3D Printing & Scanning

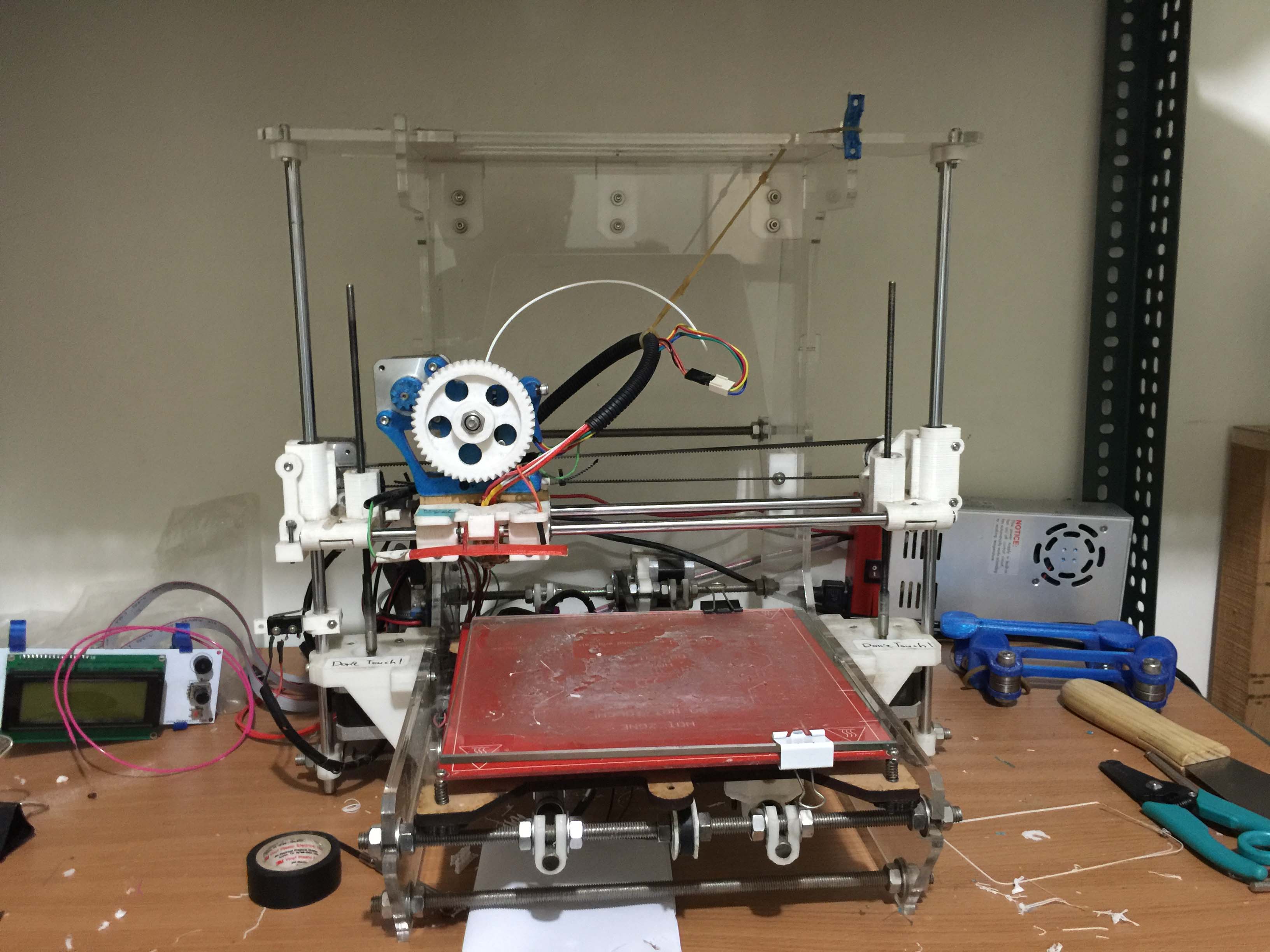

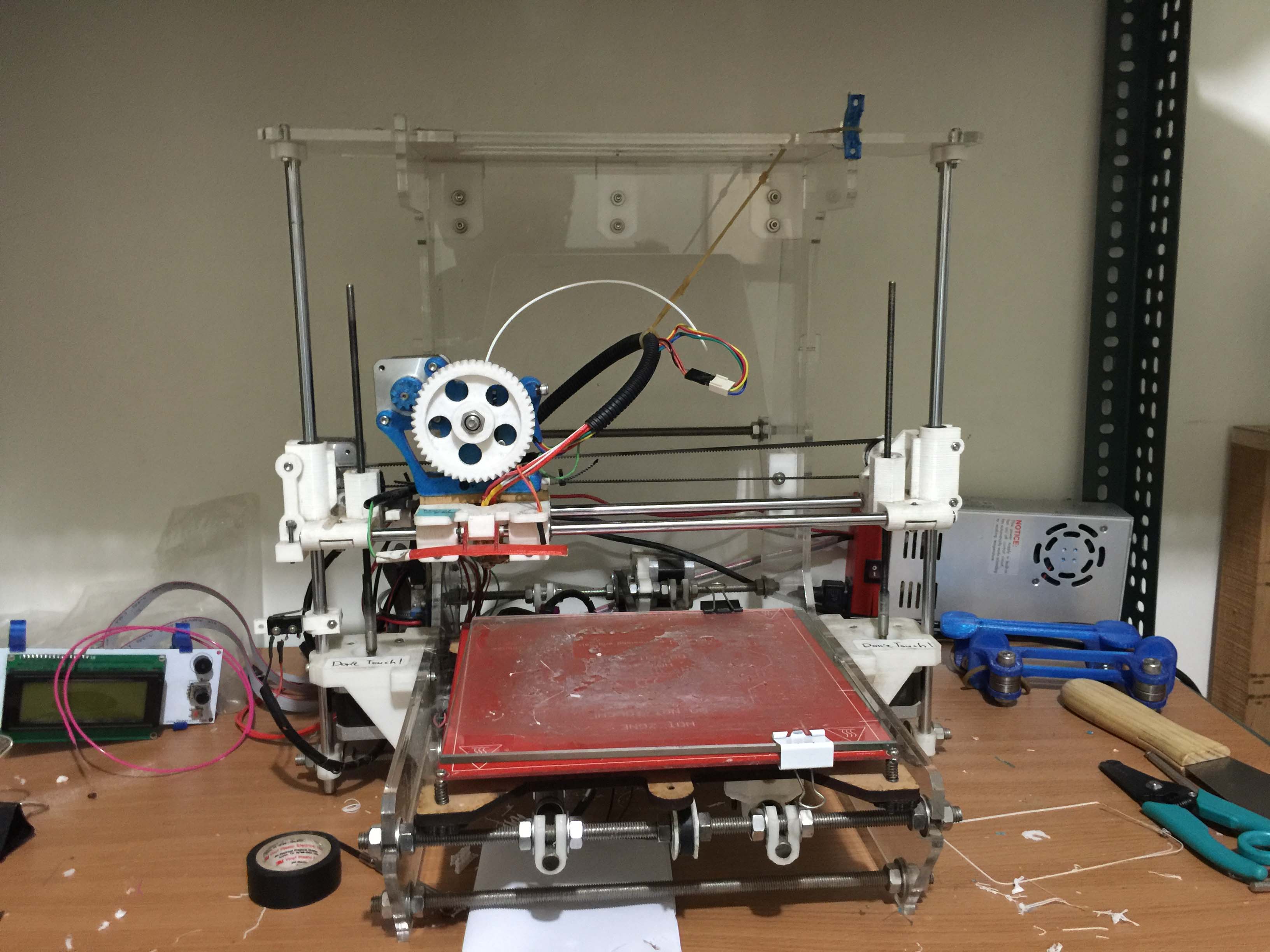

"The grand daddy" - one of the earliest RepRap 3D printer in Taiwan, a Prusa Air 2.

