#Exercise_12

13/04/2016

Assignment

Molding and CastingDesign a 3D mold, machine it, and cast parts from it.

Design and make a gear reduction and an Archimedean Screw mold

Source filesTools and materials

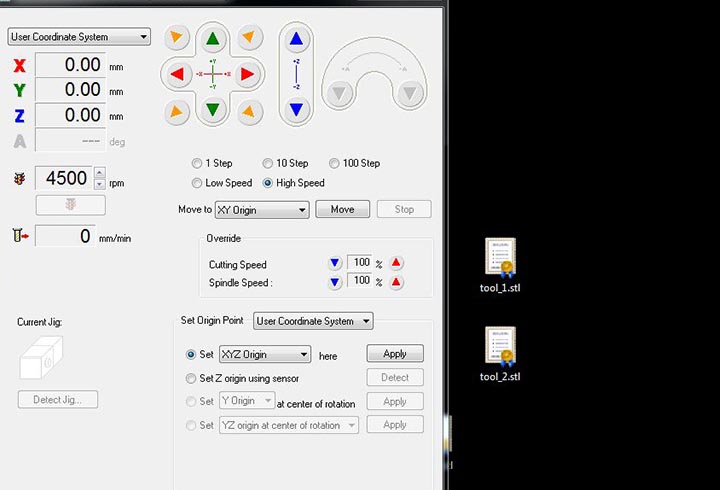

- CNC router

- 3D Printer

- Machinable Wax

- Paraffin

- Silicon rubber

- Rhinoceros CAD/CAM

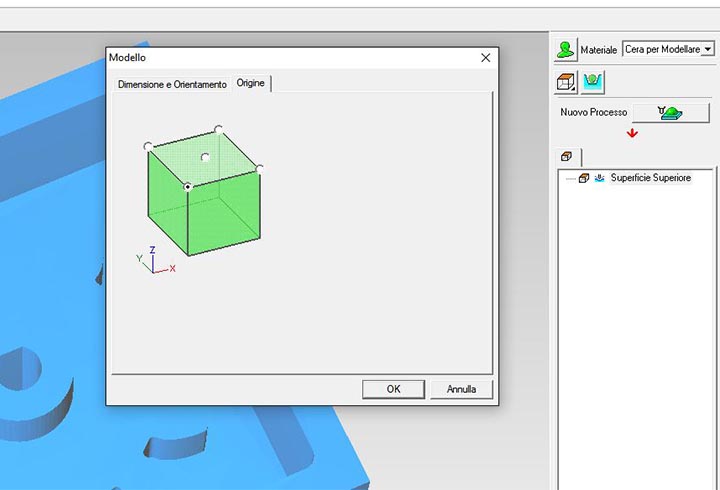

