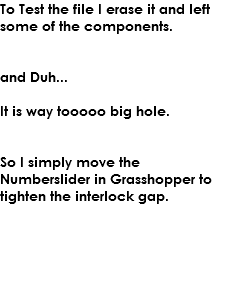

Here is my file

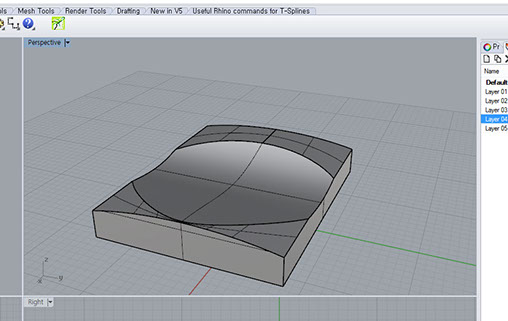

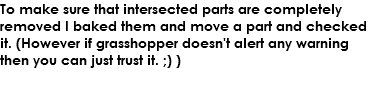

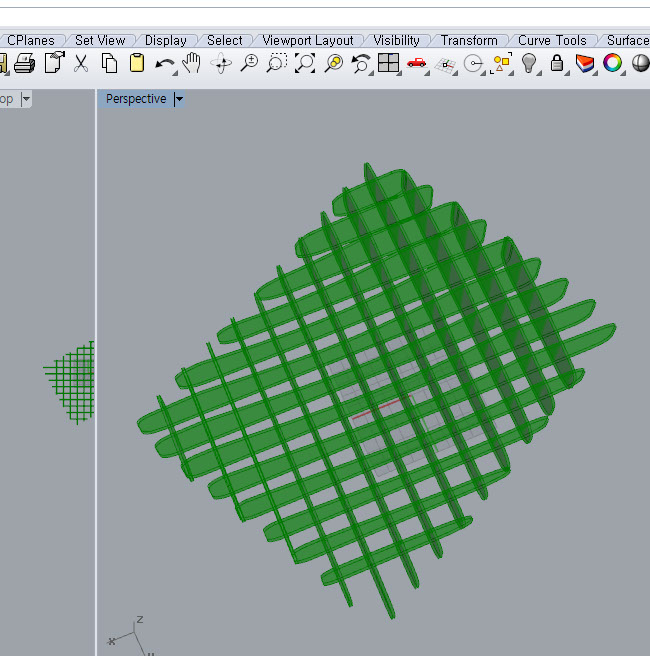

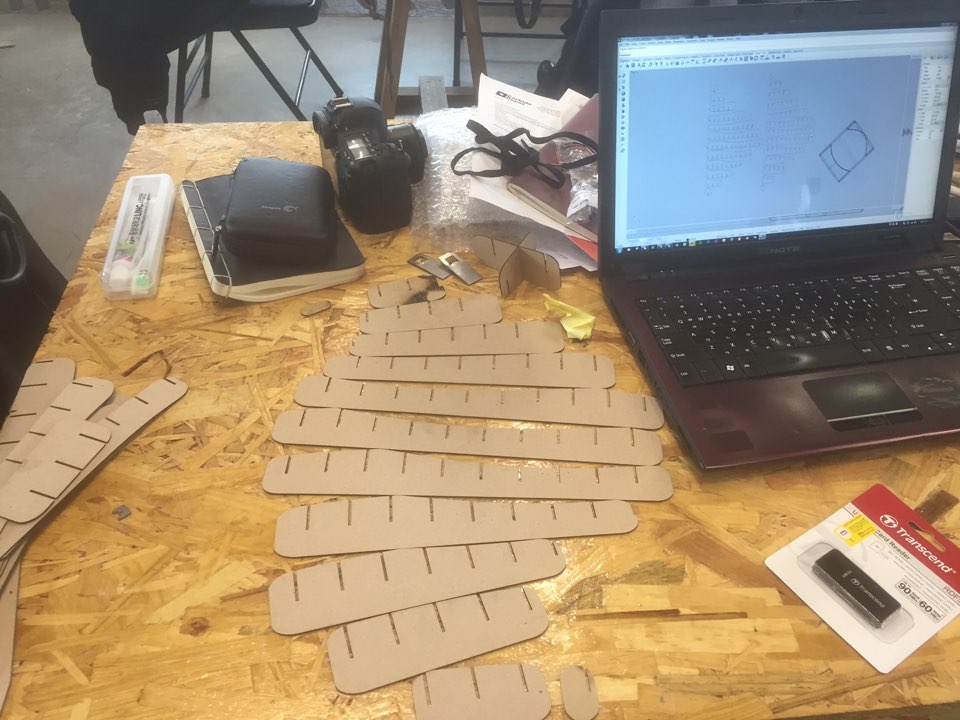

