Group Assignment

Week 1 : make a machine, including the end effector build the passive parts and operate it manually document the group project and your individual contribution

week 2 : automate your machine document the group project and your individual contribution

This is our Awesome Team

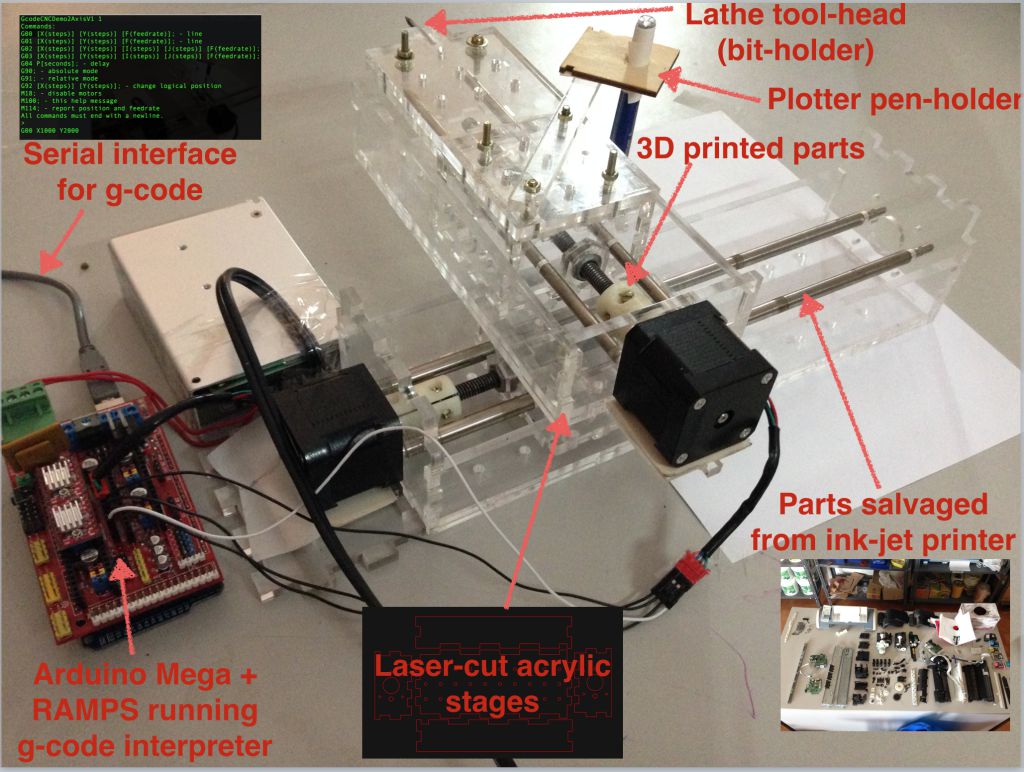

While we started thinking of a nice fab friendly project we got many ideas(Foam Cutter,Plotter,CNC Lathe etc) after a discussion with with all members we finalized to make a CNC Lathe for automated machining of diffrent metals. and we divided entire project task to each members and created a seperate page for our group project Team 1 : Project Page I am only explaining my individual contribution in this page.

My Contribution

1.Tool Header for Lathe

- I created a Tool Header for our CNC Machine at this time we are thinking of creating a lathe later we pivoted in to plotter or multipurpose fab machine .

