ELECTRONICS PRODUCTION

ELECTRONICS PRODUCTION

For this week the assignment was PCB fabrication.

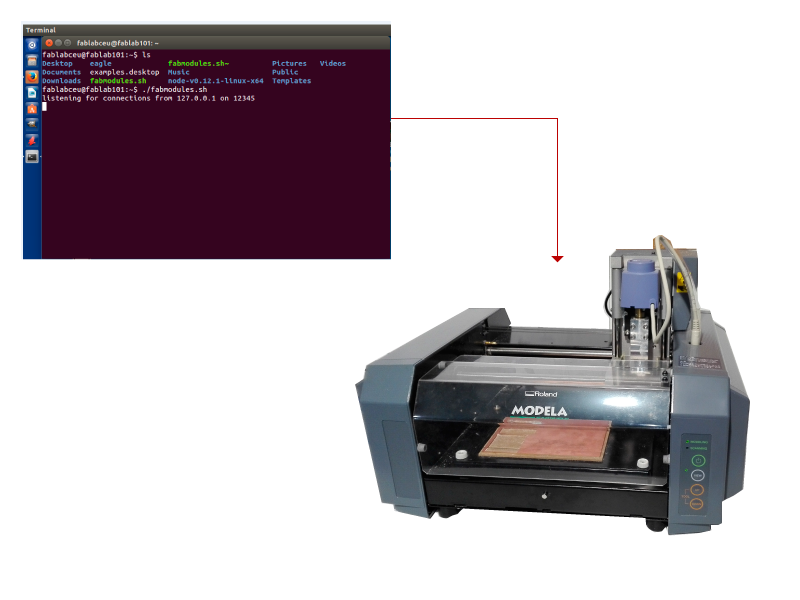

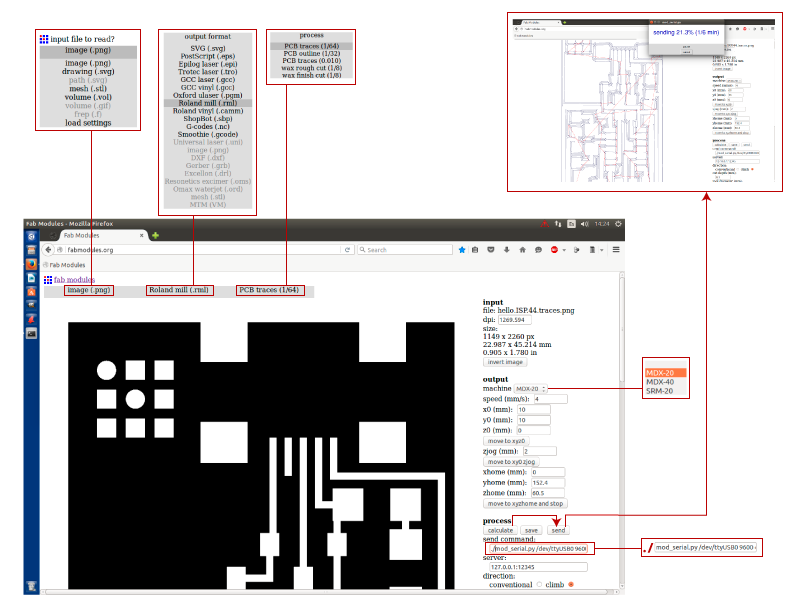

First of all I connected the computer with fabmodules.org opening a terminal.

