Introduction

For this week we need to produce a PCB board by ourselves. There are three steps in PCB drawing: schematic designing, PCB designing and PCB making. We have made a pcb board few weeks ago so this week we concentrated on designing. I have tried three different tools: EAGLE which is free, Altium Designer which is commercial and kokopelli which is geeky.

EAGLE

EAGLE is a half-free pcb designing software. It has a commercial license but if you just want to design small PCB, free lincense is enough. Eagle has version on Linux, MAC and Windows. All of them can be downloaded from their website. www.cadsoftusa.com. Following is my turtorial for EAGLE.

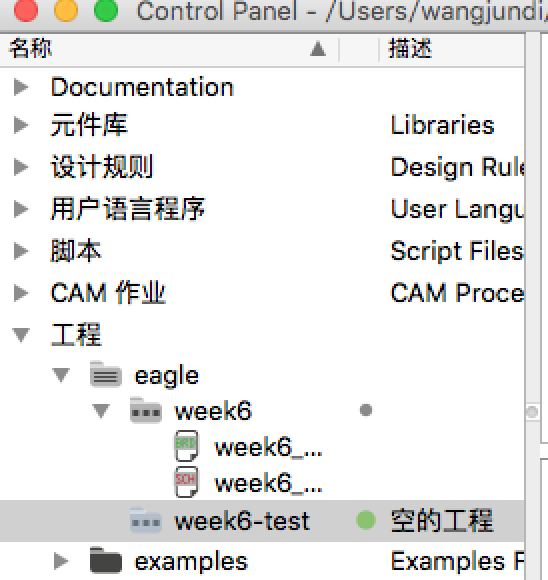

1. Setup a new project

Go to File-New-Project to start a new project. A project is consist with a schematic and a PCB borad. You have to design the schematic first them Eagle will generate some components and how their linking on the PCB board. Them you have to draw the line.

After set up a new project, you can see there is a project in the Project on the control panel.

