Week 3

Design, make, and document a parametric press-fit construction kit

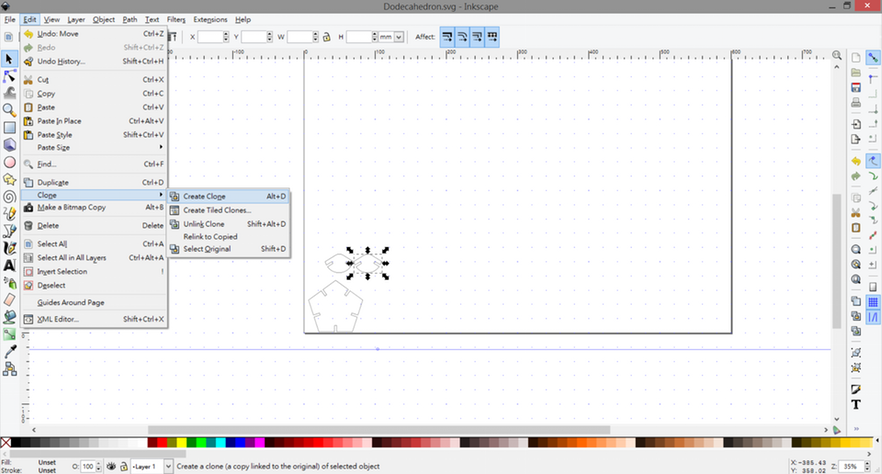

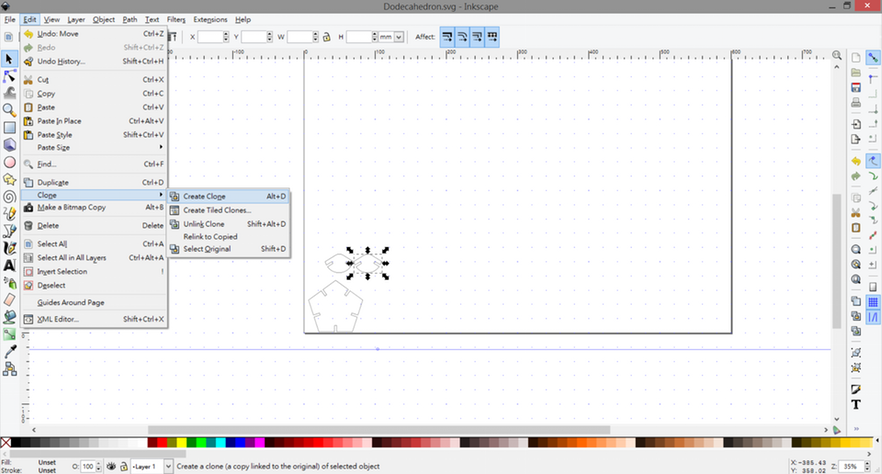

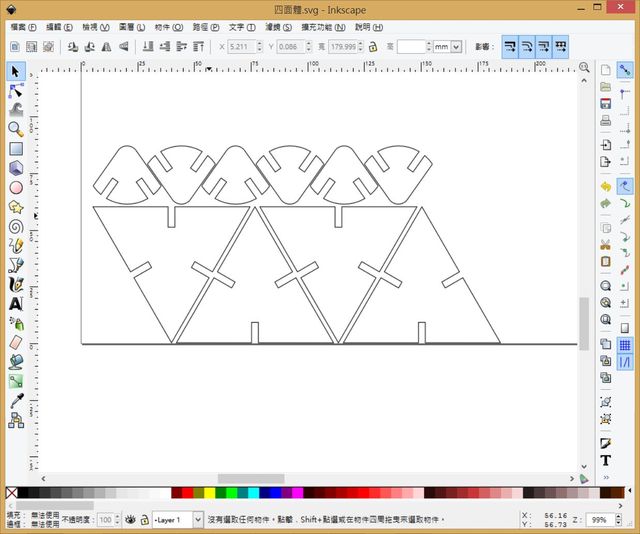

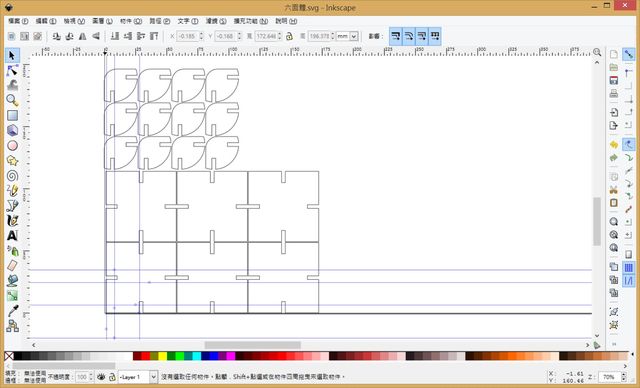

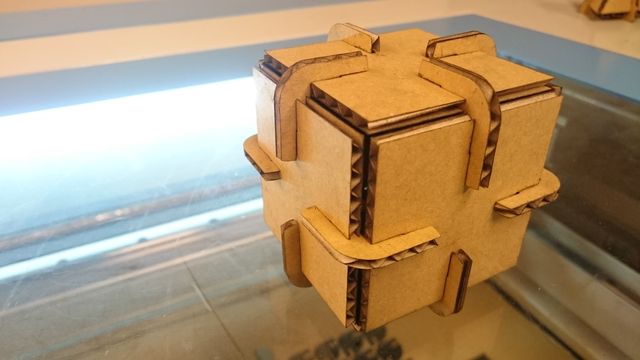

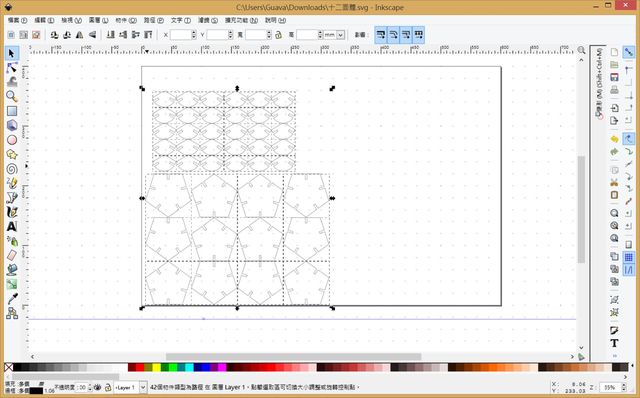

This week, I use design three polyhedron structure by inkscape. Ther are tetrahedron, hexahedron and dodecahedron. Because they have simple and repeat geometric structure, shape and joggle angle is suitable for application in designing parametric construction.First, draw regular polygon and joggle who has simple rectangular. Second, draw arc-shaped and joggle. You can refer Wiki design the joggle angle which between two simple rectangulars on the arc-shaped. Clone or copy it, I use clone because it is interlocking, changing originl plan and the otherone will follow. Finally, array they to save space.