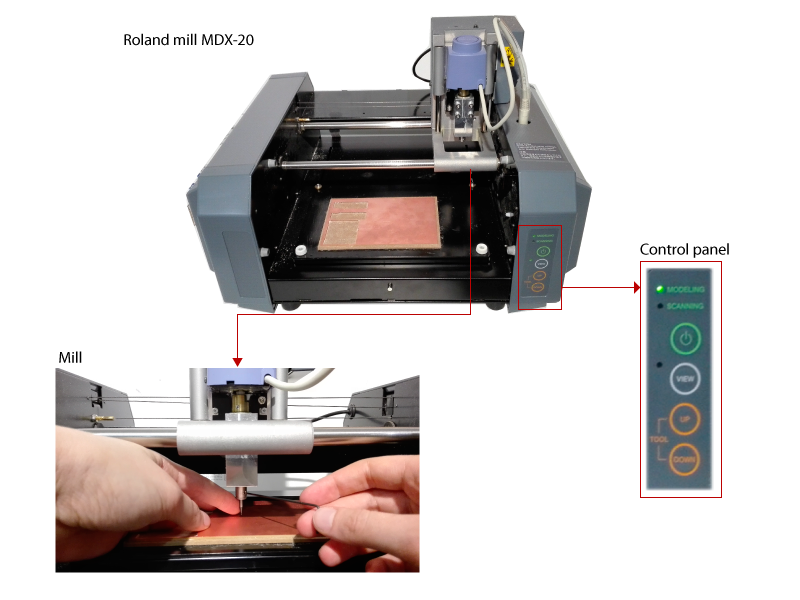

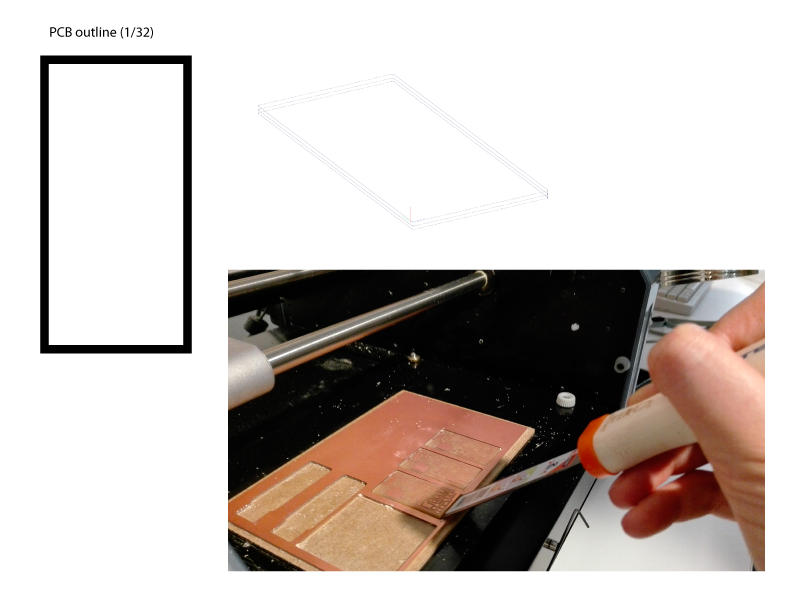

I used a Modela Roland Mill MDX-20, using two kinds of mill, PCB Traces (1/64) (to remove the PCB copper) and the PCB (1/32) (to cut the PCB).