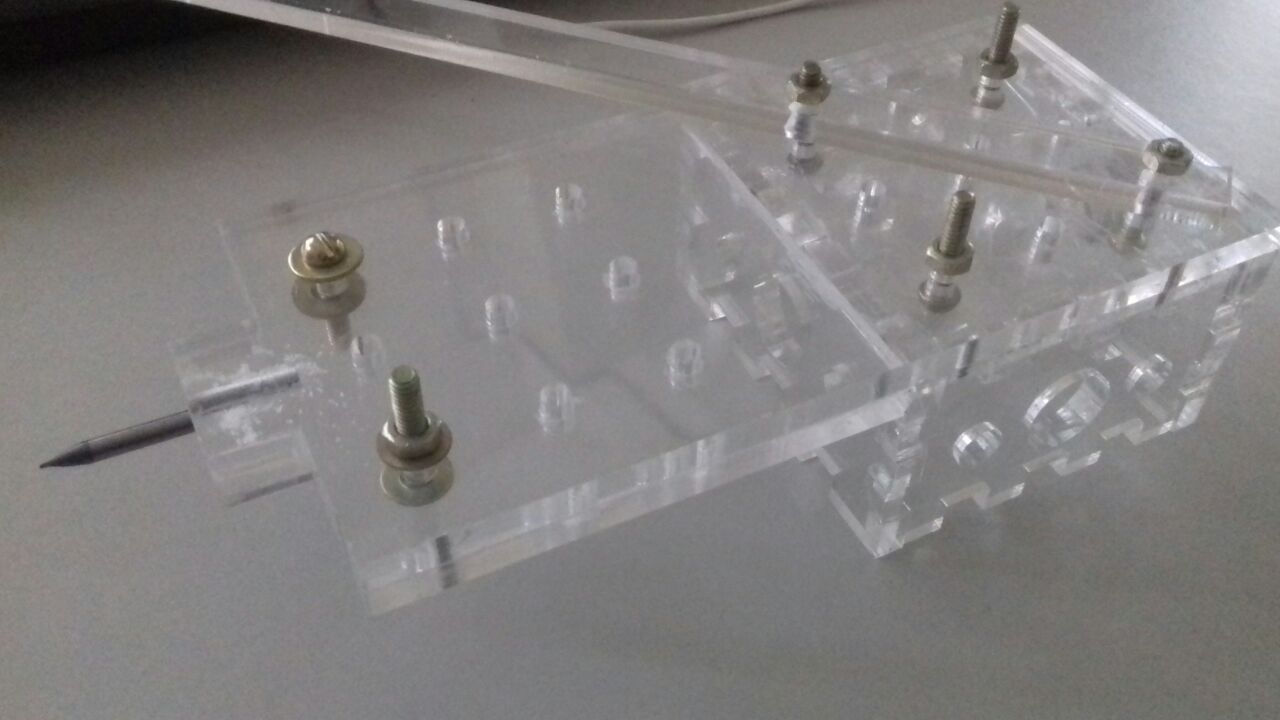

- While thinking of tool head i just googled for similar technioques but time is a main constrain because of that we decided to make a simple tool header using broken Bit.

-

I collected a 1/64 broken bit and created a tool holder for holding this bit .i used sandwiched two specially designed acrylic parts using screws to fix bit in holder .

It is not suitable for heavy machining tasks but this is enough for small tasks .

- I decigned this tool holder in Rhino,the main constrain is i want to make sure positions of screw holes for fixing this part in our CNC Machine .