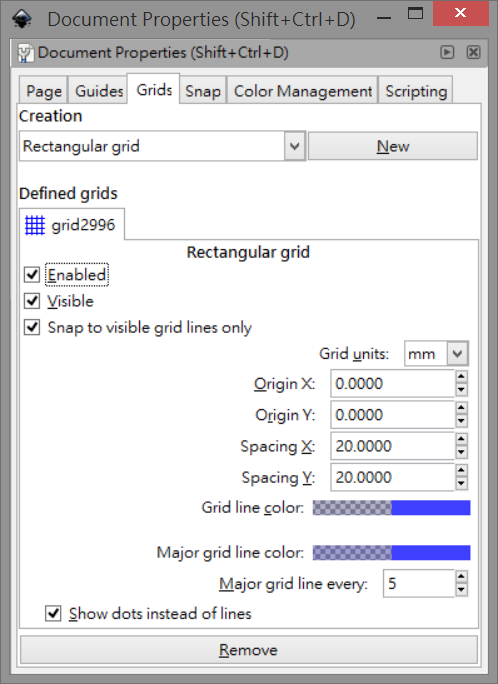

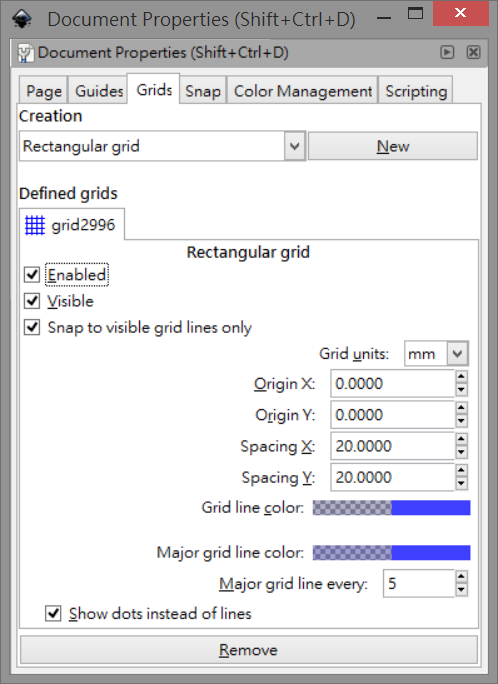

Use Grids function to automatically fit to the grid at drawing process.

