Week 5 - 3D Scanning and Printing

Tasks:

1. To test the design rules of in-house 3D printer(s).

2. To design and 3D print a 3D model that is impossible to be fabricated by any subtractive manufacturing.

3. To 3D scan a 3D model.

1. Test The Design Rules of In-house 3D-Printer(s)

This is a group project to analyse and study the limitation of in-house 3D-Printers. Fablab@SP has mostly Ultimaker 2 and Makerbot Replicator 2. The study was performed using Ultimaker 2. The test models were downloaded from Thinginverse.

|

|

| The printer is capable to print model with overhang without support up to 60 degrees. | The printer printed all the 14 features successfully. The only drawback was the finishing is not as appealing. This may be due to moisture within the filaments. |

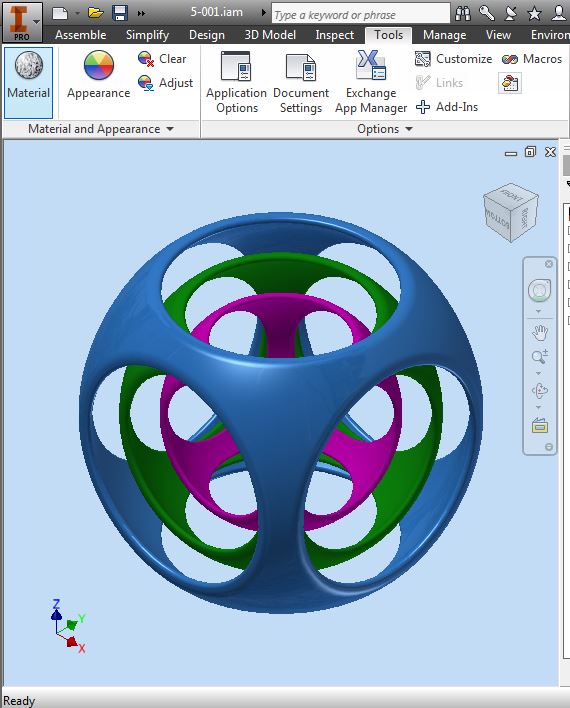

2. Design and 3D-Print a 3D Model

The following 3D model is designed using Autodesk Inventor 2014. They are of different sizes of squares within different sizes of spheres. Each models is created in a part file and assembled together (as shown) to be 3D printed.

The 3D model cannot be fabricated with any subtractive manufacturing methods. Thus, additive manufacturing is the only way to build the prototype.

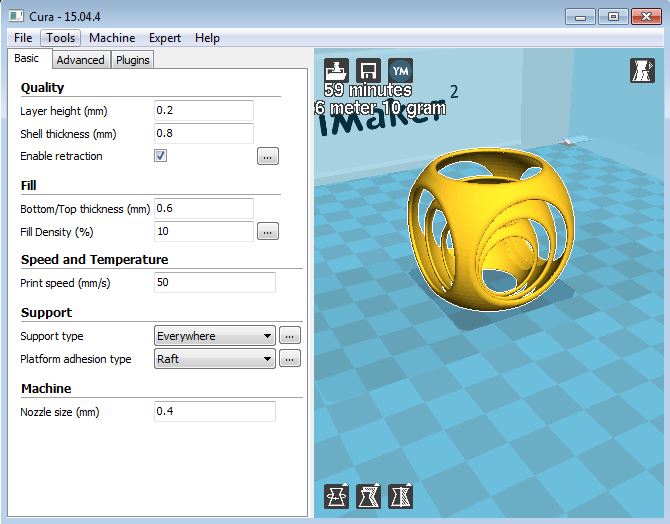

Next step is to convert the assembly into .stl file (using save a copy as). The .stl file is opened with "Cura Ultimaker" for toolpath generation (g-code) -- see below image.