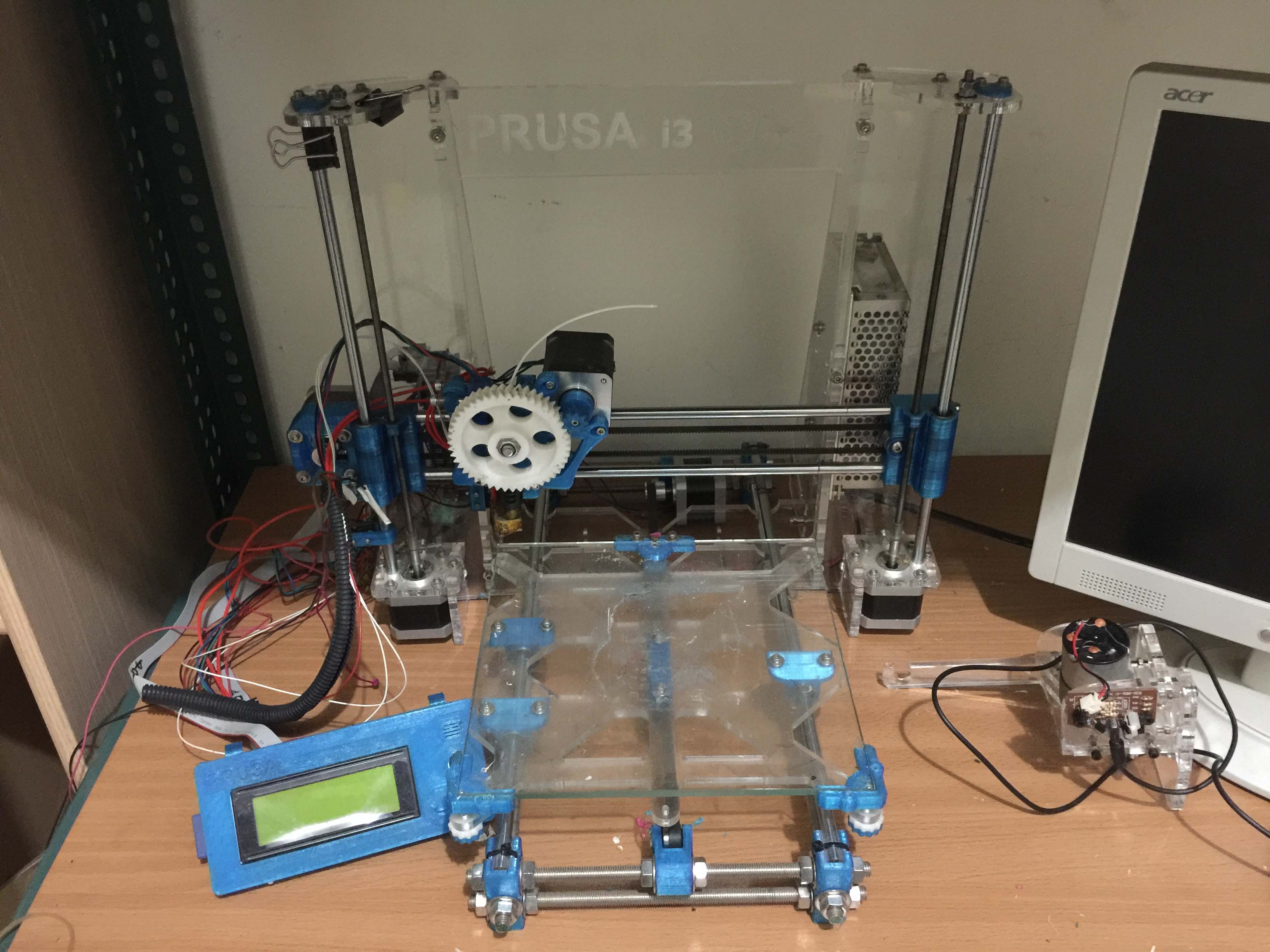

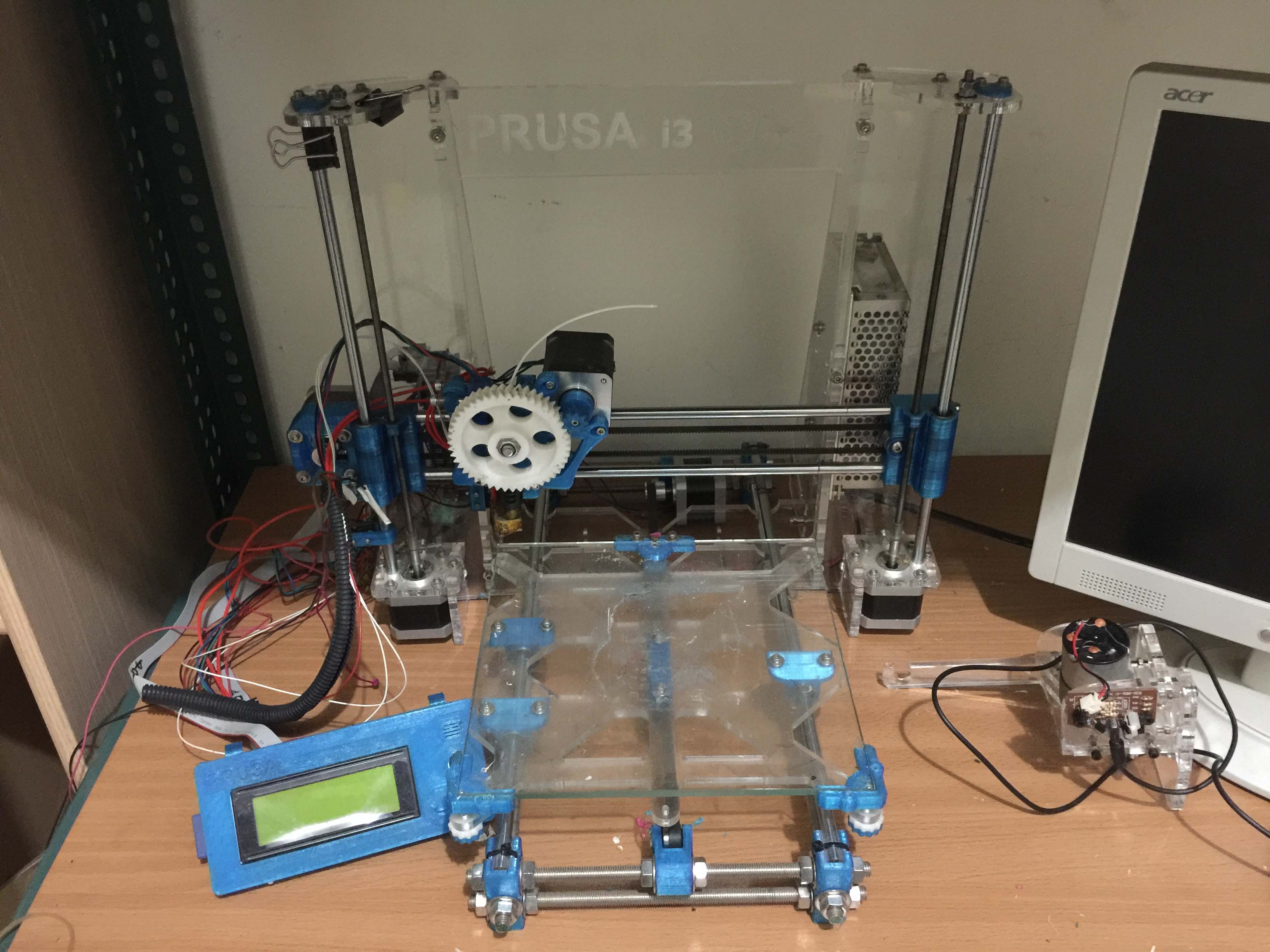

And we have popular Prusa i3 in our lab too.

