#Exercise_7

9/03/2016

Assignment

Computer controlled machiningDesign and Make something big with a CNC milling machine.

Design a valet stand and a dog bed

Source filesTools and materials

- CNC router

- Sandpaper

- Water-based trasparent wood paint

- 15mm fir playwood 2440mm x 1250mm

- Rhinoceros CAD

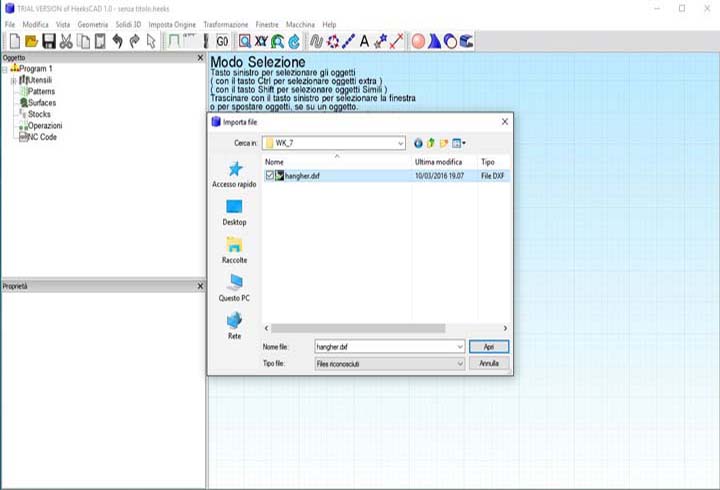

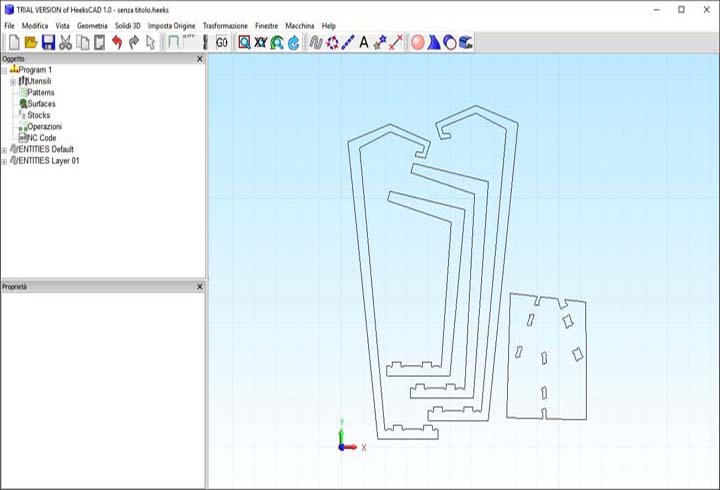

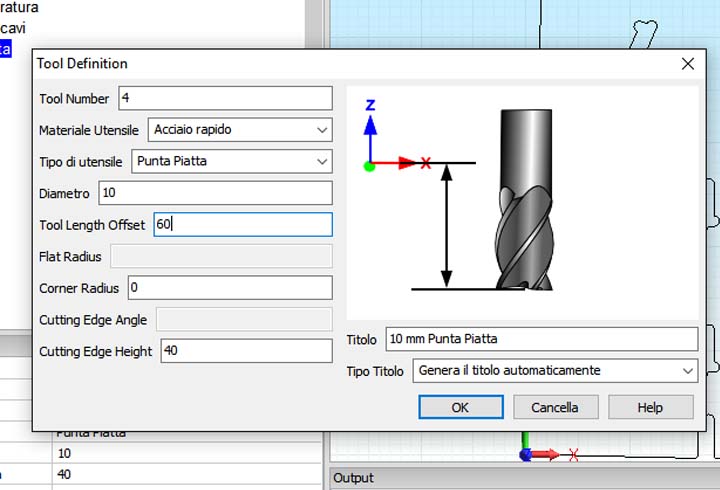

