Let's talk about my final project.

Since I failed with my time management (highly recommend you to quit your work first to focus on fab academy)

I changed my final project from making electric kart to 2axis gimbal.

Propose a final project

1. what will it do?

2. who's done what beforehand?

3. what materials and components will be required?

4. where will they come from?

5. how much will it cost?

6. what parts and systems will be made?

7. what processes will be used?

8. what tasks need to be completed?

9. what questions need to be answered?

10. what is the schedule?

11. how will it be evaluated?

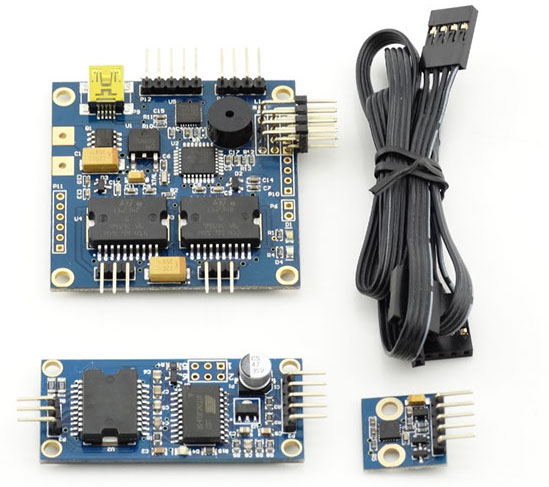

I am going to make 2 axis gimbal because I like to shoot short film with my DSLR and I only have manual stabilizer.

It means there will be may be the first L6234D Shield.

It will make you to shoot high quality video with your DSLR. High quality means "without shaking" in here.

I'll let my idea completely free so everyone can have their own dslr stabilizer with cheaper price. :)

Someone already made the 2 axis gimbal in FabAcademy 2014 but he used servo. but I am going to use Brush-less motor.

Here is the link for 2014 fab academy gimabal.

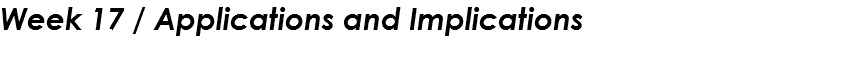

This is the famous alexmos gimbal controller. I am going to study this stuff.

And I am going to follow this basic shape of gimbal.

It is hard to find DIY gimbal control board.

What I am going to use

birch plywood for main frame - Buy from local wood shop / 30$ for one whole panel (2440*1220mm*12t)

Turnigy 5208 brushless dc motor - Hobby king / 40.88$ * 2ea

L6234D H-bridge - Digikey / 8.25$

Leather for my handle - Local Leather shop / 5$(left over)

M3 Bolts and Nuts - Local hardware store / 5$..?

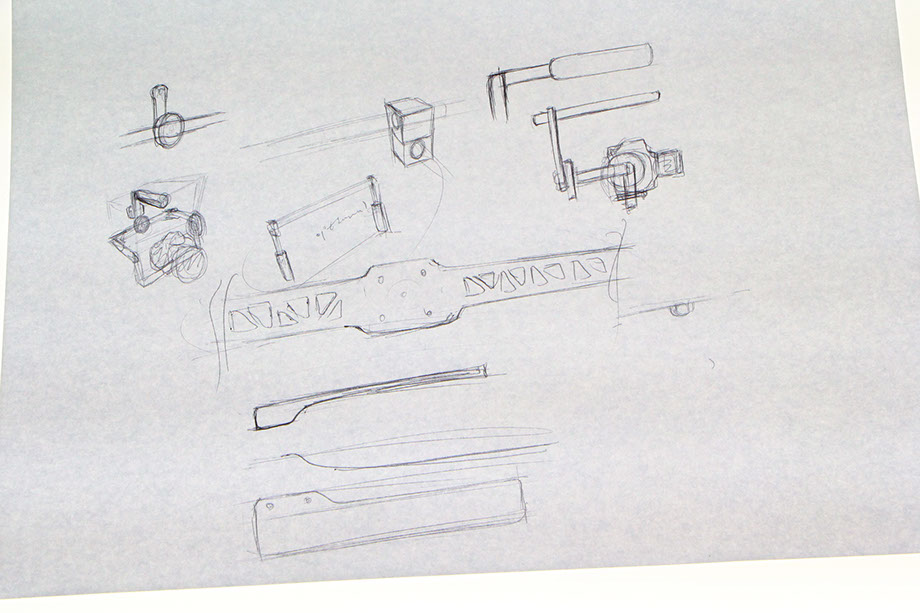

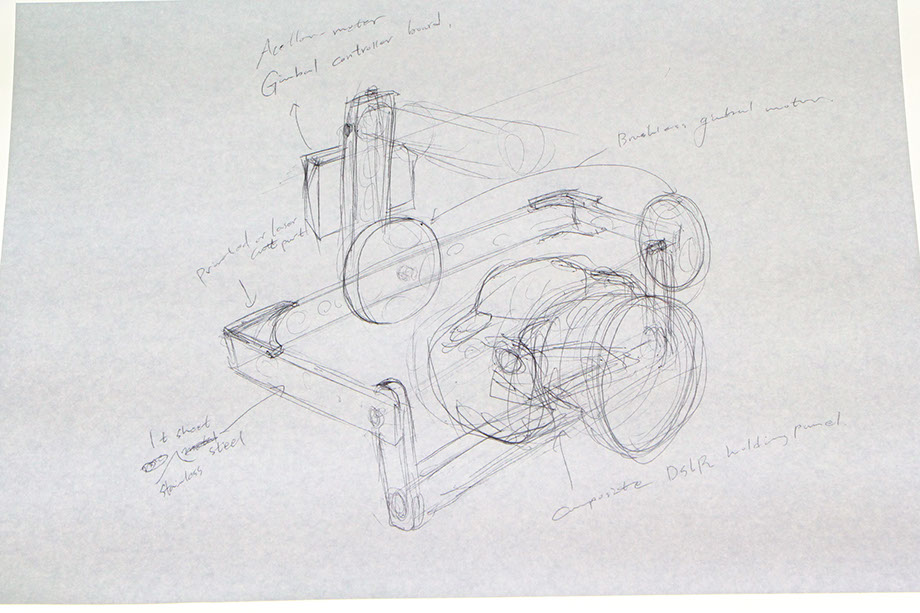

This is design for my final project for now I have no 2D or 3D CAD for now.

What parts and systems will be made?

I am going to make frame with CNC router

Handle Cover with Laser cutter.

Input device will be MPU6050.

output device will be two brushless motor so I have to make BLDC motor control board by using L6234PD h-bridge and that is use for the other Gimbal control board.

And some decorative 3d printed part can protect pcbs and battery.

What processes will be used?

1. Control BLDC Motor with Satshakit and BLDC shield I'll make.

2. CNCing and Laser cutting the frames.

3. Finishing with oil based varnish.

What tasks need to be completed?

I just set my final project so... everything has left..

Electronic Design, Frame Design, Configuration, Stabilizing.

What questions need to be answered?

Is it really possible that I can finish my fab academy?

Motor actually can hold up to 1.8kg just as data sheet said.

MPU6050 will communicate well through ftdi connector.

What is the schedule?

Day 1~2

Done Electronic Design

Day 3~4

Done frame design and cut and assemble

Day 5~6

Done Assemble everything works, Do adjusting gimbal

Day 7~8

Make final Presentation video and do presentation

How will it be evaluated?

It will be evaluated by shake amount of video. Less amount of shaking means mpu6050 and motors are communicate well through the control board. So it will going to take a lot of time to make it work.

And how smooth wooden parts are moving not touching each other.

HOME