Week 3 - Computer-Controlled Cutting

The following softwares and hardwares are used for this week assignment.

- AutoCAD

- Inventor Proffesional

- Corel Draw

- Laser Cutter EAS70

- Vinyl Cutter GS-24

Laser Cutting

TASK: Press-Fit Construction

What is "press-fit"?

An interference fit, also known as a press fit or friction fit,[1] is a fastening between two parts which is achieved by friction after the parts are pushed together, rather than by any other means of fastening. Source: https://en.wikipedia.org/wiki/Interference_fit

Depending on material and size, the fitting value may vary from 10-50 µm.

3mm thick MDF (Medium-Density Fibreboard) is used to demo the press-fit contruction. The proposed idea is to build simple alphabet builder.

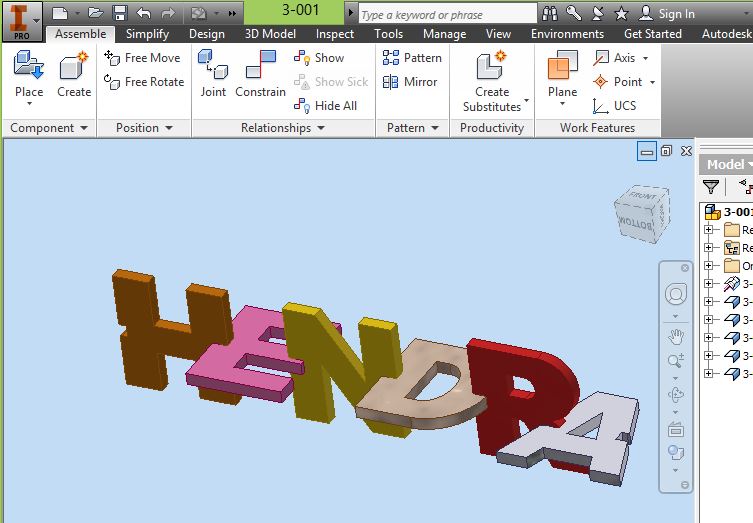

First, the idea is designed in Inventor environment to simulate the end product as shown in the following.

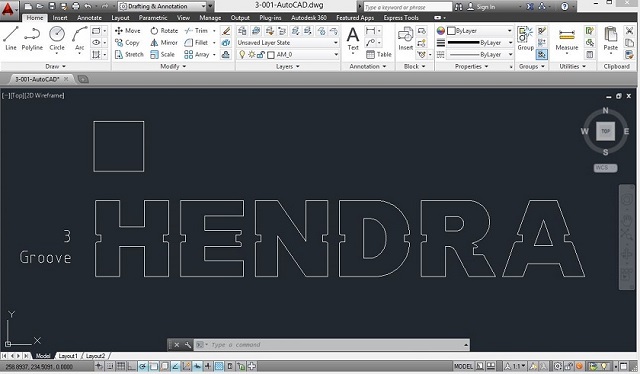

The 3D models are then transformed into 2D drawing using AutoCAD.

Before this, the kerf of the laser beam need to be found. How? Draw a square 20mm, test cut with the laser and measure the difference of the cutting, ie. the square hole and the square as shown in the following image.

Finding: the kerf for EAS70 is 0.25mm with machine setting 85% cutting power and 15mm/s cutting speed.

Kerf.dwgWith the kerf value in mind, the 2D lines of the alphabets can be offsetted by 0.140mm to achieve the press-fit(30µm).

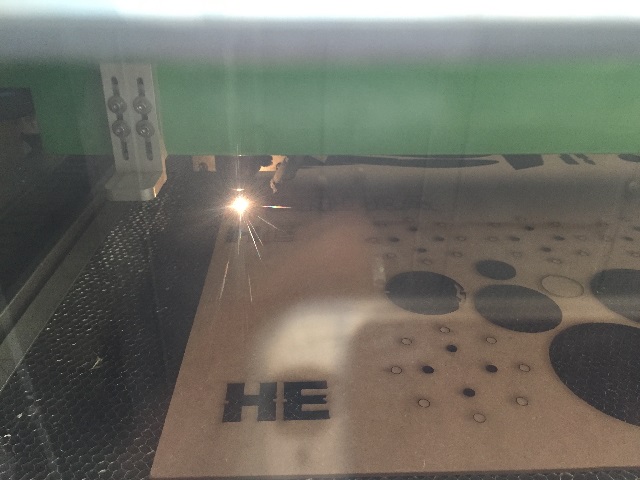

With the same machine setting, the alphabets are now laset-cut.