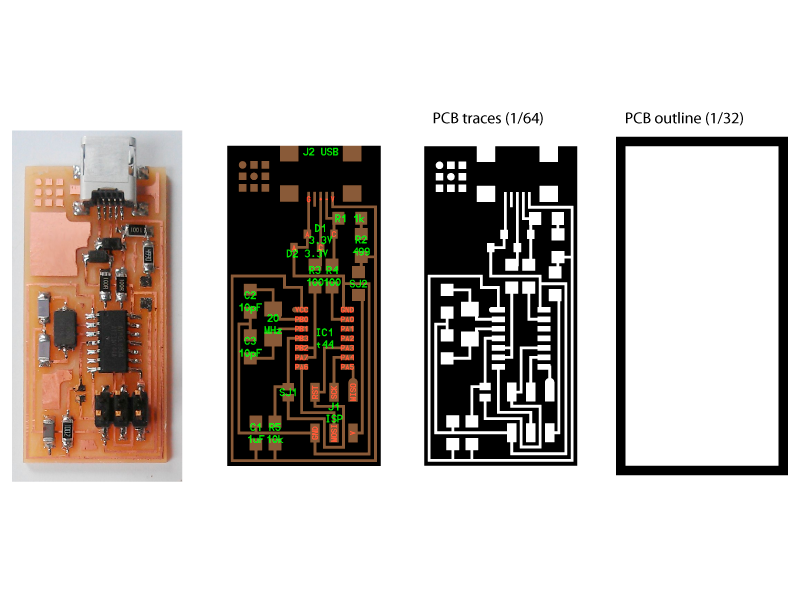

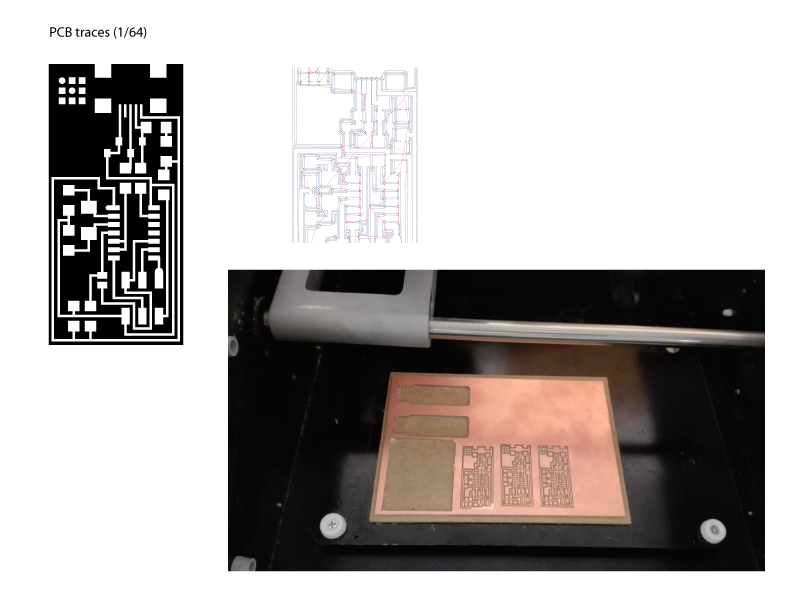

I decided to cut hello.ISP.44, so I used two png images: traces and interior, one to remove just the cooper and the other to cut the PCB.

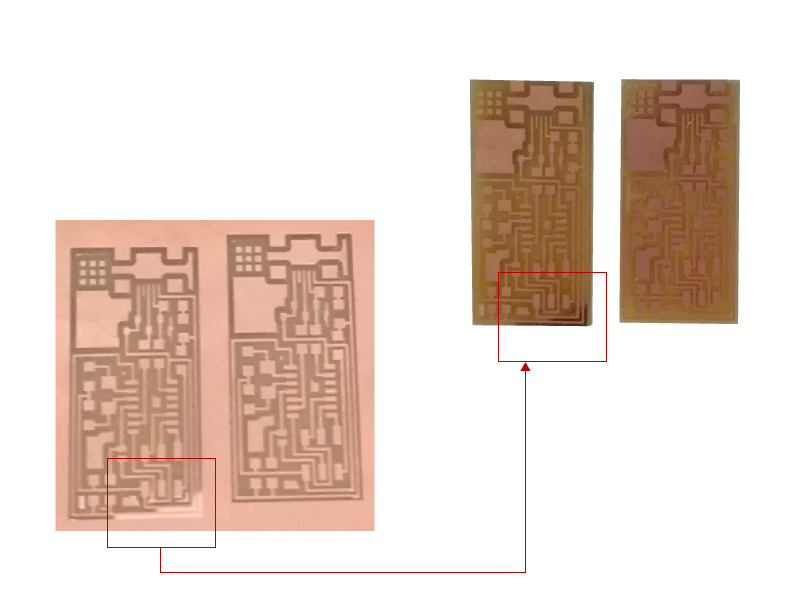

The first time I did the zeroing, I did it in the center but the high was not the same at the edge, so the cooper in the edge was not removed completely, so increased the cutting depth to 0.12, and cut it again but it happened the same, so I decided to make a new zeroing in the edge because it was much higher than the center and it worked just cutting once.

