This week’s

assignment was to create an ISP so we can program circuits later in the

class. There was a

few different versions

on the lecture page I went with Zaerc

because

I liked the features of it. The

target

power led and the data led are nice to see if the programing is doing

its

job. The other main

reason I choose this

design was the very nice and helpful website that steps you thru the

whole project. There

was only two big issues this week the first

was when Karen and I tried to cut a board it cut out but some of the

traces

were gone. After

reading all of the

milling documentation on the website we learned you had to change the

tool size

to a smaller diameter to have the software calculate some of the paths. The other problem was when

I tried to use the

programmer it would not send the code.

After some troubleshooting and use of an oscilloscope I

saw the data

being sent but then stopping so I decided to try and reset the fuses

from the

last step. This

work and the programmer is

fully functional

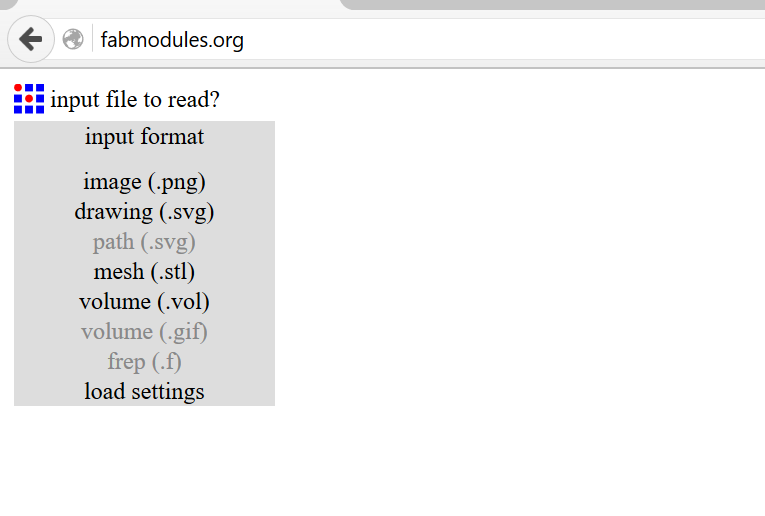

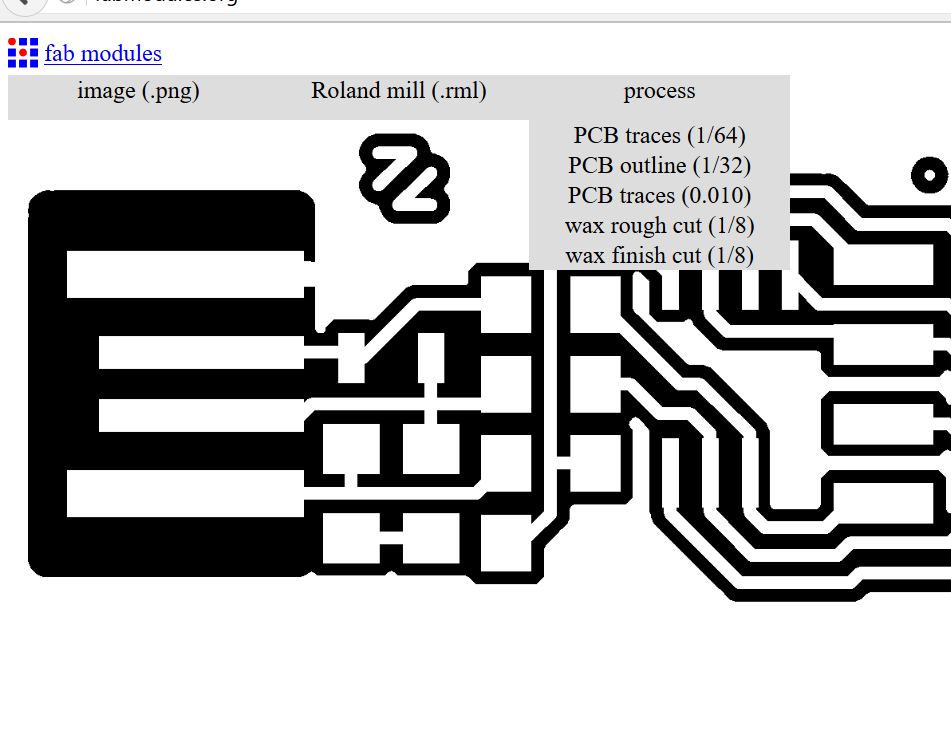

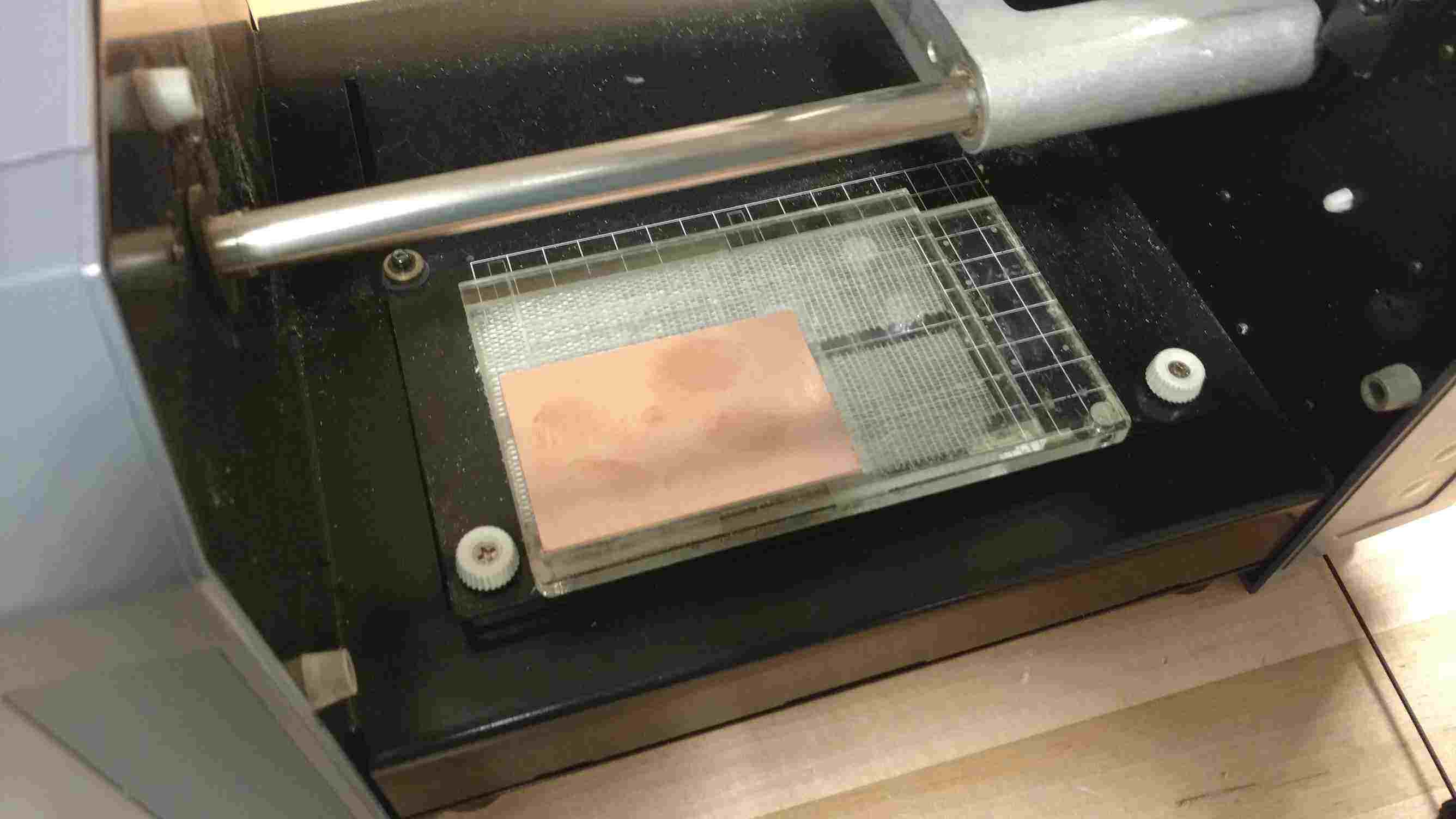

The first step to using the fab modules is to load the settings for the local lab for communication and other settings.

