Assignement

design a 3D mold, machine it, and cast parts from it

What i am going to do

- I want to make a casted wrist band using rubber .

-

Courtesy : http://www.technologystudent.com/equip1/poly2.htm

Mould

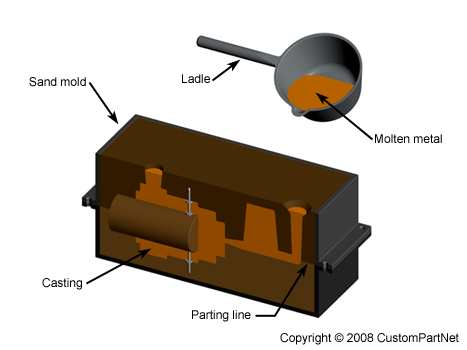

I had done sand casting in my college days

Courtesy : http://www.custompartnet.com/wu/SandCasting :  ,now i am going to make a real mould in wax,We are using Machinable Wax for it .

,now i am going to make a real mould in wax,We are using Machinable Wax for it .

Why Using Machinable Wax?

Machinable Wax is a very hard Wax having High Melting Point specially designed for Machining Applications .

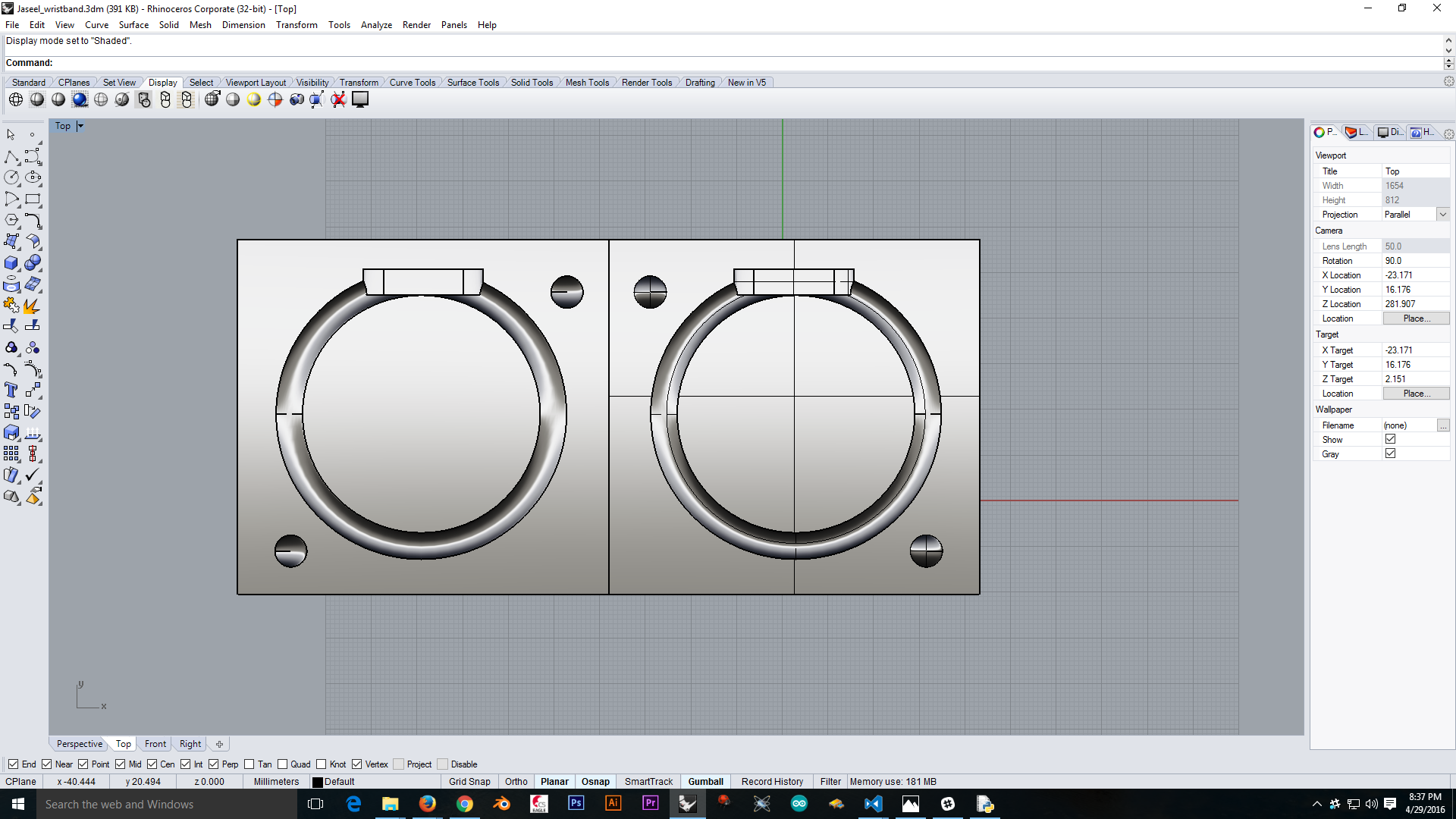

Mould Designing in Rhino

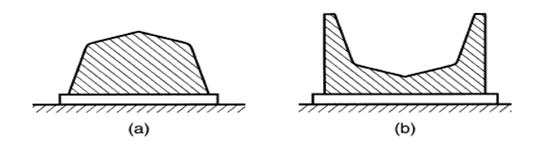

- I designed a Negative Mould in Rhino for my Wrist Band, What is Negative Mould ? You Can easily understand by looking the following picture.

