Project:

Initial idea:

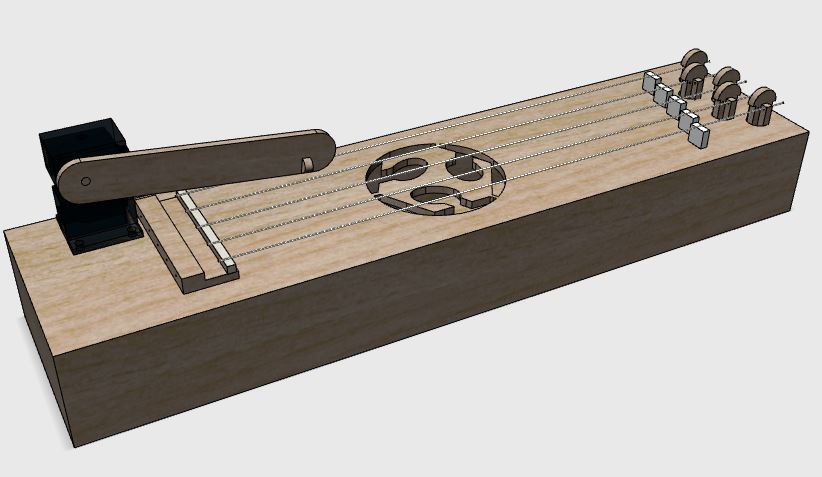

Plan C: Actually I am building an automatic Kantele, sort

of. Kantele is the national instrument of Finland. My 5-string

Kantele is automatically plucked with a mechanism built using

two servos. One servo plucks the strings and the other lifts the

pick so that strings can be skipped. A microcontroller controls

the servos according to the song to play. The default song is this.

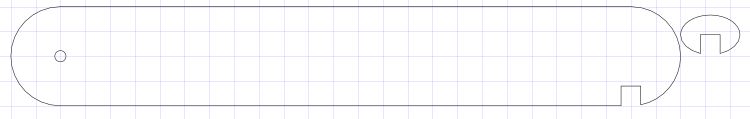

The body of the Kantele is built from laser cut plywood, and the

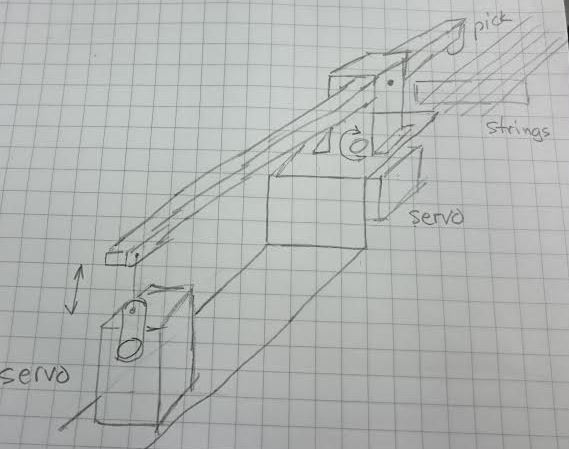

servo mechanism is 3D-printed. Below is a conceptual picture of

the body of the Kantele, with the strings missing.

Plan A: I am planning to build an automatic guitar tuning

machine. One part of the machine automatically plucks the

strings one by one, as the other part rotates the corresponding

tuner guided by the third part measuring the frequency of the

vibrating string. The construction of the machine requires

custom made 3D-printed and laser cut mechanics driven with step

motors. Pictures will follow...

Plan B: On the other hand, I also need a guitar to tune, so

maybe I'll build an electric guitar. The body, neck and

fretboard of the guitar are shaped with a 3d CNC wood router.

The microphones are wound using Juha-Pekka's Guitar

pickup coil winding machine. Laser cutter will be used for

cutting the various parts needed, such as the pickguard.

The 3D printer will be used for fabricating the accessories, if

possible.