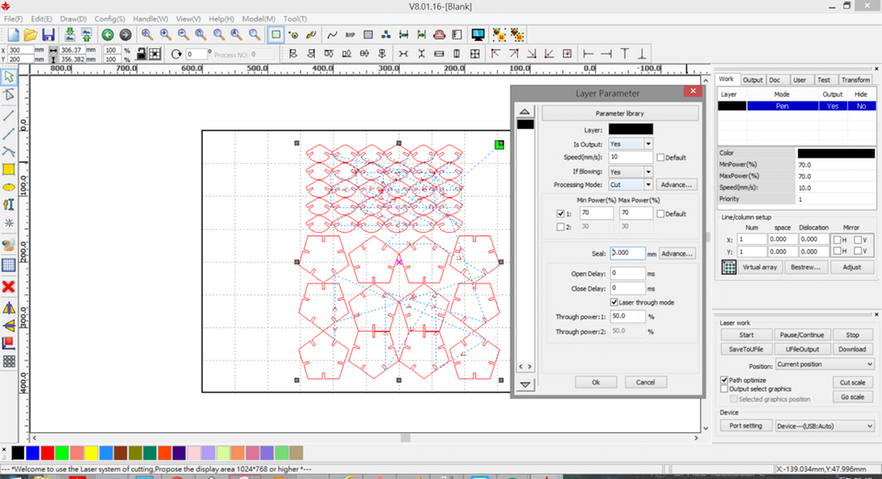

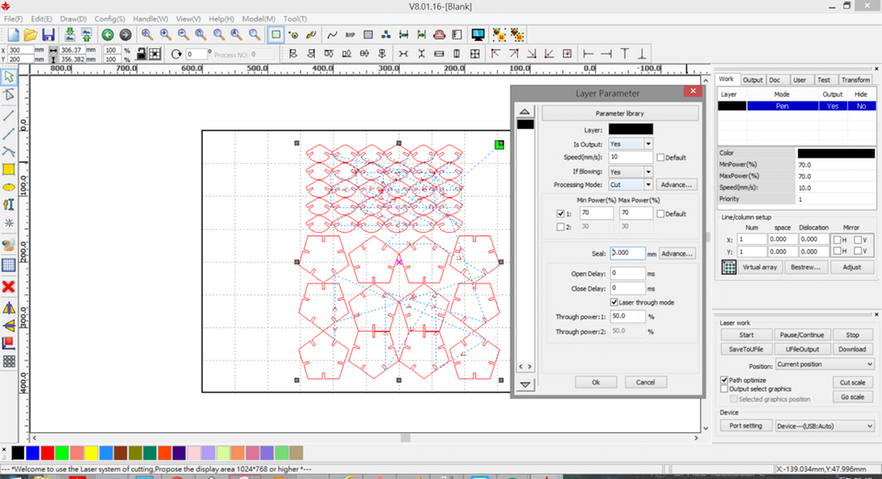

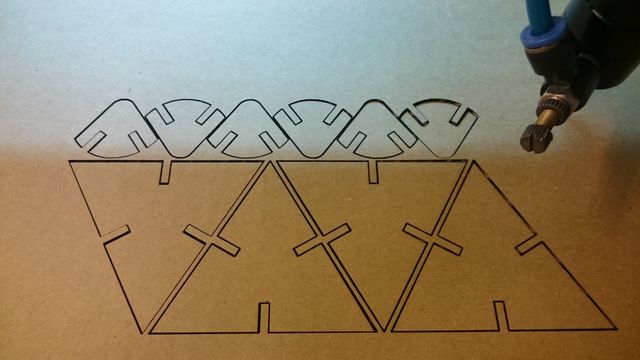

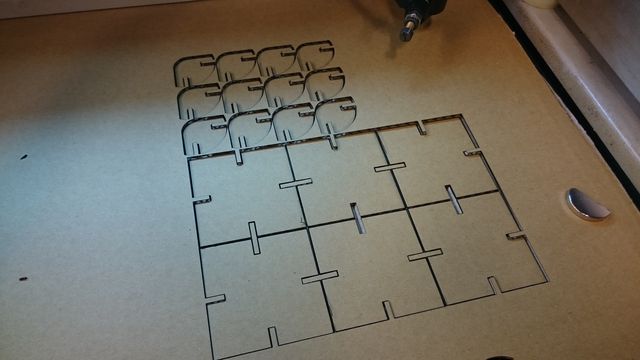

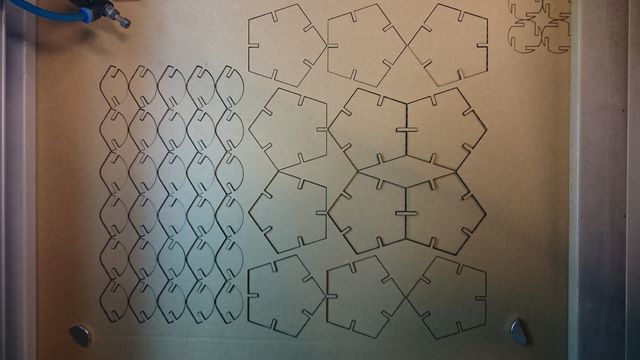

I use CO2 laser cutting which from Keway to make it. You might download the software to drive machine. Load the file, check the vector drawing and set the cutting parameter. Finally, cut it.

Import file to "LaserWork" software. The material is corrugated fiberboard which has 3mm thickness. Choose "cut", and set the cutting speed and power.

