- Stefano Galbo

Beginner

Desing

I looked for something useful for my final project, so I found this model and I used its wings to simulate Lucifero's wings.

I spent a lot of time in Rhinoceros to modify this file: first I cut a wing in half but I forgot how to mill the bottom side. So I had to create a solid with a negative wing model, and another one with the positive, in order to put resin between them.

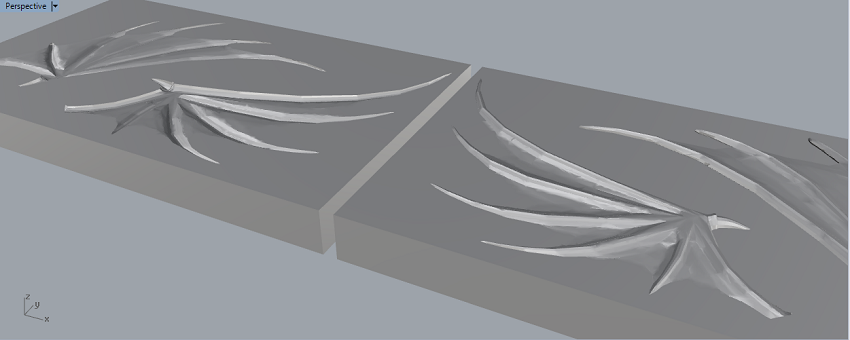

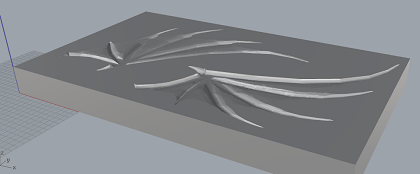

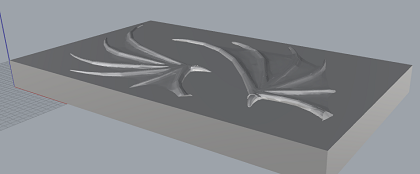

After many hours (.stl file had many problems with nurbs, mesh and boolean operation) this is my wings file:

Second step was to create a Gcode for milling machine, but I wasted time for some unusable CAM software: Vectric and Rhinocam are not free (they show all the steps but they don't let you save the Gcode), Freemill is a simple software but you couldn't set the mill diameter..very strange!

Finally I decided not to use the "big" milling machine but the little one, so I could use the Modela Player 4 (the same of molding and casting assignment). In order to do that, I had to split negative shape and the positive one, and scale them up to the working plane dimensions.

Here my negative wing and

positive wing files.

Composite

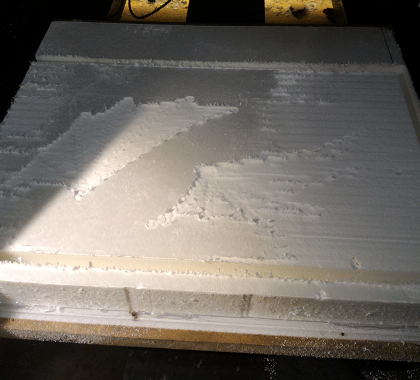

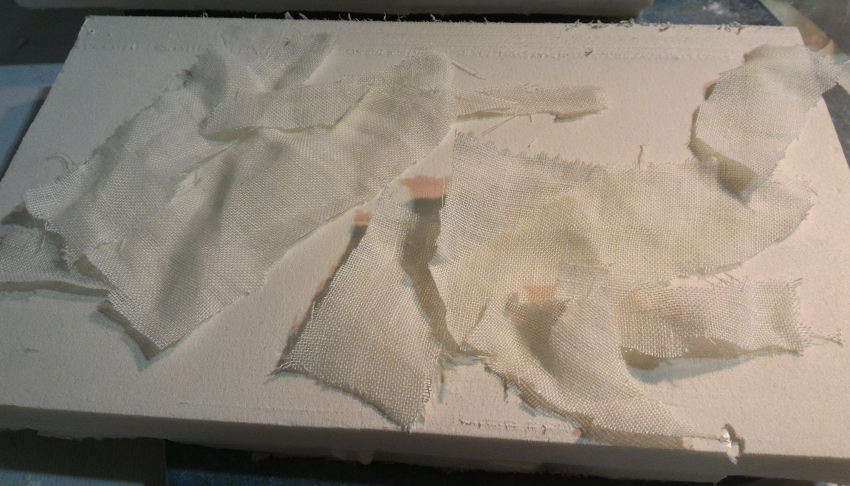

First I sprayed waxy anti-adhesive on my working plane; then I cut flax stripes in order to reach any hole of the model (one single piece could lose details).

