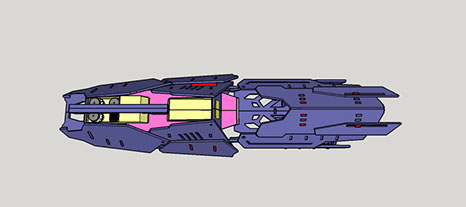

Design with SketchUp

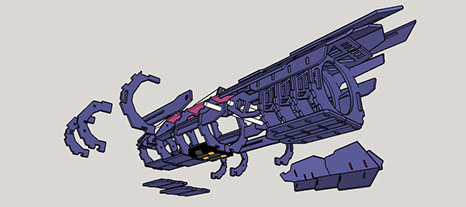

I Finish the prototyping design by 1th Jun and I will improve it in the next week.

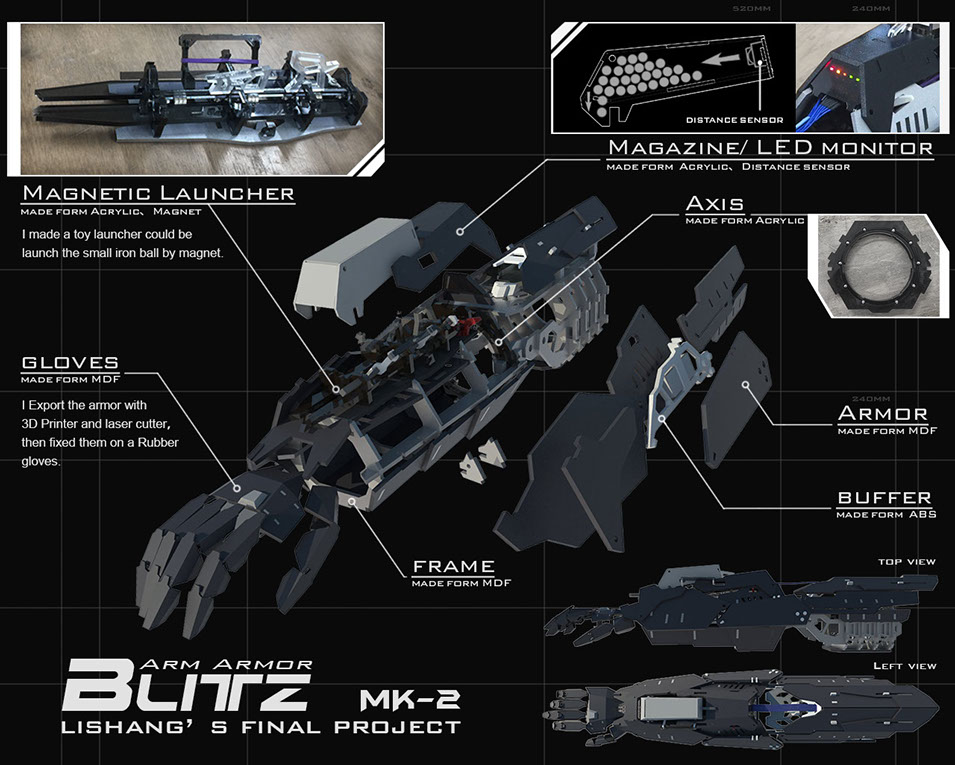

Finally I finished the final design, then add a Magnetic launcher and a magazine on my Arm Armor. But it is still in my computer, I will make this armor's frame and the circuit board before Jun 10th.

