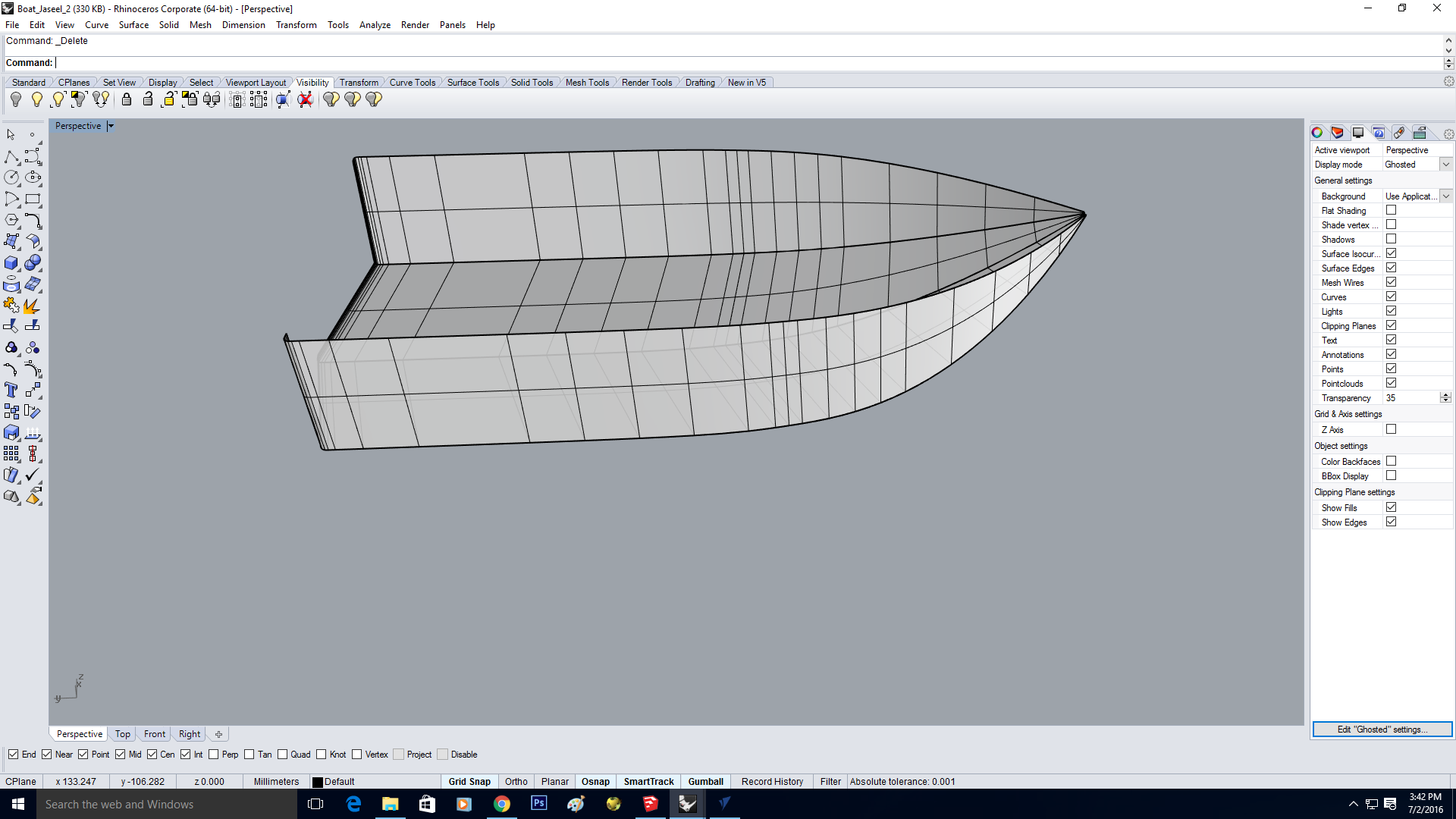

Mould Design

- I am going to design my boat in Rhino , It is very simple first i created shape of cross section and i used “Sweep2” command for making entire boat hull structure from this cross section, I added a screen video of Rhino Designing in the Composite Materials Assignment -Jaseel ,Fablab Trivandrum Video .