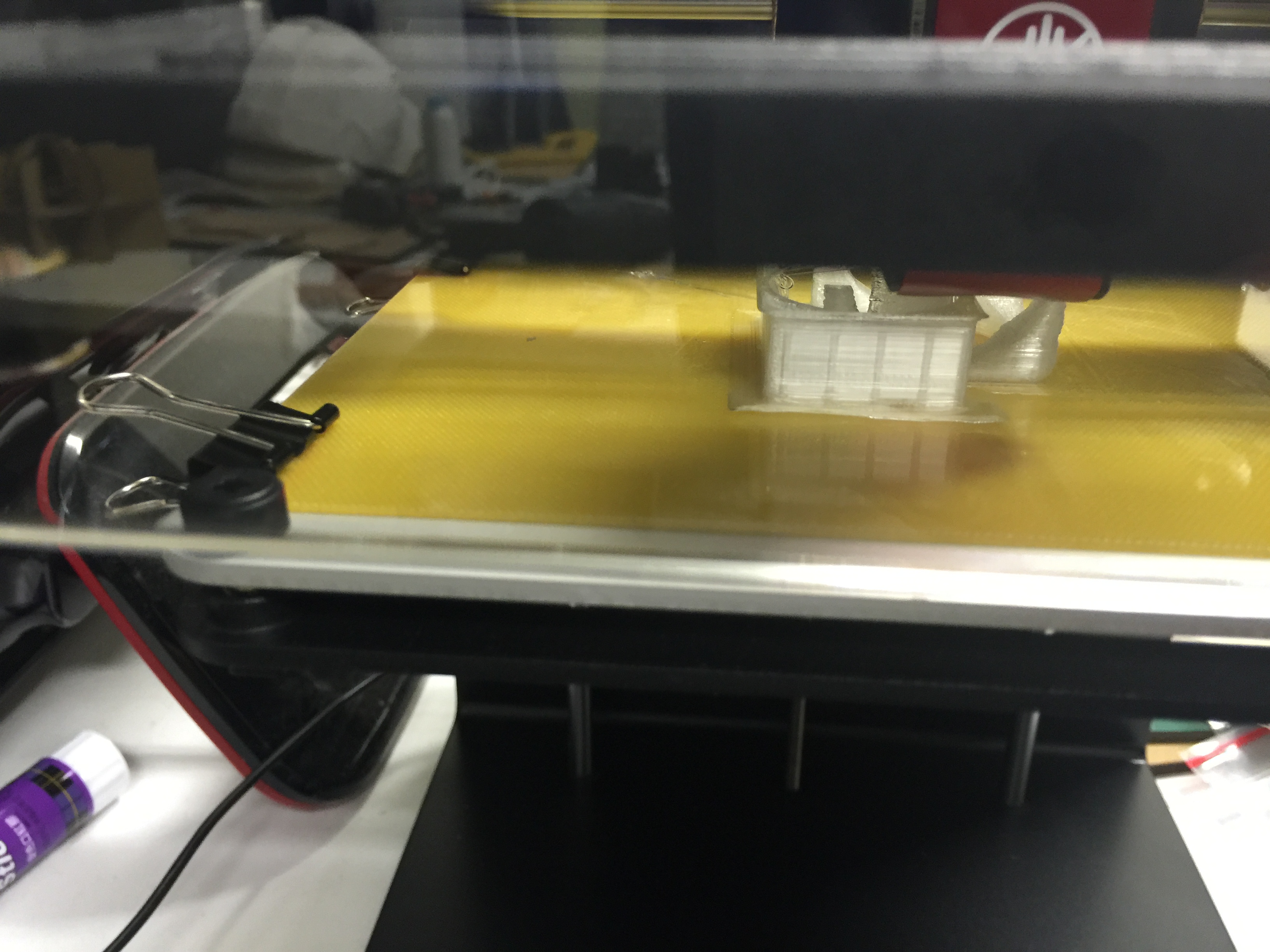

However these two machines were much tortured. Luckily a local company gave us a newly released printer!

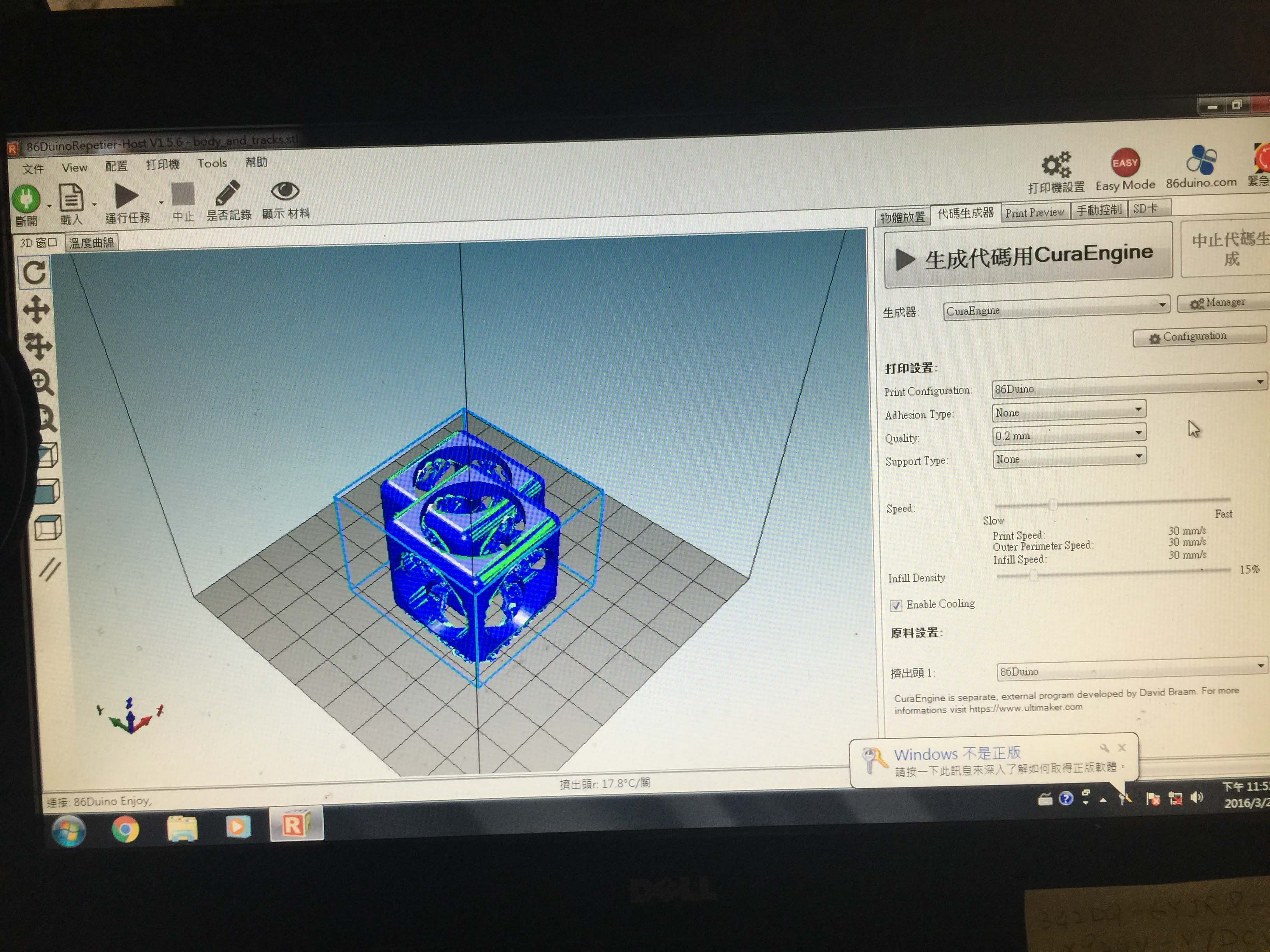

This machine comes with a customized Repetier host, and because it is build on a proprietary controller, it only left few parameters for user to adjust...