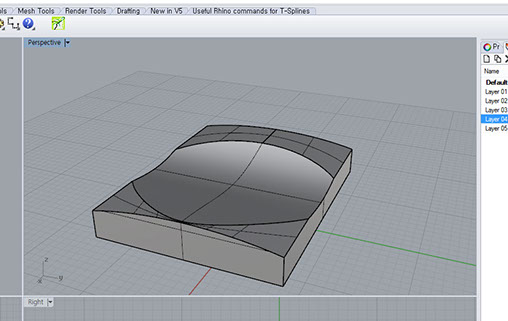

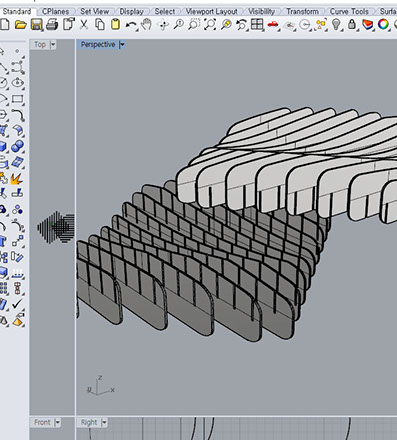

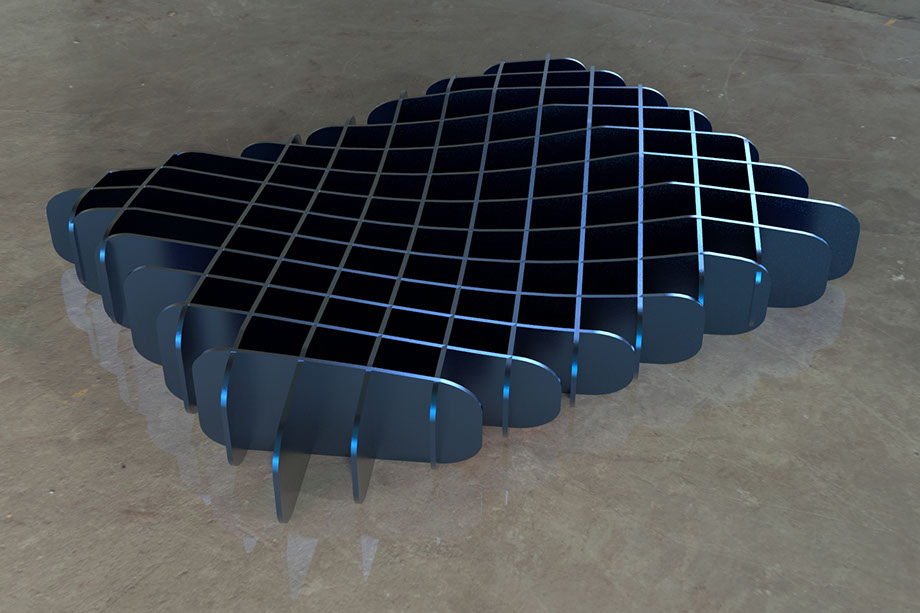

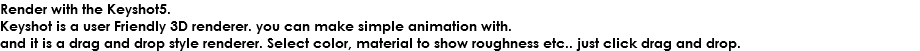

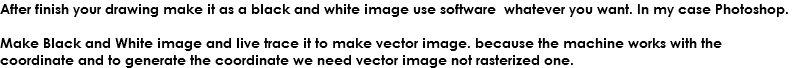

3d modeling _ chair / wheel