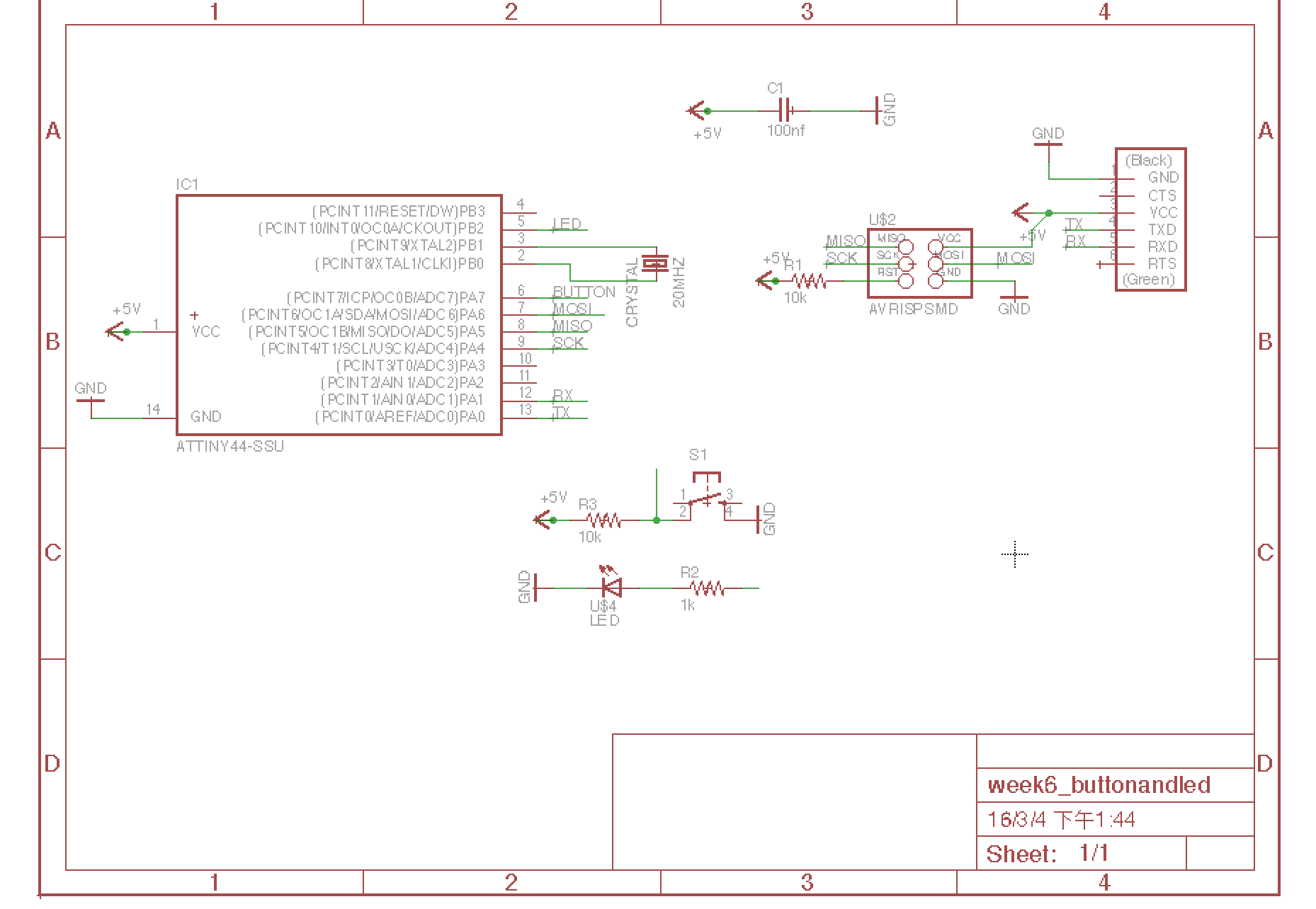

2. Setup a new schematic

Then set up a blank schematic. Before we start drawing, we need to install the library first. Eagle Libraries consist components wa may use. For fabacademy, we have Fab library right here. Don't forget to use it in the control panel.

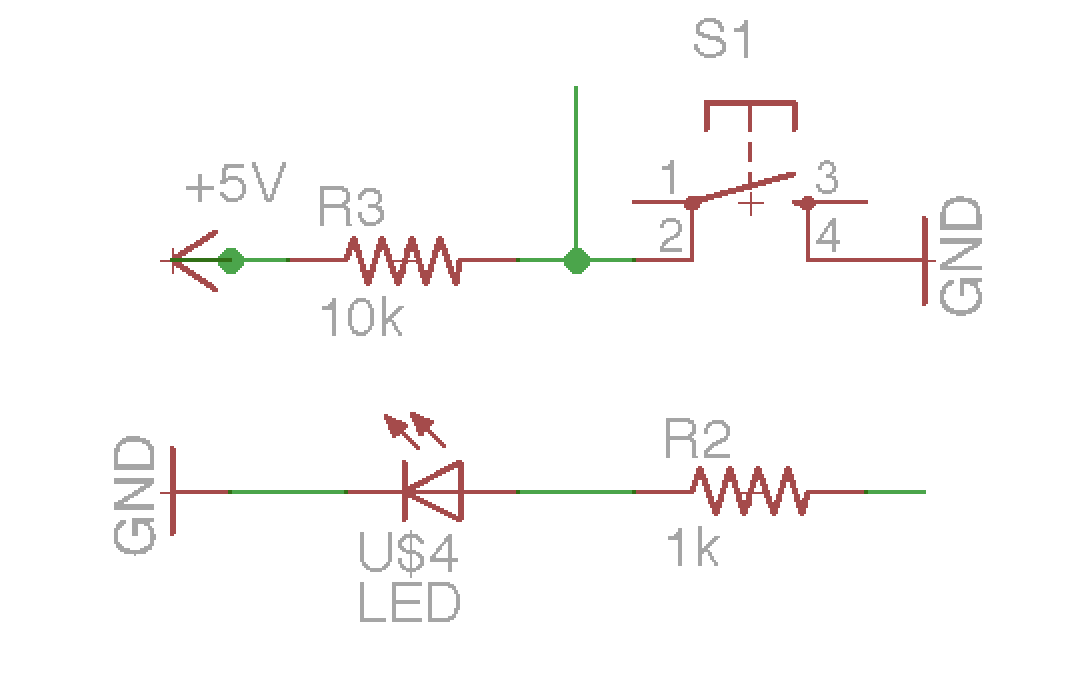

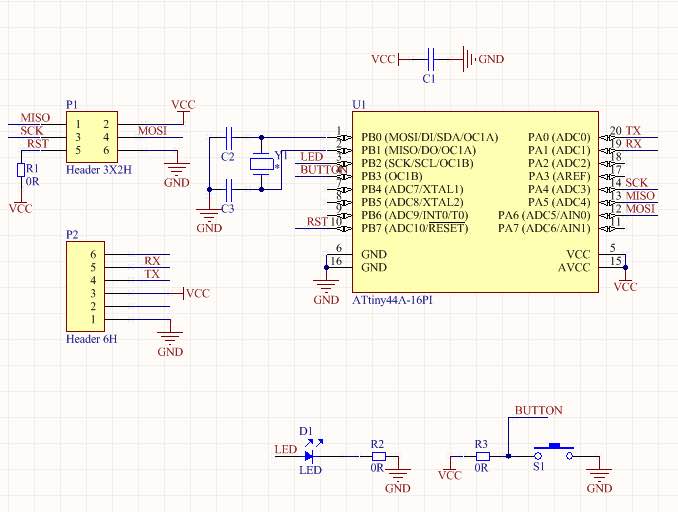

Then we can use "add" command to add components. The schematic is as follow.