-

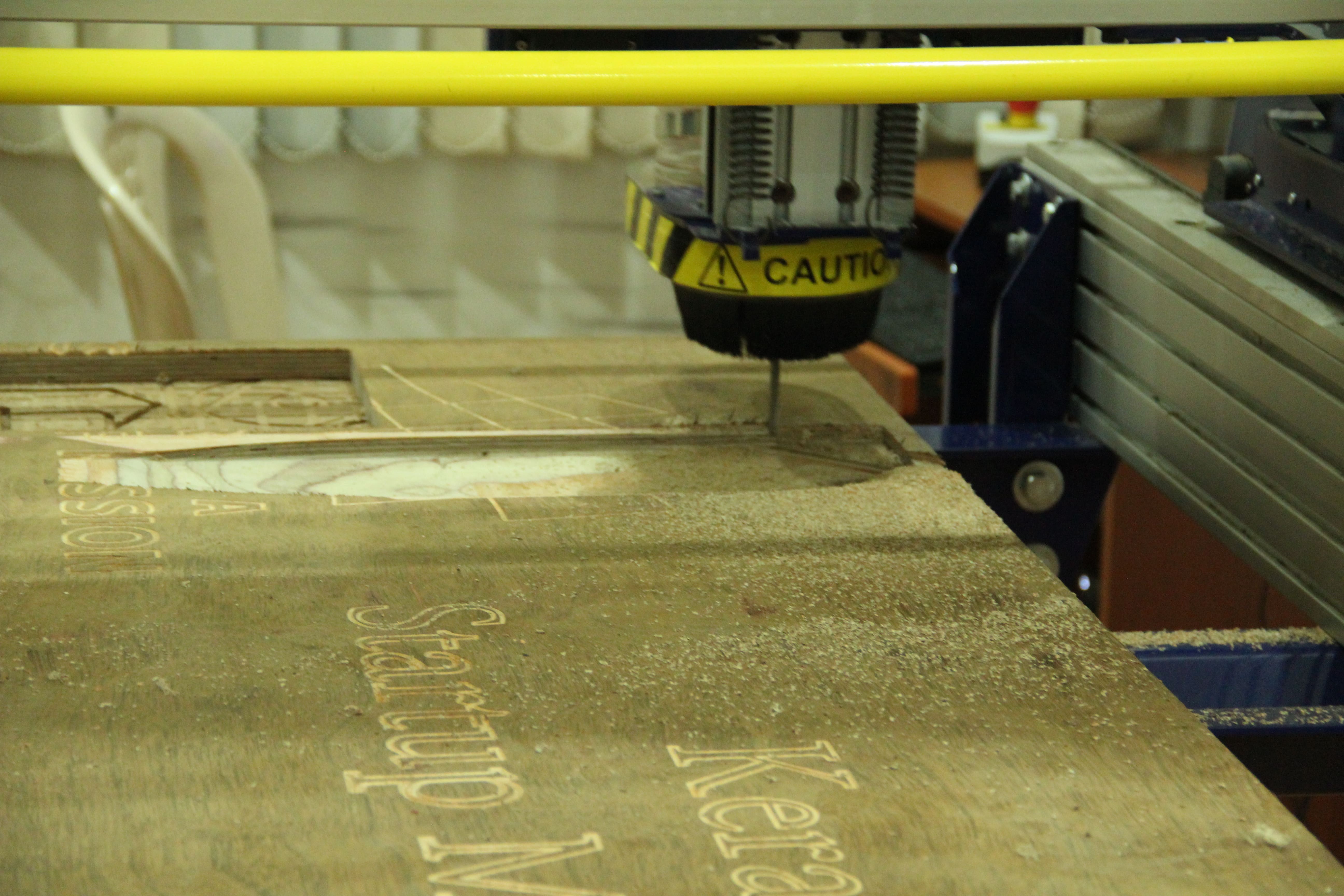

Making of Mould

- I used Shopbot CNC machine used for creating mould on 18mm Plywood .

- I explained opertaions of Shopbot in My Computer Controlled Machining Week . the diffrence is in Computer Controlled Machining Week i used 2D file .dxf file as input because it is profile cutting only and for making this mould i need carving thats why i need to use 3D(.stl) file as input .