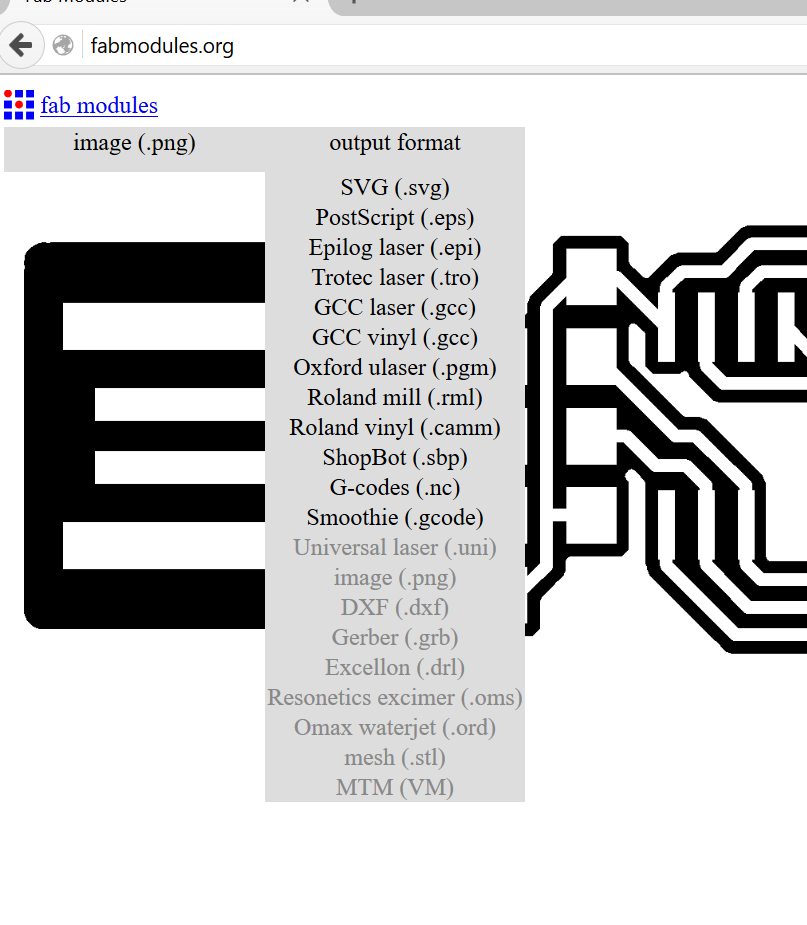

After the setting are loaded you need to select an input file format and in this case it is a .png. The png that you load first is the top traces. After the file is loaded you need to select an output format in this case it was the roland mill.

After the Roland mill was selected you need to choose the process and since it is the top of the board you need to select PCB traces (1/64).

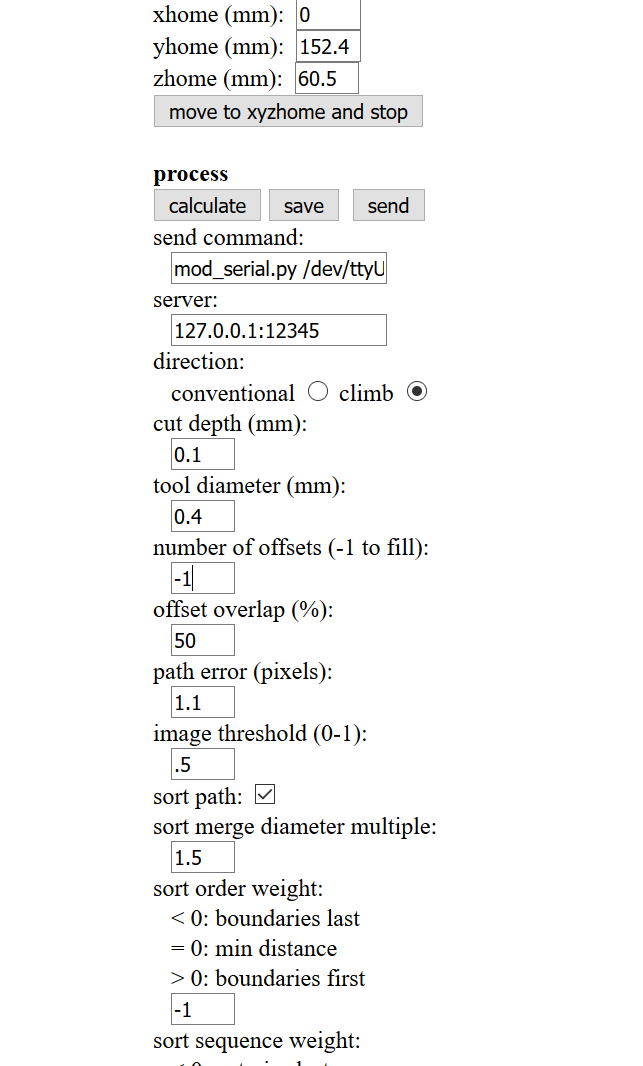

Once the file

and the process has been selected there are a

few settings you need to change the one main one is the number of

offsets. The number

of offsets this determines how

many times the bit routes out around the trace by using -1 it will

remove all

the copper that is not needed.