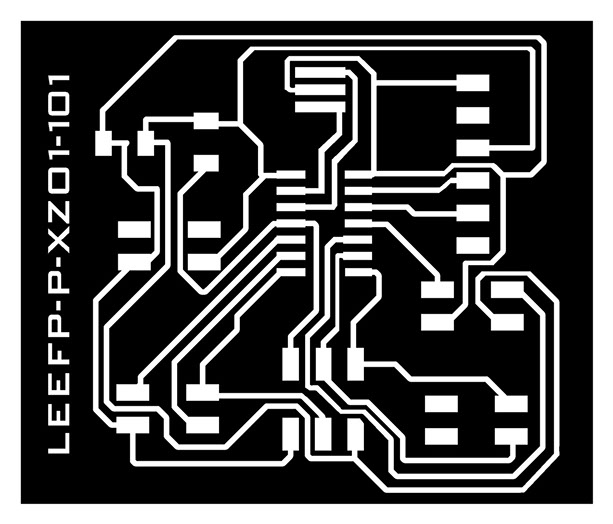

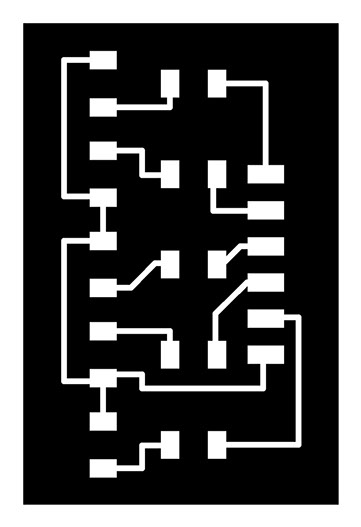

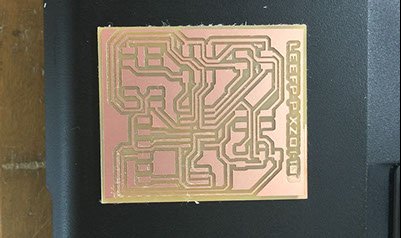

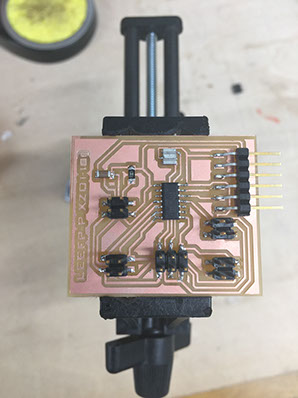

Make the circuit board

Jun 12

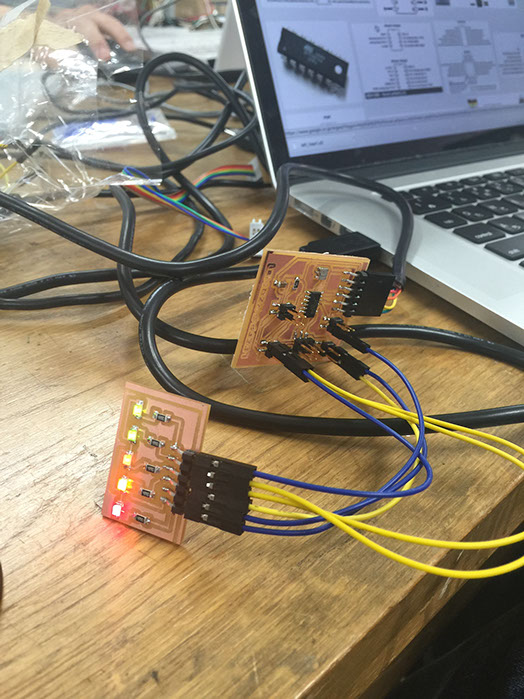

I made a circuit board with attiny44, and made a little led board for export device. Very lucky, the two boards can work smoothly, then I will use the distance sensor as my input device.

Export with laser cutting machine and 3D printer

Jun 13

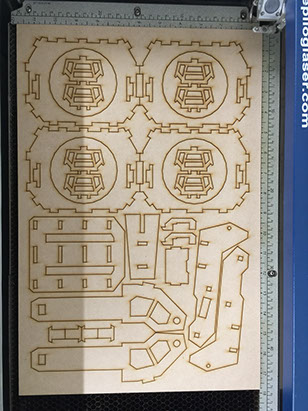

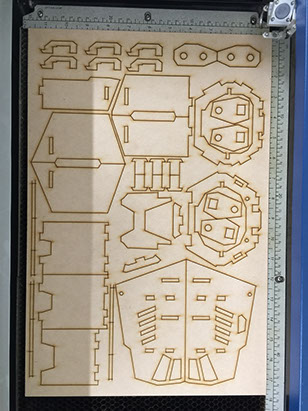

Laser Cutter: Epilog Laser Mini 50w, work area: 600mm x 300mm

AI line: Color: R(255) G(0) B(0), Weight:0.01

Mechanical setting:

Export 4mm MDF:Power75, speed20

Export 5mm Acrylic:Power90, speed18

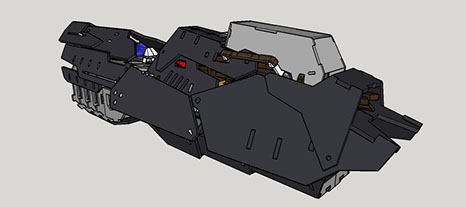

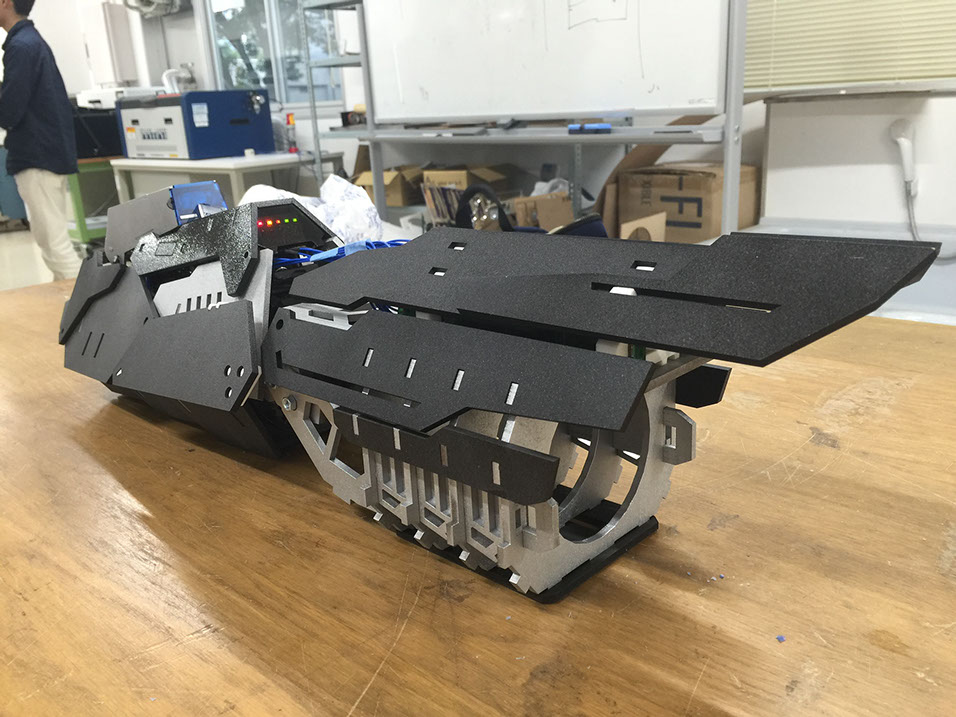

Because on the computer I do a complete design, and check a lot of times, so this part is very smooth. After getting the armor parts, I started painting.

question: Due to the rain, it's very not conducive to the paint dry, but I used the hot air conditioning to solve this problem successfully.