Parameter for adjustment:

layer height: 0.1 / 0.2

infill: varies

speed: varies, official claim 80 mm/s stable for normal printing

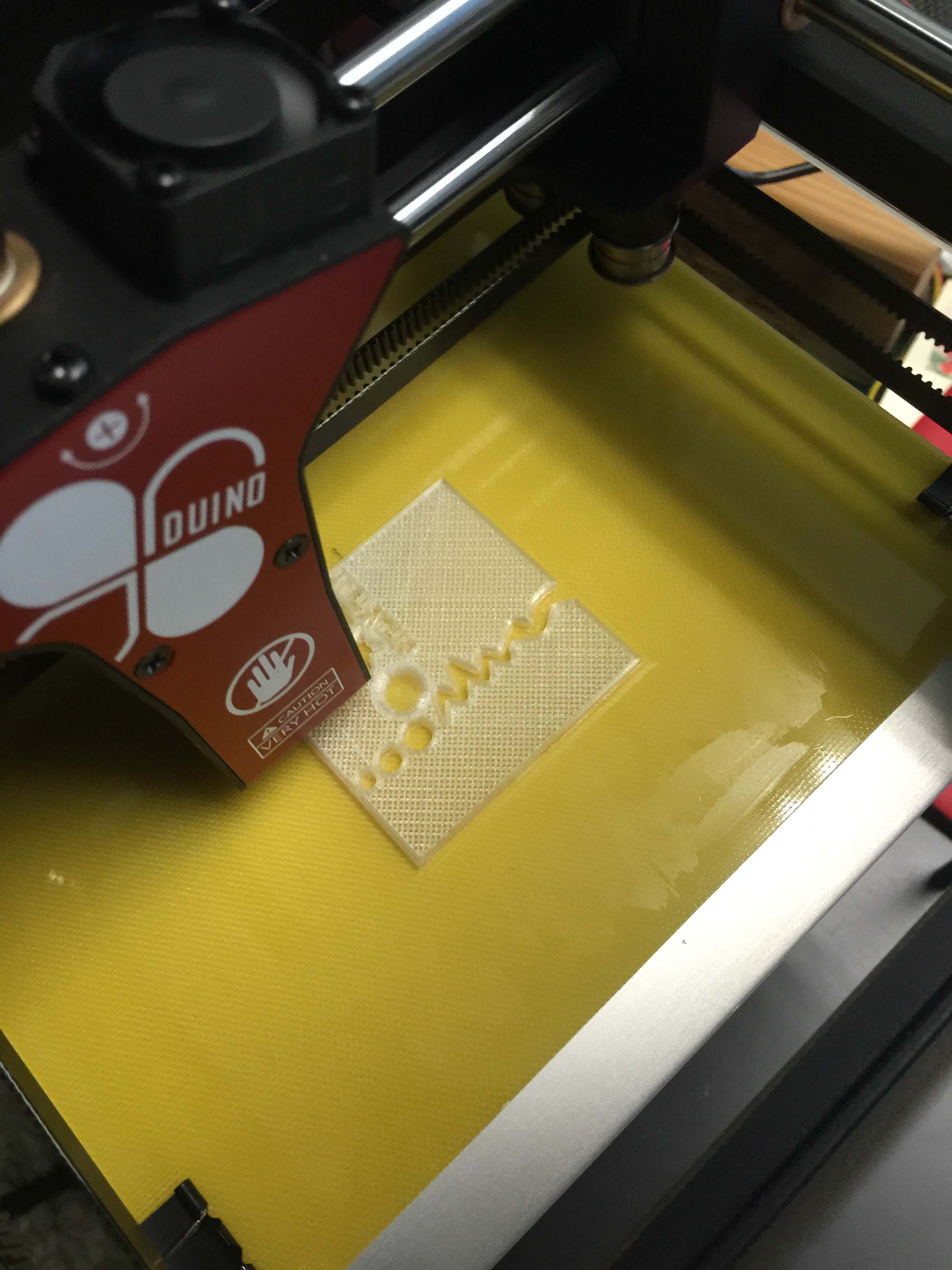

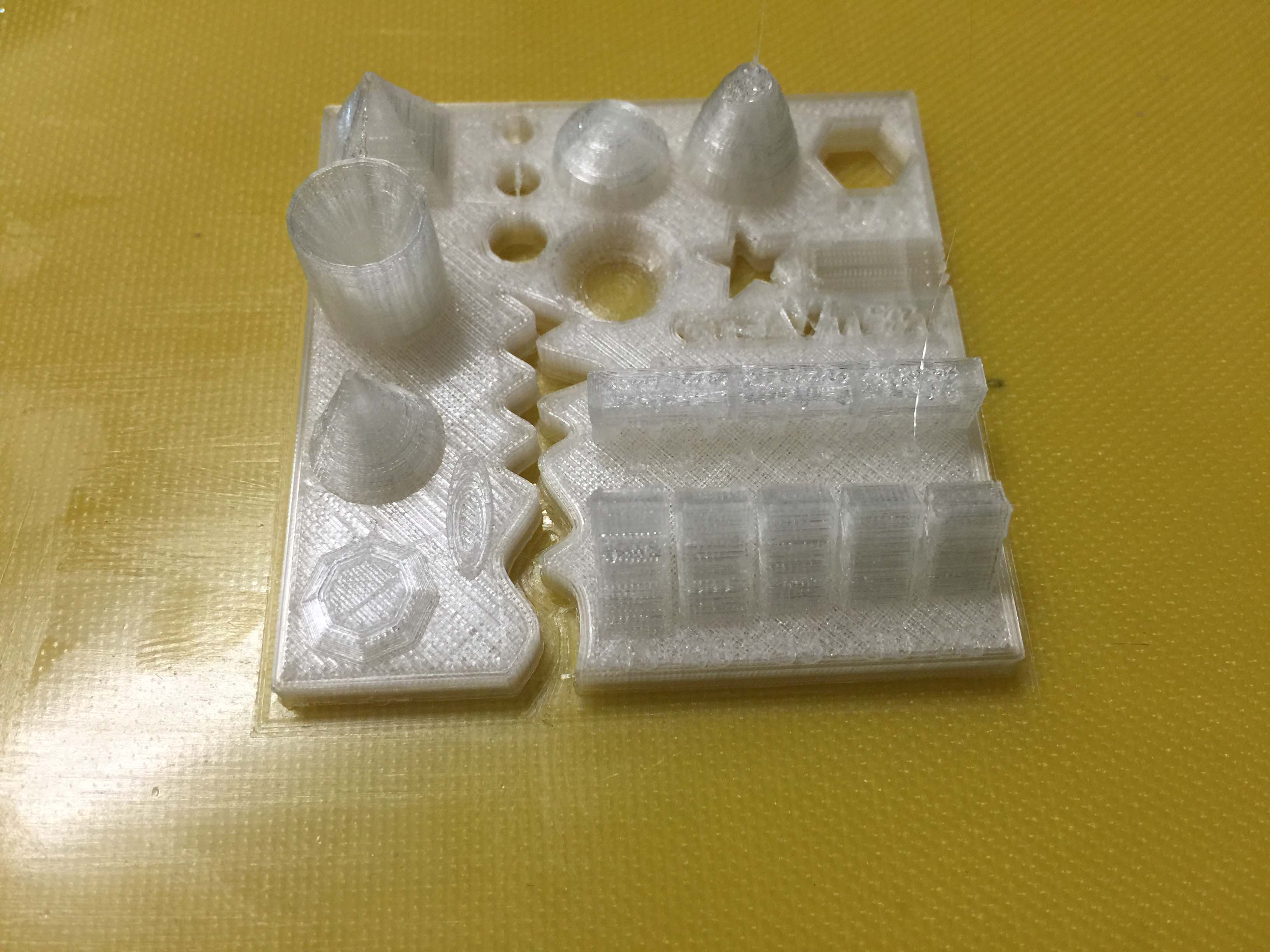