After the

setting are enter you can click the calculate

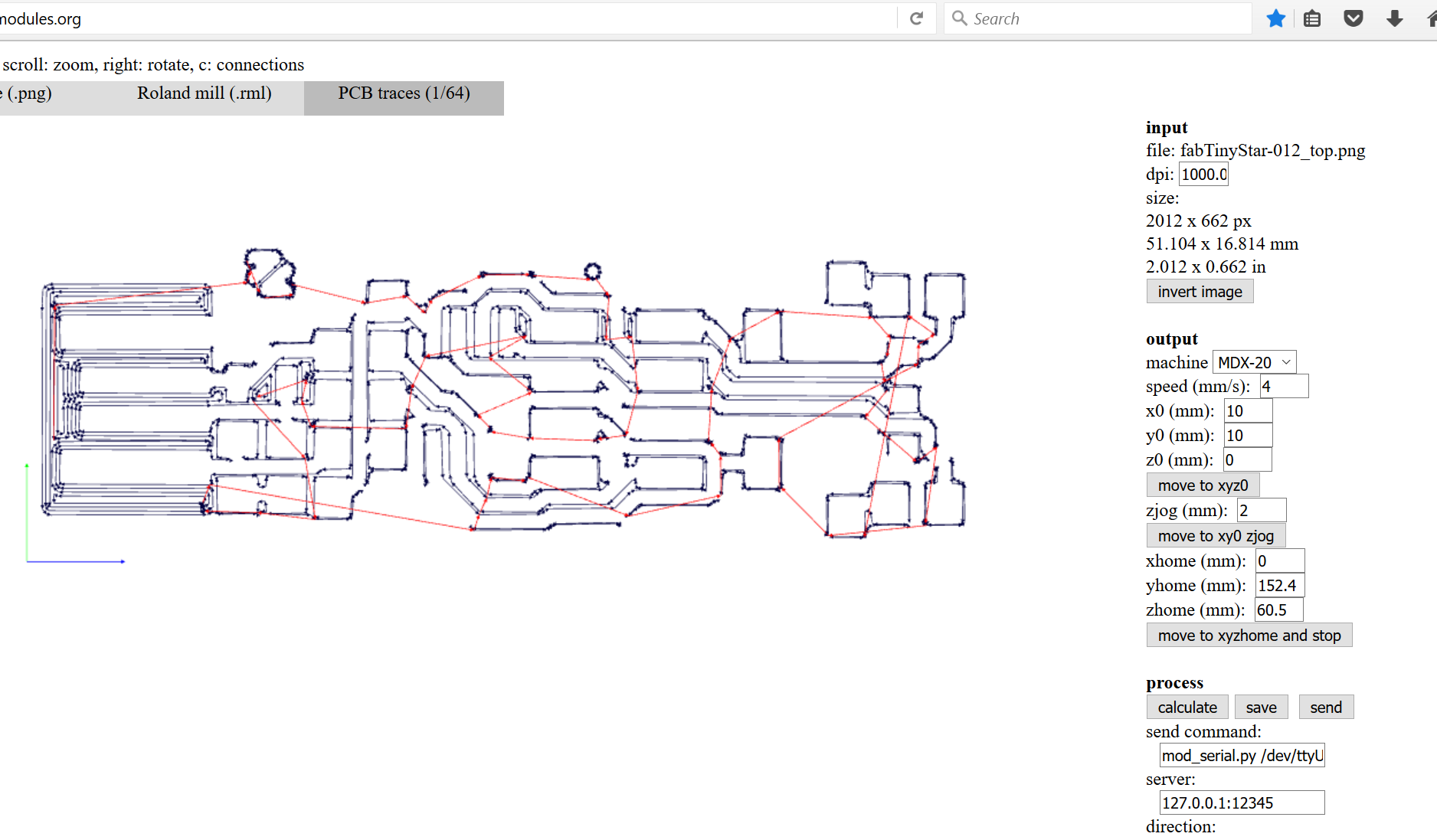

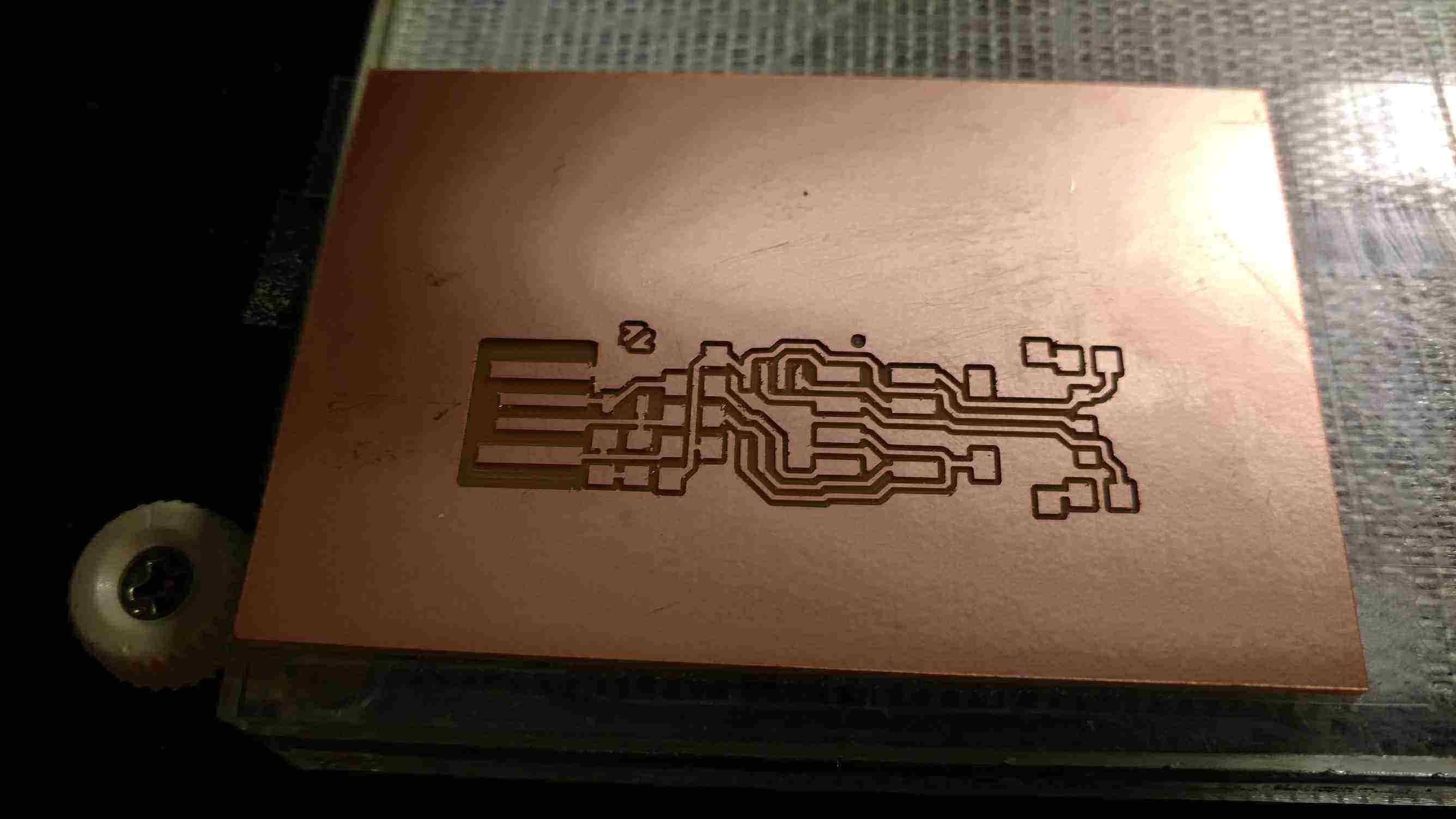

button and it will generate the tool path.

