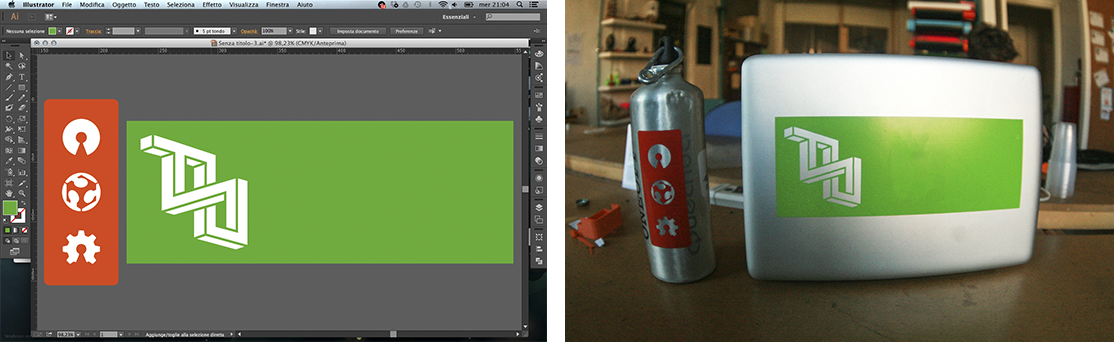

Something I vinylcutted

I hade a some projects connections with some street artists, so I was used to work a lot with stencils and other plotter-cutted stuff like

Christian

or Alice.

I am used to the Roland GX24, the same we have in the lab but,

until I have a nice idea that involve using vinyl cutter I've just made this pieces shown here.

Cheers!

Here you can find .svg files I produced with Adobe Illustrator for the macbook and aluminium bottle application.