Fabrication process:

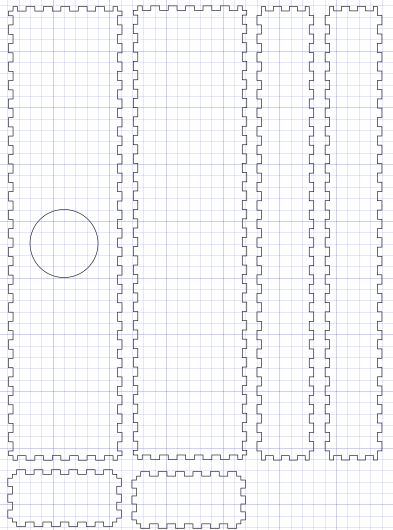

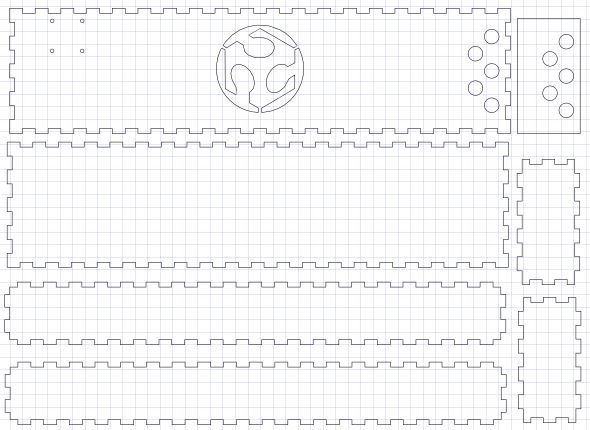

The sound box is made of 4 mm birch plywood laser cut with

tabs to fit the parts together. I designed the sound box with

Inkscape extension KM Laser Tabbed

Box Maker. The parts are glued with Titebond Original wood

glue. The holes for the tuners are reinforced and made longer

with a piece of 4 mm birch plywood with identical holes glued

inside the sound board, i.e. the top of the sound box. The sound

hole is a Fab Lab logo, naturally.

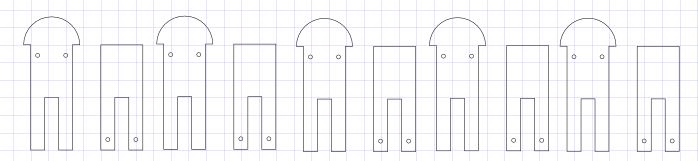

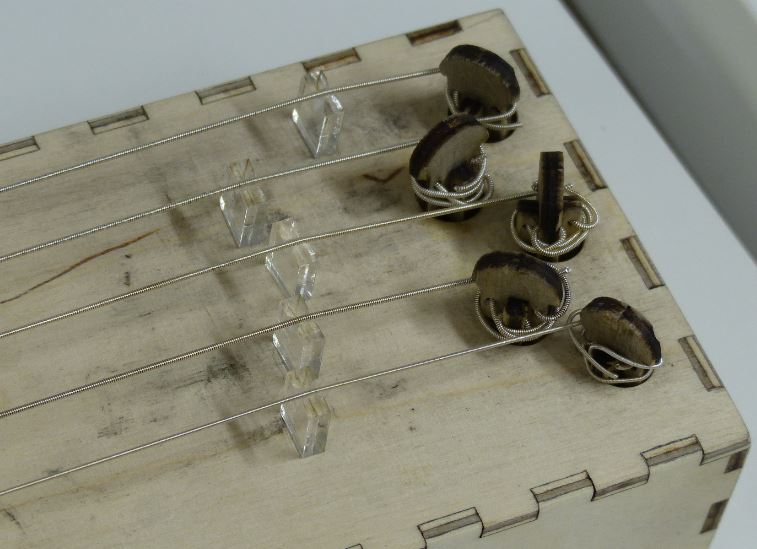

The tuners are also made of 4 mm birch plywood, designed with

Inkscape and laser cut. The two pieces form a tuning peg. The

tuners alone aren't really precise enough to actually tune the

instrument by adjusting the tension, and they are too small to

twist for the turning force needed. Therefore there are movable

nuts, which then determine the tuning of each string by changing

the length of the string. The nuts were laser cut from clear 4mm

acrylic.

The bridge is laser cut from 4 mm birch plywood, and glued from

two pieces. The pieces have laser cut grooves for the strings.