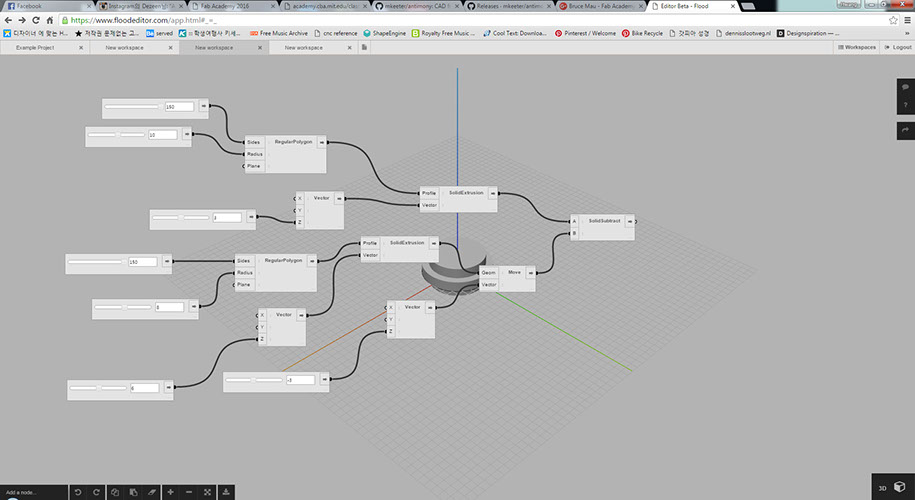

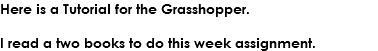

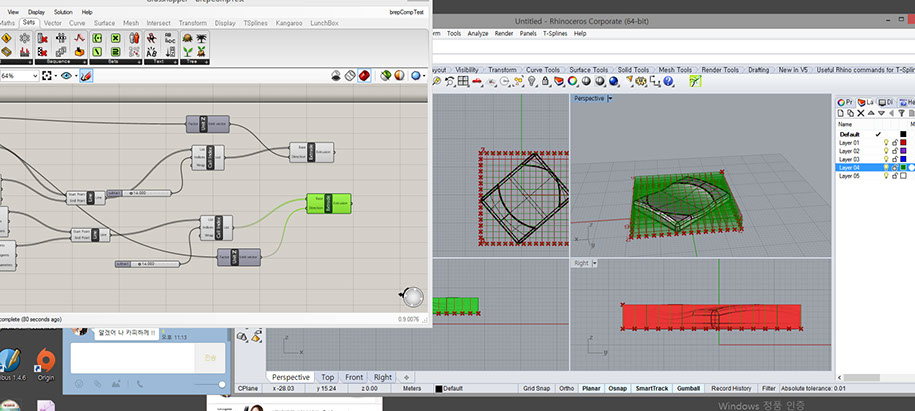

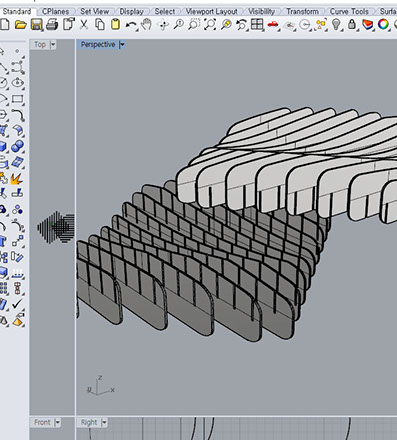

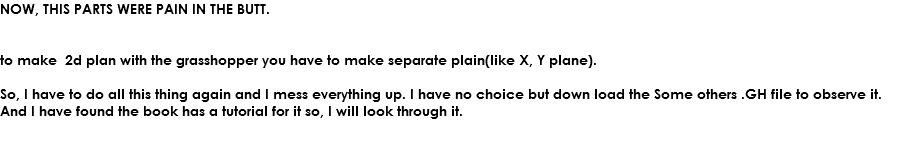