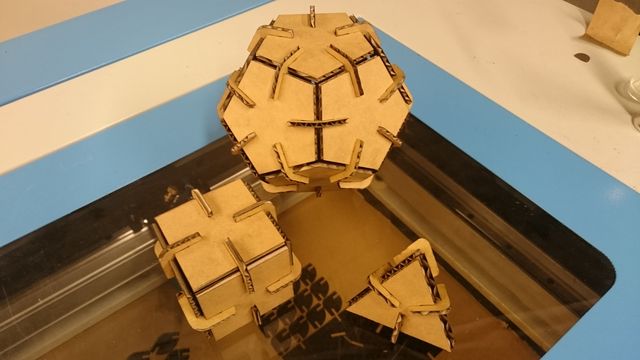

Tetrahedron

Hexahedron

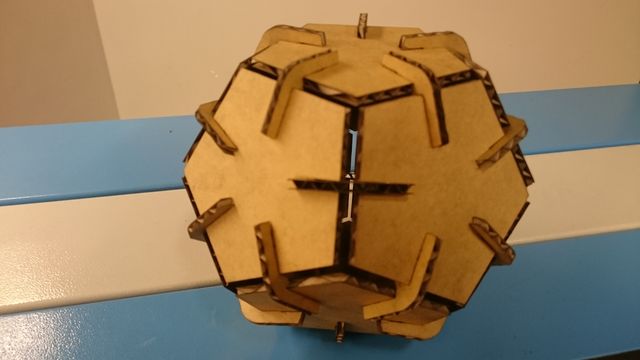

Dodecahedron

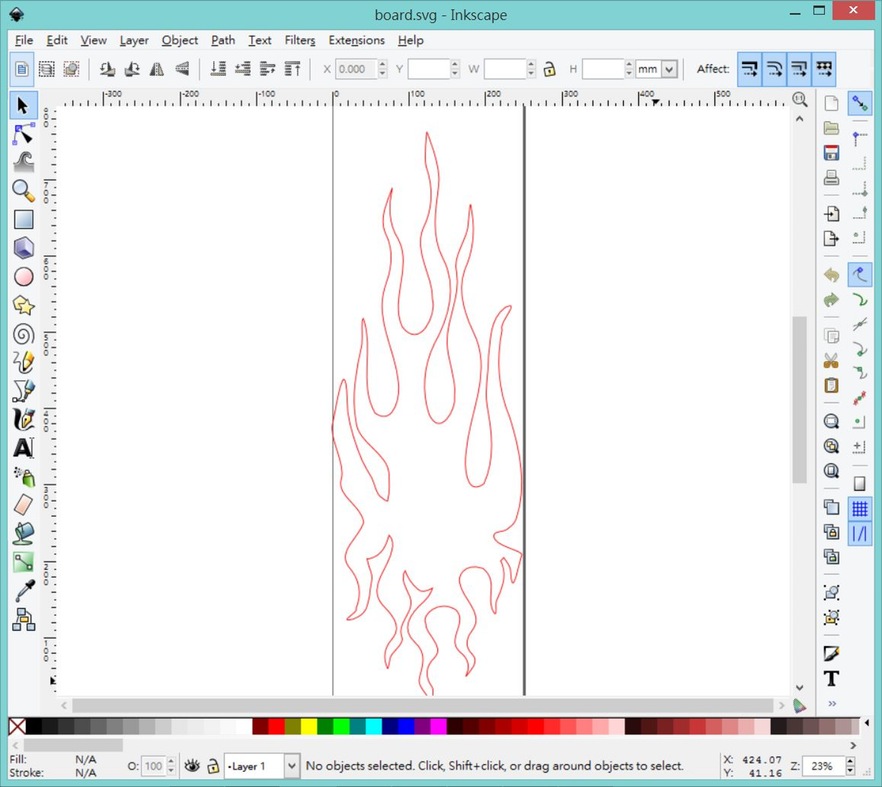

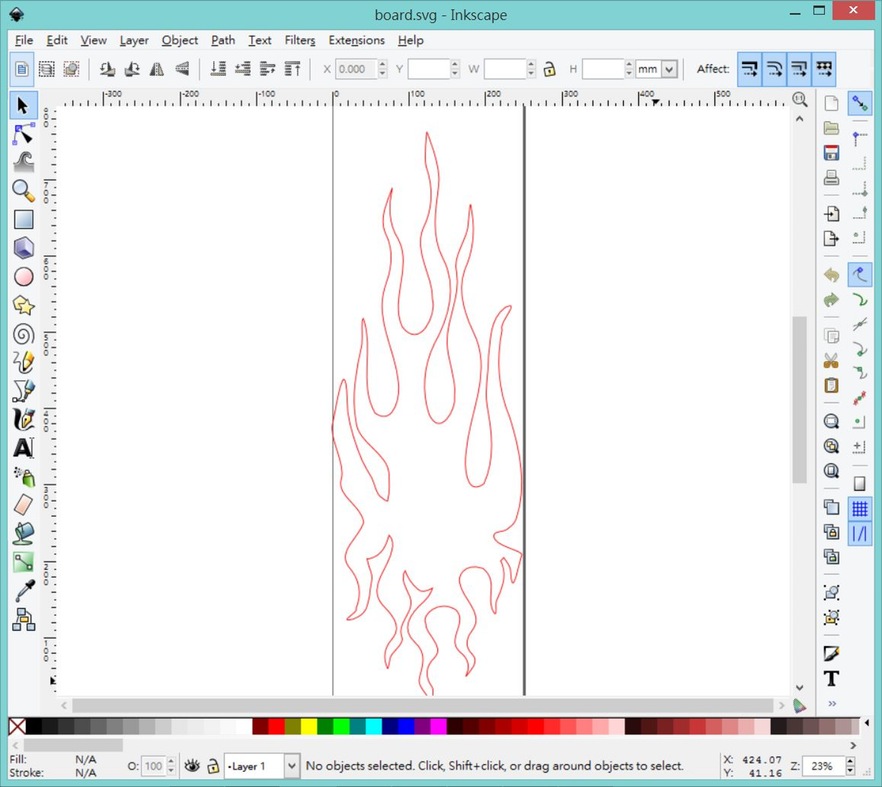

I designed a cutting plane graphics. This is my skateboard sticker design, which I cutting Cutting Sheet will use Inkscape to draw. And save as a vector file formats * .dxf