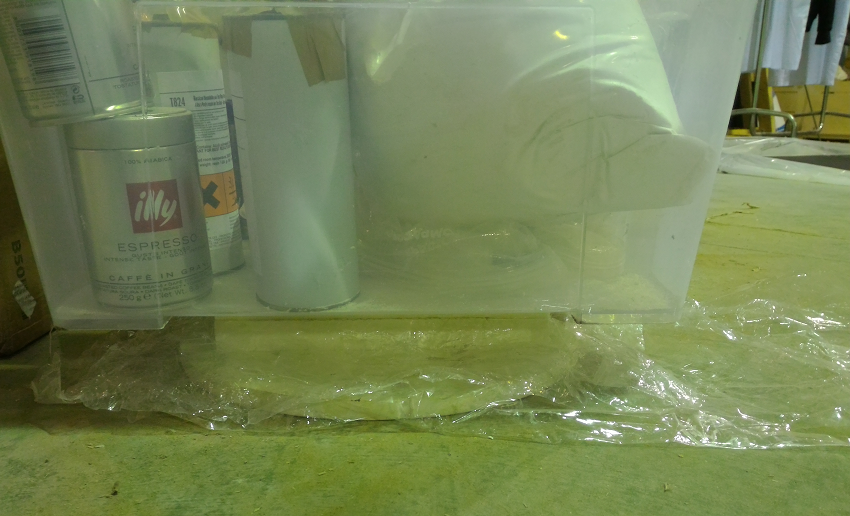

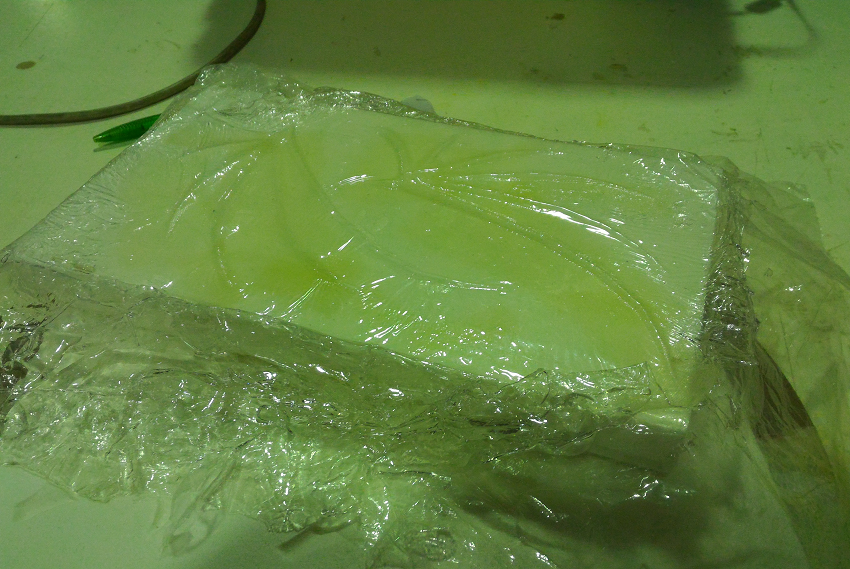

Now let's go with composite: I put a cellophane film (so it would be more easy to remove my object from the mold) , then I mixed 100 gr of epoxy resin and 60 gr of hardener, I put this mixture on the mold and I covered it with the flax stripes; finally another layer of mixture and another one of cellophane film.

Finally I choose not to use the vacuum system, but I used the "positive" mold with an heavy weight on all the structure.

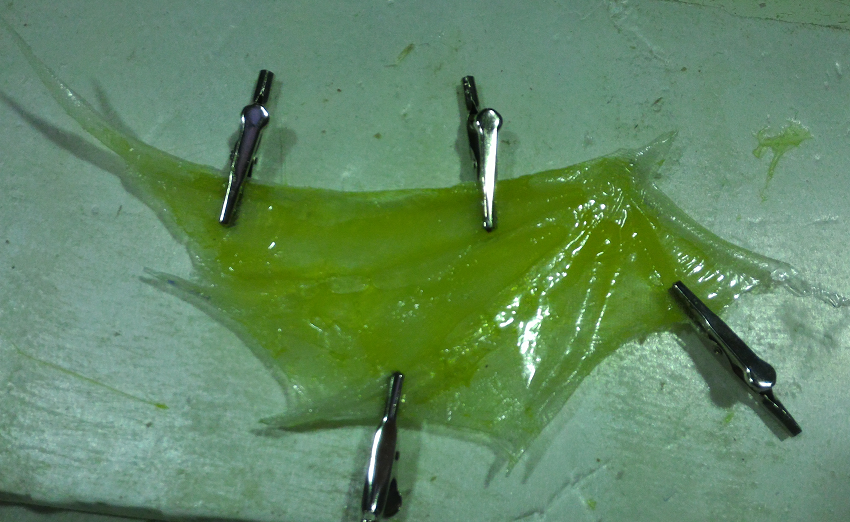

After 20 hours I opened my mold and it looked good at first sight, but I found many difficulties to separate resin from cellophane film; moreover I understood that my object is too thin, resin couldn't reach all holes and replicate the mold form correctly.

However I tried to cut excess parts, paste two halves and the result is this: not really good, but I have learned the process and I will try again for my final project, probably with a bigger wing!

Review

I know that a correct casting provides more layers, at least 4 of resin+fiber, but I would a wing elastic and transparent , and I was afraid that with further layers it would become too rigid, so I left just 2 layers (1 resin+fiber for each half).