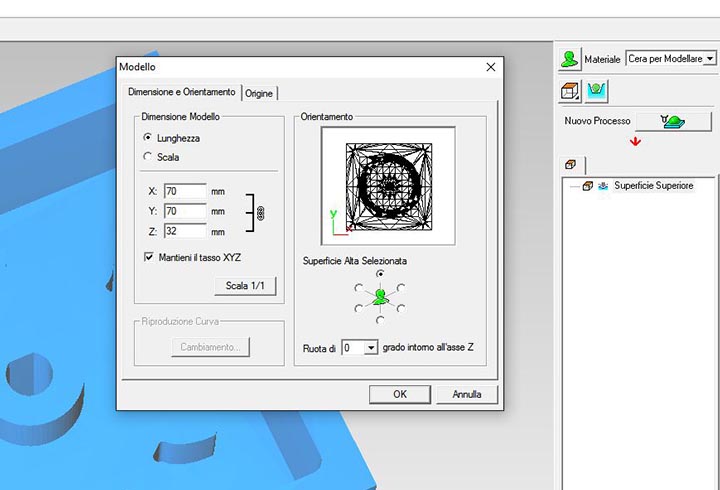

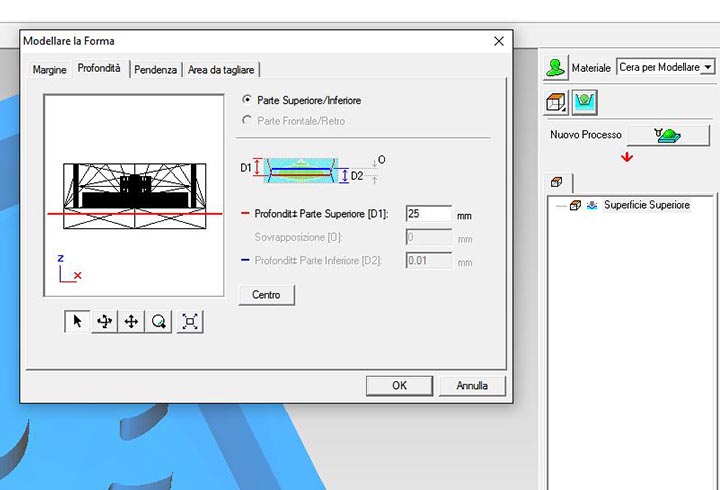

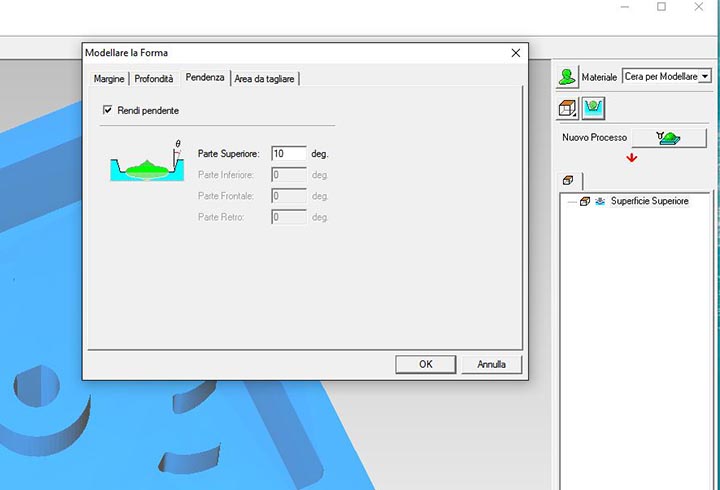

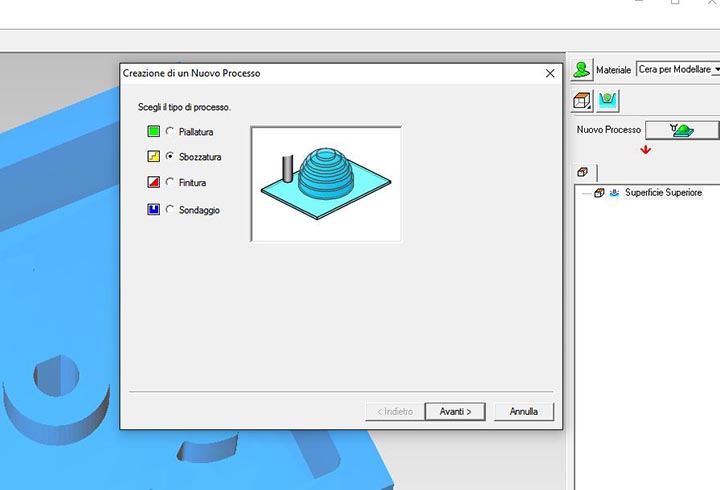

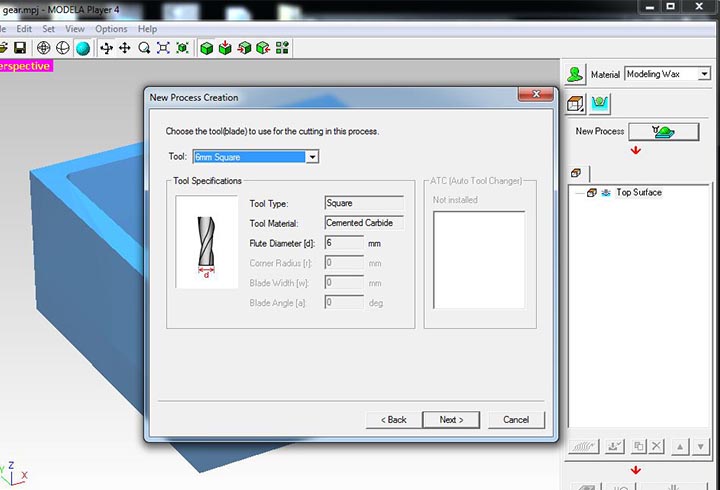

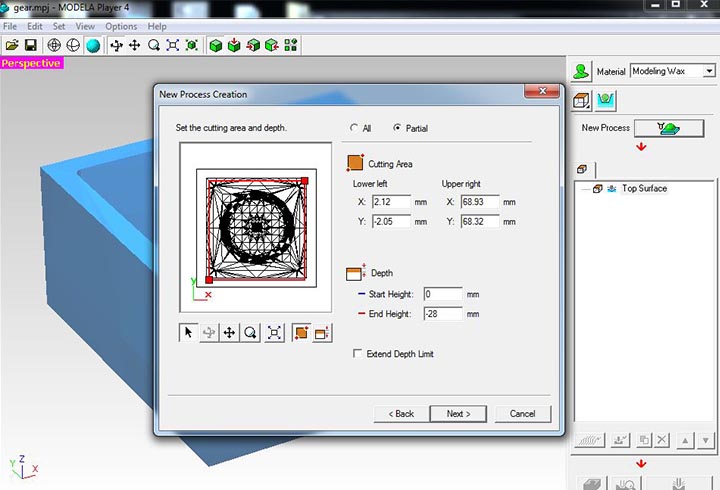

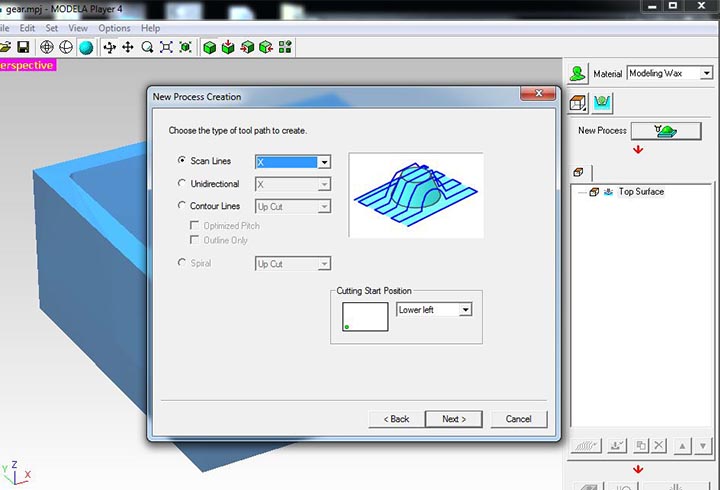

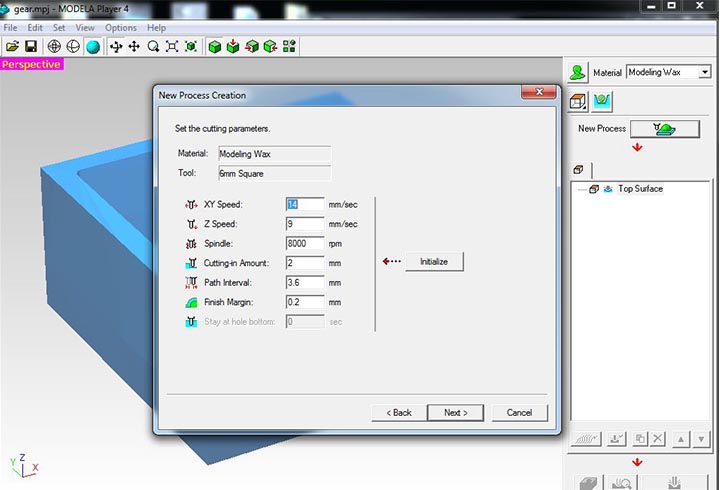

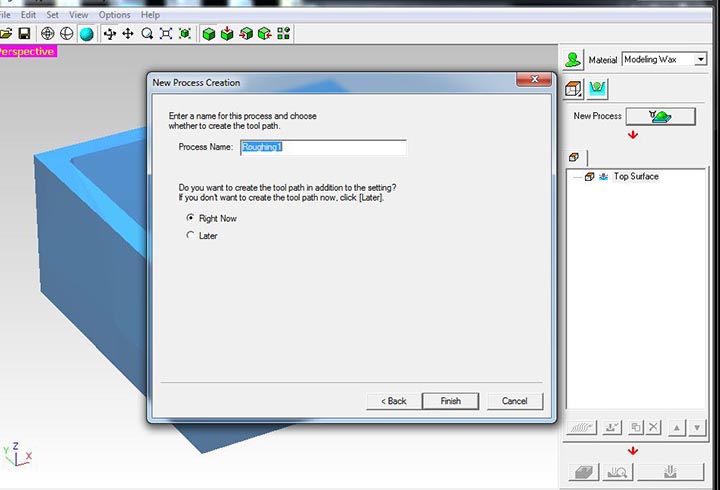

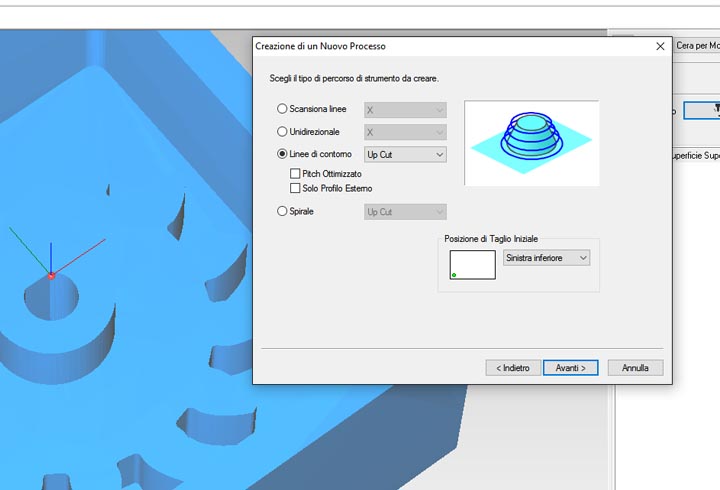