設計平面切割的圖形,這是我所設計的滑板貼紙,將切割卡點西德(Cutting Sheet)。由Inkscapeㄧ繪製,並轉存成*.dxf向量圖檔格式。

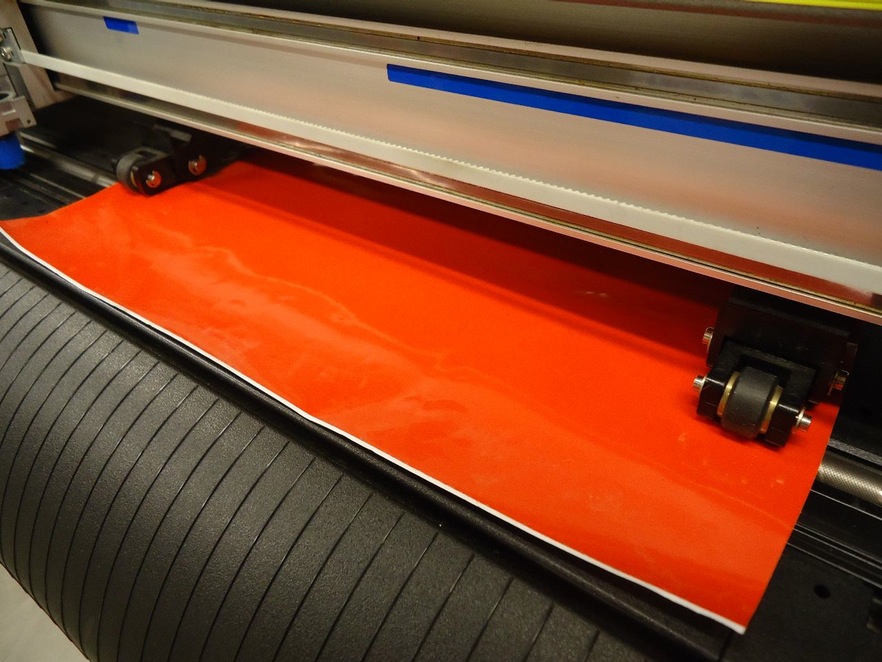

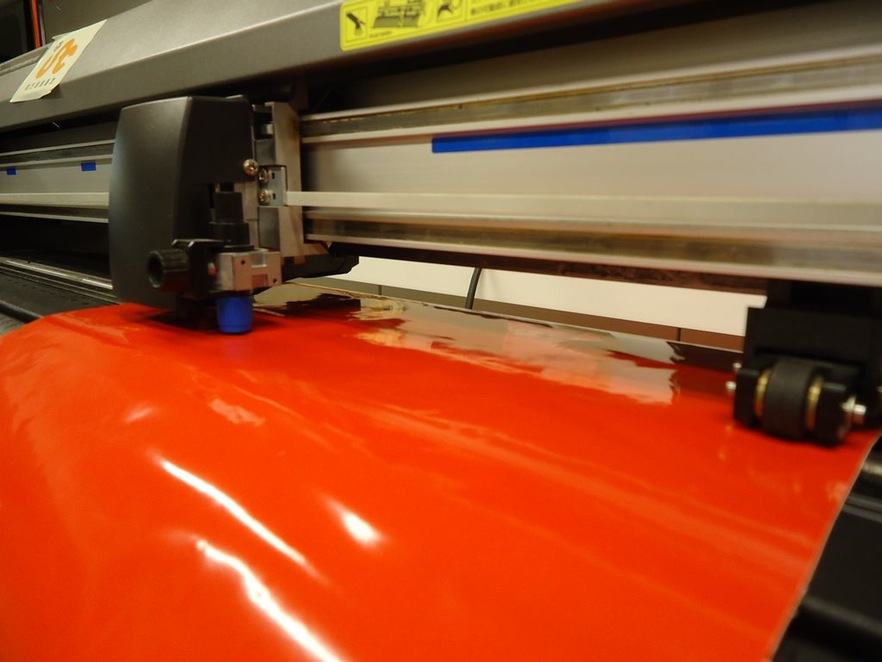

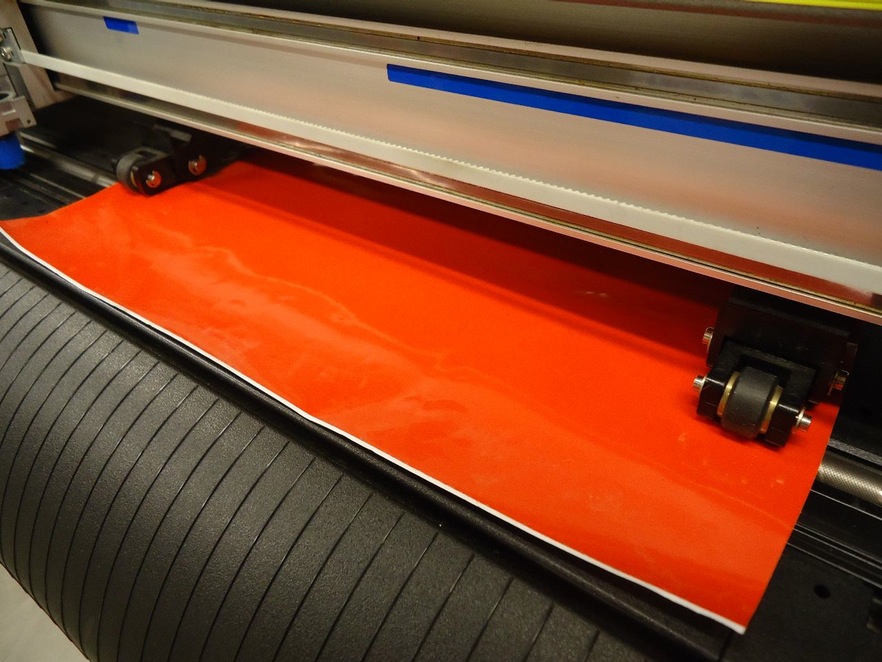

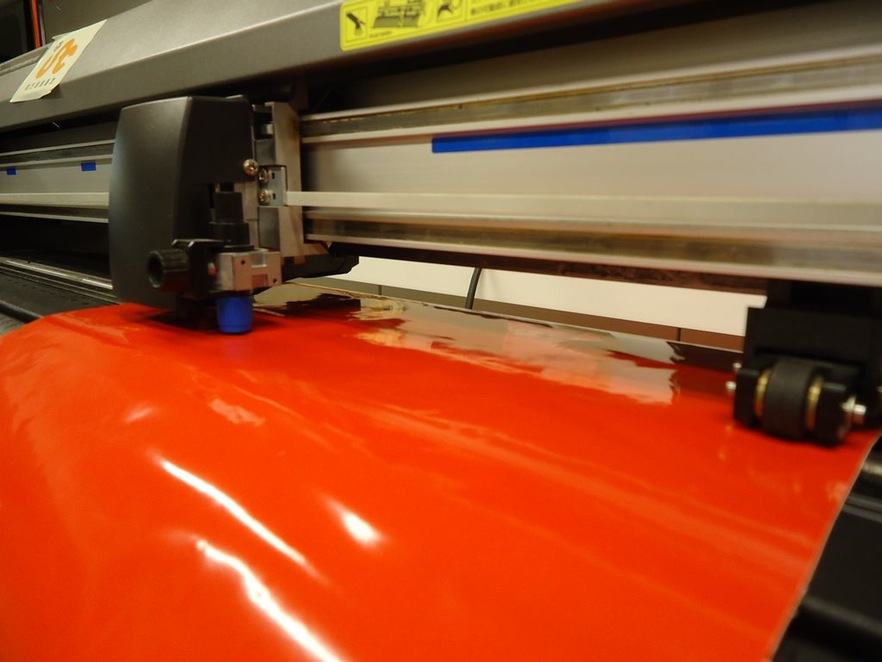

Using the device of Graphtec CE6000-60. Be ready to cut the paper into the device.

使用設備為Graphtec CE6000-60,將要切割紙張放入設備。

Connect the power and computer by USB .

連接電源與電腦USB通訊

Into a flat paper between the two rollers.