When the pieces are glued together, the grooves form holes

through the bridge, but I had to clear the holes with a small

drill bit. The strings are tied the same way as in a classical

guitar. There is also a laser cut groove to hold the saddle

laser cut from clear 4 mm acrylic.

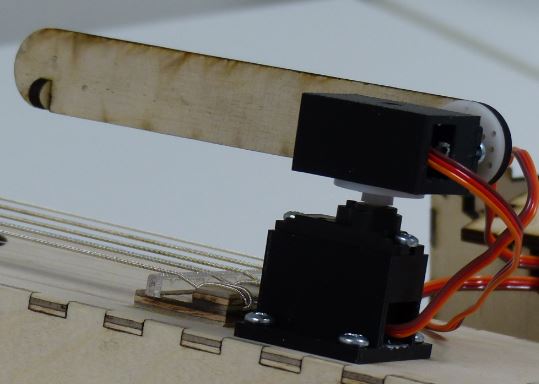

The servos have 3D-printed housing. The housing of the lower

servo, the one moving the arm above the desired string, is

attached to the top of the instrument with screws. The housing of the upper

servo is attached to the axis of the lower servo with a screw

going through the housing of the upper servo. The upper Servo

holder has connecting pins to attach it to the plate that came

with the servo. The original sketch for connecting the servos

was much too complicated and flimsy.

The arm playing the strings is laser cut from 4 mm birch

plywood. The upper servo moves the arm up and down so that the

strings are played by tapping them, instead of picking, like one

would normally do when playing an ordinary Kantele. I tried the

picking method, but soon realised, that I probably don't have

enough time to make it work by finding the correct flexibility

for the pick and arm. However, I am pleased with the current

sound of the instrument, so I'll stick with the tapping method.

It looks something like this when everything is put together. I

found a 3D model for the servo from here: http://www.123dapp.com/123D_Design/Servo-Radio-Shack-2730765/3195924#

Control electronics:

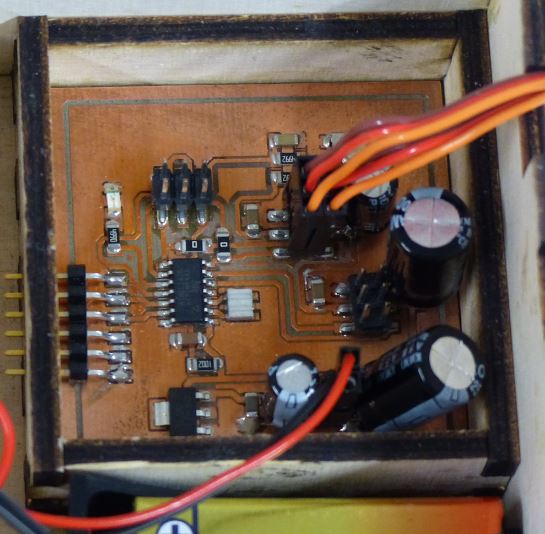

The control electronics uses the PCB made for the output devices week. I connected

all four outputs labelled PWM to 3-pin connectors to be on the

safe side. I ended up using the outputs related to the

Timer/Counter1 of ATtiny44A. Neil's

example code for hardware pwm was a perfect starting

point. I needed two hardware PWM outputs for Timer/Counter1,

i.e. outputs PA5 and PA6. Neil's example code had only one PWM

output, but a modification to TCCR1A solved the problem, with

the help from Jani of course! The complete datasheet for the

ATtinys is a handful, and finding and understanding what one

needs can really be a lot of work:

TCCR1A = (1 << COM1A1) | ((1 << COM1B1)); // clear

OC1A and OC1B on compare match, | ((1 << COM1B1) was added here

Otherwise I just had to adjust the correct

values for OCR1A and OCR1B registers to move the arm on

correct string and to tap the string to play the instrument.

The current version can play two songs: "Vaka Vanha Wδinδmφinen

(Steady old Wainamoinen)" is an old Finnish folk song from the

Kalevala, the national epic of Finland, traditionally played on

Kantele. The other song I composed myself, sort of. One can

change the song by pressing the SONG button before the song

begins and hold the button until the song begins. The state of

the button is polled before playing a song.