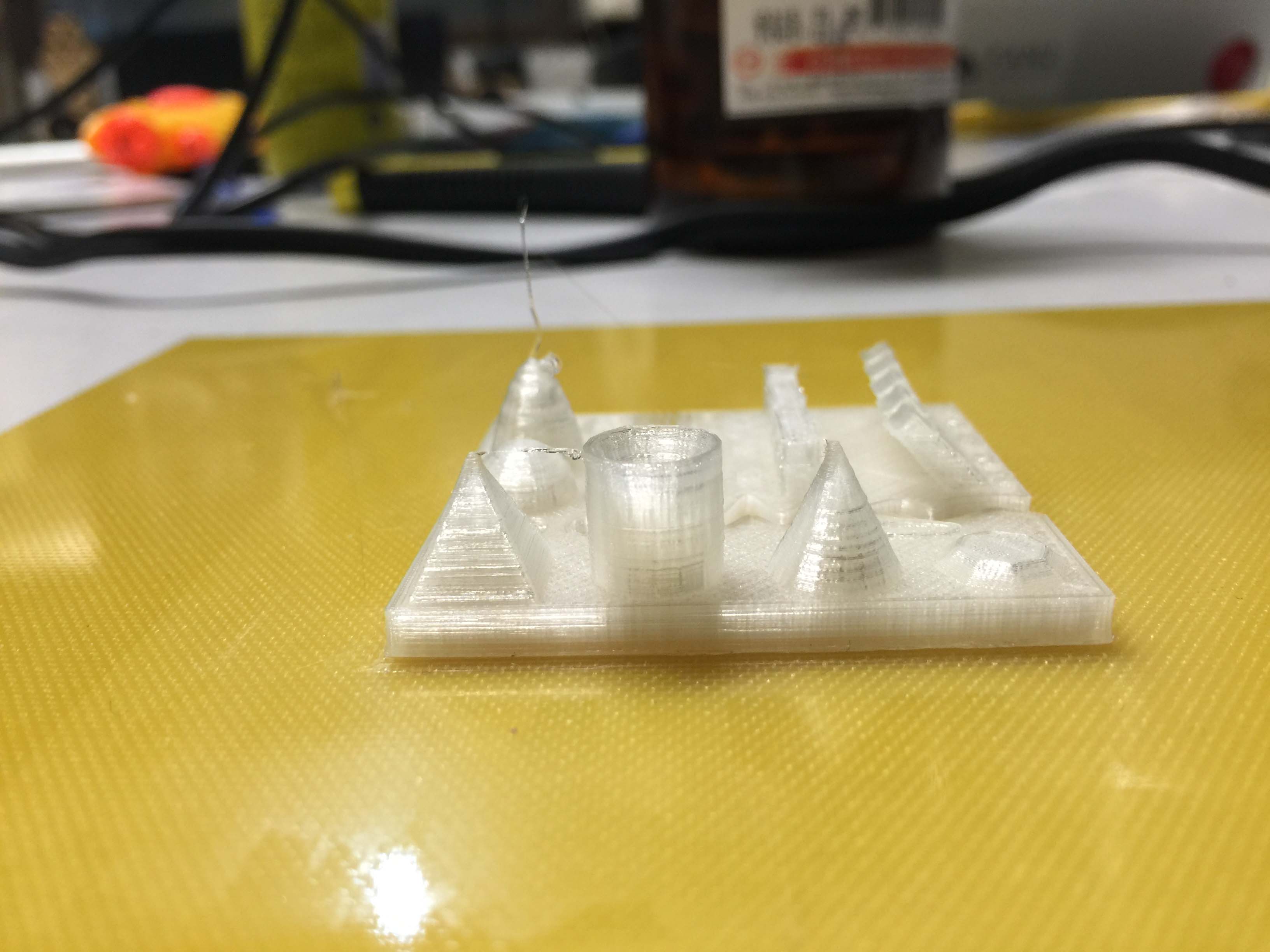

temperature: fixed at 195 degree CI grabbed a test model from thingiverse: http://www.thingiverse.com/thing:704409

The result was very decent!