將紙張平整放入兩滾輪中

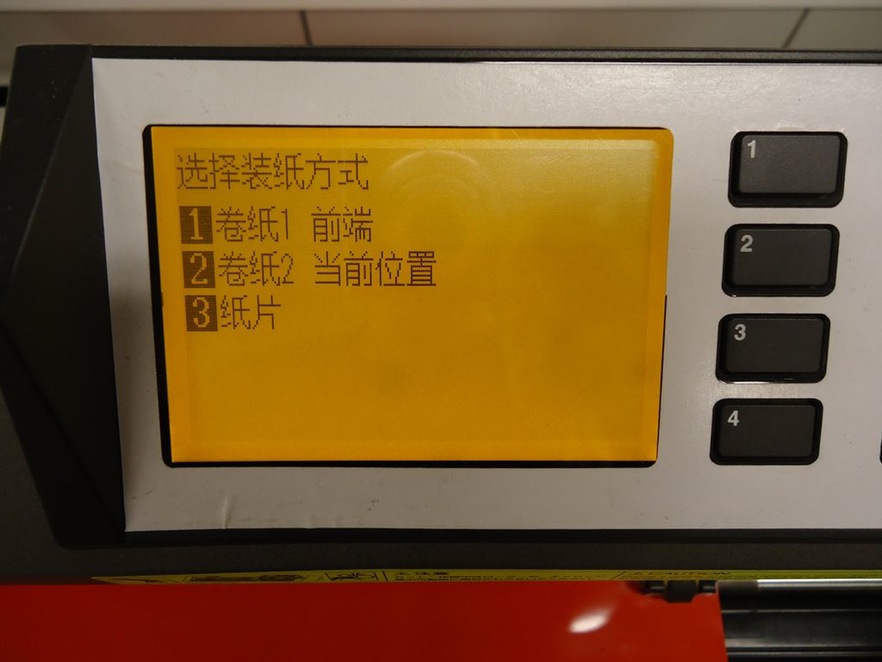

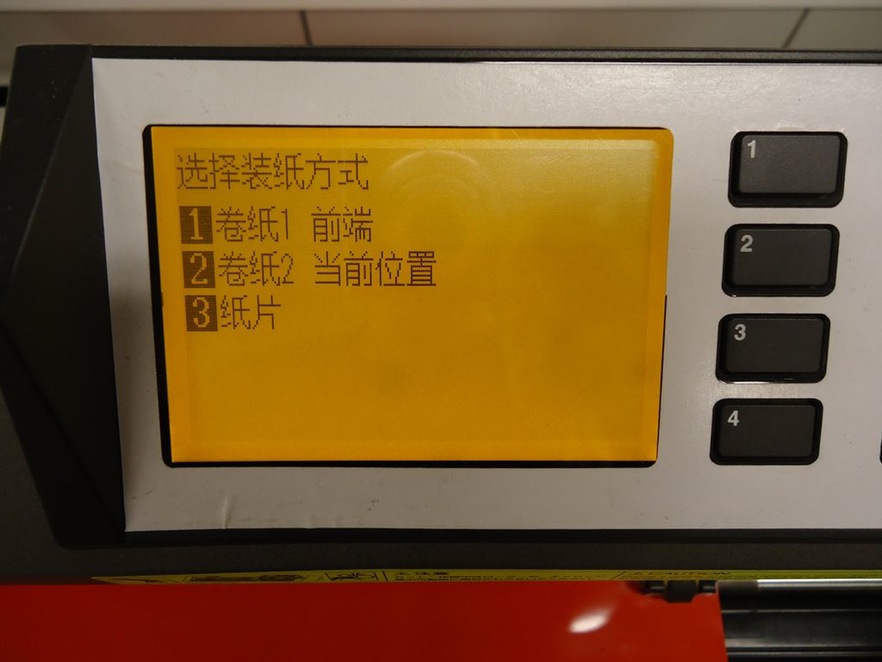

Choose "paper"

選擇"紙片"

Machine will automatically detect the paper size.