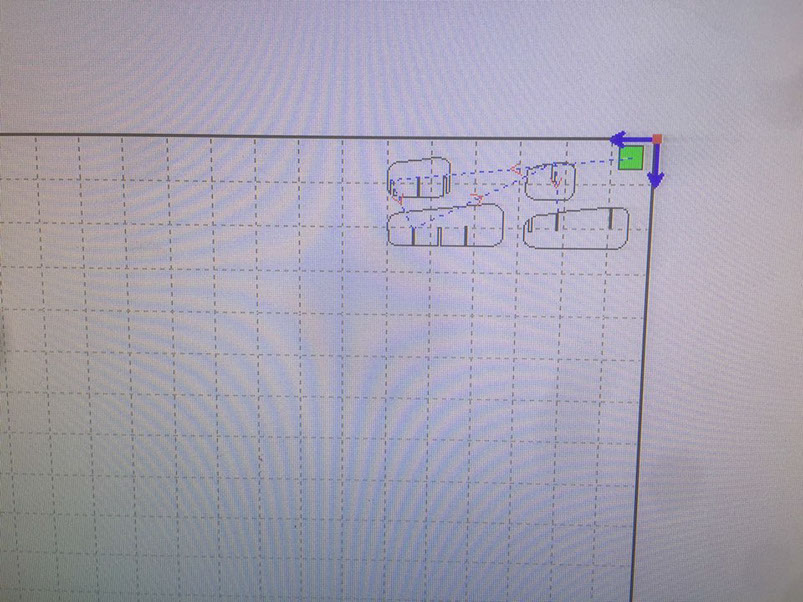

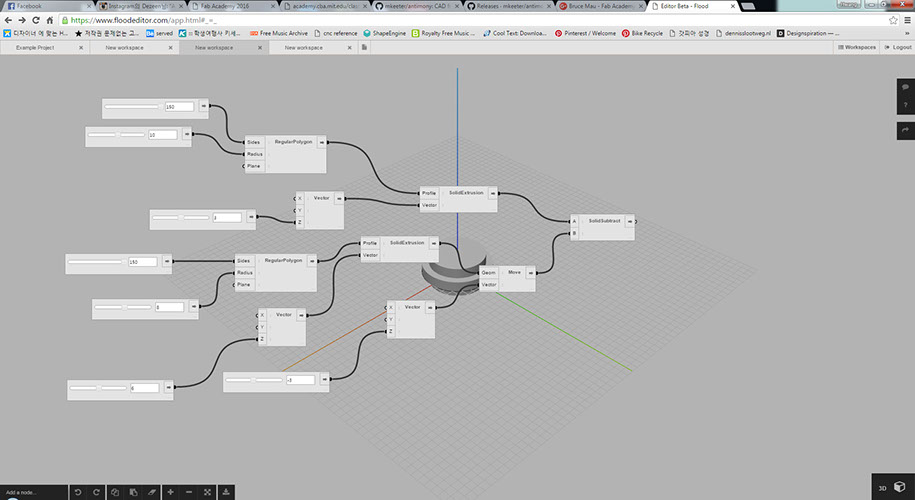

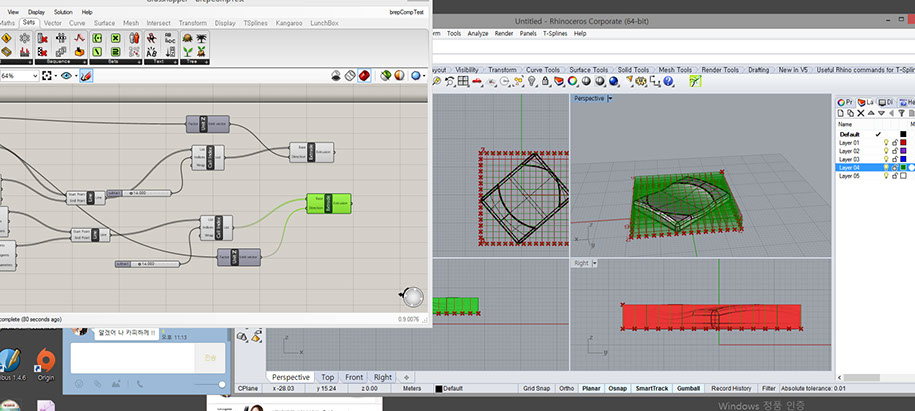

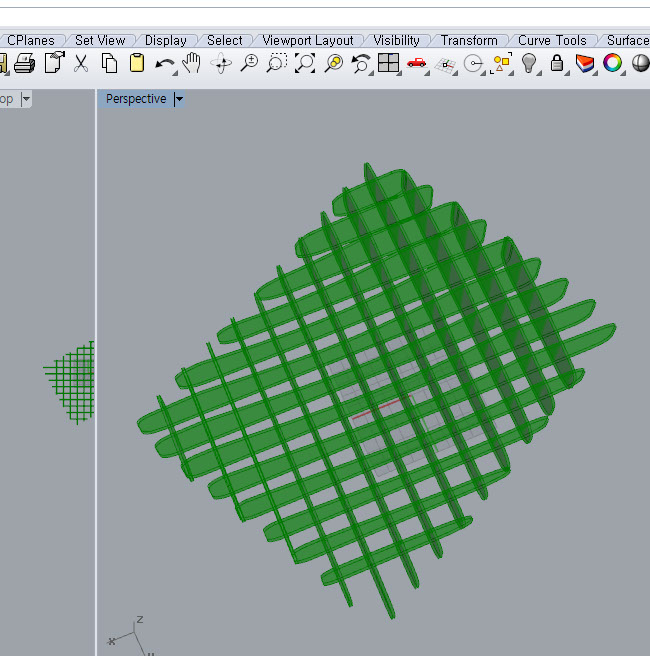

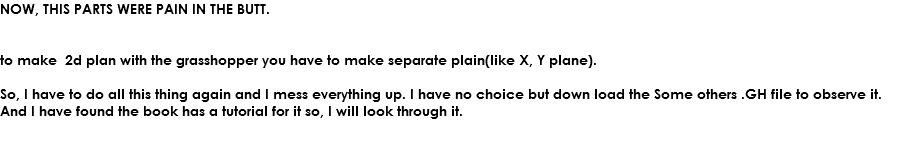

Grasshopper file _ 1 / 2