Parametric Lasercutted project

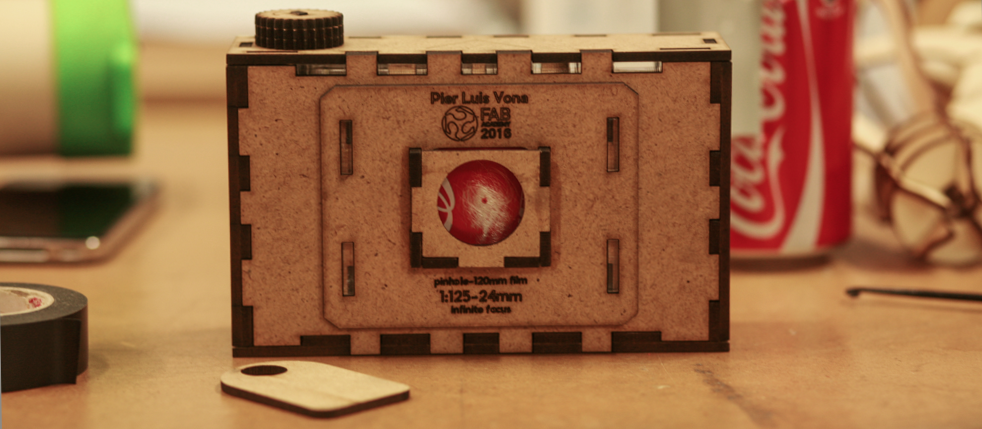

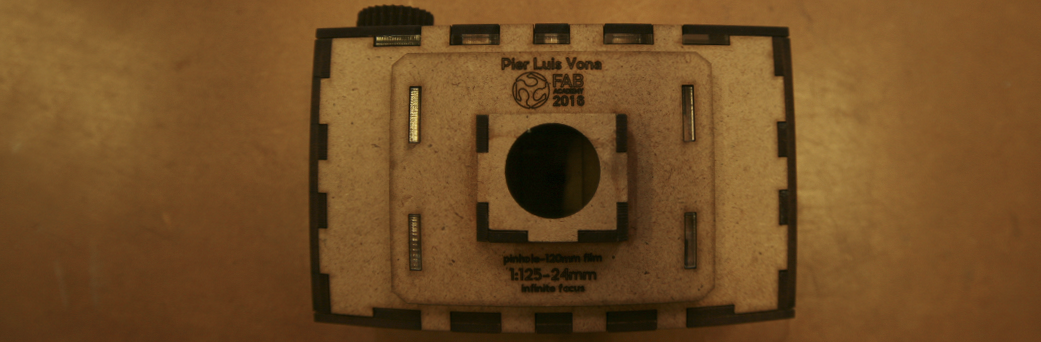

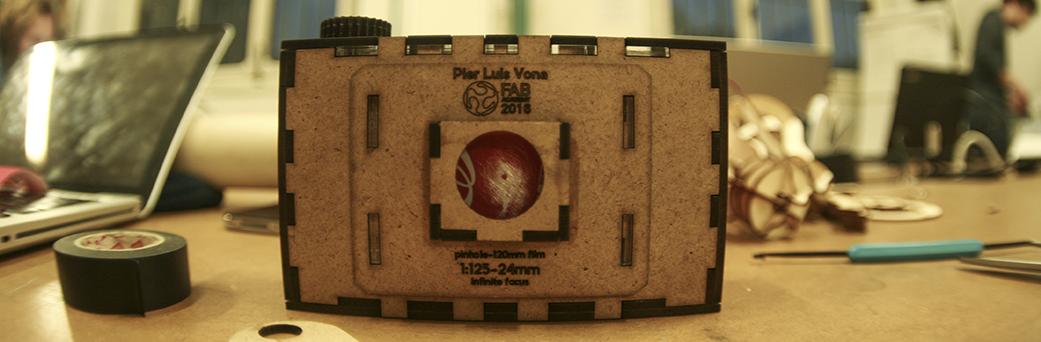

During the week I've made a parametric design for a lasercutted pinhole camera.

Some times ago I founded a nice open source project called focal camera.

I met the guy who was designing all those lasercut camera module and I strat contributing;

here I've decided to make the pinhole design parametric.

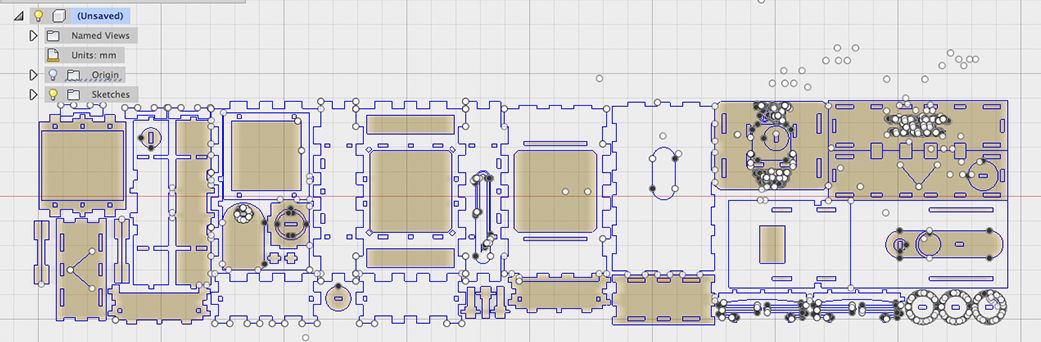

I redrown it on Fusion360. Using a Constraint systems for the dimension of the camera and the plywood thickness.

Here you can download the .dxf file I've sent to the lasercut machine.