機器會自動偵測紙張大小

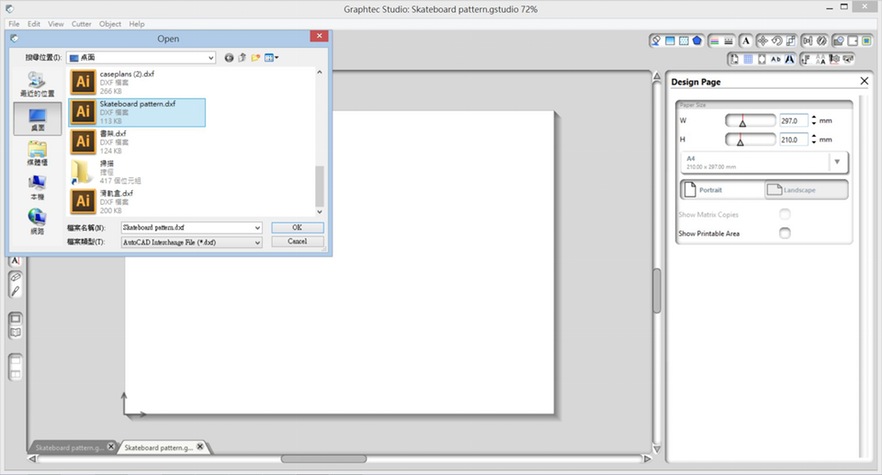

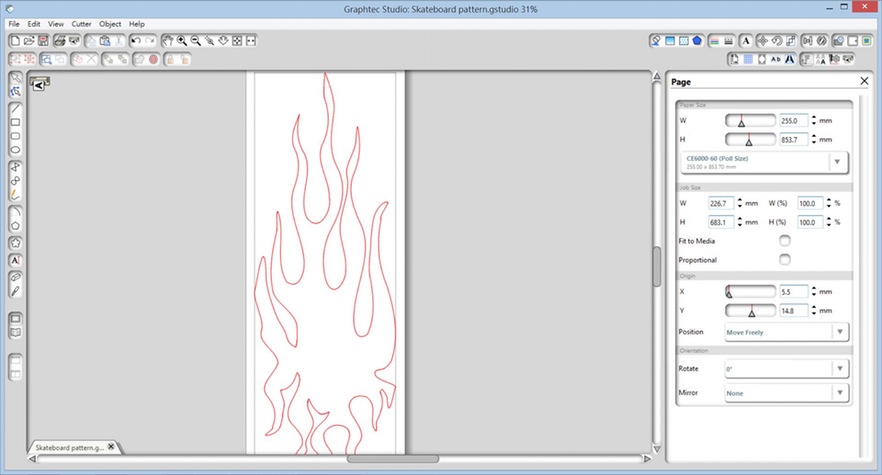

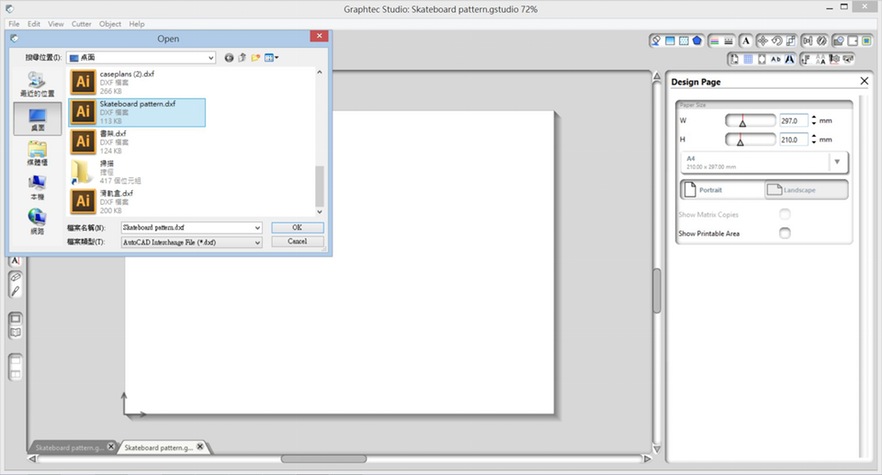

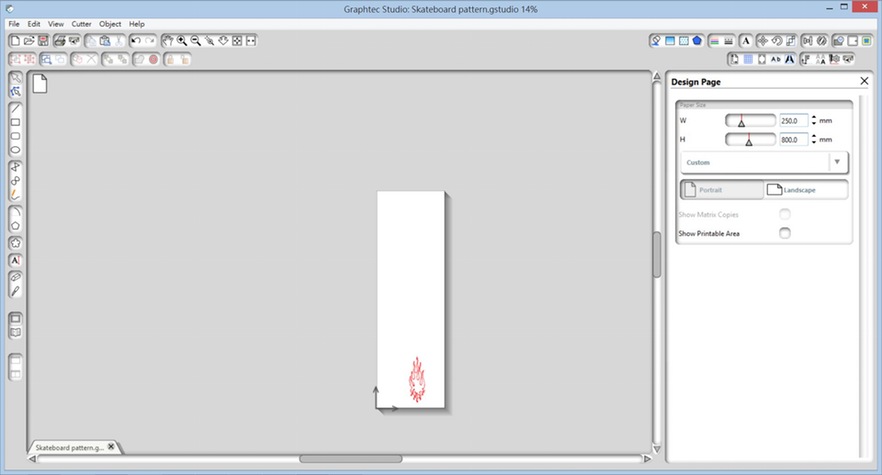

Open the file which we save by Graphtec-Graphtec Studio

由Graphtec 的軟體Graphtec Studio開啟剛所儲存的圖檔。

Adjust the paper size to be cut.

調整要切割的紙張大小。

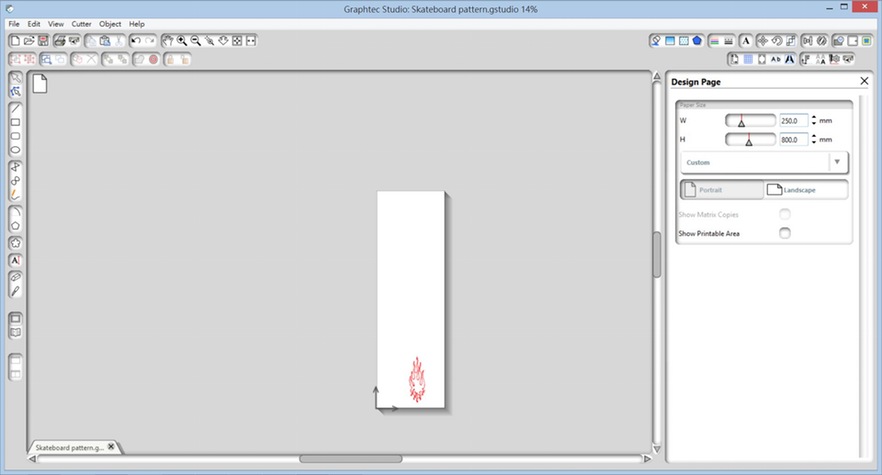

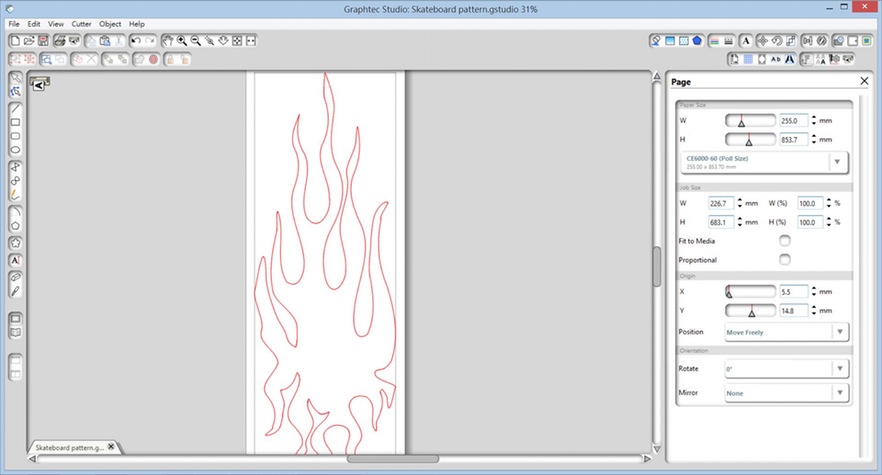

Adjustment of the cutting pattern proportional to the desired size.