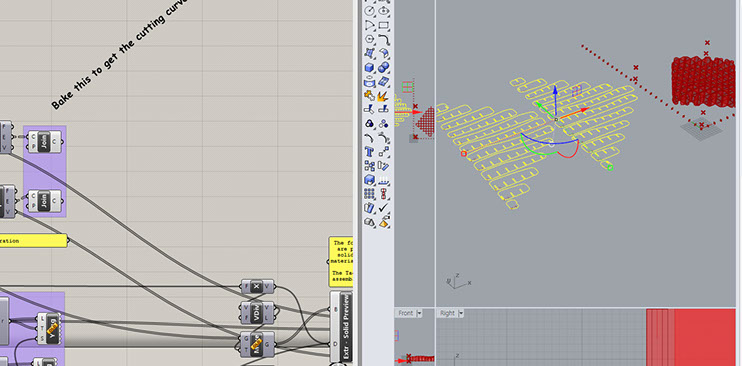

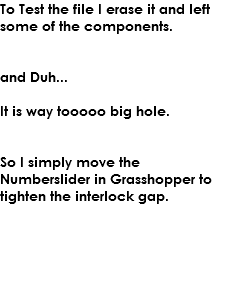

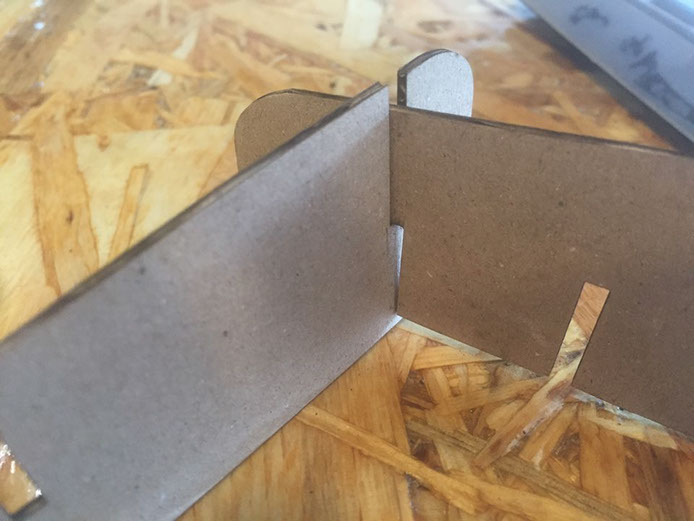

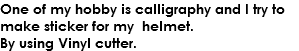

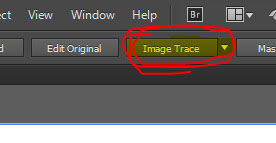

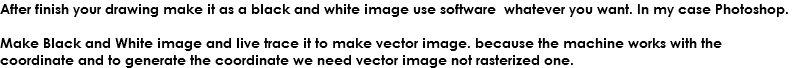