-

2.Optical Encoder

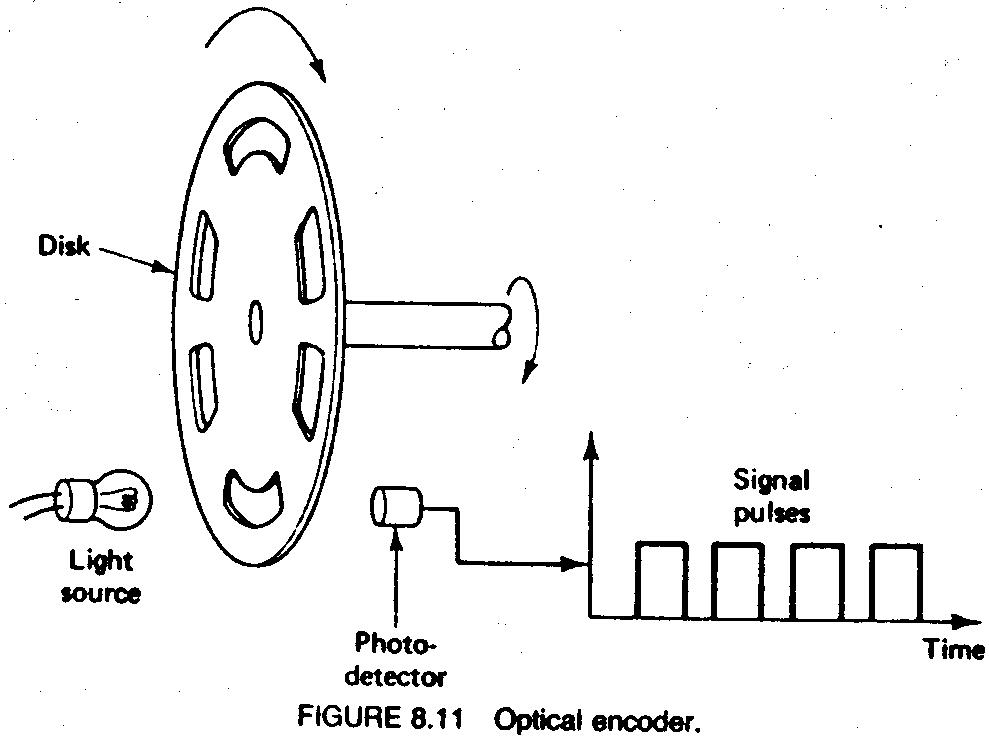

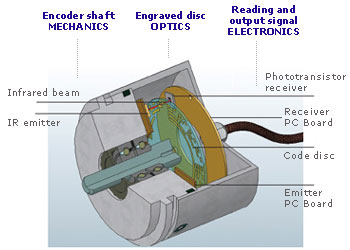

An optical encoder is an electromechanical device which has an electrical output proportional to the angular position of the input shaft.

It is normally used for Closed Loop Control in Printers,CNC Machines etc…

Encoder Principle:  Encoder Attached to Motor:

Encoder Attached to Motor:

Reading from Encoder

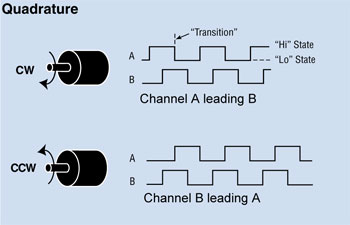

I am using Quadrature Encoder which have Two digital outputs (Channel A and Channel B) ,Quardrature encoder gives direction of rotation using this two channels

Quadrature Encoder Working:

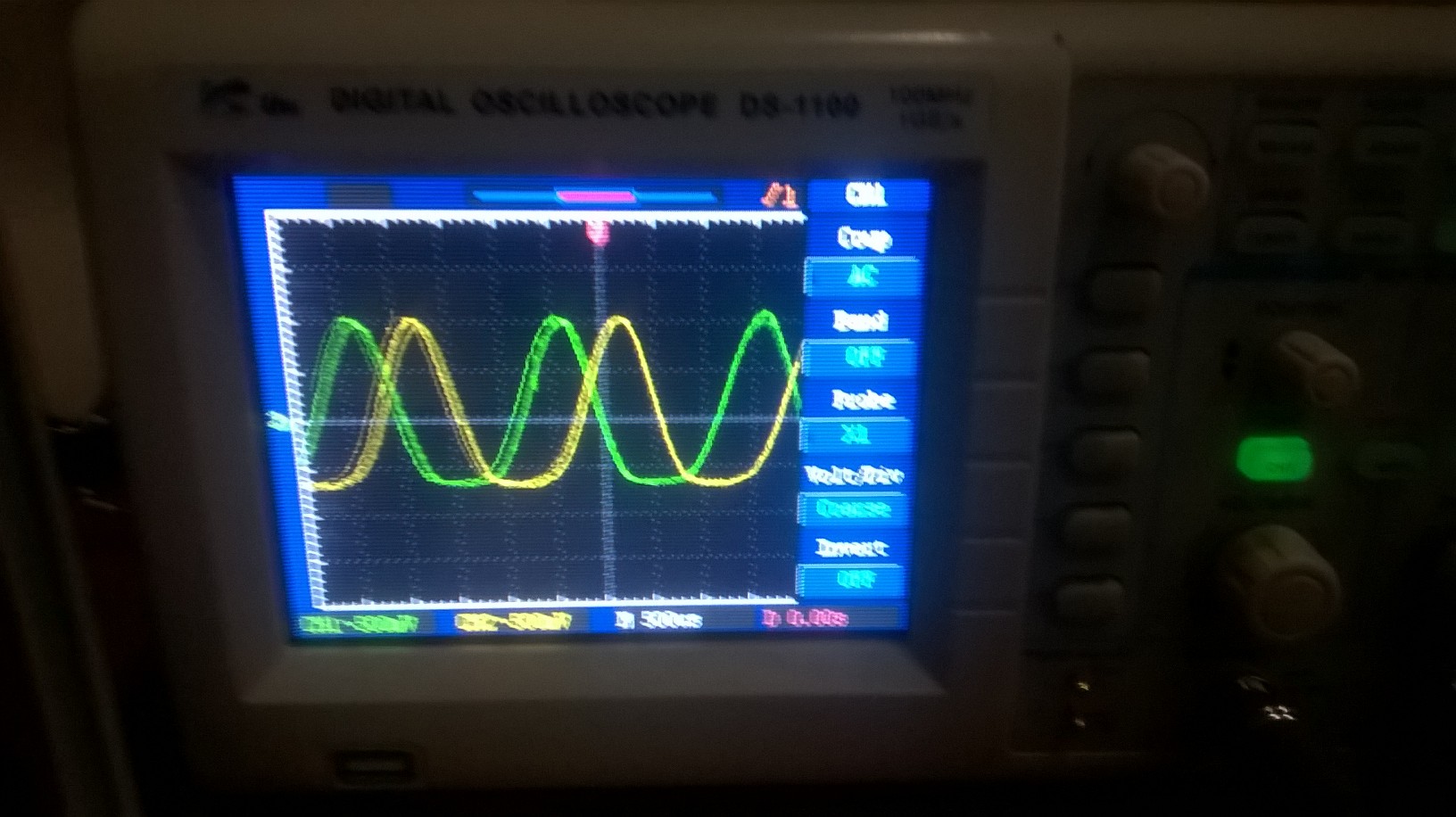

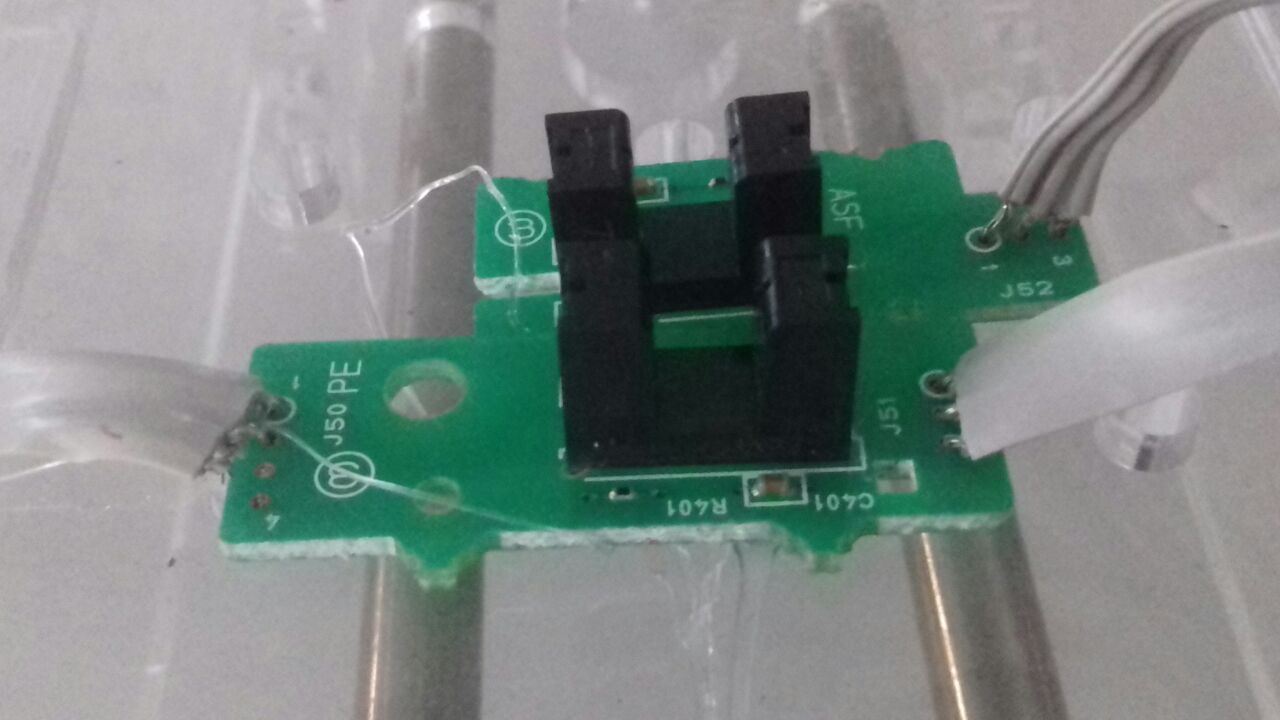

I got a Quadrature Encoder from an old Printer ,thats shown below .

Encoder from Old Printer:

We can easily get direction and no of rotations from analyzing this outputs.

