The last class we talked about 2D cutting technology,the principal tools to use are the laser cut and the plotter cut machines, with the software CAD and differents materials.

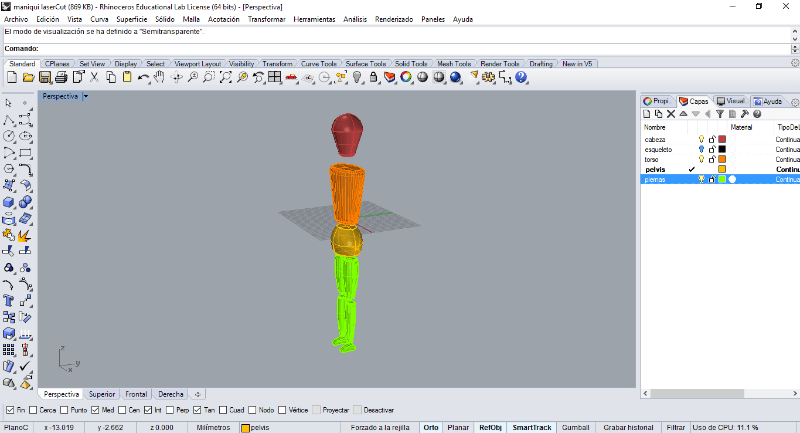

For experiment with this and the cad software like 123 make and others, i designed a draw maniqui in rhino, and generated layers assembly whit 123 make. But the result was not as expected, in my opinion the settings to make inserts in 123 make are highly standardized and does not give you the flexibility to try new things.

Stop to design, for the complexity of mobile joints with each body part, for such a short time, because it did not fulfill the task of being a Kit. But i would like to try again in next time.

The Vector settings configuration: Speed:50 % Power:40 % Freq:500 Hz

| Tools | Software | Material | Aplication |

|---|---|---|---|

| Knife | Rhino | Corrugated Cardboard | Vector-cut |

| Laser-Epilog | 123 Make | 600x900mm e=4mm |

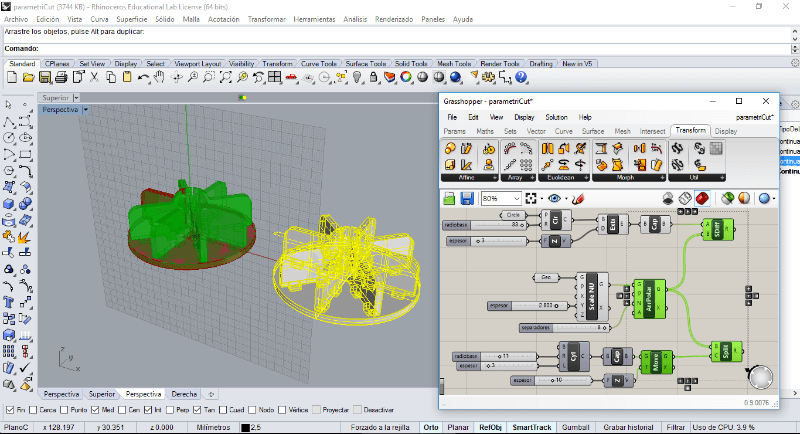

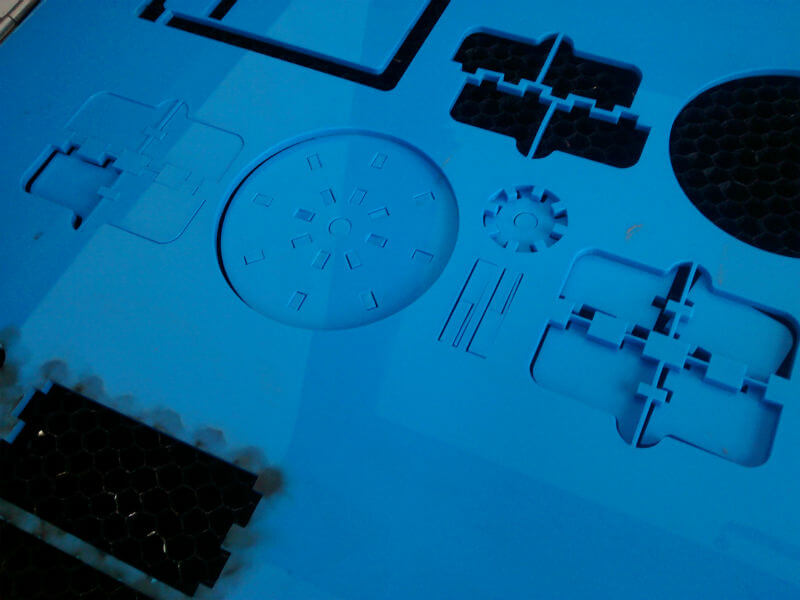

To test the acrylic, I redesigned the inner container pill dispenser to cut and assemble. I had the disadvantage that the laser generates certain area of waste with cutting, so the subtraction area is larger. For this reason, i used to parameterize grasshopper, that way solve unions to generate two different planes by varying the value of the material thickness, lying to the machine and getting a better result.

The Vector settings configuration: Speed:20 % Power:100 % Freq:5000 Hz

| Tools | Software | Material | Aplication |

|---|---|---|---|

| Laser-Epilog | Rhino-Grasshopper | Acrylic | Vector-cut |

| CorelDraw | e=3mm |

Ddispenser - LaserCut from Gabi Mojoli on Vimeo.

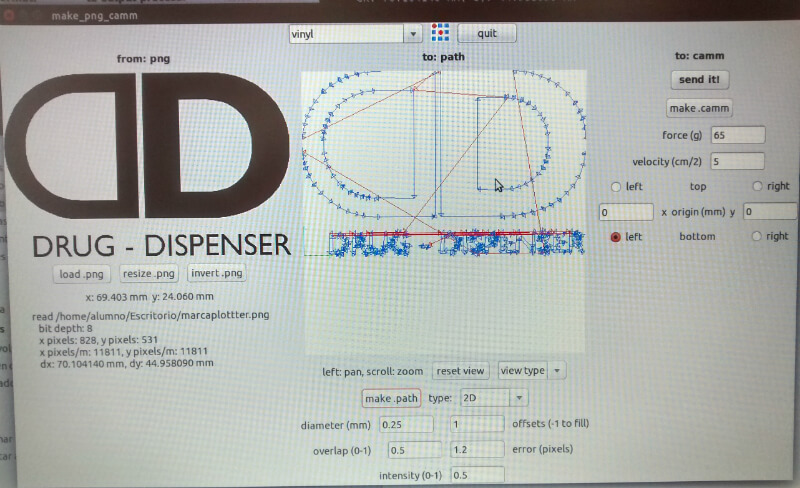

To cut the vinyl in the Fab they explained how to use the fab modules. I take to cut the logo of the brand of my final project.

The assignment consisted in designing, make, and document a parametric press-fit construction kit. I designed a camera cell phone support, to meet the need to hold the phone when it's filming the documentation for my assignments.

The particularity of this kit makes it constructive, is it allowed to grow vertically, so when you needed take photos from top view. When not using the extension pieces, can be saved within the same.

The Vector settings configuration: Speed:50 % Power:40 % Freq:500 Hz

The Vector settings configuration: Speed:100 % Power:60 %

| Tools | Software | Material | Aplication |

|---|---|---|---|

| Knife | Rhino | Corrugated Cardboard | Vector-cut |

| Laser-Epilog | CorelDraw | 600x900mm e=4mm | Raster-brand |