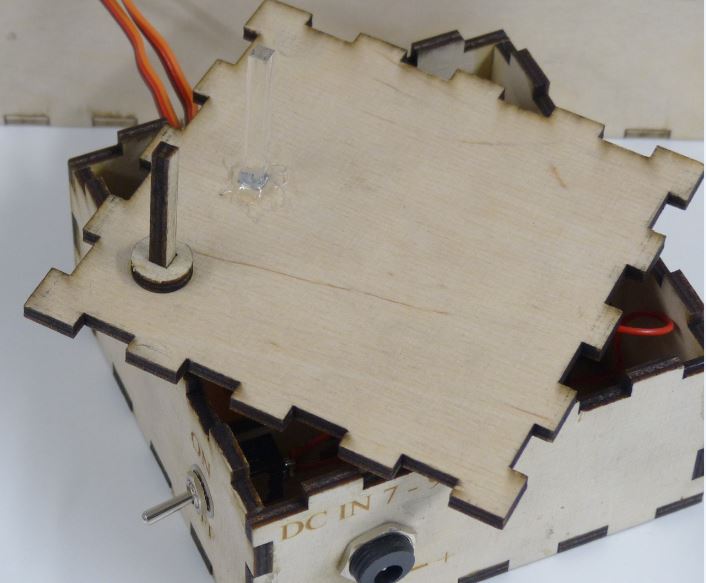

The electronics is installed in a laser cut 4 mm birch plywood

box. As the LED and push button are in the PCB in the bottom of

the box, a light conductor made of clear 4 mm acrylic brings the

light to the top of the box. The light conductor is hot glued to

the top of the electronics box. The push button is reached with

an extension arm made of 4 mm plywood. The 4 by 4 mm stick is

glued with the other round plate to make the button. The other

plate is glued to the inside of the top of the electronics box

to guide the extension arm on top of the push button. The LED

blinks in time with the song. The PCB is installed in a frame

made of 4 mm plywood.

The power comes either from a 9 V battery or from an external

7.5 - 9 V DC power supply. When then plug of the external power

is connected the 9 V battery is disconnected by the power jack.

Final Instrument:

I installed old classical guitar strings which I cut in

half. I use two low E strings and one A string. Having strings

with the same width works, because the tuning is in d minor

(defga), so that the differences between the frequencies is

small. I tuned the strings and started testing.

Testing:

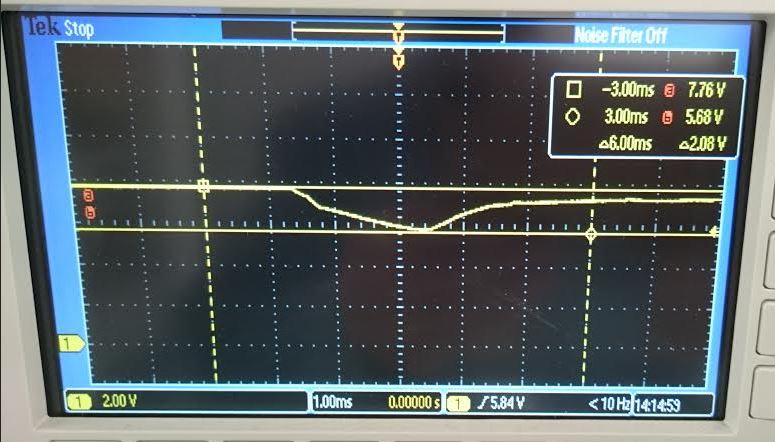

The initial tests with the servos showed occasional erratic

movements. I suspected the reason to be too small power supply

bypass capacitors. So, I installed 100 uF capacitors on both

sides of the voltage regulator. The erratic movements almost

disappeared. Now that it almost now worked, I decided to measure

the voltages. In the worst case the regulator input voltage

drops from 7.5 V to 5.7 V, and the 5 V output drops to 2.9 V.