Encoder Channel analyzing:

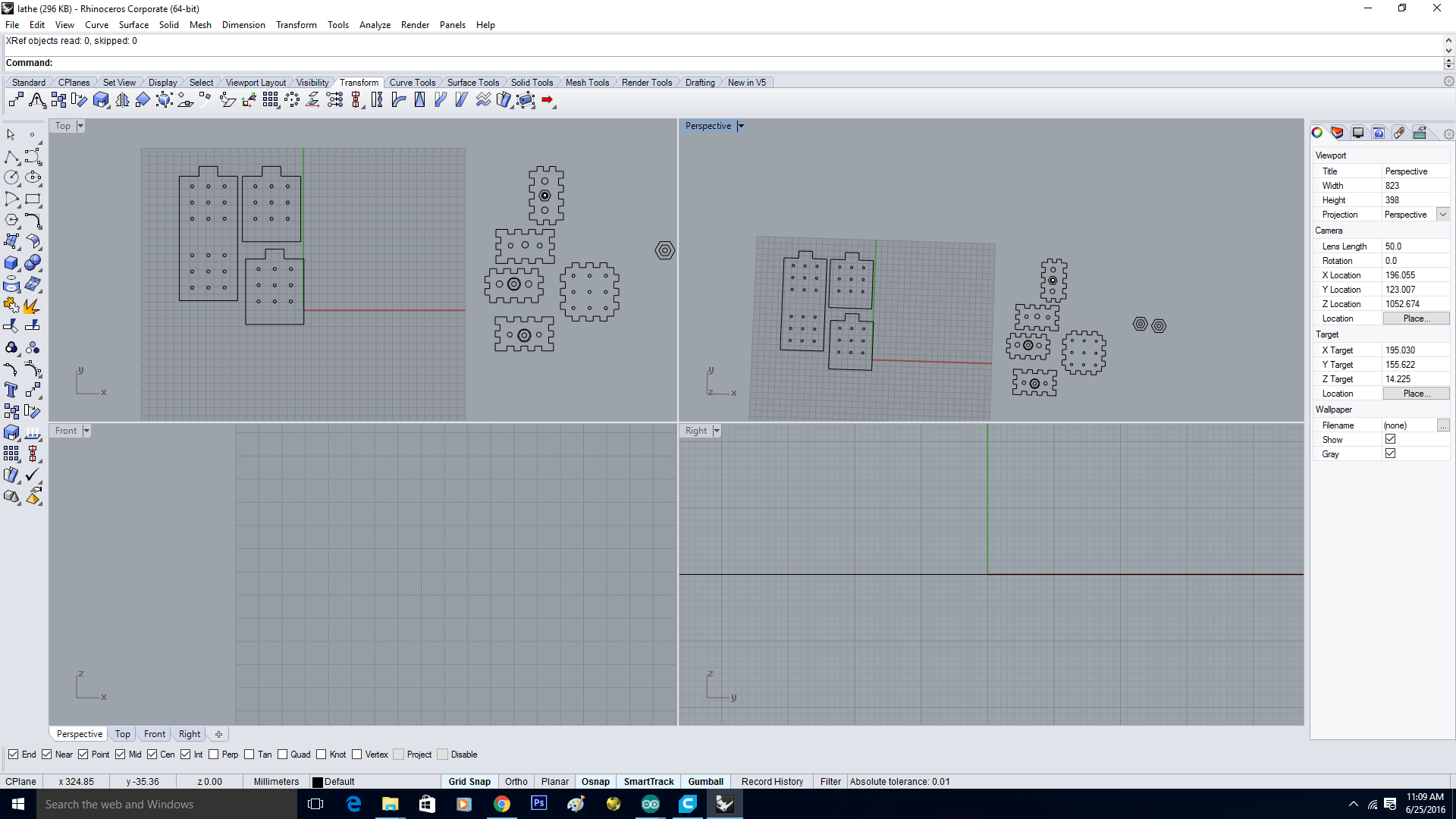

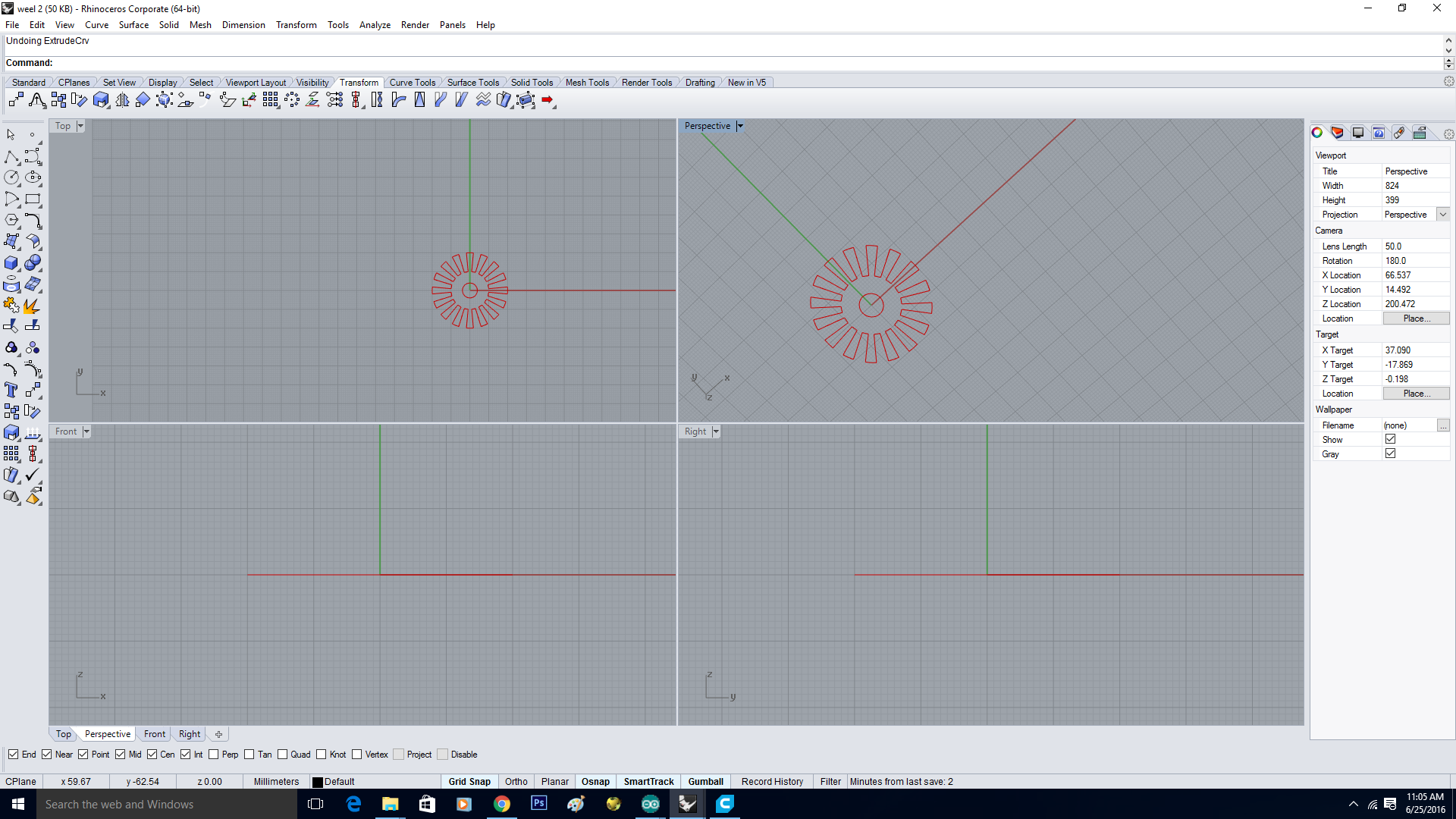

- I designed my own Encoder Wheel for our CNC Machine in Rhino and laser cut in 3mm acrylic

-

Laser Cut

Laser Cut  Encoder Wheel Mounted on Stepper Motor:

Encoder Wheel Mounted on Stepper Motor:  I used Optical Encoder Transmitter/Reciever Part from an OLD Printer.

I used Optical Encoder Transmitter/Reciever Part from an OLD Printer.

and I connected this encoder wheel to our Motor but unfortunately it is not easy to implement in this stage thats why we droped that plan to add an encoder inour machine but i learned working of encoder and how it is meaasuring value.

Possible Improvements

Make an UI for Controlling CNC Machine Add a Machining Mechanisom instead of Simple Tool Head

Problem Faced and Solution

Small Vibrations in Machine it effects the qulaity of the plotter

Solution : We need to replace threaded rode mechanisom with Rack and Pinion or Belt Mechanisom .