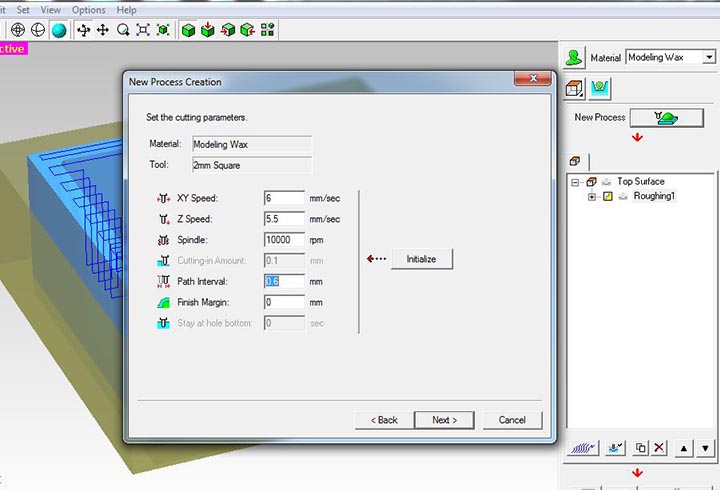

- Modela Player4

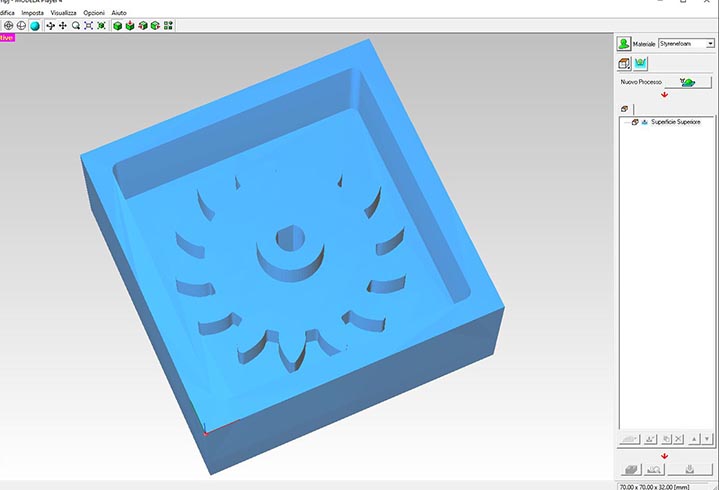

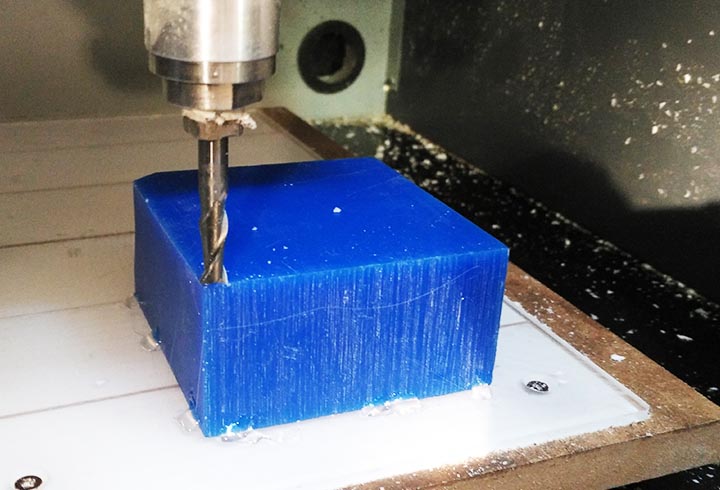

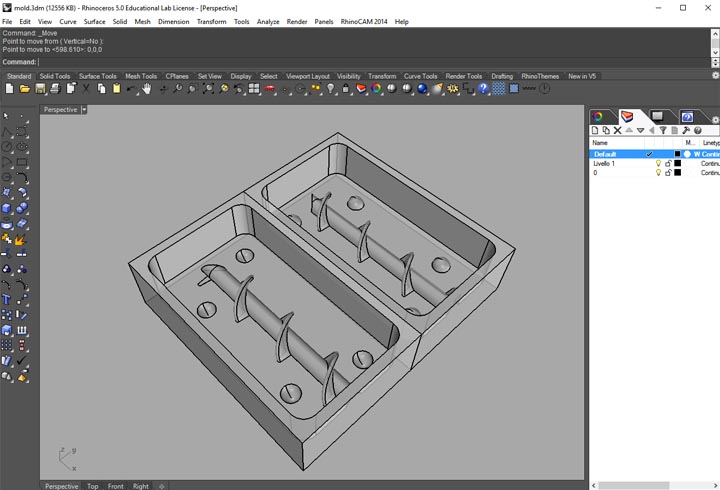

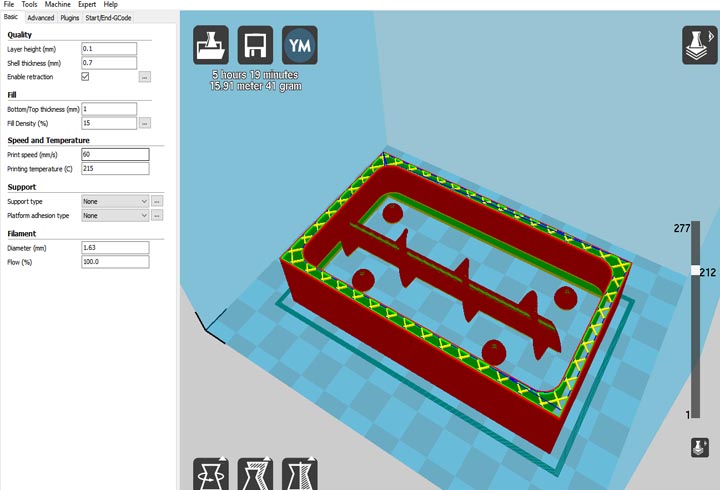

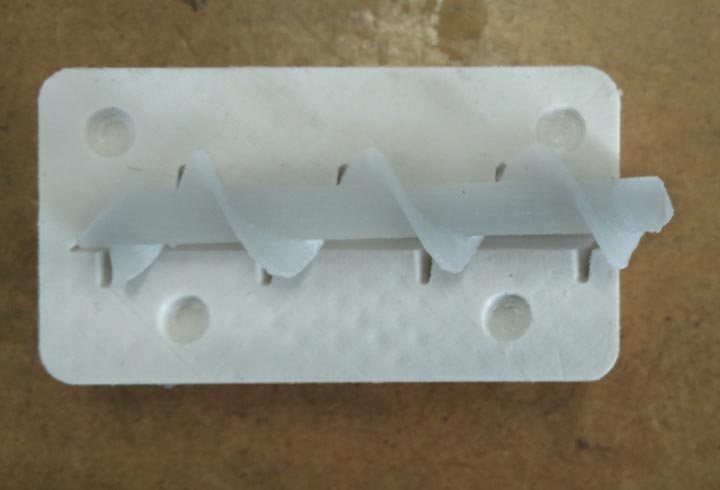

For the assignment I have decided to make some different experiments, the first one will be to make a silicon