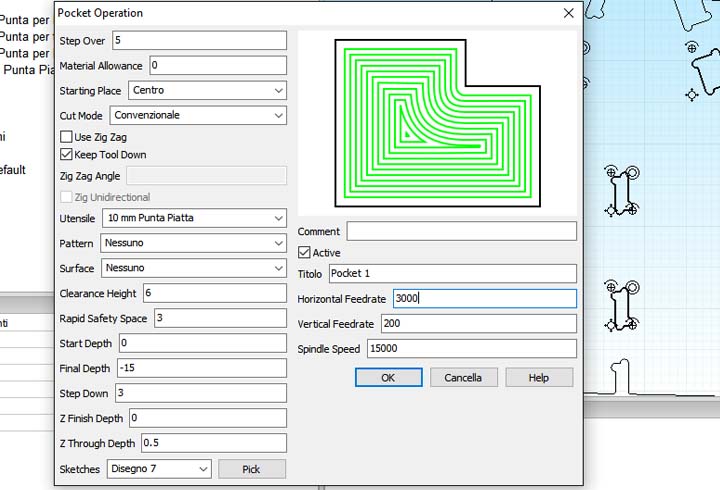

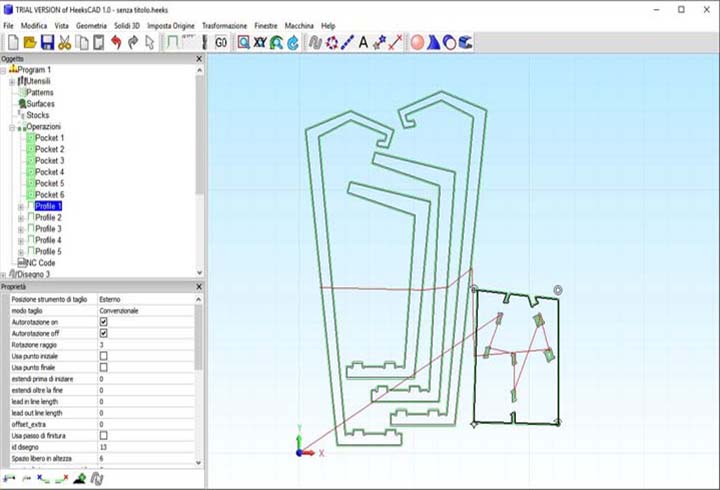

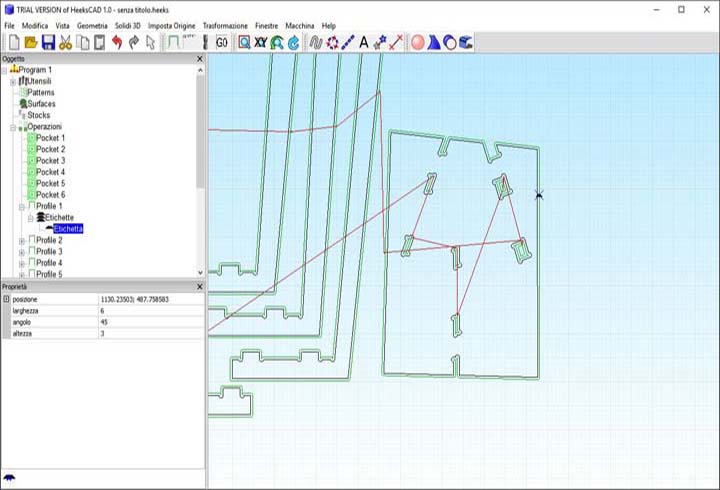

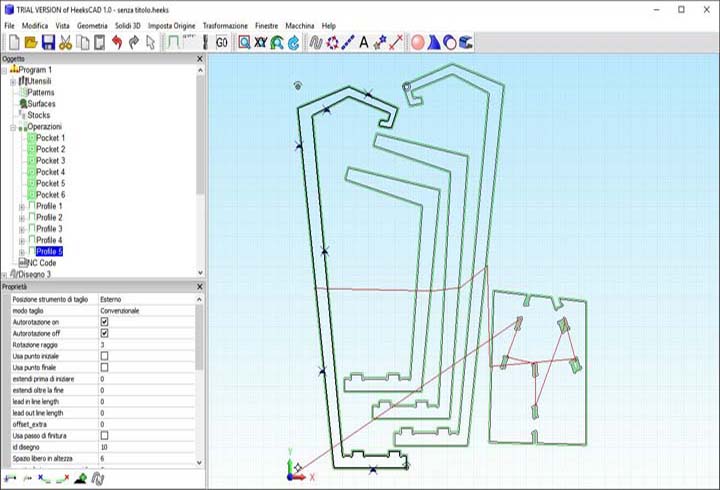

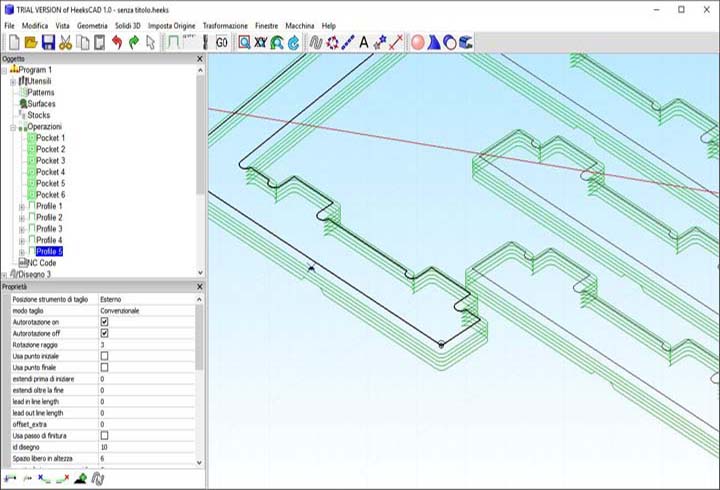

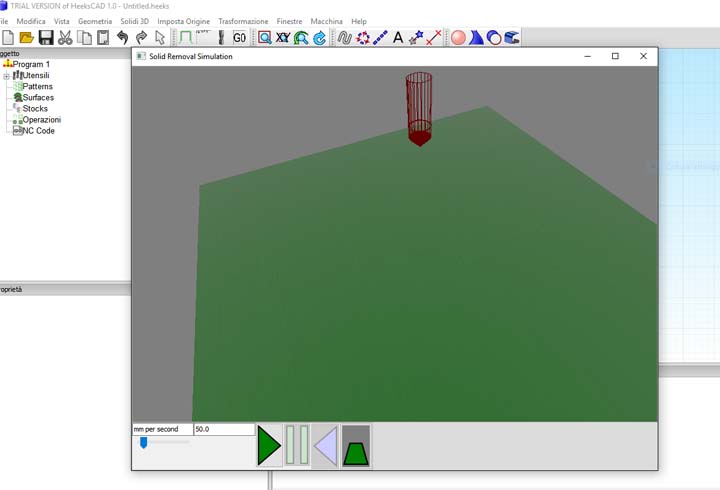

- HeeksCNC CAM

For the assignment I have decided to use Heeks CNC an opensource cam software available for windows and linux that have a very simple and intuitive interface; I have made a lot of experiment with several cam (RhinoCAM, Fusion360, PowerMILL and camBAM) my favourite still remain RhinoCAM, all of these softwares are very complete but at the same time difficult to use and expensive; so for a 2.5 axis works and simple 3 axis works HeeksCNC will be perfect.

To design the objects I used Rhinoceros, I haven't use grasshopper or Solid Works because I didn't need a parametric objects.