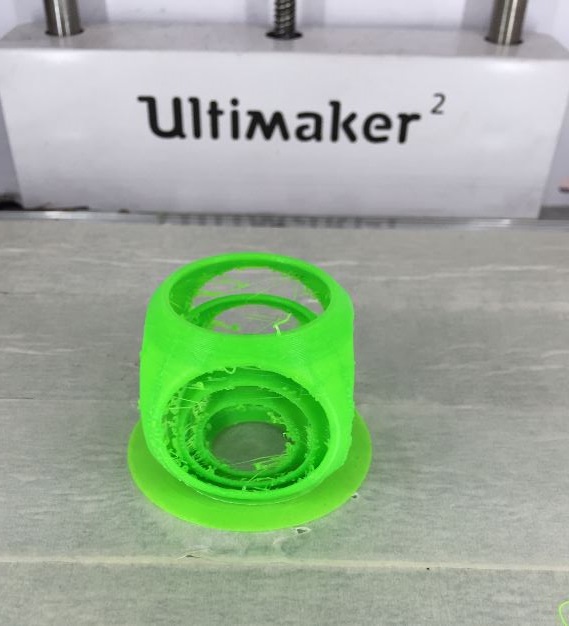

Lastly, the toolpath is loaded and read by 3D printer (Ultimaker 2) to execute the 3D printing. In this printing, the material used is ABS and the heating temperature is set at 230 degrees C.

3. 3D Scan and 3D Print a 3D Model

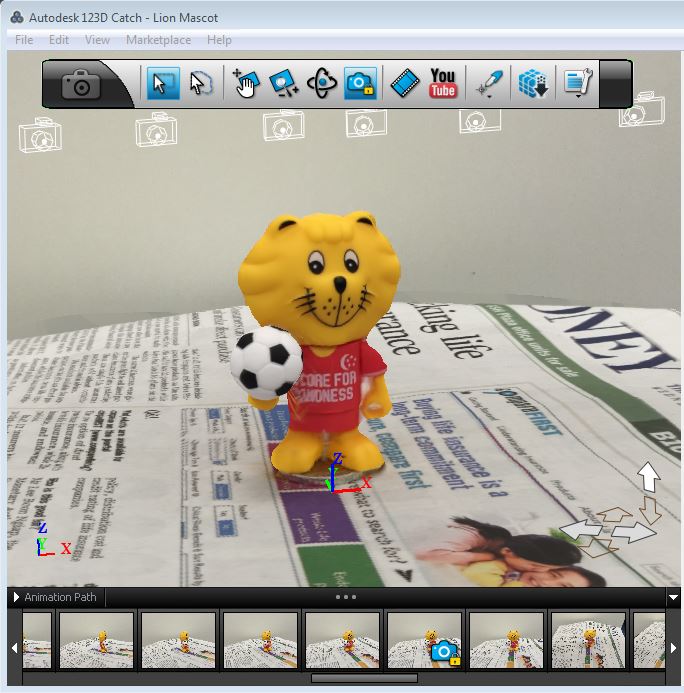

3D Scan is done using 123D Catch. The model scanned is a Singapore Lion Mascot.

With reference to website, the scanning takes place with a total of 40 shots for more/better details captured.