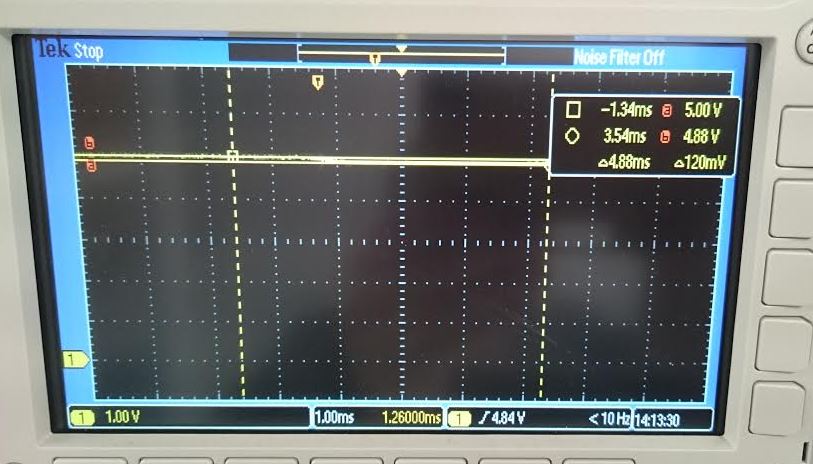

I added more

capacitance, this time 1000 uF on both sides of the

regulator. Now the input drops to 6.7 V and output to 3.9 V.

Even more capacitance is needed, but this seems to work now.

Update: I added 2 x 1000 uF and 220 uF to the +5 V power

rail. Now the +5 V voltage drops to 4.88 V with 3320 uF

capacitance. Problem solved.

Regulator voltage drop with 100 uF capacitors:

Regulator voltage drop with

1100 uF capacitors:

Making of the Video:

The servos are rather loud. So, for the video I made a

cardboard box to hold a microphone under the instrument to catch

more the actual sound of the instrument, but not the sound of

the servos.

I recorded the video in Full HD with my compact camera,

compressed the video bitrate to 1500 kbps with Handbrake, which

also added the subtitles I made in SRT-format. Then to make

sure, that the video is playable in browsers, I used avconv with

the following parameters

provided by Neil:

HTML5 MP4 encoding

variable bit rate 1080p MP3:

avconv -i input_video -vcodec libx264 -crf 25

-preset medium -vf scale=-1:1080 -acodec libmp3lame -q:a 4 -ar

48000 -ac 2 output_video.mp4

Problems and solutions:

- It took a while to understand that the initial servo mechanism

was too complicated and flimsy. Bolting the servos together in

90 degree angle is simple and solid.

- I had many complex ideas for the tuners, most of them

borrowing from guitars, but a simple tuning peg in a hole does

the trick, with movable nut of course.

- The initial idea was to pick the strings sidewards, but it

turned out to be too time consuming to succeed. I happened to

tap the strings with a pencil and got a decent sound, which was

even better when done with a servo.

- The behavior of the servos was erratic in the first tests. A

lot of capacitance had to be added to keep the power supply

stable.

- The servos are too loud, probably because of the internal

gears. However, now that I know, that I can get a decent sound

by tapping the strings, why not replace the servos with

solenoids, one for each string. The vertical movement is easy

the accomplish with a simple solenoid. The solenoids can even be

made inhouse with Juha's

Guitar pickup coil winding machine.

Bill of materials:

-

0.15 m2 4 mm birch plywood, 12 /m² = 1,8

- Titebond Original glue < 1

- recycled classical guitar strings 0

- 3D printed parts 100 cm3 PLA ~ 3

- HobbyKing servo HK939MG 5 * 2 = 10

- recycled 7.2 - 7.4 V battery 0

- microcontroller board:

- ATtiny44A 1.3

- 20 MHz resonator 0.53

- 5 V regulator 0,92

- 51 * 51 mm PCB 1,3 (127.0mm x 76.2mm

4,93 )

- resistors, capacitors, connectors, switch 2

- total ~ 20

Source files:

Initial design:

Kantele 123D Design

Kantele Inkscape

Final product:

Kantele Box

Tuners

Nuts

Bridge

Saddle

Lower Servo

Holder

Upper

Servo Holder

Pick arm

Electronics box

PCB box

LED Light Guide

Push Button Extension

PCB eagle

schema

PCB eagle

layout

PCB_traces

PCB_outline

Presentation

video

Presentation

slide

Home

-

This work is licensed under a Creative

Commons Attribution-NonCommercial-ShareAlike 4.0 International

License.