Combination

Jun 14

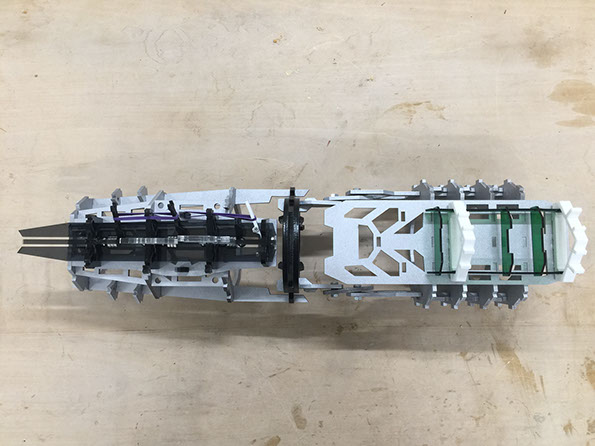

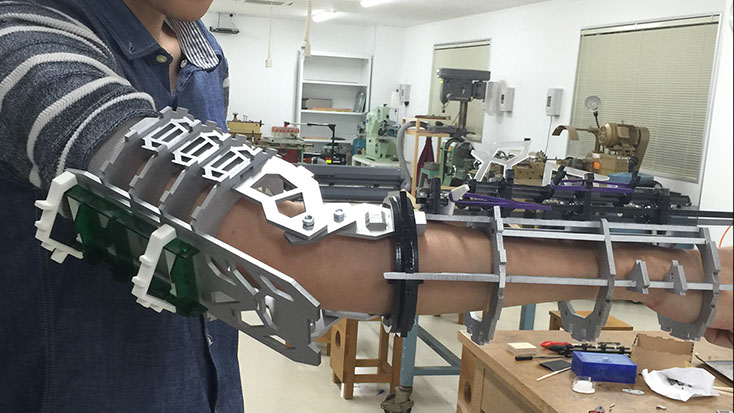

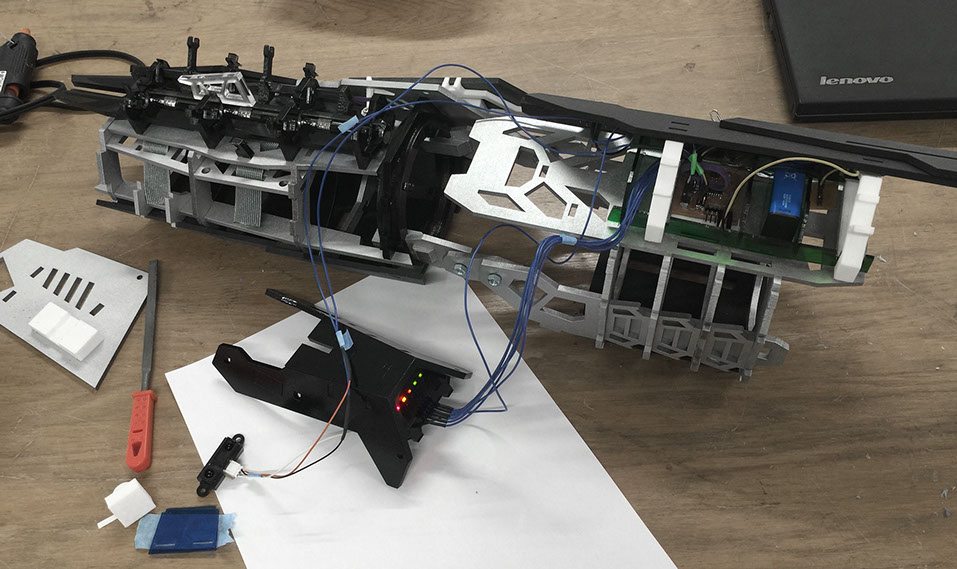

After the paint is completely dry, I started to bolt the components together. This part does not have any problems, all the parts were combined successfully.

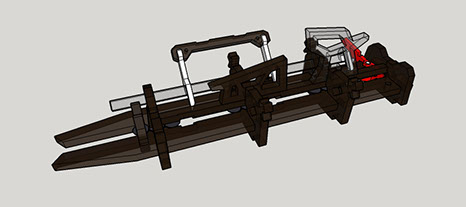

The magnetic launcher can launch the iron ball, I designed a track, it can fix the magnet and just let the ball move inside.

Except the joint of the arms, I also designed an acrylic Bearing allows the forearm to have a 180 degrees rotation. The Bearing using acrylic and iron balls, I am very happy and it can work smoothly.

question:

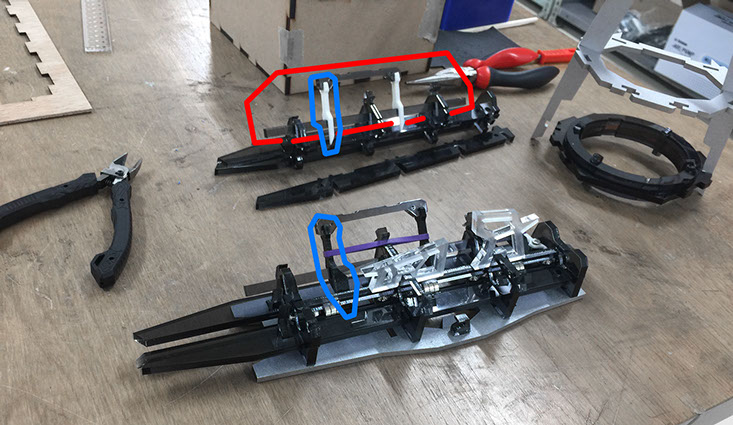

After the launch, all the ball will be go to the front, in order to re launch I need to moving all of the ball back to the original position, so I designed a device (red) can be moving all of the ball back to the original position one time, but unexpectedly, the magnetic field of the magnet is too strong. So I improved the parts of the device(blue), regret is still not successful.