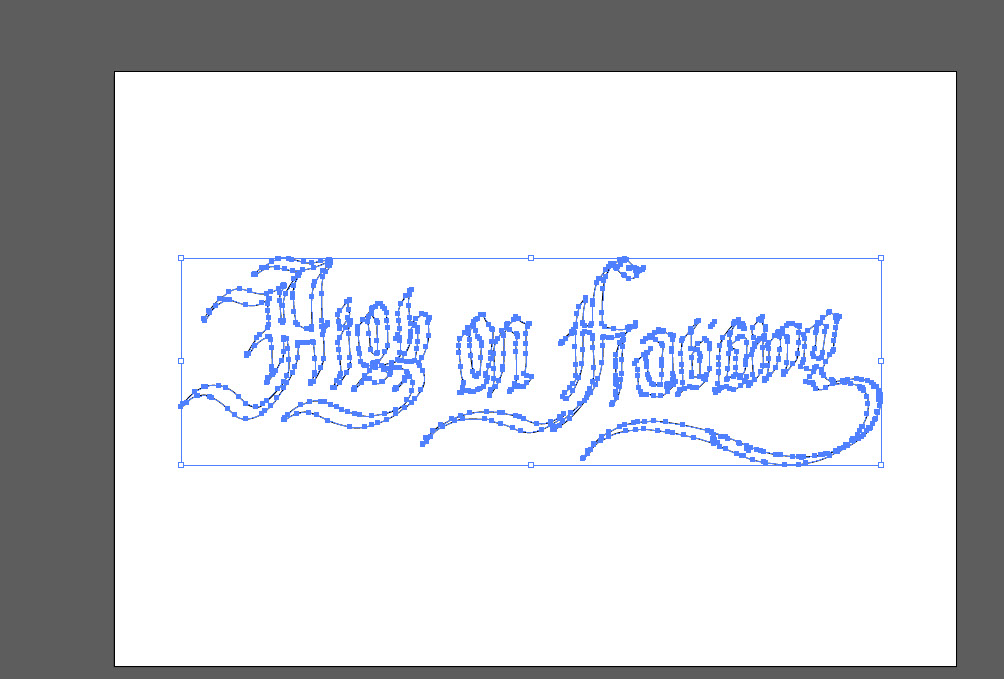

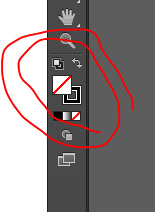

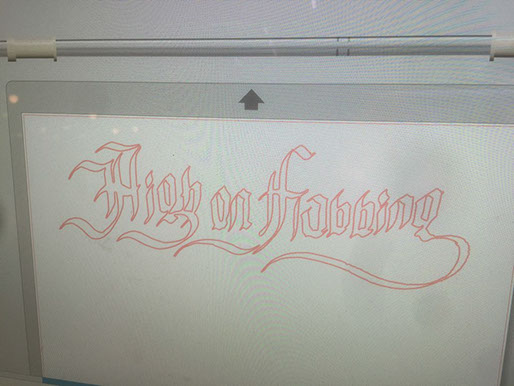

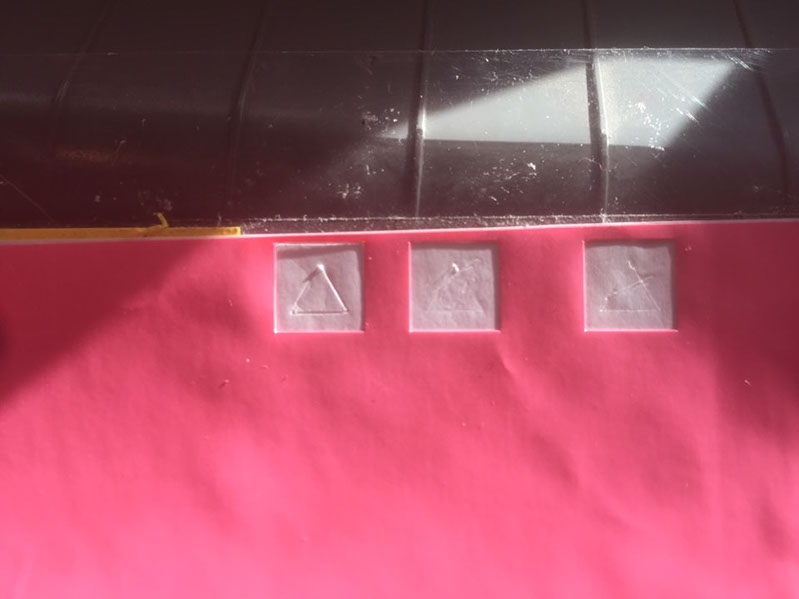

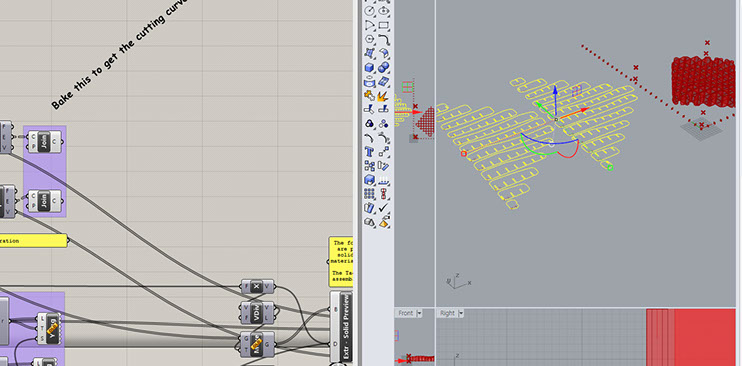

