Applications and Implications

In this week we have to propose our final project that integrates the range of units covered, answering

what will it do?

who's done what beforehand?

what materials and components will be required?

where will they come from?

how much will it cost?

what parts and systems will be made?

what processes will be used?

what tasks need to be completed?

what questions need to be answered?

what is the schedule?

how will it be evaluated?

I have already fixed and proposed my project in the first week itself and i am not going to change it. I am putting more details here.

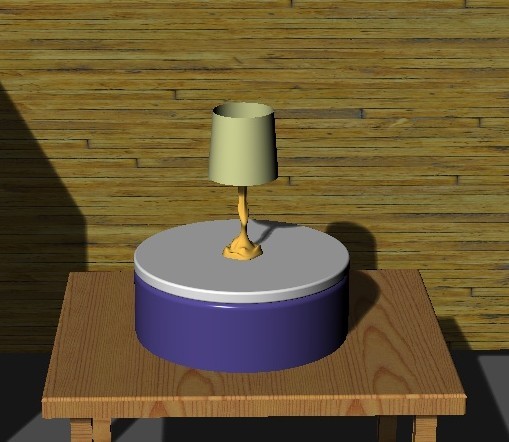

Revolve 360 - 360 degree photography device

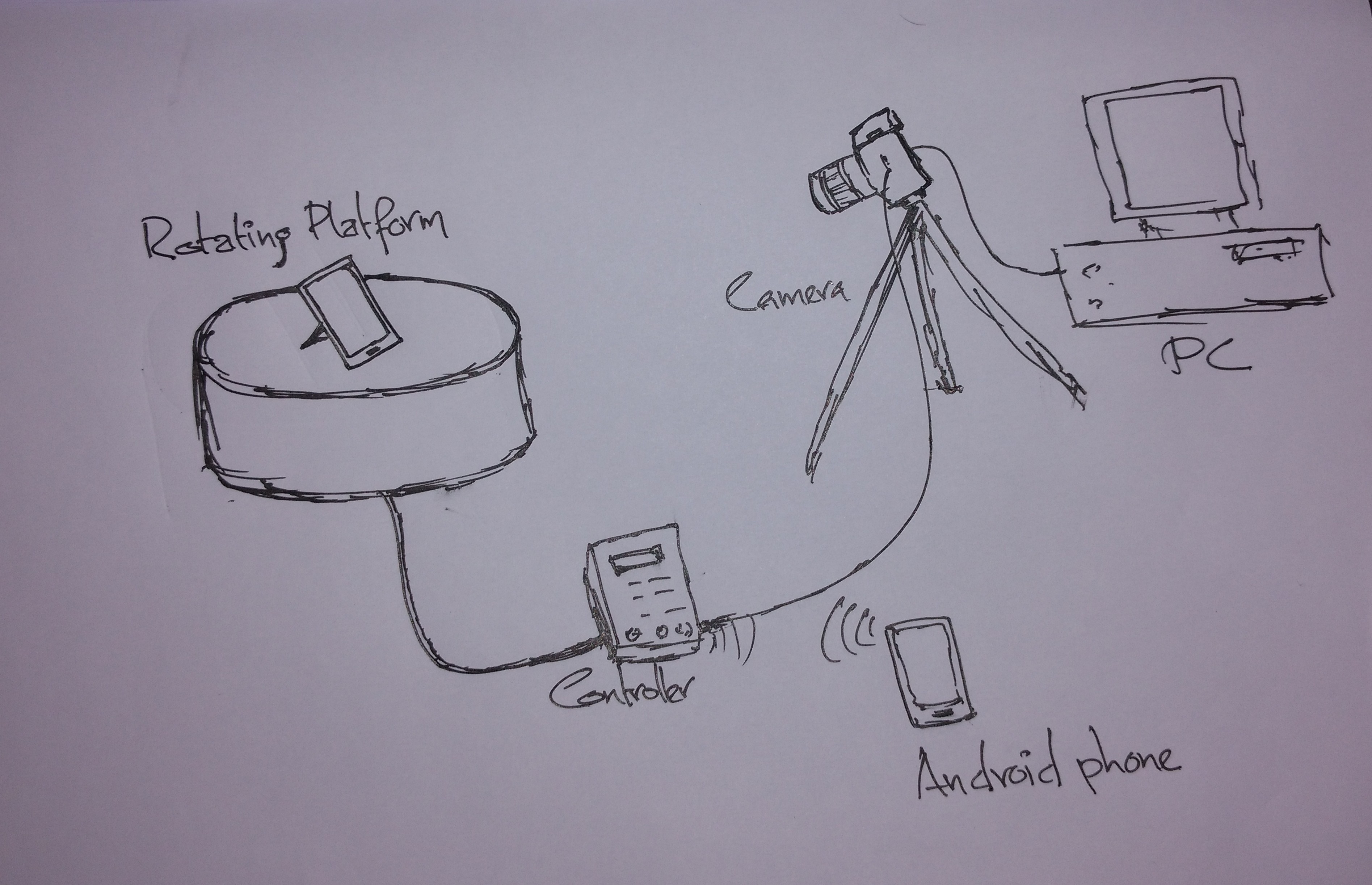

The idea is, to make a rotating platform which helps for 360 degree product photography. The product is placed on the device which will rotate by fixed angles and the camera is kept stationary. The platform will get rotated by a fixed angle and will wait for a while for capturing the image of that instant. This process will continue till the total angle becomes 360 degree. So by merging all the images captured, we can make a 360 degree visual of the product. For controlling the parameters like rpm and all, I am planning to add an android connectivity also other than the normal hardware switches.

Working

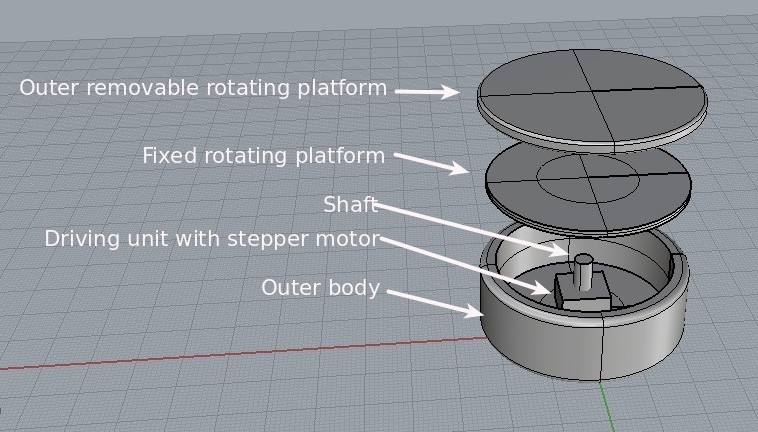

The important parts of this device are

The controller part will be a separate module. There will be a joystick or a rotary switch to control the parameters like rpm,delay time etc and a LCD to show the parameters. The controller will gives pulses to the steper motor driver to rotate a particular angle then give pulse to trigger the camera. For triggering camera i will use either a wired connection or a wireless connection using RF module.

Image merging

Once we get the images from the camera we have to merge it for getting a 360 degree visual. actually image is not processed or stitched, but the images should be loaded one by one when we click and drag the mouse. Here is an example i tried with Sirv. When u drag the mouse over the lamp u can see it is turning.Who's done what beforehand?

