Desinging something big

I had plenty of ideas for something big but I also wanted to make something usefull or fun. several things came to mind like a japanese Tool box, knife stand also a storrage/display box like this for my Whaleknife.

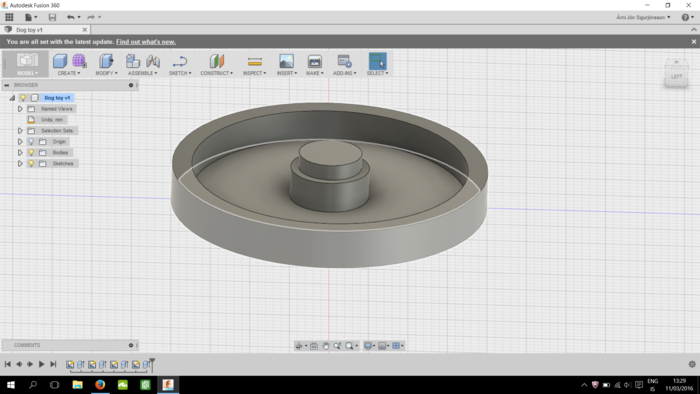

I decided on a puzzle toy for my dog. Its design is fairly simple based on a toy like this

link

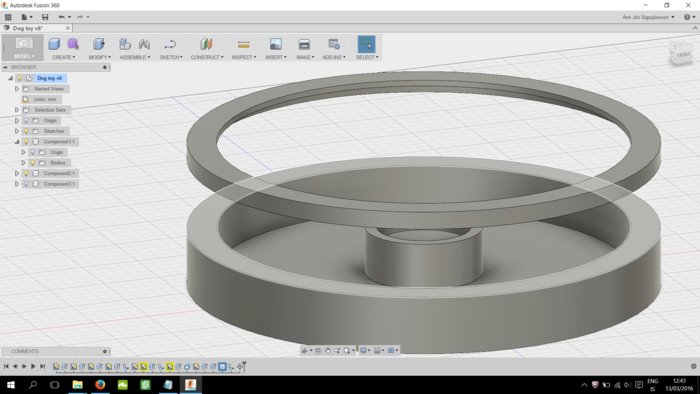

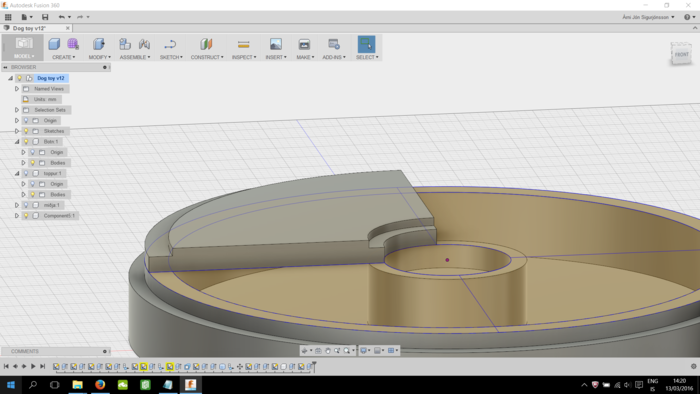

This toy consists of a rotating lid that covers a bowl with treats. Mine will have 3 covers and four bowls also the whole thing can be disassembeld for cleaning the bowls are also removable for a larger treat.

I then set on making it in Fusion 360.

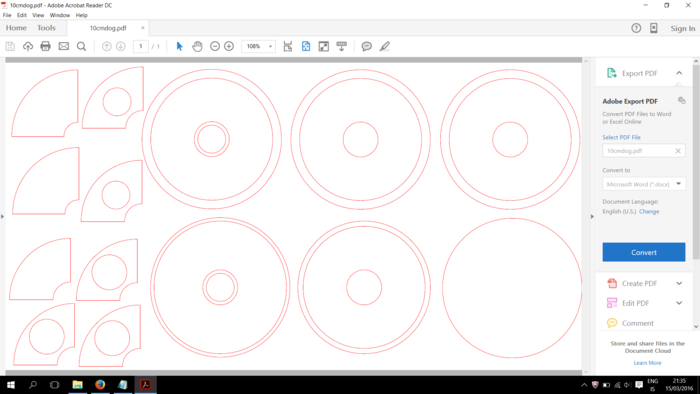

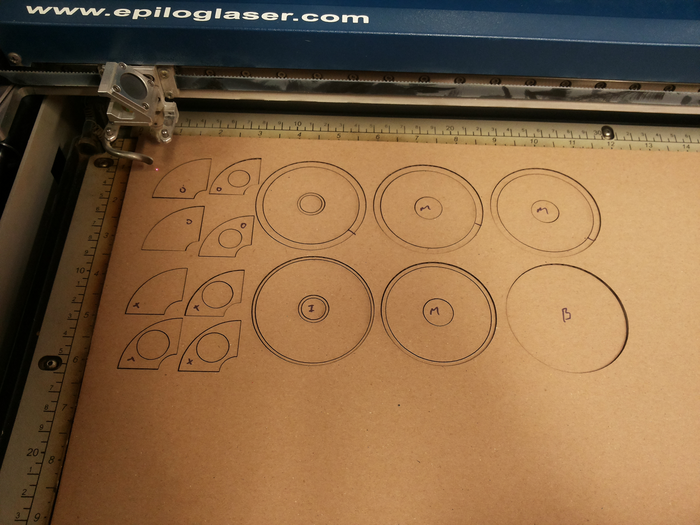

had to make a laser cut version of it to see how it would function so i had to export it as a pdf but sinc fusion does not really have that option unless

you pay for a addon i had to put each part in the desing part to get a line drawing then move it over in inkscape to vectorise it for the lasercutter

again with the lasercutting i enterd 0.2mm instead of 0.02mm a number i must commit to memmory since its my main misstake with the lasercutter.

once cut I marked it so i knew wich part went where then it got assembeld. I will later cut the full size version of the toy.