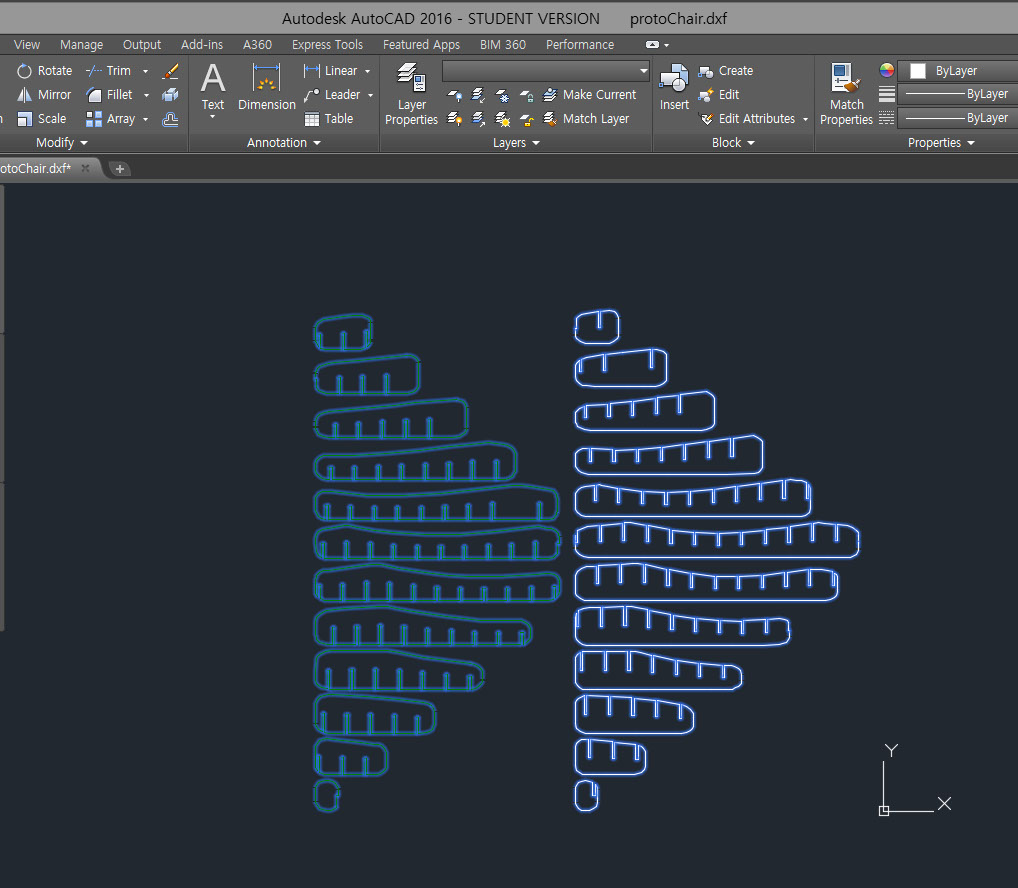

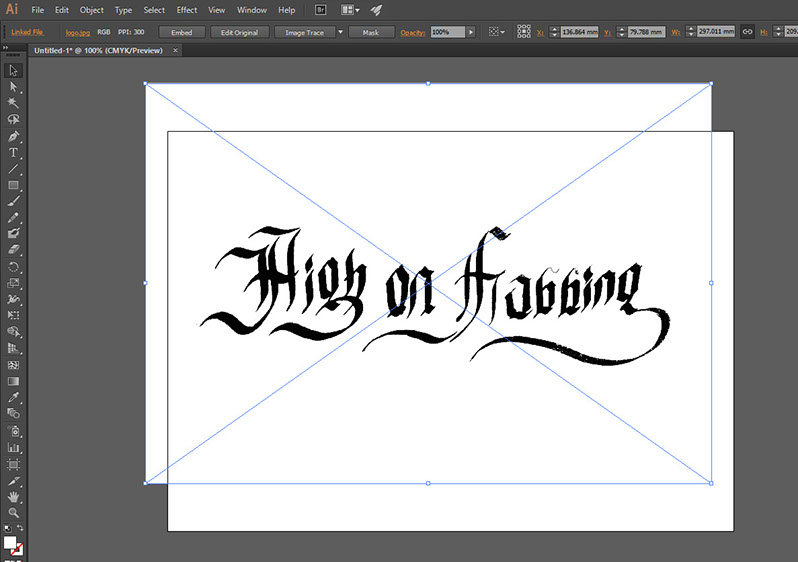

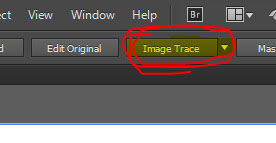

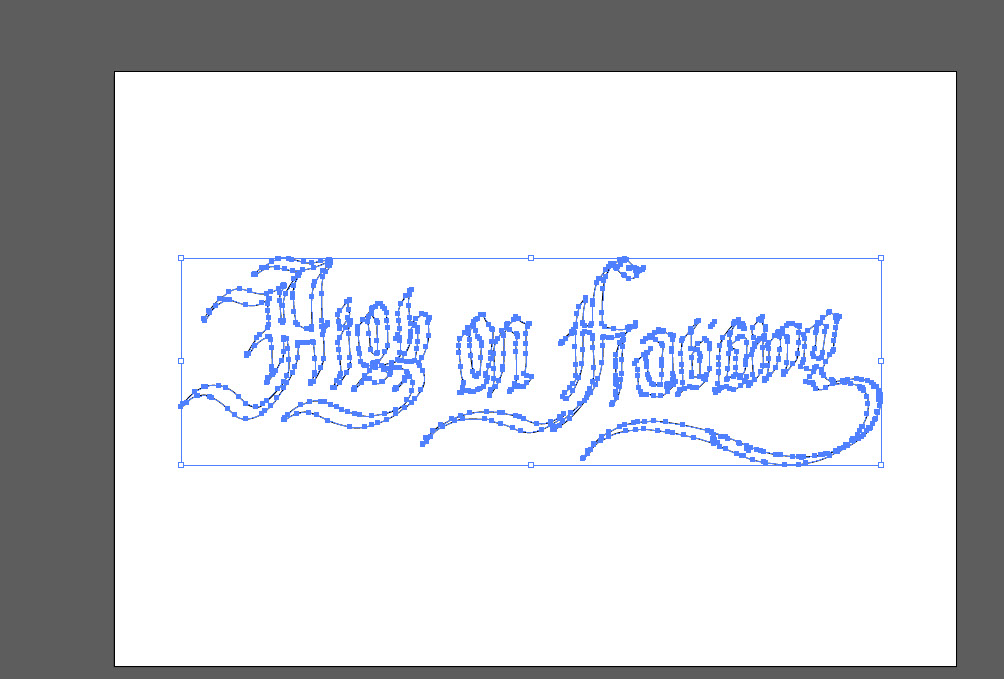

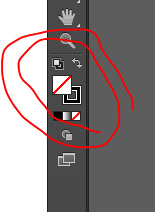