-

A)Positive Mould b)Negative Mould

Source :http://www.fibre-reinforced-plastic.com/2011_12_01_archive.html

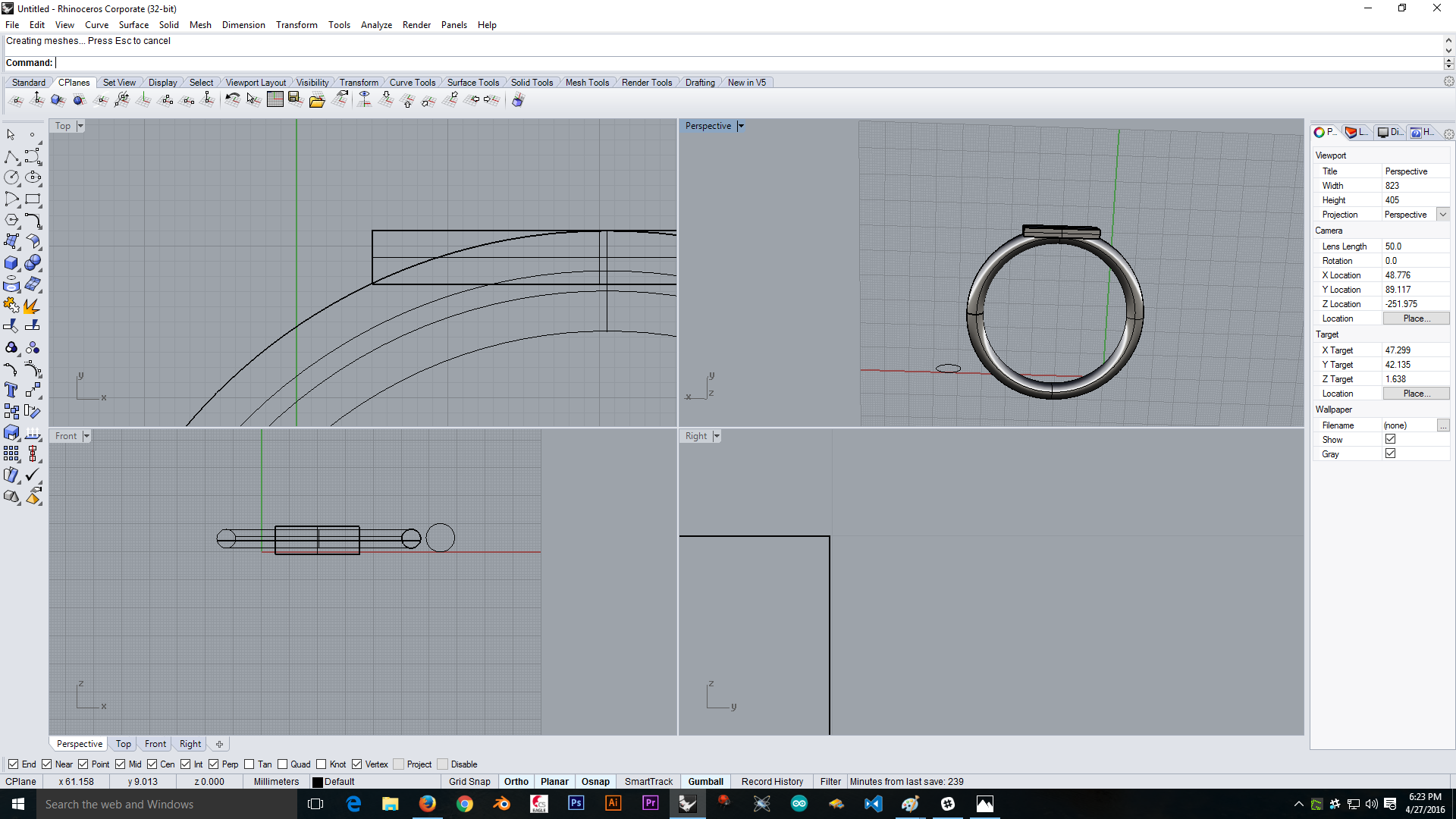

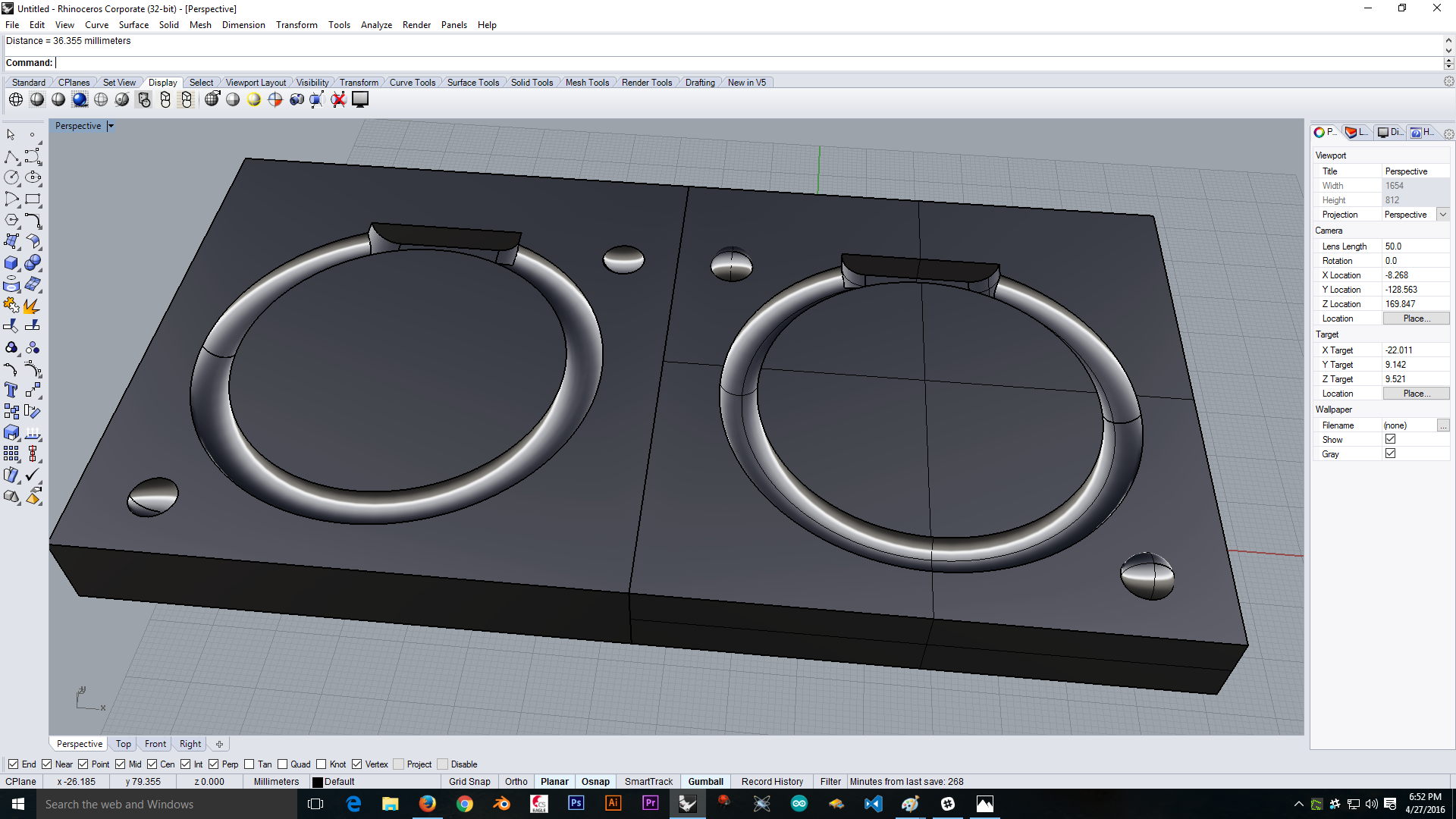

Rhino Designing Screenshots

- :

Yaa, I created a mould design in Rhino , Now it is ready to Export to .STL format for Milling in Modella or ShopBot . Download Rhino File