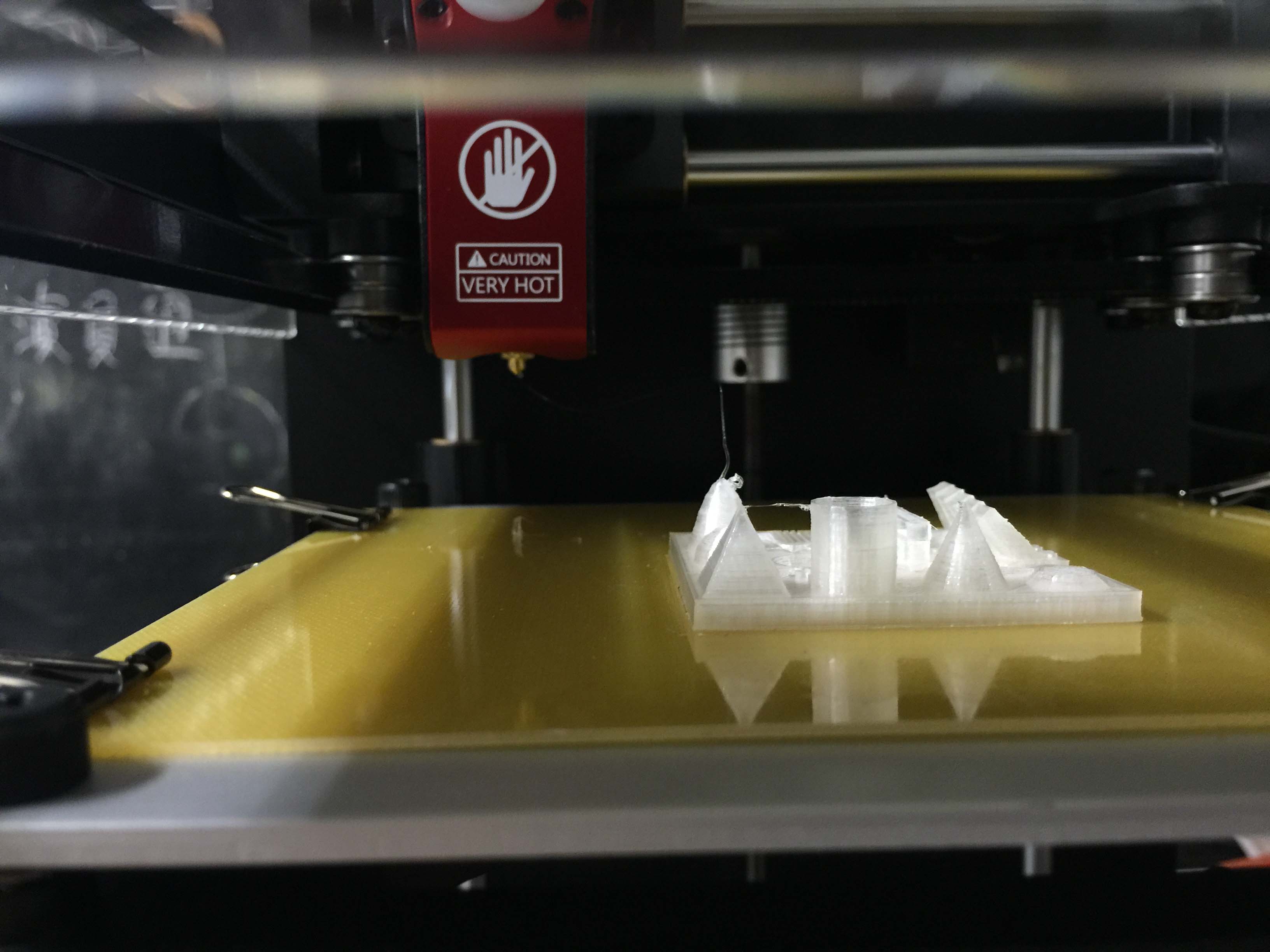

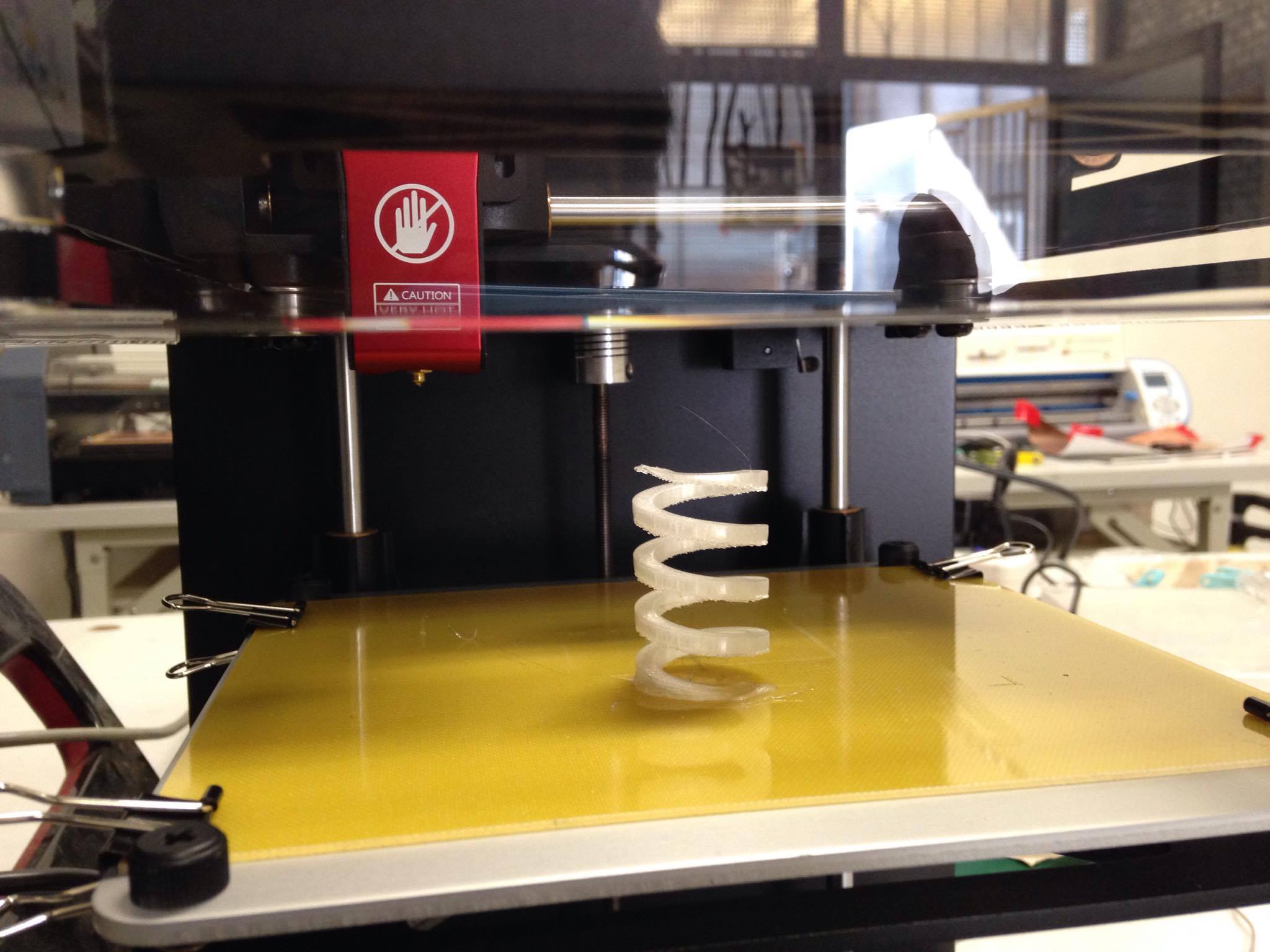

To do extra test I downloaded another file: http://www.thingiverse.com/thing:687668

This is a spring with no support at all, must be very challenging.