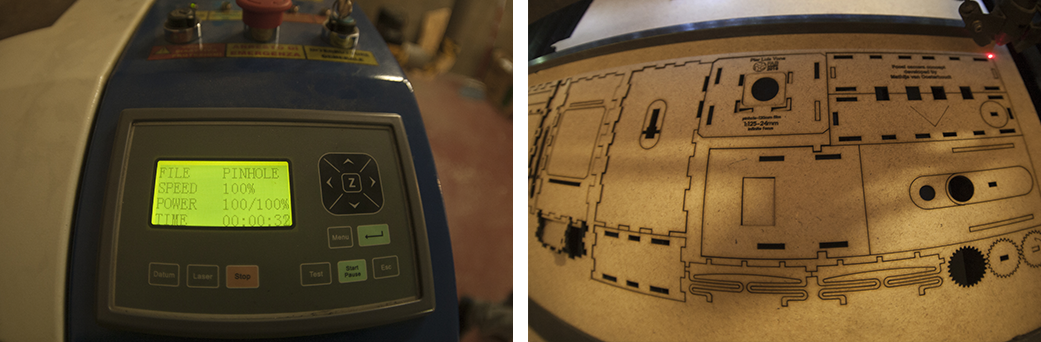

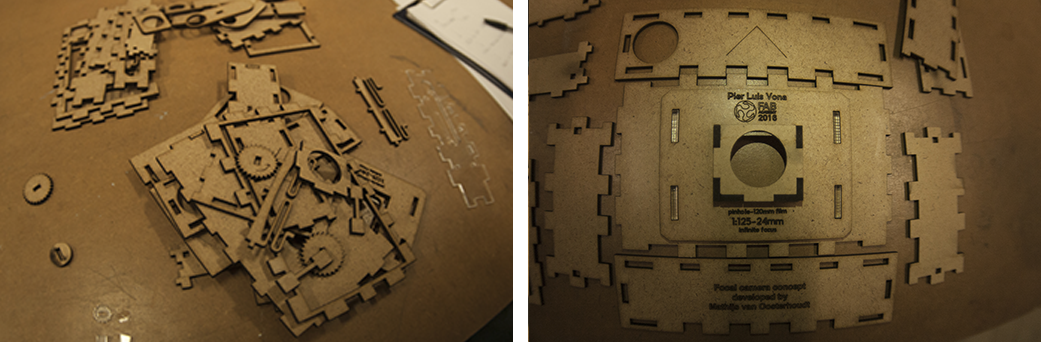

Lasercutting

The camera was cutted from a 600x400 4mm mdf board.

To produce good lasercutted pieces I've done some test on the material. Using this 130watt lasercut, I cut at 50% power at 20mm/s (almost the same with 4mm plexyglass).

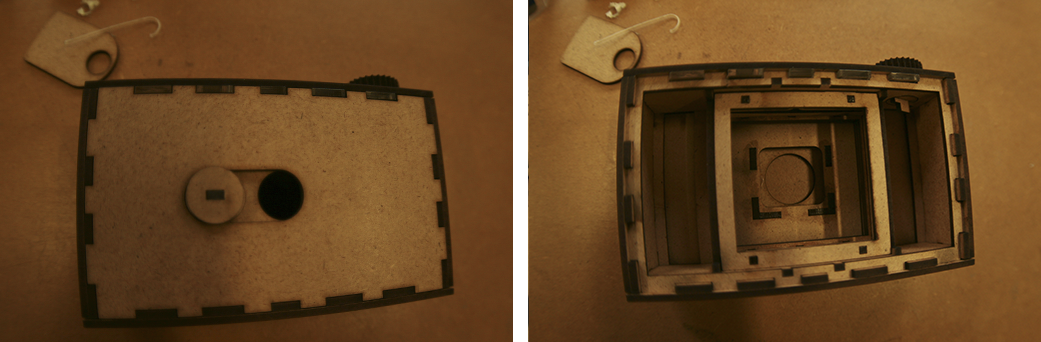

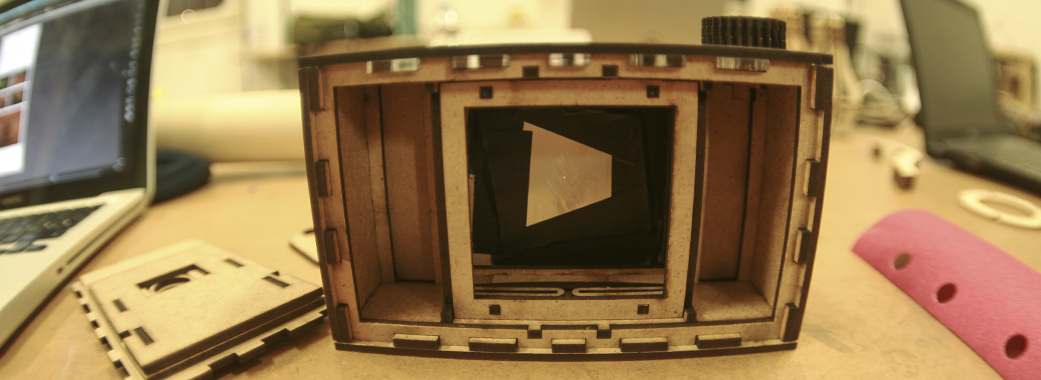

Assembling

After the lasercutting process I started assembling the camera.

Every piece fits good with the next one but I admit I've used some superglue.

This is the back with the slicing window, that allows to see the exposure numbers.

Than the last step is the pinhole itself wich I've just created cutting a coke can.

LAST MODEL

That's the last model I lasercutted, it's made with black opaque plexyglass wich is the maretial I wanna use for my Final Project tank.