I have seen some videos of some turntables which is similar to my device in the youtube. But i couldn't get more information about it. Anyway I could n't find anyone who has done it before in our country (India). So there is no reference files or design for my project and i made all the design from scratch.

What materials and components will be required? The materials and components are

Where will they come from?

Most of the components rea available in the lab so i can use it. Things which are not available is plastic sheet, bearings, shaft rod etc. SO i have to buy it from local market.

How much will it cost?

The item which costs most will be stepper motor. Which cost around 20$. All other things are cheaper comparatively. According to my calculations the total cost for making my device will be below 40$. The materials that I should buy from local market costs oly 3$ or 4$.

what parts and systems will be made?

Almost all the parts will be made except the bearings. Even gears I am planning to make using the acrylic sheet. The power source (12V SMPS) is already available in the lab , so i wont m=be making a SMPS but will use it directly.

What processes will be used?

The processes I have to go through are :Task to be completed

I have done a rough sketch and a rough design which is shown in this page. Another thing I made is controller board. The controller board is not complete but I milled the board and soldered some components. I have to complete it. Some of the pulleys for the motor shaft is also made already by 3D printing

what questions need to be answered?

The GUI part is something I may want a help. I know the basics and to make a simple UI in python, but for better and attractive UI i need to learn more.

What is the schedule?

Right now my plan is to build the hardware first. After making the hardware i will start the programming part. My plan is to make a working prototype before 22nd July. The UI will be made after that only. Right now i have trouble with the android interface since i don't know android programming. So after completing all other work i will start working on Android. I know i can use MIT app inventor but for better UI and more options, I should use the native android.