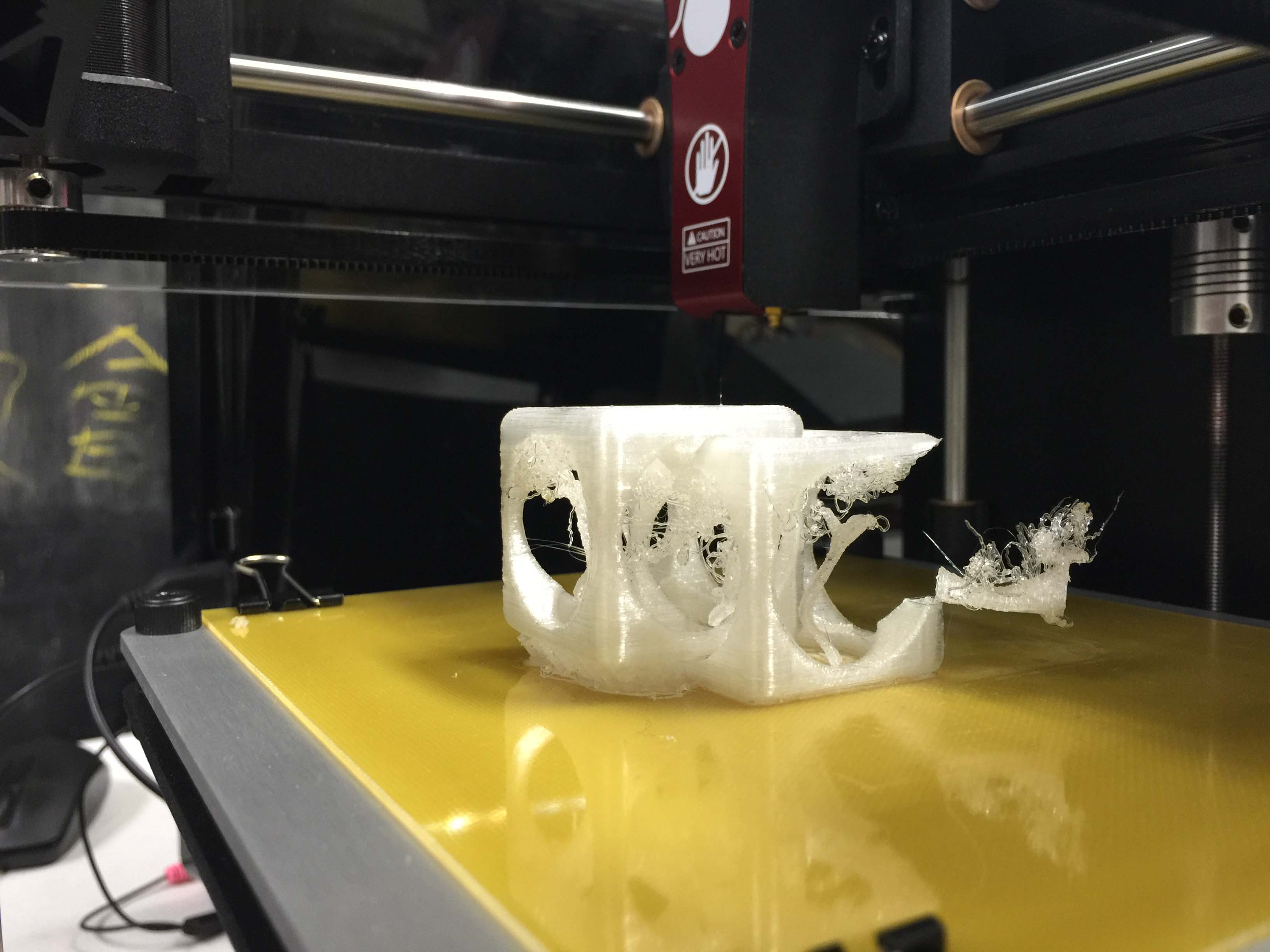

First try was not so well

Second try is near perfect!

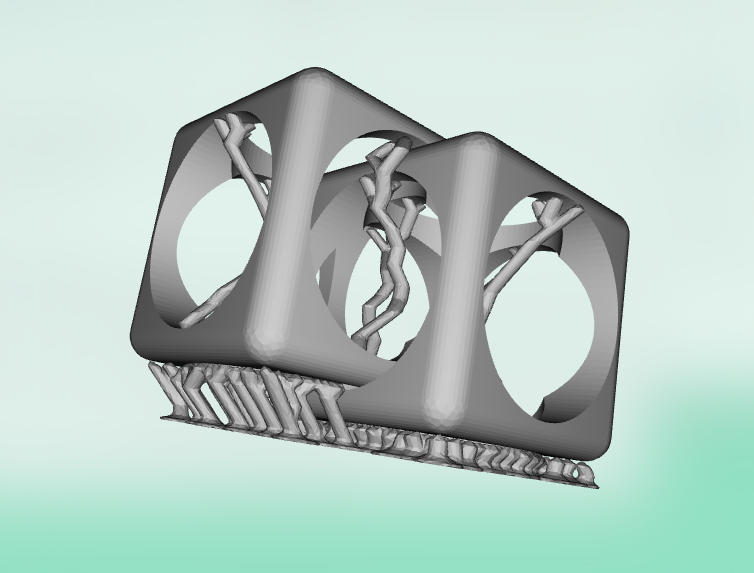

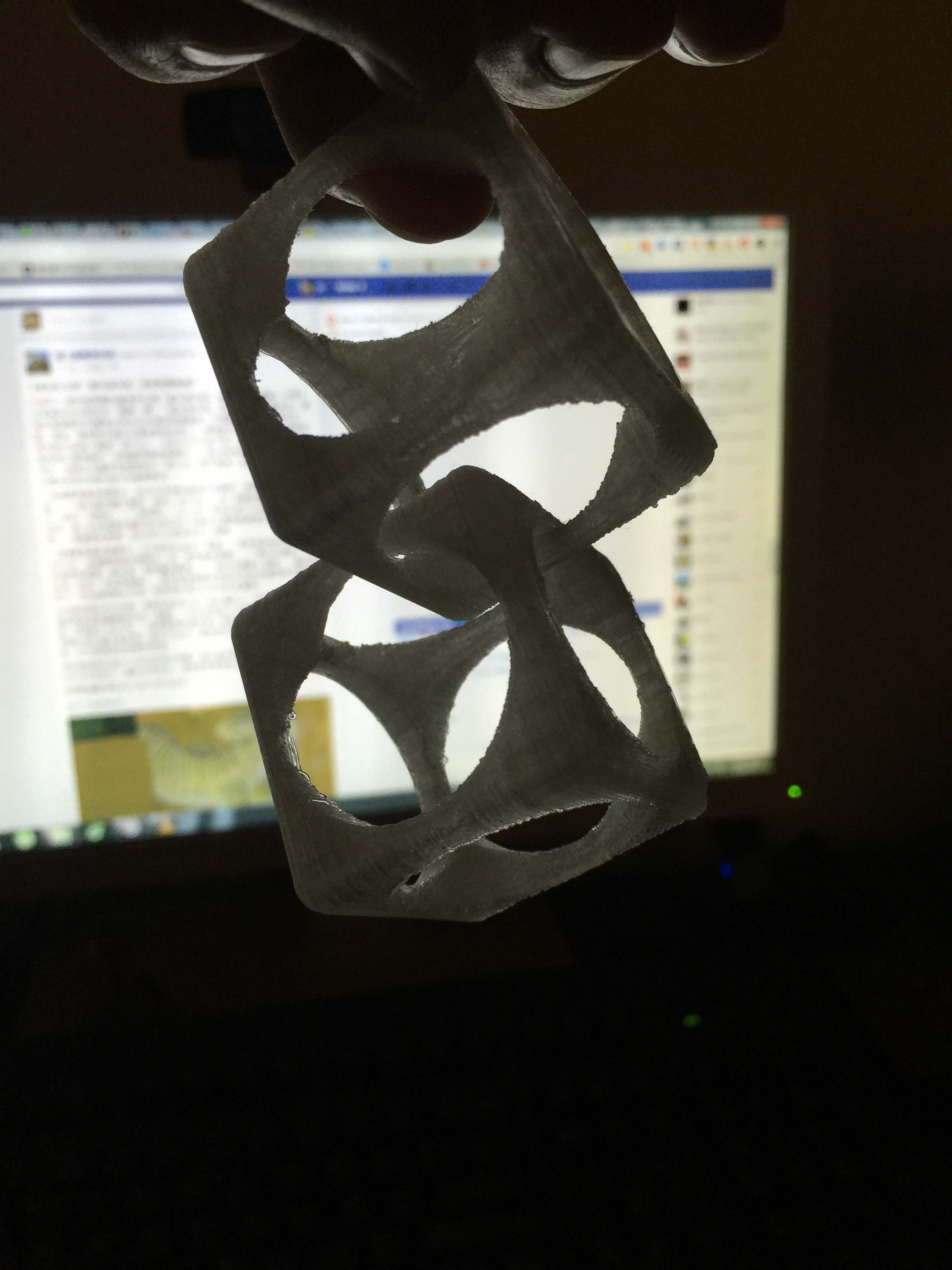

I designed a "2-bit cube-chain" (file here) with Fusion 360. The process is very simple, just grew a cube, and made hollow holes from three directions then duplicate the object and put it together but not interact with each other.

This object cannot be made by 3-axis machining, simple, for you cannot do the milling sideway, plus the cubes are "chained" together, these all made it impossible to mill from oneside to fabricate this object.

I used Meshmixer to generate some support for the object

Here is how you use Meshmixer to grow support.