You need to check to make sure that all the traces have

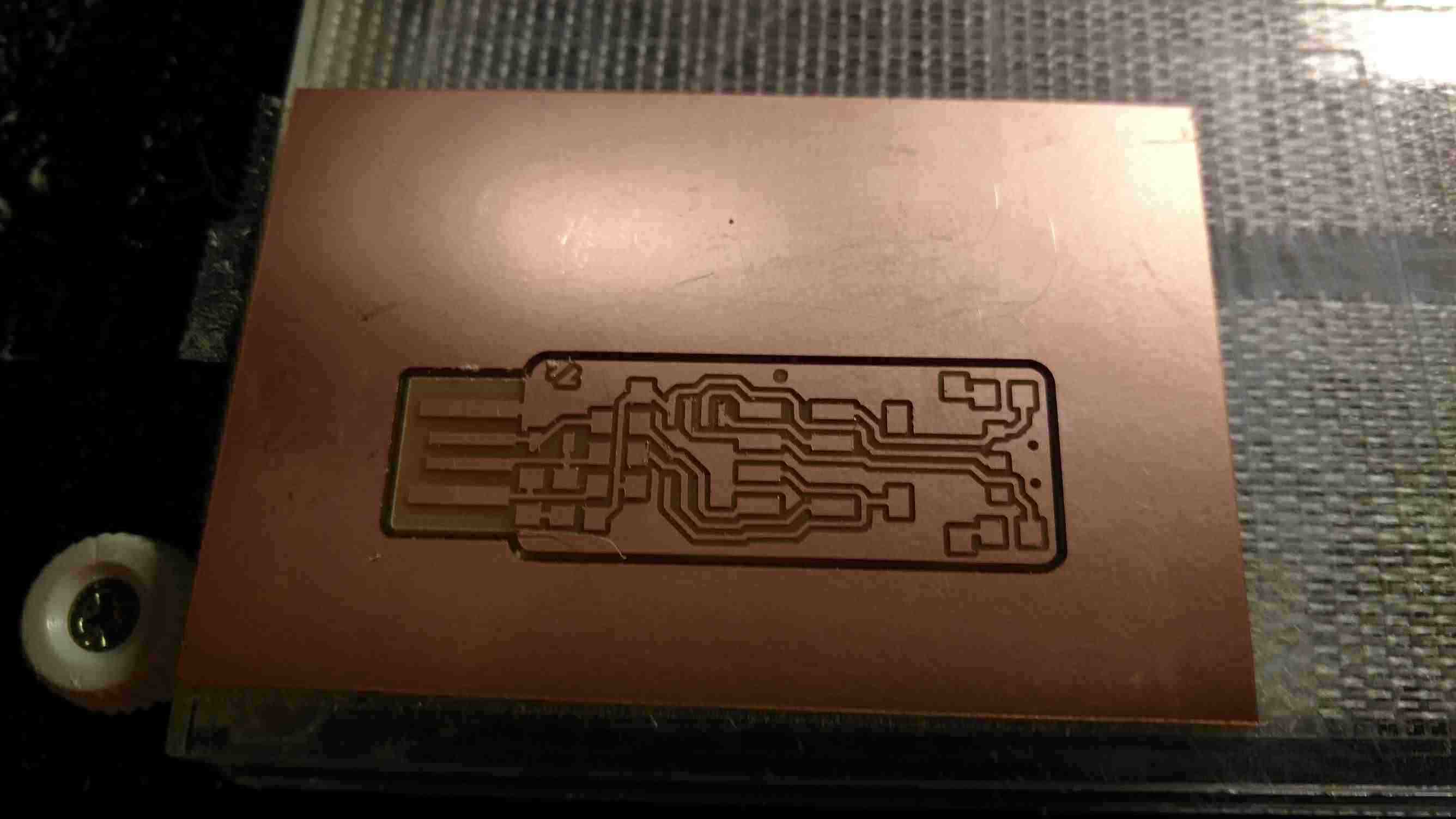

come out. The below

picture show that the default

setting for the tool width does not work so I had to change it to .35

from

.4mm.

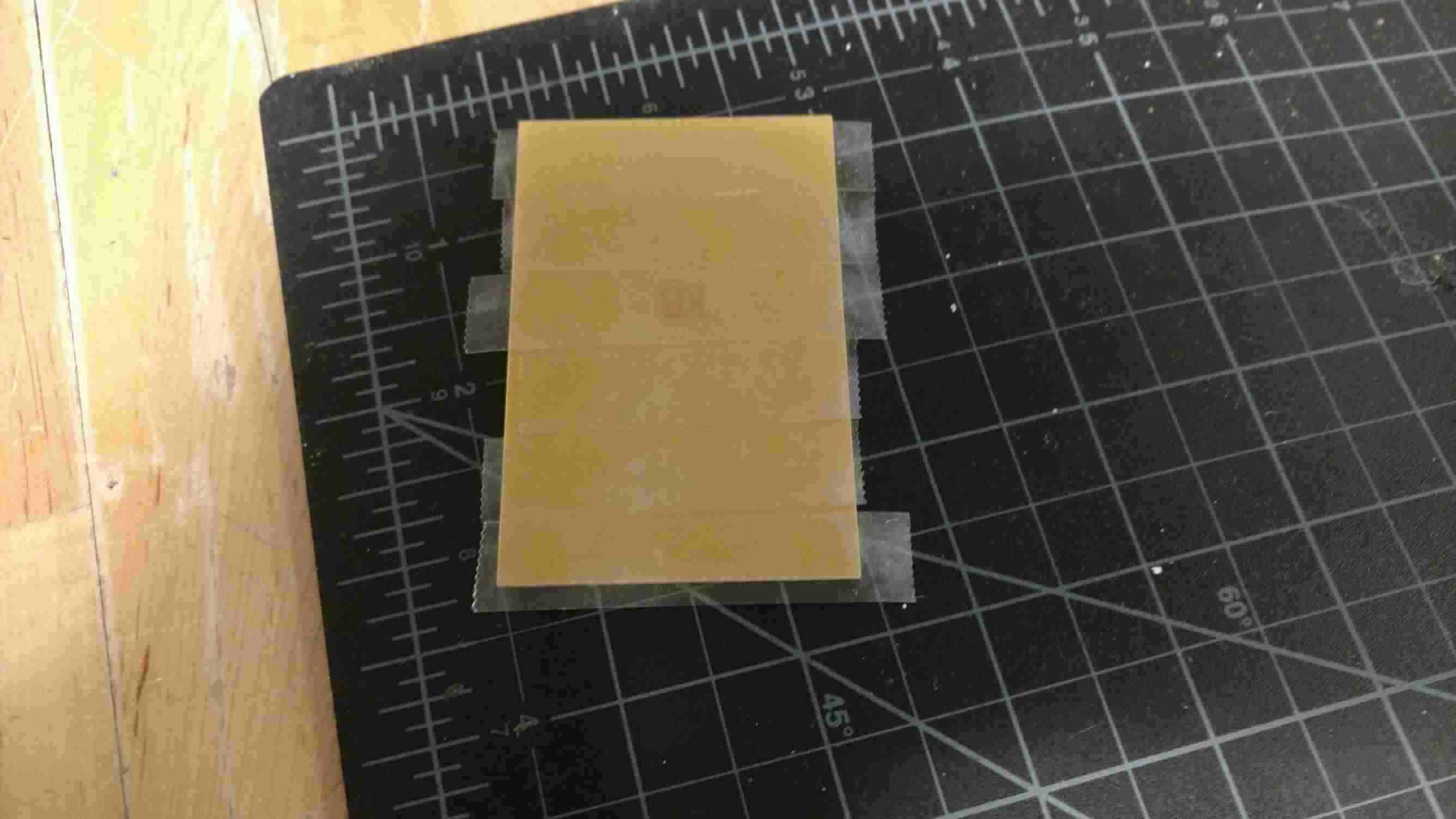

Once the traces

have been generated we need to setup the

mill. Step one is

to mount the material

by using double face tape.

Step two is to place the board close to the origin of the machine.