For the MCU and FTDI and ISP ports, all we have to do is link the ports one by one. For the led, we need a current-limiting resistor. Usually it is 1k ohm. For the button, we need a pull-up resistor to keep the Pin status high when no one push the button.

You can download my schematic from here.

3. PCB design

Then comes the pcb disign. Click the "switch to pcb" button on the panel then you can see the board with all of your components. Arrange them and line them. Just be careful with the gap between the lines.

I have encountered some problems about the line and gap. Because the milling machine has its max precision, if you make the line to thick and get narrow gap, the fab module cannot distinguish it. So you have to keep the line thin enough and what I chose was 0.01.

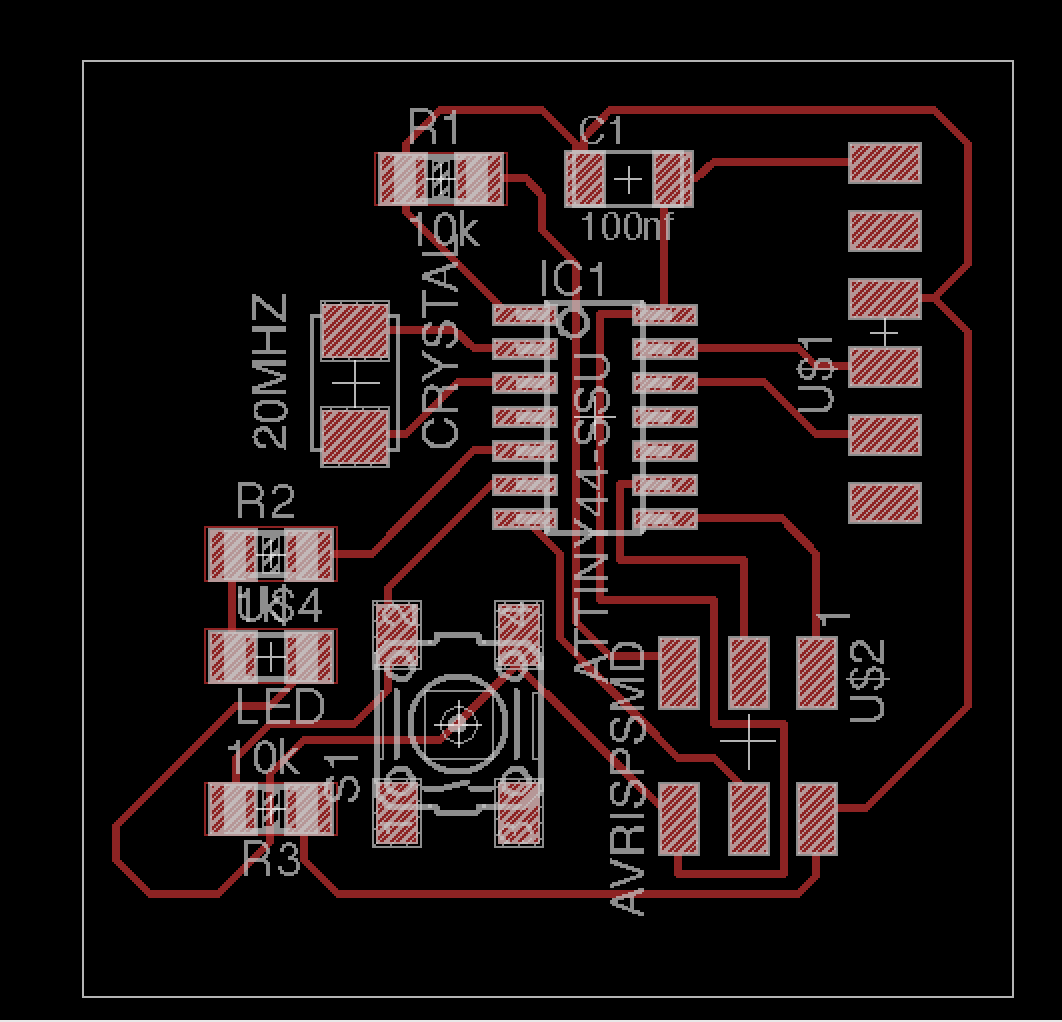

Here is my pcb board.

PCB files trace edge

And then send it to the fabmodule, mill it and sold it. Here is my final work.

Altium Designer

In my opinion, Altium Designer is far more convenient than any other PCB tools, except Cadence. But you know, it's very expensive. Thanks to my start-up company, we have an altium designer lincense. AD has the same function with eagle, but it has many assist tools to help you with the PCB design.Here is my schematic.

You can download here.