(Mar 8 update)

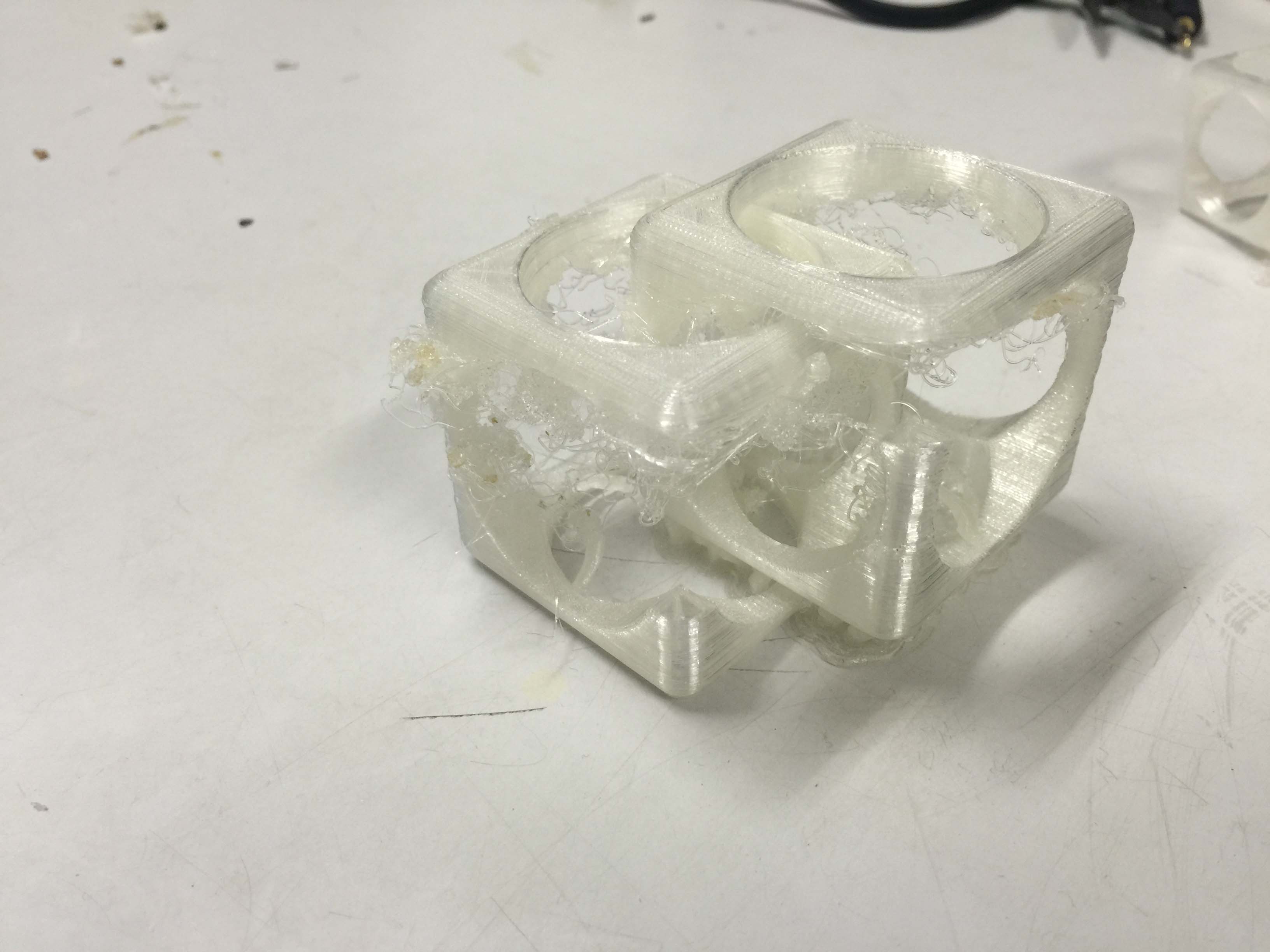

Harder to print then expected...

...To be continued

(Mar 9)

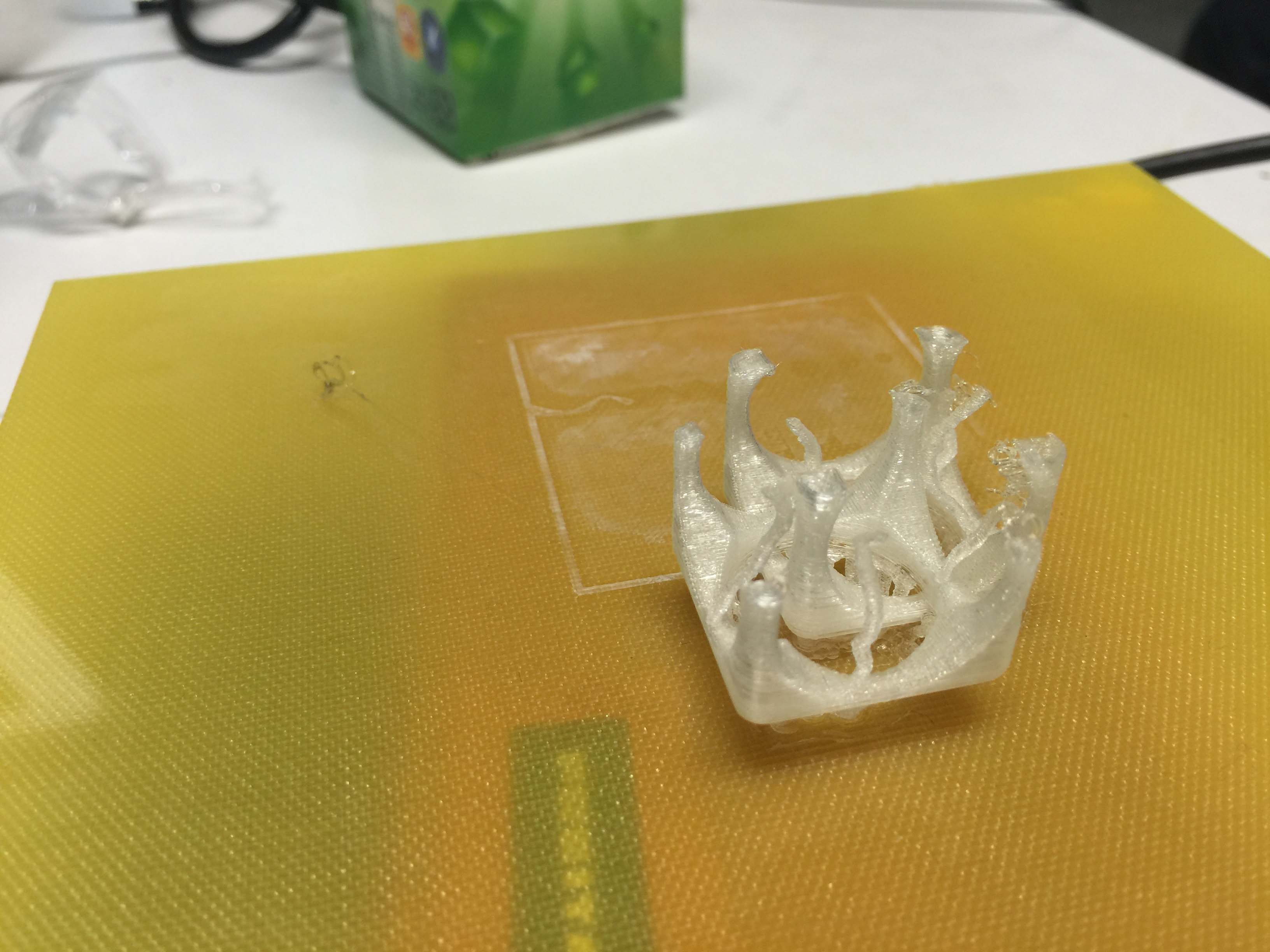

It was actually the extra support generated by Meshmixer cannot hold its own weight, and interfered with the objects. After I removed the supports inside the cube, it was a success.

Lesson learned: plan your support for 3D printing object carefully, for ill-placed supports might bring down the structure.

Scanner: Structure Sensor

It is a sophisticated commercial product, so pretty simple, just download the app and plug it into your iPhone/iPad, and scan the object like the video did.

(no record of using the gadget for I cannot scan and take photos or video at the same time...)

It generates .obj file automatically into your app then your can share it or save it.

Scanning result here: original fragments fixed