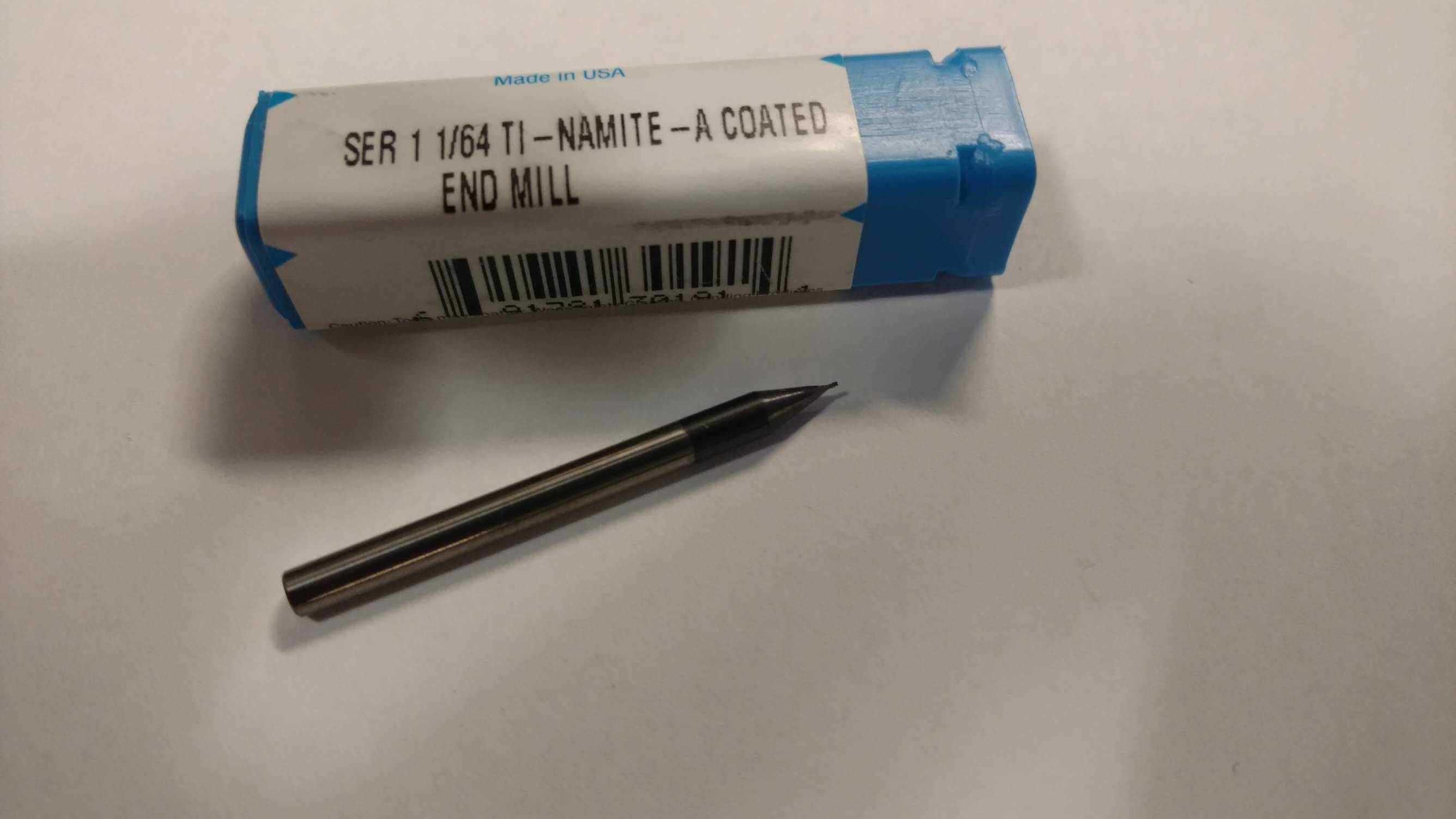

Once the board

is mounted the 1/64 end mill is selected and

inserted in the spindle. After

the end

mill is in you need to adjust the tool height by moving the head to a

blank

spot on the material and lowing the head to close but not touching

after that

you loosen the set screw for the end mill and gently lower it and hold

it on

the surface. The

next step is to tighten

the set screw and get ready to send the data.

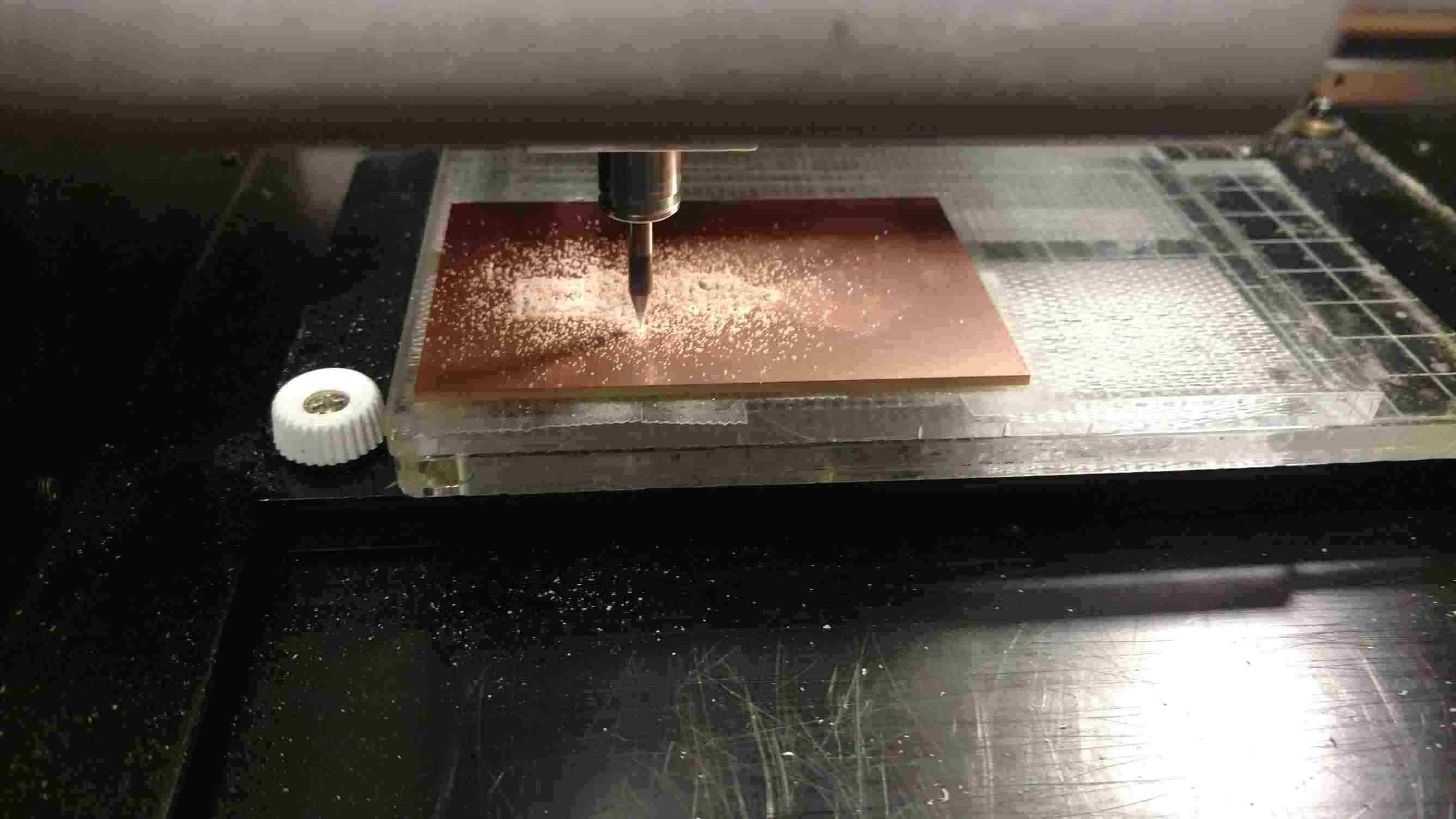

After the tool and tool height is set we can send the path to the machine and watch to make sure nothing goes wrong.