rubber gear reduction mold, using the Modela MDX40-A to machining a blue Machinable Wax. After I decided to experiment to machine the same piece using paraffin (less expensive and easy to find) instead of using the machinable wax. The second experiment was to produce a mold for a section of an Archimedean Screw, using a 3D Printer to solve the problem of the undercuts.

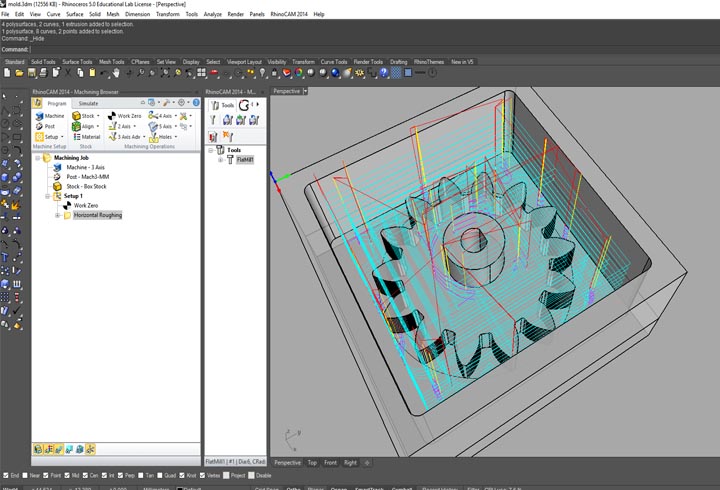

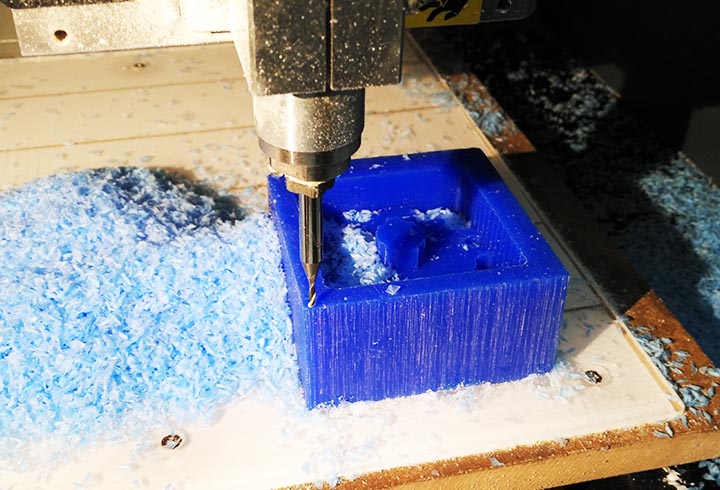

18th step: in the second part of the exercise I have milled the same part but with a different material, paraffin, that is less expensive and very available in different kind of shop. So I have decide to use the second milling machine that we have, a big cnc router and using rhinoCAM to generate the toolpath in order to experiment different software and possibility. In order to prepare the toolpath I have followed this rhinoCAM tutorial.

I have made a simple system with a pressure cooker and a Venturi vacuum pump, in order to remove the air bubbles. So I putted the mold inside at -0,6bar for 5 minutes and attached the cooker to the compressor.

Gear moul design: the mold dimension is 70x70x32mm, 14 teeht and 52mm gear.