2d cutting file _ Laser Pattern / vinyl cutter

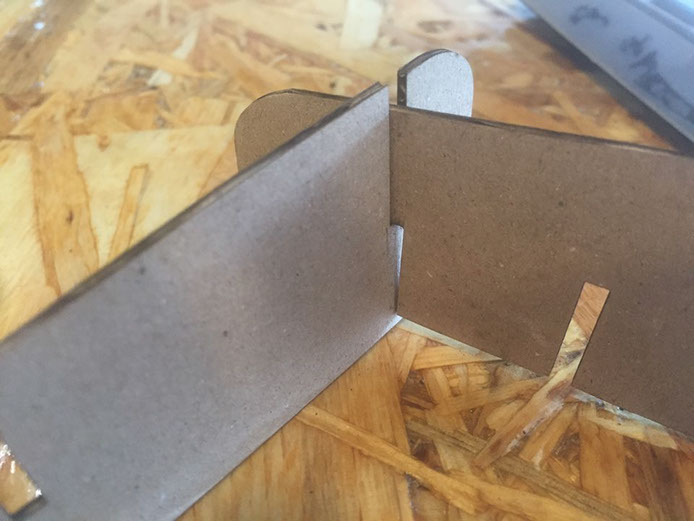

Here is my file

3d modeling _ chair / wheel

Grasshopper file _ 1 / 2

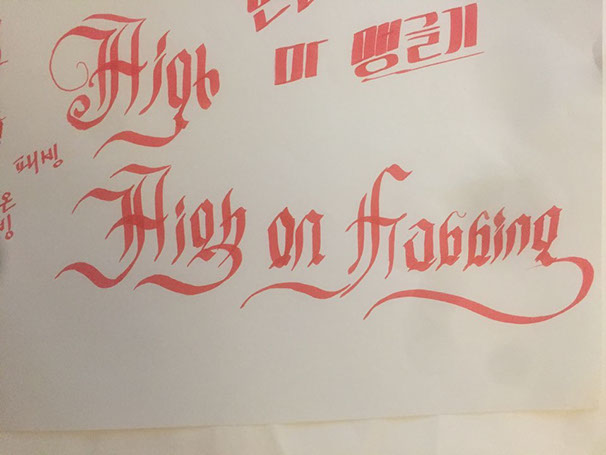

2d cutting file _ Laser Pattern / vinyl cutter