After the top

is milled it needs to be cleaned to remove the

residue from milling this is easily accomplished with a small vacuum.

The last step is to use the fab modules and use the outline picture to generate a tool path to cut the board out with any luck you should now have a board.

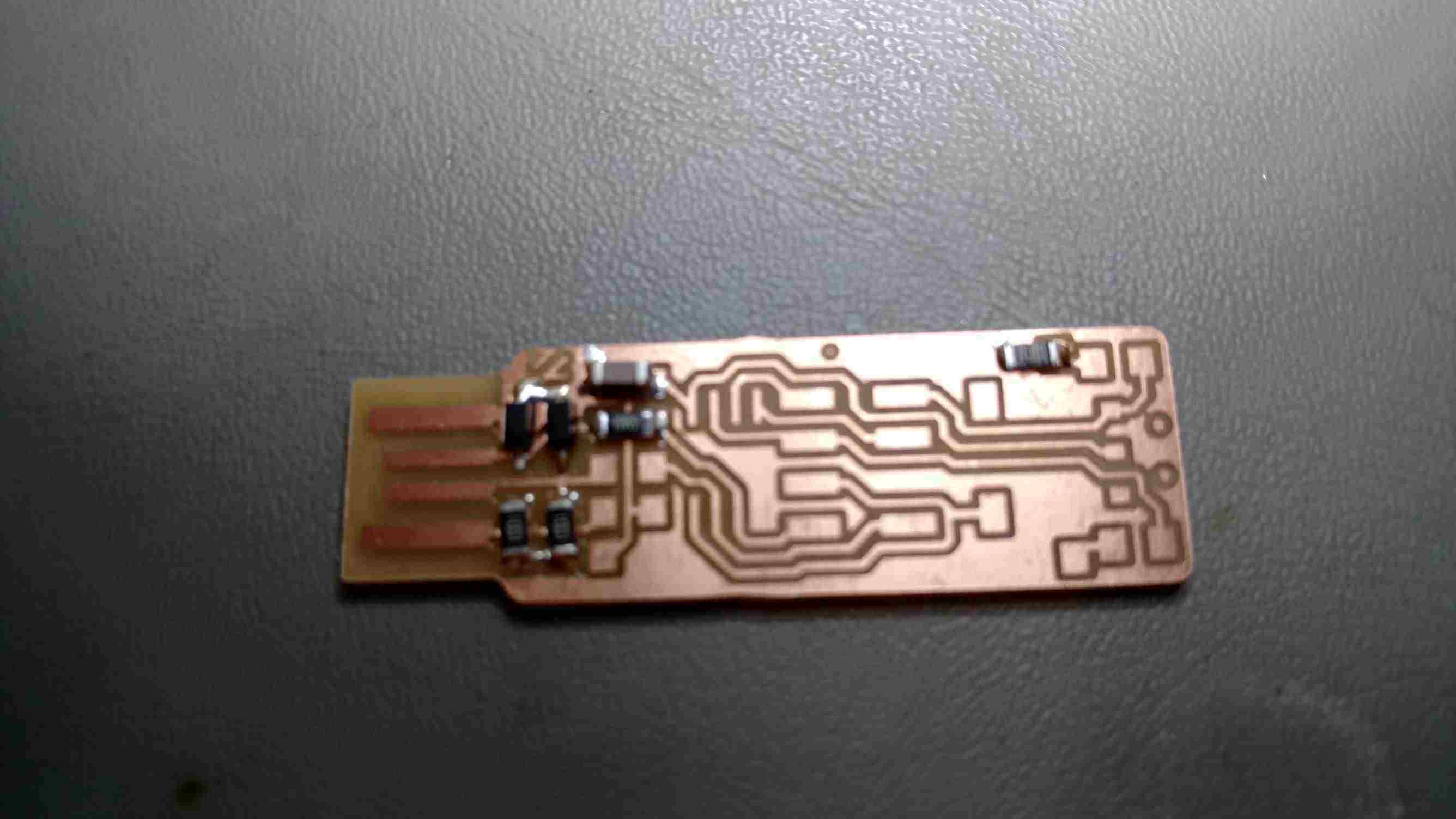