Programming

Jun 16

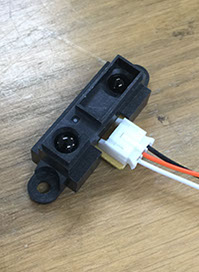

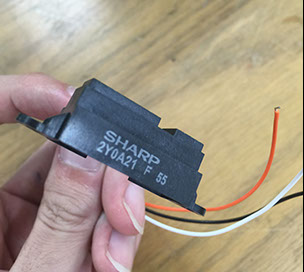

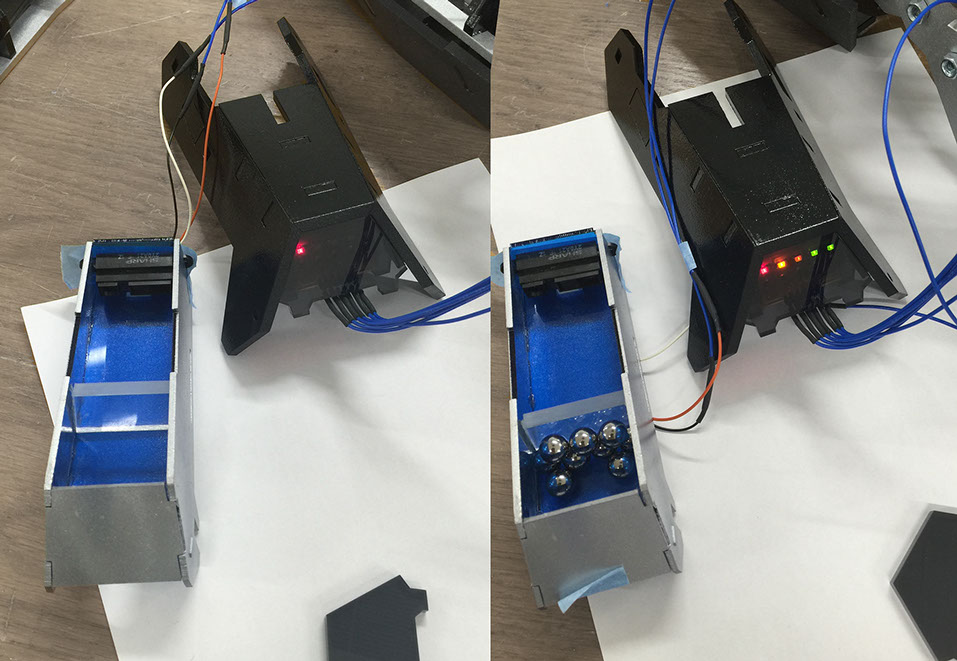

The forearm have a little magnet iron ball-ejector and a magazine, remain iron ball could be inductived by a distance sensor in the magzine, then projected on a LED screen.