Cutting in operation

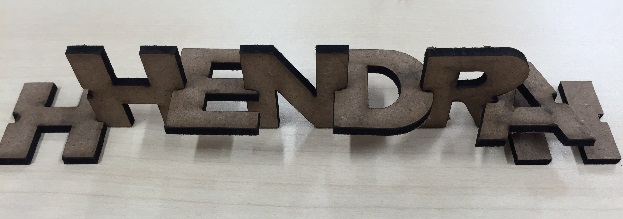

Cutting ends & separated from the raw MDF board

Tested 2 alphabets and the press-fit works well as intended. Final word "HENDRA" can now be assembled.

Press-Fit ALPHABET BUILDER Kit

3-001H.ipt; 3-001E.ipt; 3-001N.ipt; 3-001D.ipt; 3-001R.ipt; 3-001A.ipt;

Vinyl Cutting

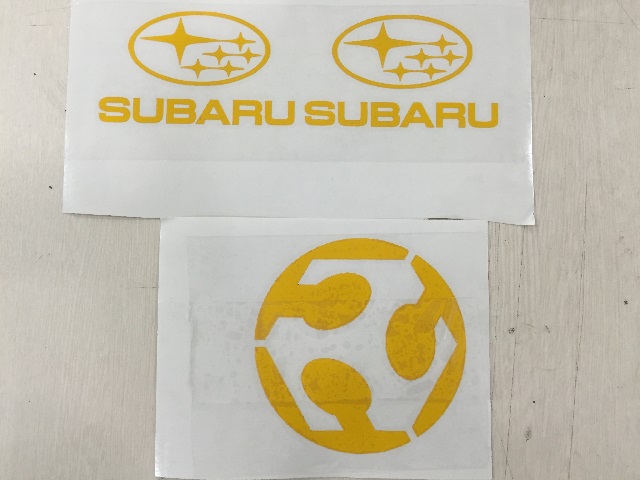

Subaru and fablab logo is downloaded from the webpage as form of raster images. The images are transformed into boundary lines in Corel Draw before cutting using Vinyl Cutting machine.

The vinyl cutting is very simple. It is similar to paper printing.

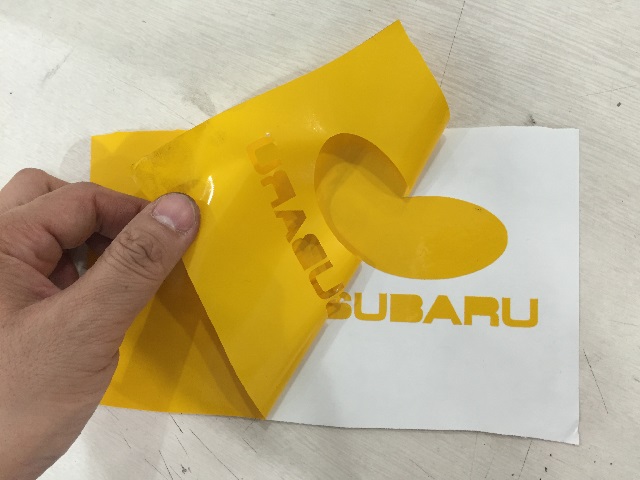

The following shows the vinyl cutting in operation to removing the unwanted vinyl film and applying transfer film on the sticker. The cutting depth of the vinyl cutter is set at 0.1mm for this opeartion."

Vinyl cutting of subaru logo in operation

Peeling off the unwanted vinyl film

Applied the transfer film onto the sticker

If you like to print one, you may like to click download and try it yourself.