-

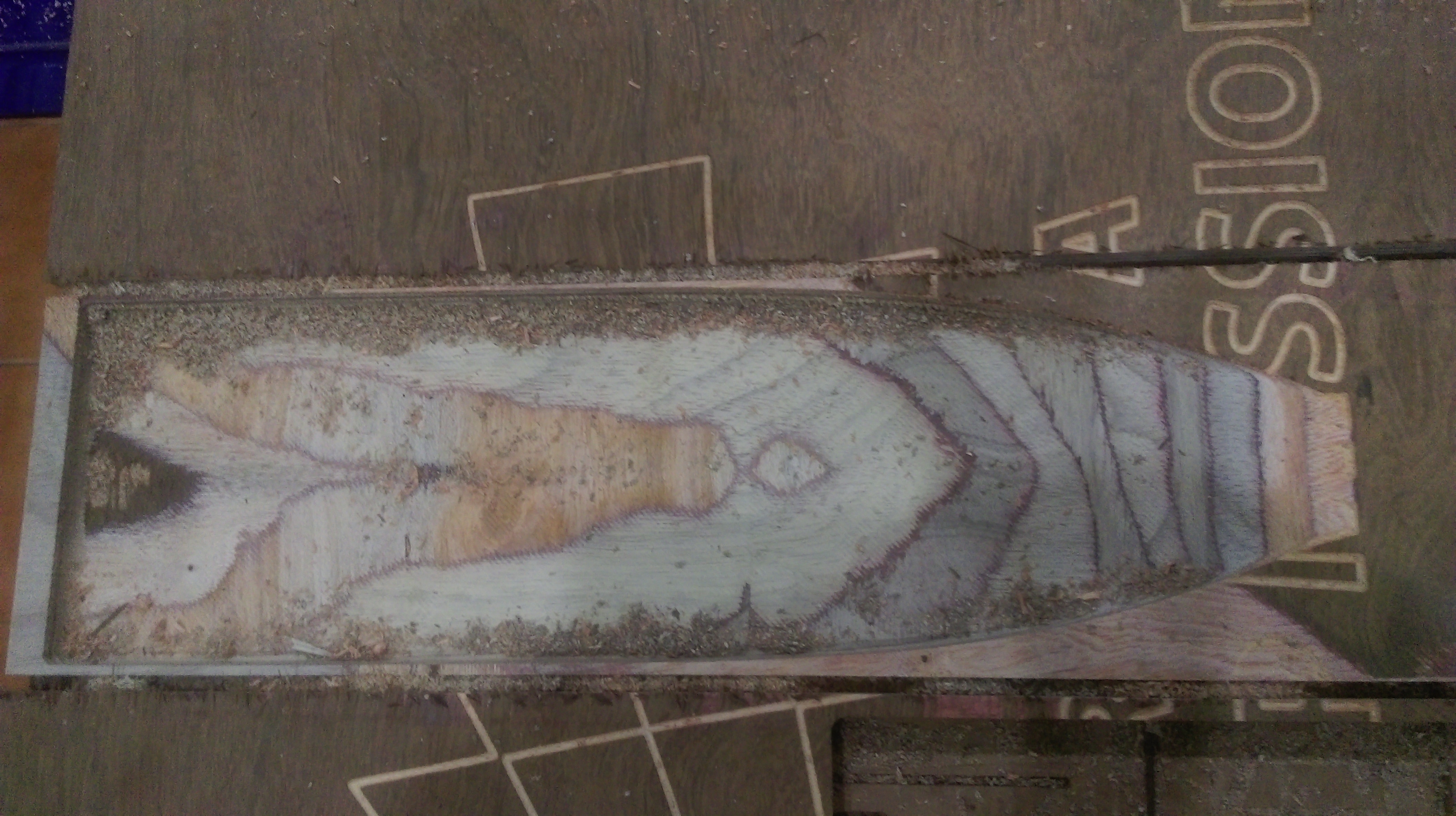

Shopbot started its opertaion , it taken 15 Minutes for Rough Cut and 30 Minutes for Fine Cut .

Shopbot started its opertaion , it taken 15 Minutes for Rough Cut and 30 Minutes for Fine Cut .- Mould Output from Shopbot , The Mould is ready next step is adding composite to this mould.

Materials Used

1)Matrix Material

Matrix Material (2 Part epoxy ARALDITE Multipurpose epoxy resin)

- Resin and Hardner in 1:1 ratio.

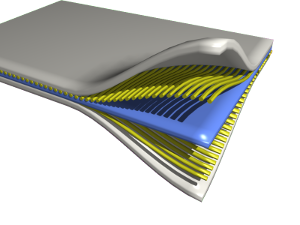

2)Fibers

Nylon and Jute

- I taken 2 layer of Nylon and a layer of Jute in between them .

-

Process

1)Mould Design(Explained above) 2)Mould Making(Explained above) 3)Preperation of Resin and Composite Materials(Explained above)

4)Creating composite layers

I created 3 layer composite , i sandwiched two nylon layers with jute and we need to wet all fiber layers using Resin Mix(Resin+Hardner 1:1) and do it slowelly and carefully.

5)Vaccum Bagging

After covering with a plastic sheet we need to vaccum bagging using a Vaccum bag and vaccum cleaner .

- I forgot to take picture of this process thats why i am adding the picture of my colegue Rashid .

-

6)De Moulding

Normmaly it takes 24 Hours to set in room temperature but i taken after 12 hours need to remove excessive material using a tremel or blade .

7)Final

- This the final product, bot is waiting for water :) .

Process Video

Composite Materials Assignment - Muhammed Jaseel ,Fablab Trivandrum from Jaseel on Vimeo.

Problems Faced and Solutions

After making composite materials i covered my workpiece with a breather cloth and i created some vent holes air passage, unfortunatellly small amount of resin coming from composite to that breather cloth then it sets . thats why some amount of breather cloth sticked in my boat.

Solution

never add excessive amount of resin in especially in top layer .

New Things I Learned

I learned lot of new things in this week , mainly i learnded how to make composite materials for our needsmainly using resin .