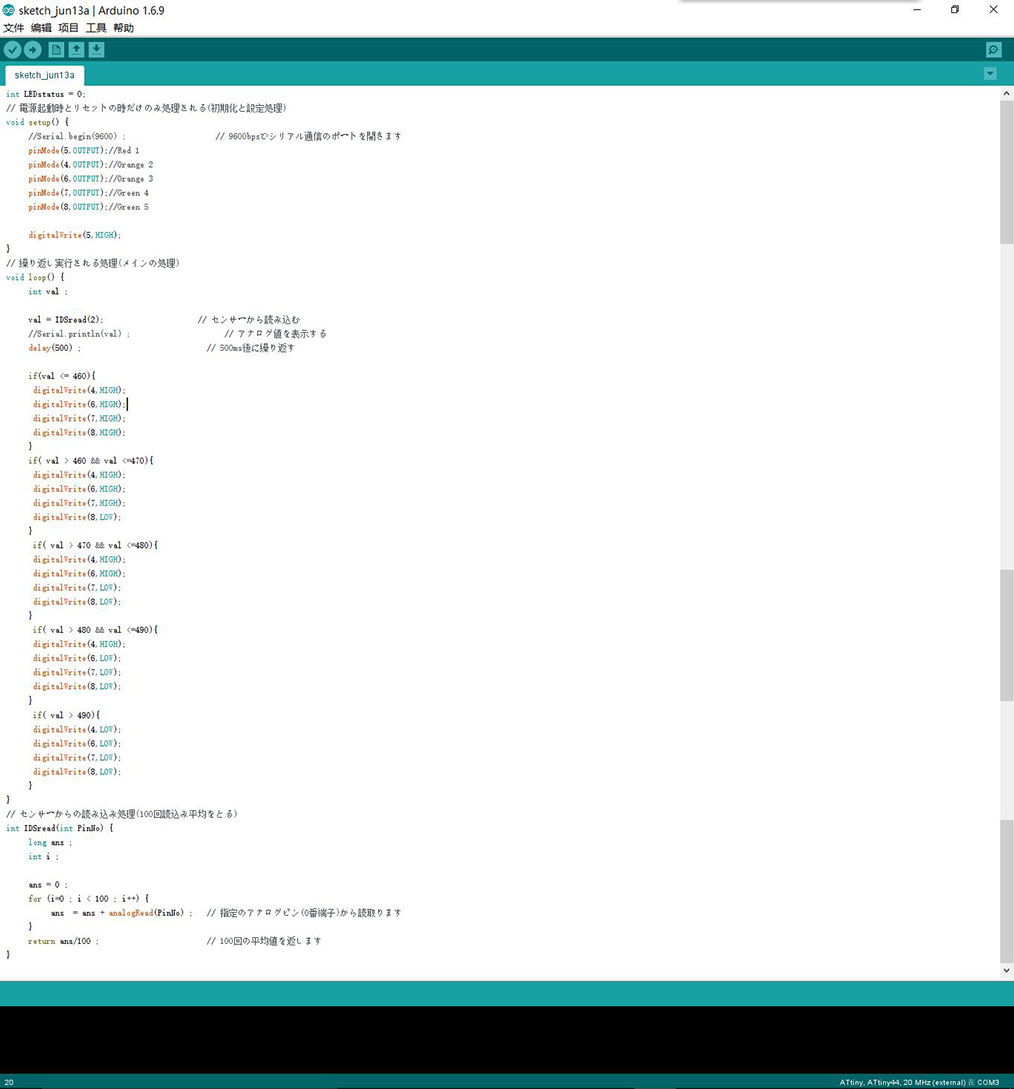

At first, I put the distance sensor in the magazine, then tested the sensor's reading, the value is 490-460. When the object nearest by the sensor, the value is 460. when the object is farthest from the sensor, the value is 490.

Because I want to use 5 LED to represent the remaining bullets. I divide the value into 5 groups: val<= 460, val> 460, val> 470, val> 480, val> 490. Then, set the LED' working condition for each group.

if(val <= 460)

digitalWrite(4,HIGH);

digitalWrite(6,HIGH);

digitalWrite(7,HIGH);

digitalWrite(8,HIGH);

f( val > 460 && val <=470)

digitalWrite(4,HIGH);

digitalWrite(6,HIGH);

digitalWrite(7,HIGH);

digitalWrite(8,LOW);

if( val > 470 && val <=480)

digitalWrite(4,HIGH);

digitalWrite(6,HIGH);

digitalWrite(7,LOW);

digitalWrite(8,LOW);

if( val > 480 && val <=490)

digitalWrite(4,HIGH);

digitalWrite(6,LOW);

digitalWrite(7,LOW);

digitalWrite(8,LOW);

if( val > 490)

digitalWrite(4,LOW);

digitalWrite(6,LOW);

digitalWrite(7,LOW);

digitalWrite(8,LOW);

Testing the distance sensor

So by this program the number of the led will reflect the left iron balls, full magazine with five LEDs and if the magazine is empty, there is only one red LED left.

Jun 17

Step6:Test the distance sensor

question

Finished

Jun 18

I made a transparent acrylic magazine. But the test result is not good, in order to solve this problem, I painted the magazine. Now it can work properly

With the current speed, the final project will be complete successfully before Jun 20th.

All the system can work normally, that makes me very happy. Soon, I assembled my arm armor.

what have I learned:

In this final project, I learned how the use of laser cutting machine, 3D printer, milling machine, and how to write programs. Although there is no contact with my major, but I think it is very interesting. I often do the design in the computer before, but this is the first time, I turned it into a reality.