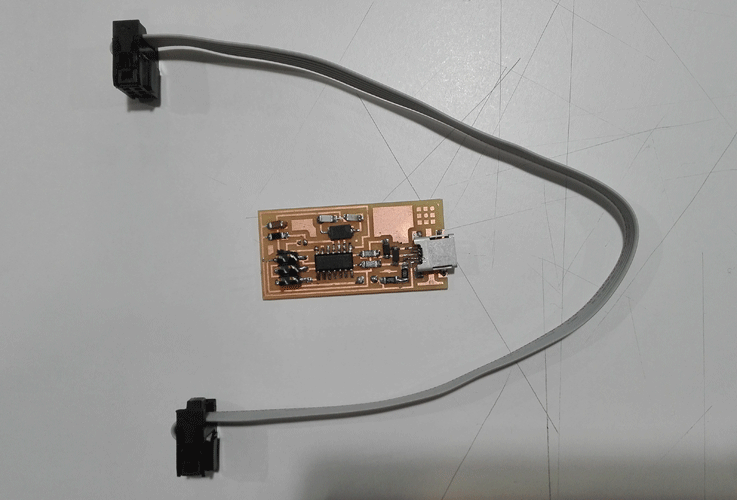

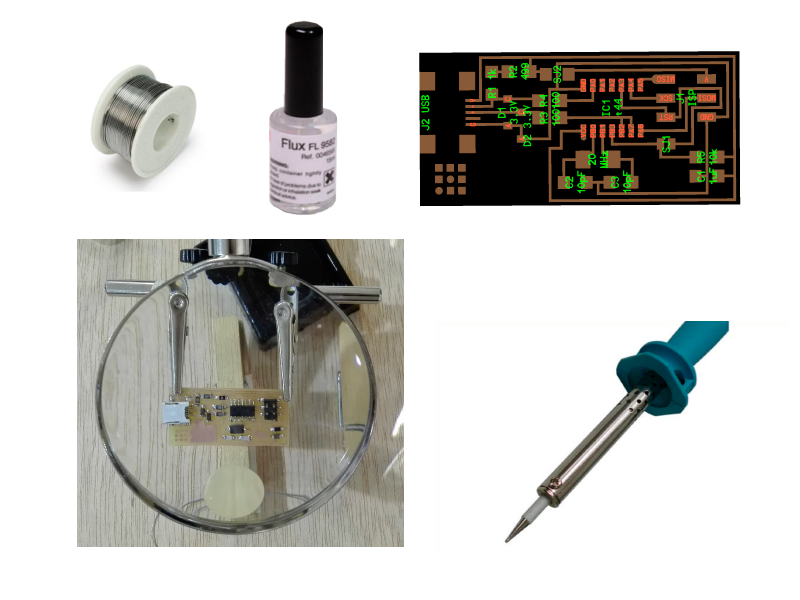

I searched for all the components that I need for the hello.ISP.44 and I soldered them to the PCB using soldering iron, pewter and flux.

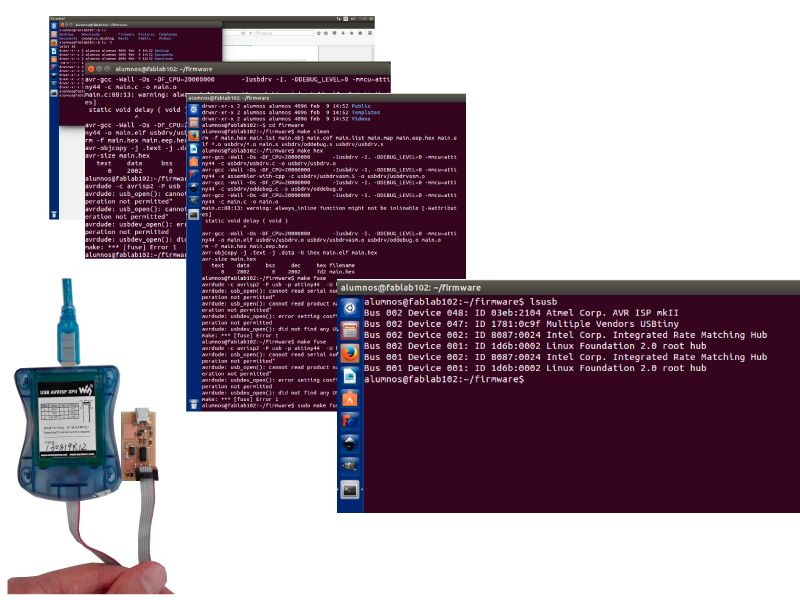

Programing, I opened a terminal and when I “make clean” and “make hex” I didn´t have any problem but when I did “make fuse” and “make program” even doing it using “sudo” I found an error, so I verify that every welding join were fine and I found the welding join error and I fixed it.

Later I desoldered SJ1 and SJ2 and I made the IDC ISP cable