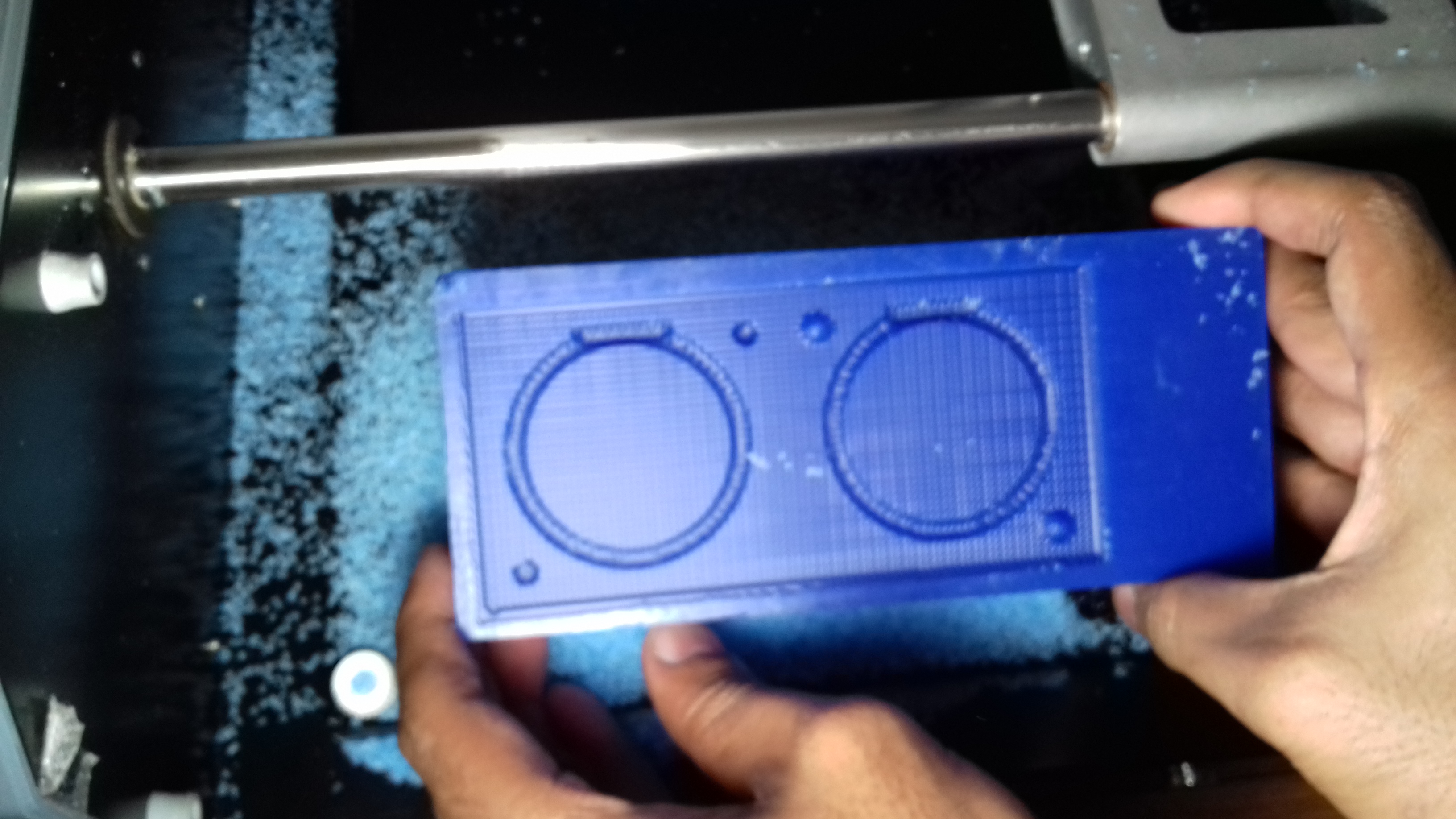

Milling Mould in Modella

Modella supports STL file thats a new information to me also have an option to convert .STL to .PNG , I used 1/8” Bits for both Rough Cut and Finishing Cut .

Rough Cut and Finishing Cut

- This 2 level cuting method saves energy and time also gives a good finishing , Yaa rough cut removes major portion of the unwanted wax by milling and same time finishing cuts makes smooth and accurate.

-

:

:

Yaa, Mould is Ready . Next step is Casting.

Casting Process

This is the process of filling mould by which material we want to use ie, Rubber, Silicone,Plastic,Metal etc…