Making this didnt go as i intedned becouse i thought at first that i would be able to use a T milling bit to get to the sides and make the base of this onc solid pice

but instead i had to desgin it with the top lip coming off as well as the middle plice wich was suposed to be the only thing to remove to put the lids in and under the lip

Fusion and inkscape testfit files

I imported the parts as drawings from fusion as drawings and then cut them out in the lasercuter .svg PDF PDF Fusion

The Box for the nerf turret

I initialy inteded on making the dog puzzle then i changed by mind and wanted to make adiffrent type of dog puzzle and a trebuchet but due to not having the propper tooling and me wanting to make it with a diffrent sock, also not being good with the programms plus

me not managing my time better those were nerver made. But now i made a carry case for my final project, Just a siple box that split in half to carry the gun at its base.

it was sketched up in Inkscape and what not then moved over to Vcarve to set it up for cutting , tho first it had to be prototyped in the lasercutter so it had to be scaled down to for 3mm material that was done by scaling it down 44.44% from 12mm wich i forgot to change to 9mm when

I first started putting in the numbers in makercase also makercase has a thing where the inside button just turns grey but does not actually scale to the inside diamiter. so all that was fixed by scale it down by creating a 3 by 3 mm box placing it at a corner and then

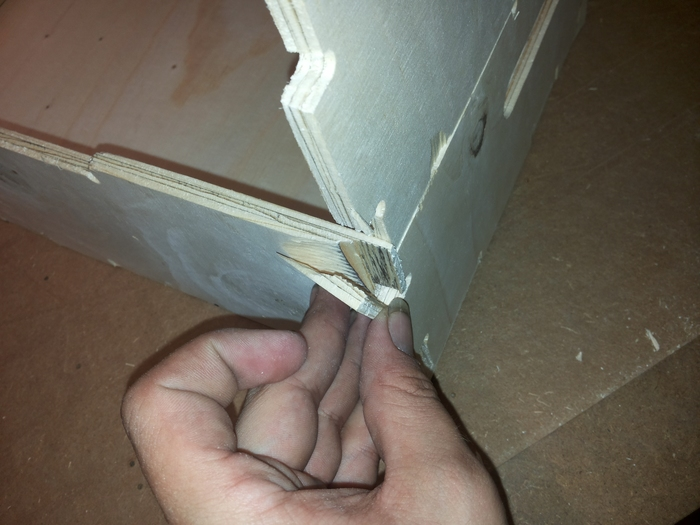

moving the nodes to snap on its edge. Somewhere in that prosess or a error by the programm the pices of the lip did not fully fit togeather and the walls were shorter so that created a gap when

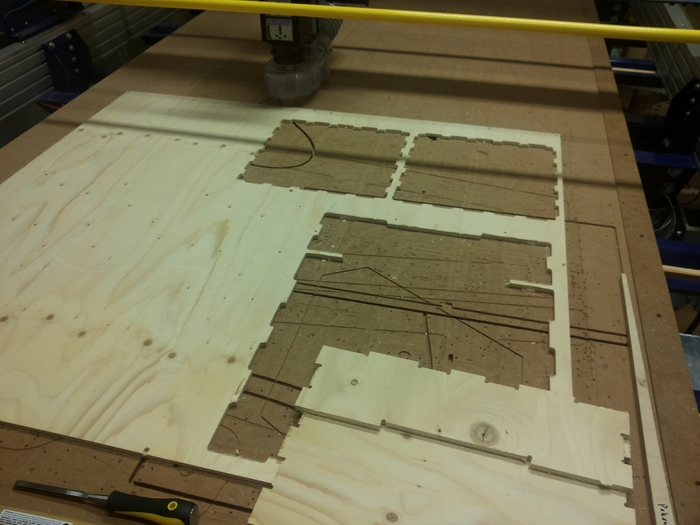

in the lazer cut result.  once we were satisfyed with the file being correct now it was fitted to suit the stock wich was previusly cut leftover stock we cut it with a three quarters of an inch upcut endmill bit and it cut all the way through at 14000 rpm. We had accounted for the hole in the plate and its size but

once we were satisfyed with the file being correct now it was fitted to suit the stock wich was previusly cut leftover stock we cut it with a three quarters of an inch upcut endmill bit and it cut all the way through at 14000 rpm. We had accounted for the hole in the plate and its size but

got one of the mesurements wrong so that resulted in it cutting air when done with the first 2 pices wich ment that we had thought the plate larger that it was so we went to the file put in the new mesurements

and had to remove two pices out wich then due to time being short and it was late were not cut out. but the other pices of it fitted fine with help form the Smashything.

The friendly reminder that the the cut down will be 9.2mm deeper than the actual stock is so it cuts through

Nothing but air

Broke a little

finished

Designfiles

12mmBox.svgCase with footprint for 12mm stock NERFcase2.crv Vcarve for 9mm plywood NerfCase2.pdf for 3mm lasercut NerfCase2.svg all with footprint