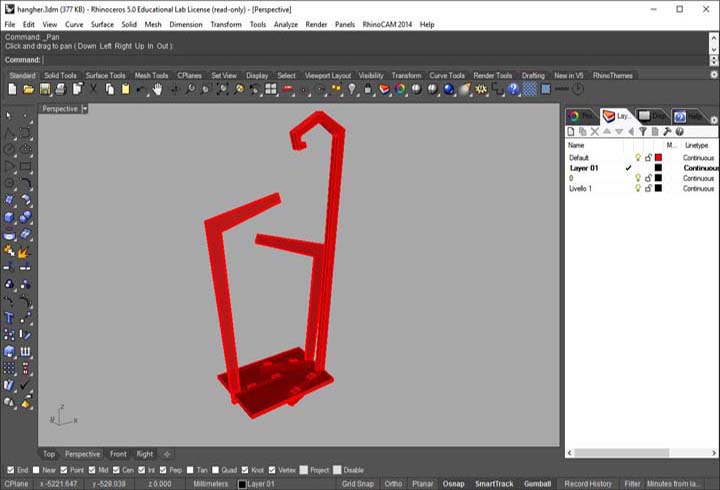

1st step: I designed this stand to put in the bedroom, it's a useful hanger for pants and vests used during the day.

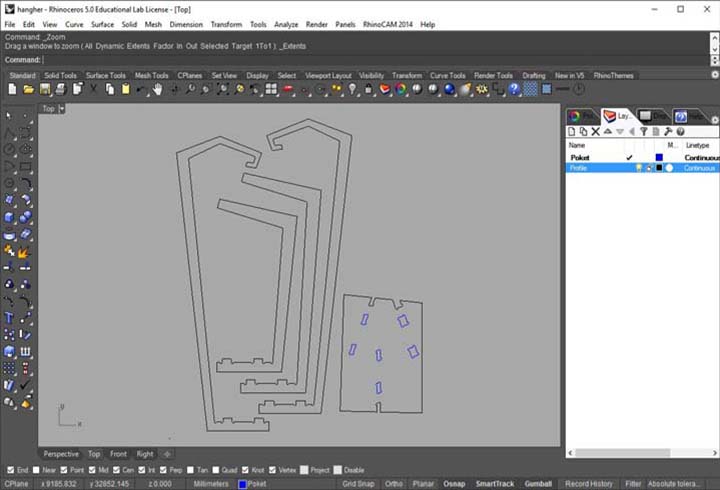

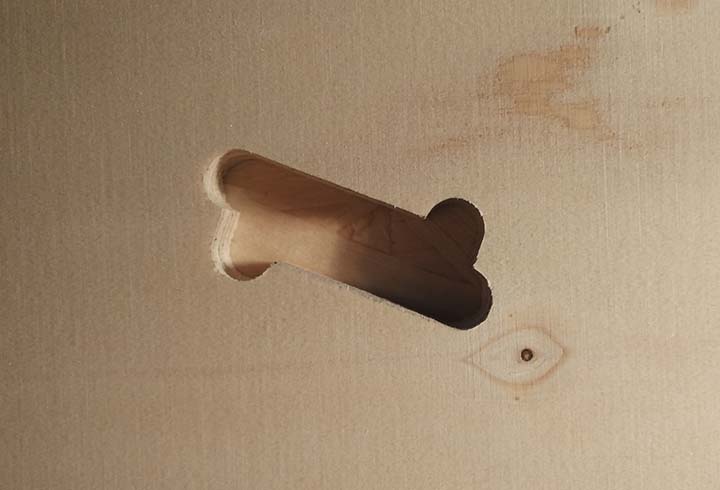

2nd step: preparing the 2D CAD file to postprocess with the CAM. For the valet stand I used the classical CNC wood joints. Nest all the peaces and export it in .dxf R12 Natural pay attention to put the in the right-down origin in 0,0,0).

CNC router: our machine have a 2000mm x 1250mm x 100mm of work area, a 3KW and 30000rpm water-cooled spindle, and a vacuum pump or MDF plane. This router allow to work with aluminum too without problem.