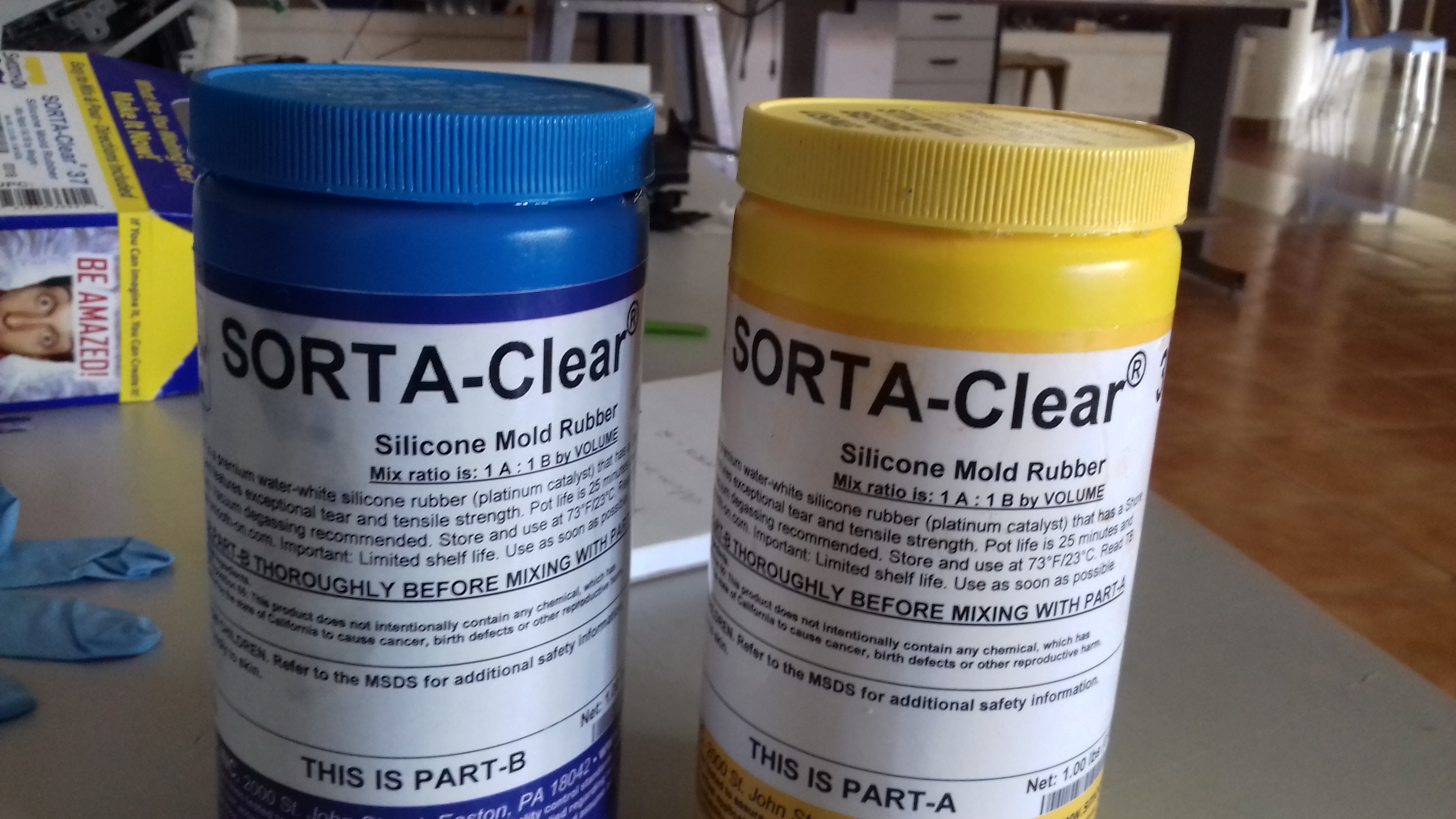

Now i am going to use Silicone Rubber(SORTA Clear 37)

SORTA Clear 37

It is a Water white translucent silicone rubbers which cure at room temperature with negligible shrinkage and feature high tensile and tear strength.

SORTA Clear Part A and Part B:

List of Materials needs for Casting

- 1.Mould

- 2.Sorta Clear 37 :Part A

- 3.Sorta Clear 37 :Part B

- 4.Water

- 5.Plastic Cup

- 6.Wooden Stick

- 7.Aluminium Foil

- 8.Patience :) :) Your Patience will indicate in your final Result .