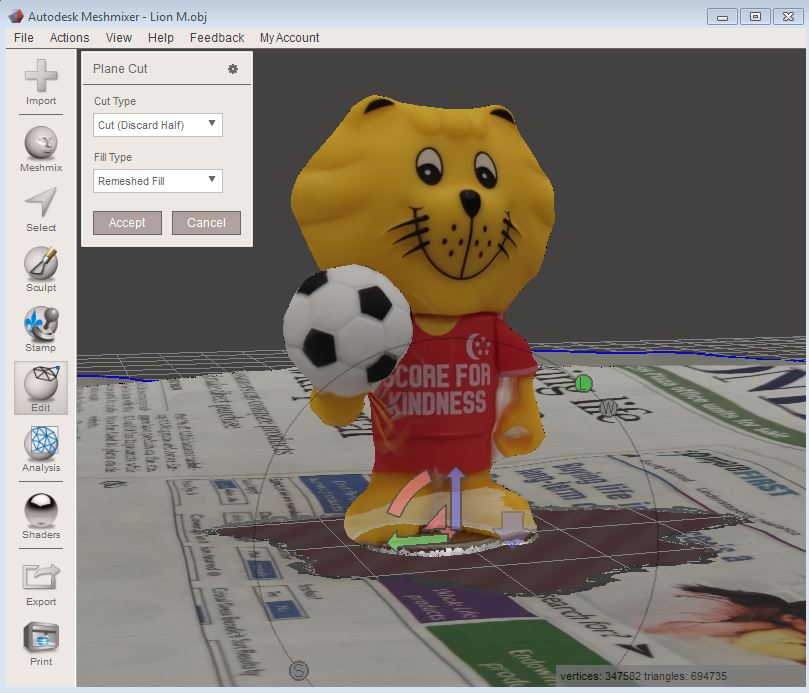

The file is saved as .obj in 123D Catch. Next, open the .obj file from Meshmixer. and remove those unwanted surfaces (ie. the newspaper).

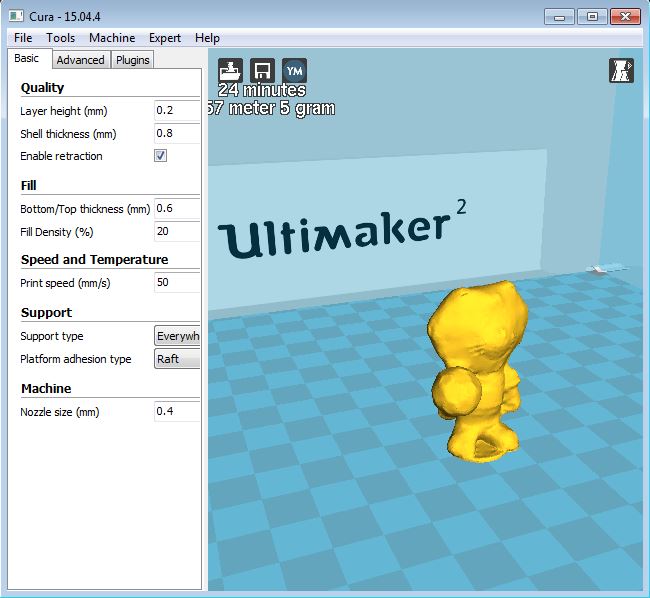

Next step is to save the file into either .obj or .stl so that 3D-Printer software (in this case is Cura Ultimaker) is able to read and generate the toolpath for printing.

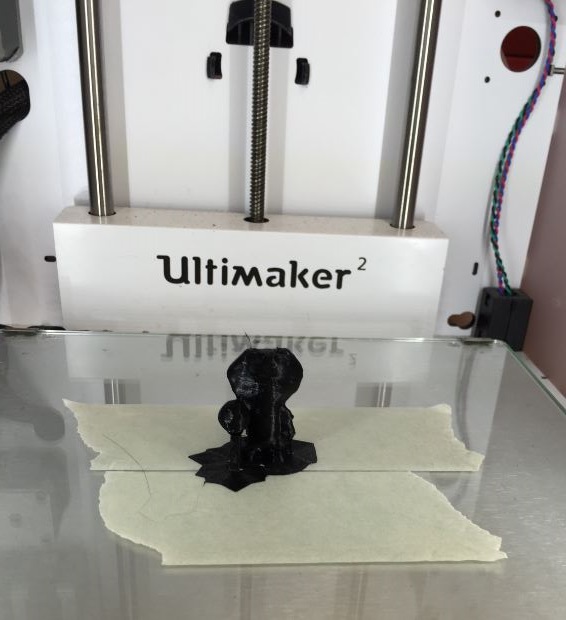

Here is the printed model and original model.

Comment: 123D Catch is a very handy scanner. The resolution on the scan can still be improved by taking many more shots and using a better camera. Anyway, the scan is considered reasonable quality since the overall shape is reproduced and most of the details are there other than the fine tiny details such as the gaps within the legs, gaps within the palm, etc..

If anyone is interested to re-produce the work in other fablab, click the following link to download the files.