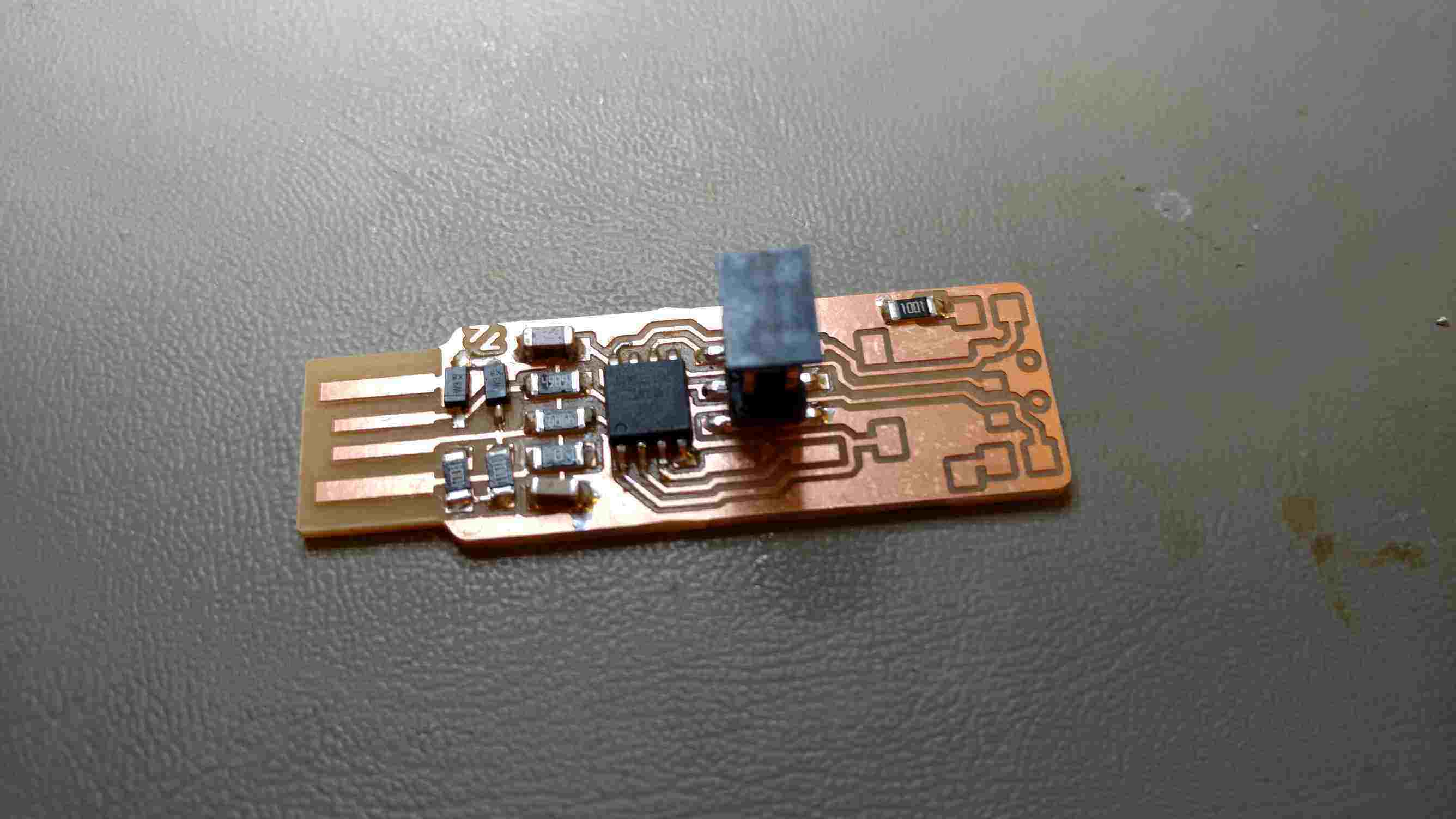

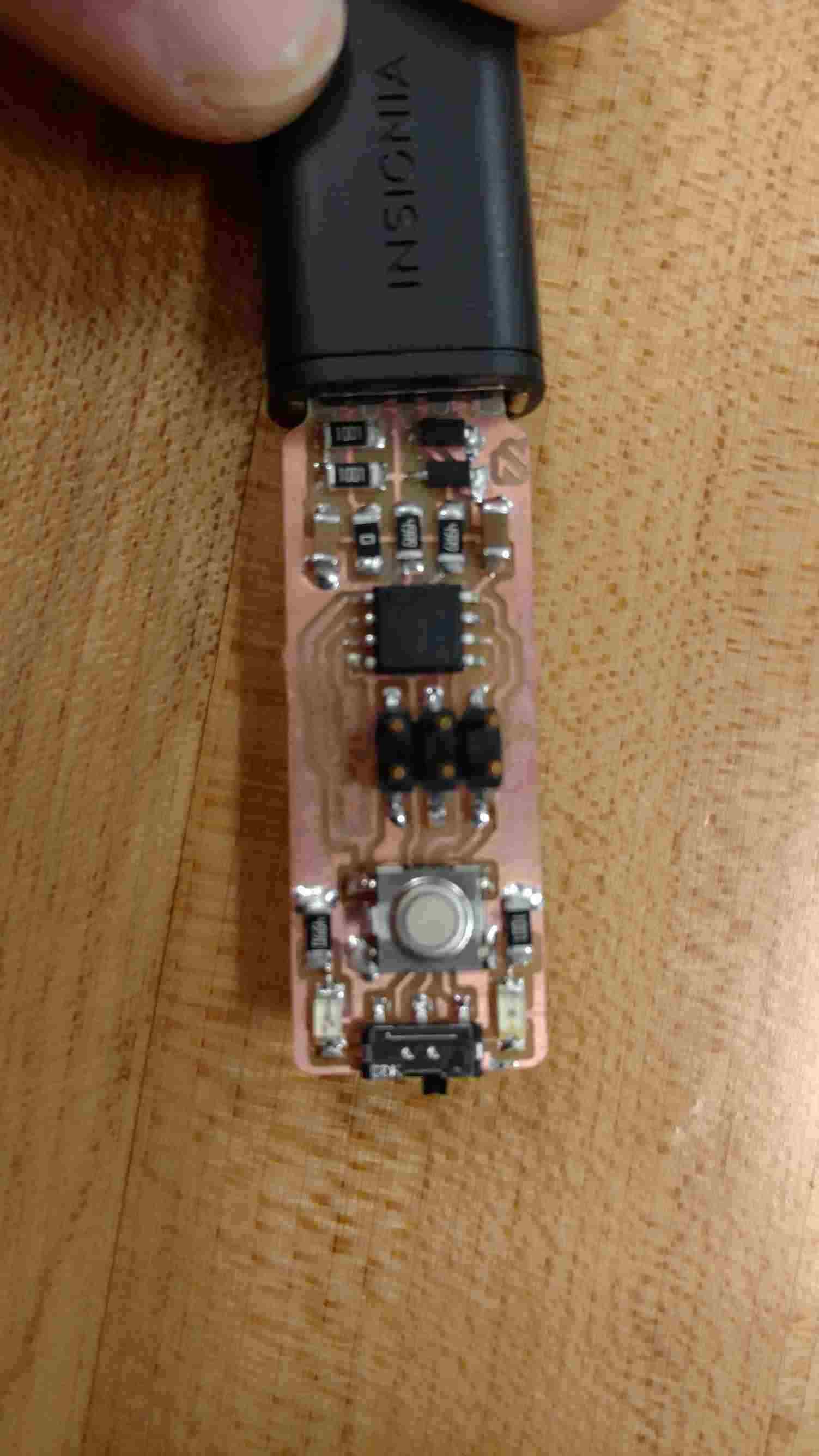

After the board it cut a quick check to verify the traces are all good you can then populate the board. Gathering all the components can take some time but after they are collected you can solder them down.