-

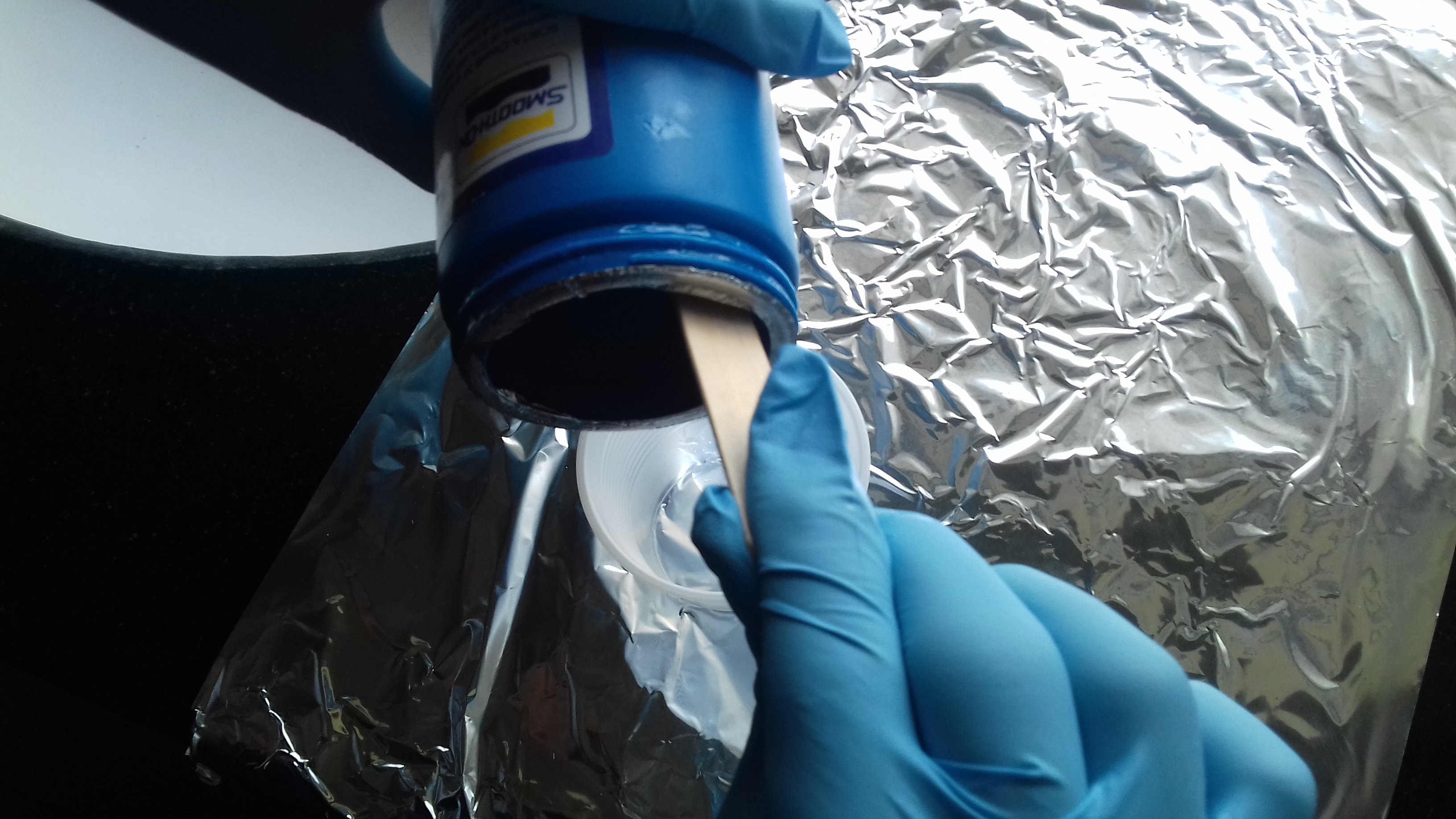

Process

- 1.First fill your Mould with water and pour that water into a Vaccant Glass (It is for measuring the volume of mould)

- 2.Take Part A and Part B in Glasses (Equal to 1/2 Volume of Mould)

- 3:Mix It(1:1 Ratio)

- 4:Add 1 drop of Coloring Agent(If you need color)

- 5.Pour the mixed material carefully to Mould (Be careful to air bubbles that makes holes in final product)

- 6.Remove Unwanted Material from Mould

- 7.Wait 4 Hours then Open the Mould

-

Wait 4 Hours to set .

Finished Product

- :

Problem Faced : I designed this bracelet to my hand but after casting shrinkage happen

Solution :

Need to add some shrinkage allowance in mould design.