Kokopelli

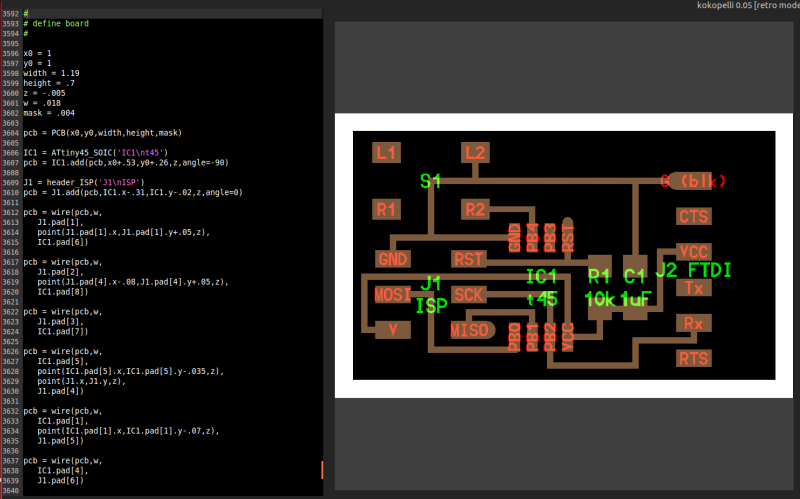

Kokopelli is a PCB design tool. It use code to design the pcb. So it's very geeky.

1. Install

Fab module local.

http://kokompe.cba.mit.edu/

Unzip to a folder open a terminal in that folder and do:

make clean

make fab

sudo make install # recommended and needed for kokopelli retro

2. Hello.button.45.cad

This file contains all the function. We just need to modify the function to make the traces. These are it's structure:

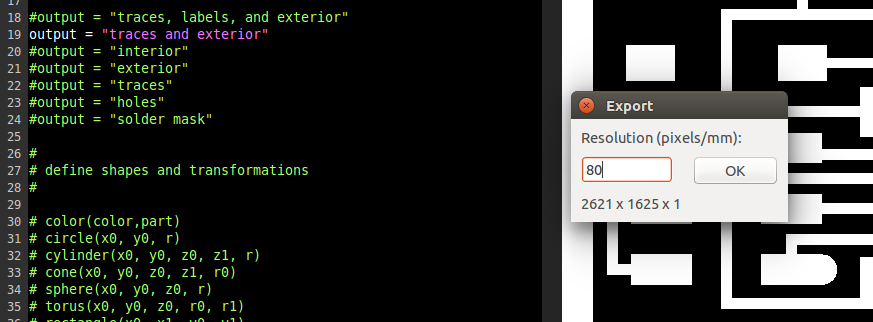

LINE 18 - 24

For exporting, uncoment the line depending on what output image you want. to render out.

LINE 82 - 165

Defines basic shapes 2D and 3D

LINE 172 -422

Define functions

LINE 425 - 905

Text classes and definitions

LINE 908 - 996

PCB classes and definitions. Modify the PCB class if you want to change the shape of your PCB to be eg. round

LINE 999 - 3551

PCB Library Here you find all your parts you can use, or create your own pars.

LINE 3555 -3590

Graphics

LINE 3593 - 3690

Define Board

LINE 3697 - 3714

Code for defining exporting options

LINE 3716 - 3726

Set limits and parameters

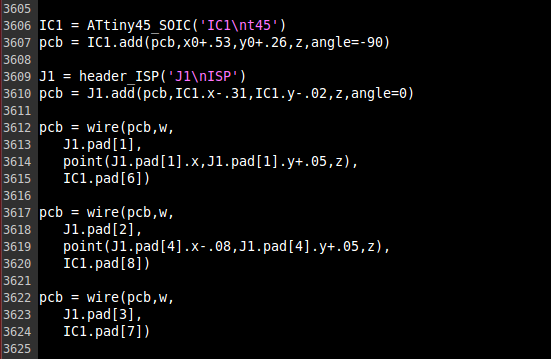

2. Adding components

First Component a MCU ATtiny 45 and placeing it on the pcb rotated -90.

3. Wires

To draw Wires betwen components pads you first define a wire and then specify wrom which components pad to other components pad.

pcb = wire(pcb,w, J1.pad[3], IC1.pad[7])

RULE: Wires will ALWAYS be drawn, first Horizontally then vertically.

If you need to go vertically first you add a point like this

pcb = wire(pcb,w, J1.pad[2],point(J1.pad[4].x-.08,J1.pad[4].y+.05,z), IC1.pad[8])

4. Exporting

In the Export menu choose .png. You want to export a high resolution image to get the best tracing and milling result. Depending on the size of your PCB the number you put n may vary, a general rule of thumb is for a 5cm * 5cm PCB you should have around 2000px * 2000px.

But this only works with some simple circuit. If you go with a huge circuit board, tools like kokopelli will make you mad.