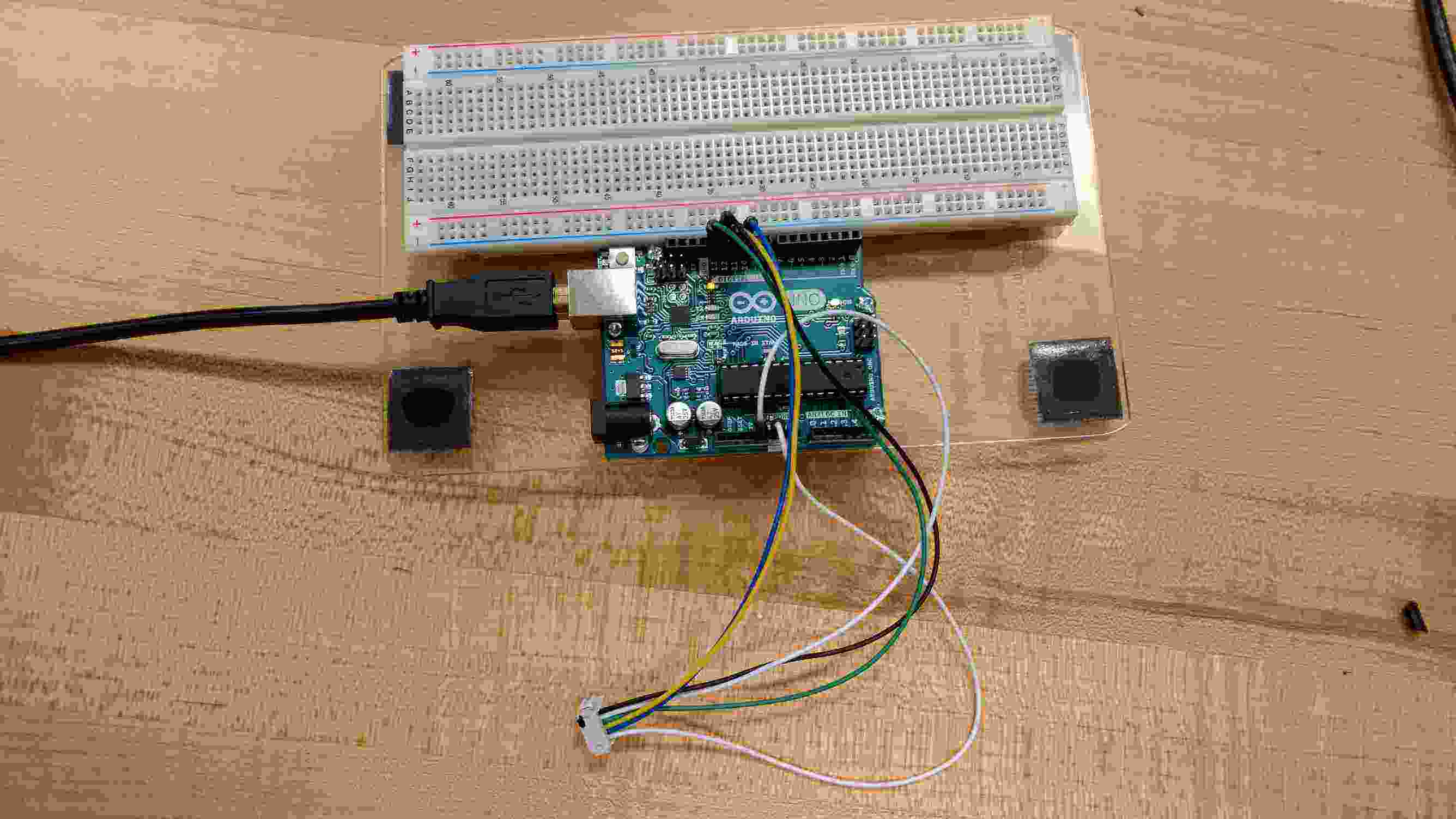

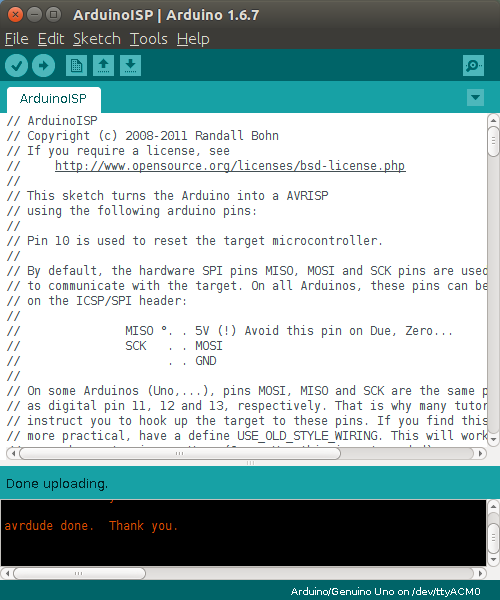

To program the ISP I followed the instructions on Zaerc website. I set up an Arduino and loaded the example ISP program and then followed the rest of the instructions on the page.

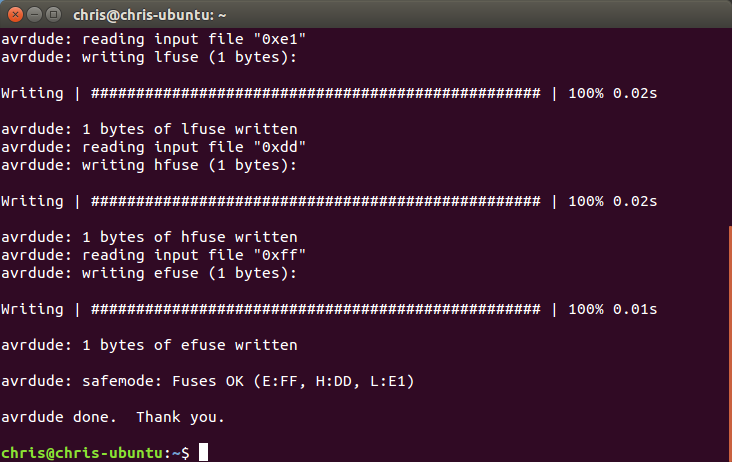

after hooking up the arduinio uno as a ISP and flashing the code it was time to burn teh fuses

Set or burn fueses

Avrdude -c stk500v1 -P/dev/ttyACM0 -b19200 -p t45 -V -U

lfuse:w:0xe1:m -U hfuse:w:0xdd:m -U efuse:w:0xff:m

program

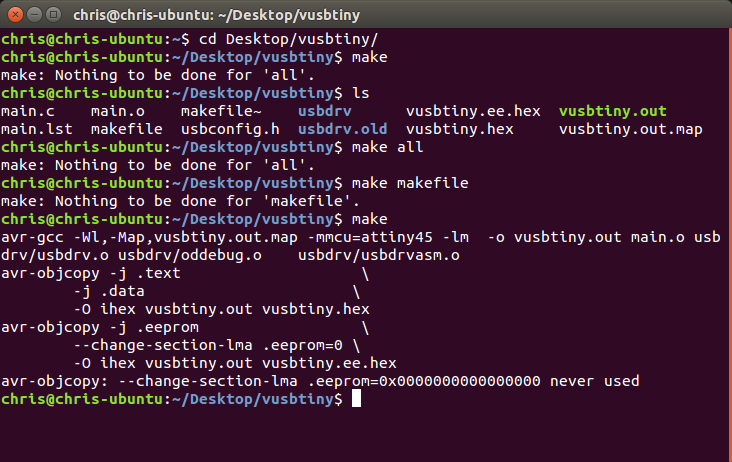

you need to change two line in the usbconfig.h

//#define USB_CFG_DMINUS_BIT 4 comment out

#define USB_CFG_DMINUS_BIT 3

//#define USB_CFG_DPLUS_BIT 3 comment out

#define USB_CFG_DPLUS_BIT 4

you need to run the make command from the download of the

firemware

now its time to write the code to the attiny 45

in the make file you need to make sure you have the ritgh

programmer selescted in this case scine the arduino is being used as a ISP you

can use the fallowing

#AVRDUDE_PROGRAMMERID=usbtiny remove this

AVRDUDE_PROGRAMMERID=stk500v1 -P/dev/ttyACM0

-b19200 add this

now all you have to do is type in make install

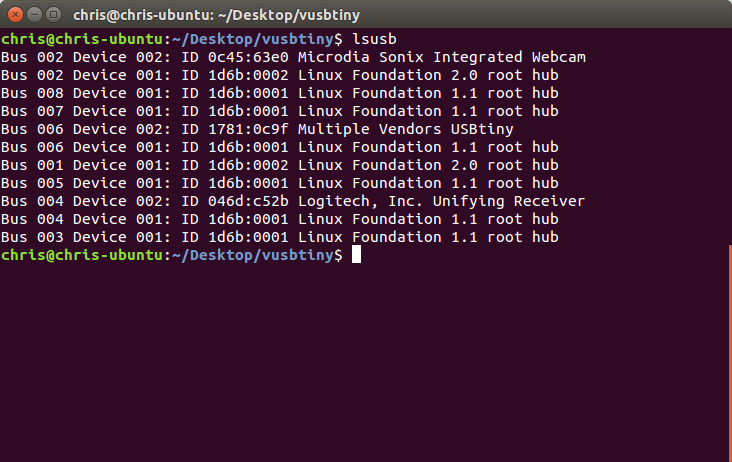

if it is all good when you plug in the your programmer and

use lsusb it should show up as multiple

vendors USBtiny

once you can see that its time to disable the reset-disable

fuse

avrdude -c tk500v1 -P/dev/ttyACM0 -b19200 -p t45 -V -U

lfuse:w:0xe1:m -U hfuse:w:0x5d:m -U efuse:w:0xff:m

after that its time to test.