調整切割圖案比例至所需大小。

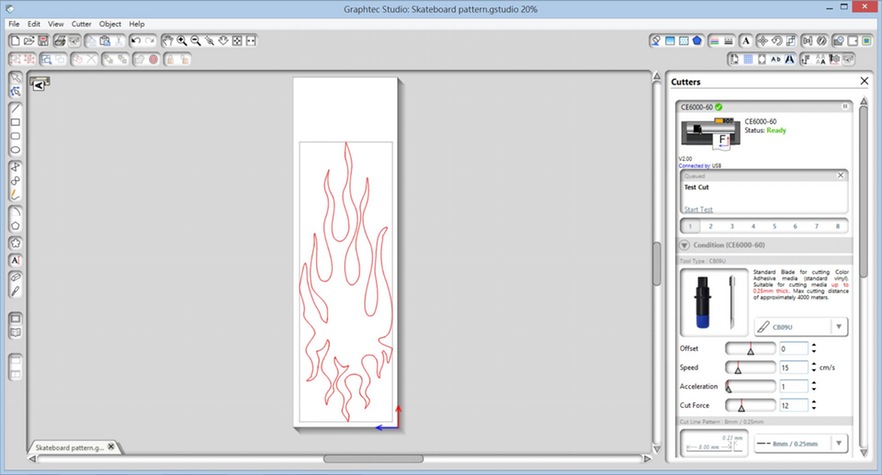

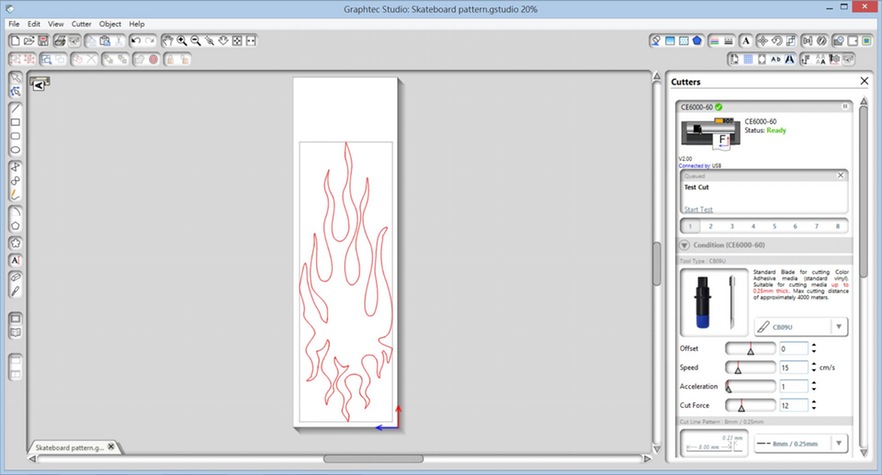

Adjustment of the cutting tool and choose the direction and the engraving parameters, after then sent to the engraving machine engraving.

調整切割切割方向並選擇刀具與雕刻參數,完成後發送至雕刻機進行雕刻。

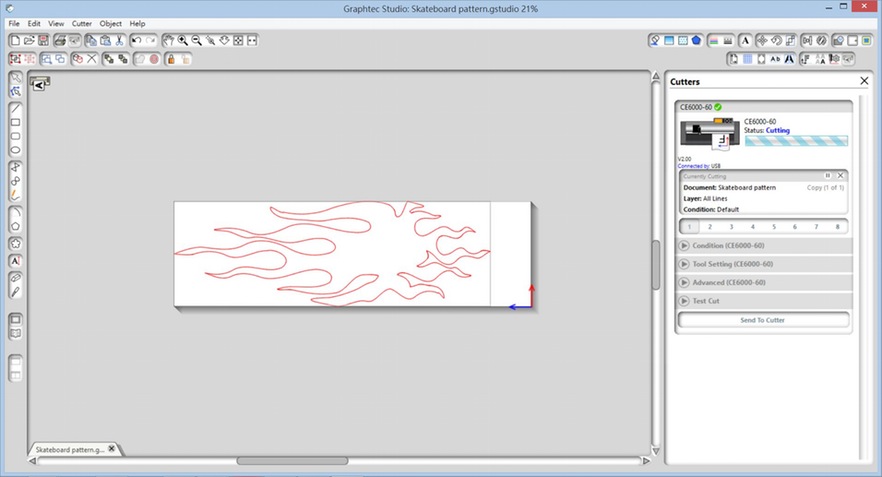

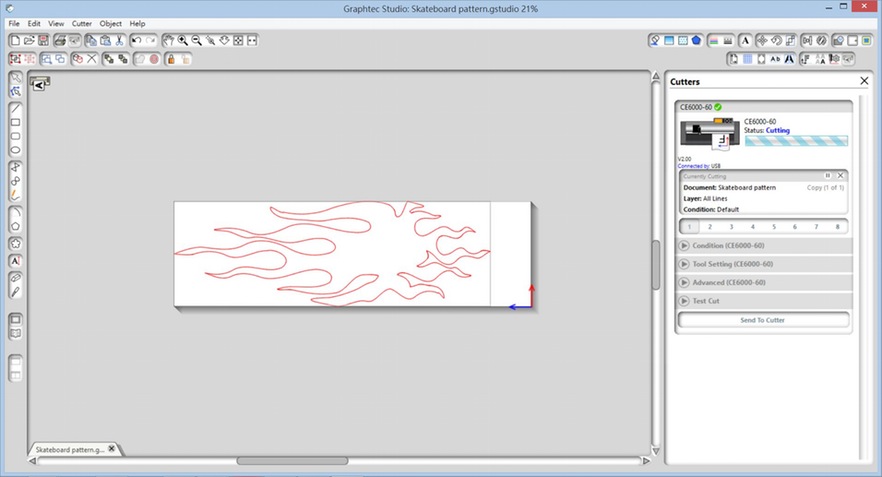

Knife will down to cutting

刀子下壓進行切割

Remove the sticker and stick on skateboard. Due to the larger area, we can be moistened with water. IR will easier to adjust the position.

拆下貼紙並黏上滑板,因面較大所以滑板上可以用水沾濕,較易調整位置。

Troubleshooting:

Try different cutting parameters until a cutting off cardboard. The mainly influenced of Laser cutting is mechanism moving speed and power. The two parameters are inversely proportional. Unable to cutting off at first, reduce speed and modify the parameters to improve power.

嘗試不同切割參數,直到能順利切斷紙板。雷射切割主要由機構移動速度及功率此兩種成反比的參數所影響,起初無法順利切斷,修改參數降低速度及提高功率。

It has being set up the cutting size at drawing. But when it loading Graphtec Studio, the size is Incorrect. Something I did not notice.

繪製貼紙圖案時應該已設定好所要切的尺寸,傳入Graphtec Studio理論上不需再次調整,尚有我未注意到的設定需修改。

Tools:

Inkscape

Laster Cut

Graphtec CE6000-60

File:

Tetrahedron

Hexahedron

Dodecahedron

Boardsticker.svg

Reference:

Polyhedron - Wikipedia