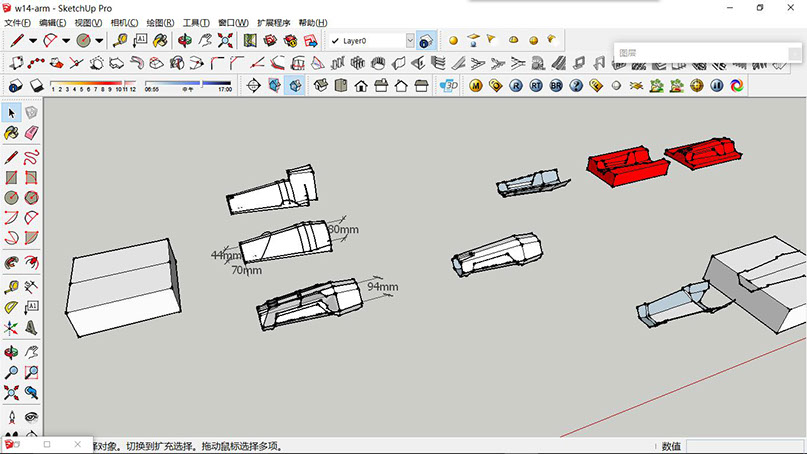

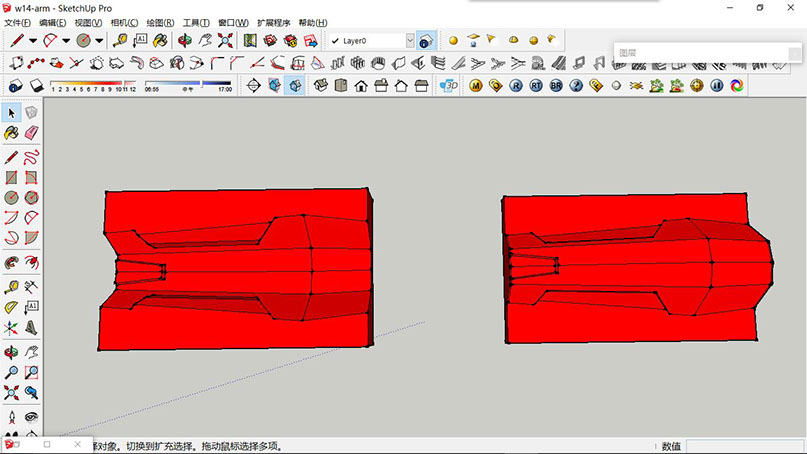

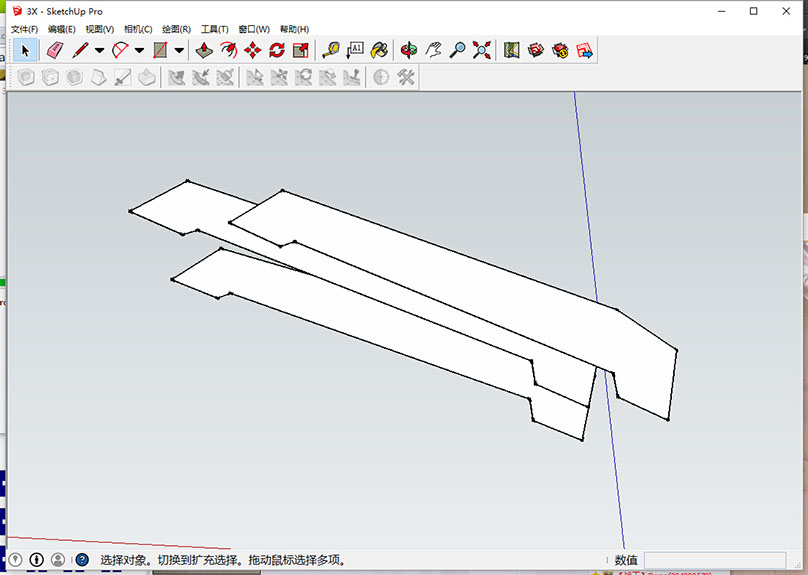

At first I wanted to use Roland SRM-20 to Milling the 300mm×300mm×100mm foam, then I'll get my arm armor shape, and I could make my arm armor by composites. So I spent a lot of time to do the design.

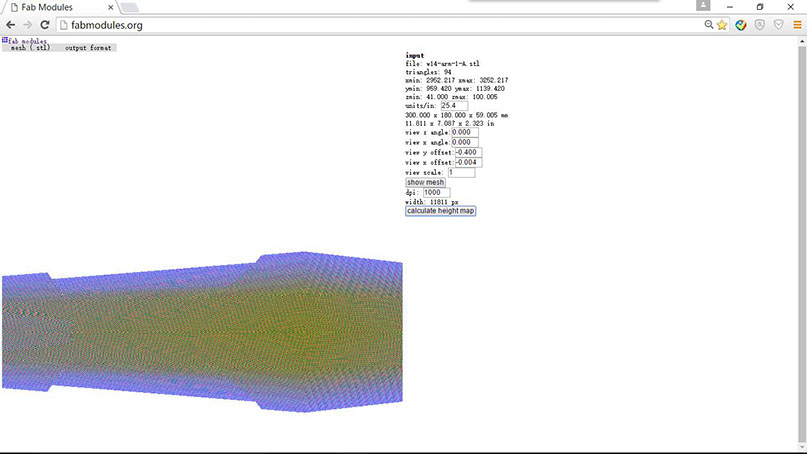

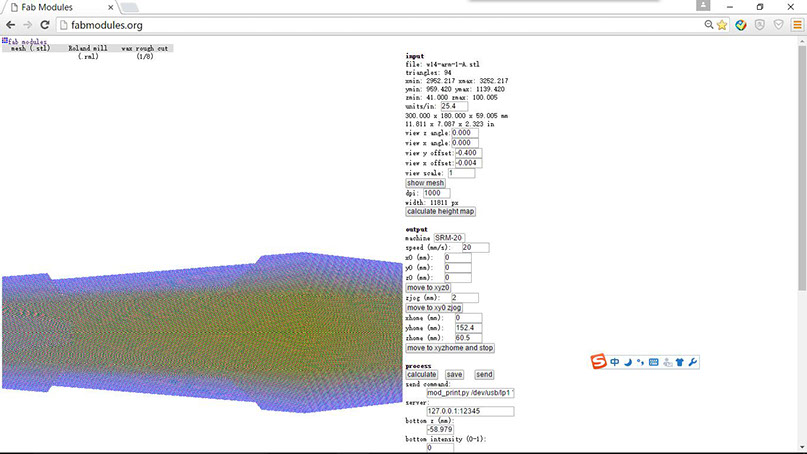

After the design I exported the STL file From the Sketchup and input the file to Fabmodules.

But when I press the caculate, the page of Fab Modules was collapsed. I tried many times, and failed each time. Occasionally it's start to calculations, but it takes a couple of days to complete just ten percent, So I need to make a model that doesn't need a lot of calculations with Fab Modules.

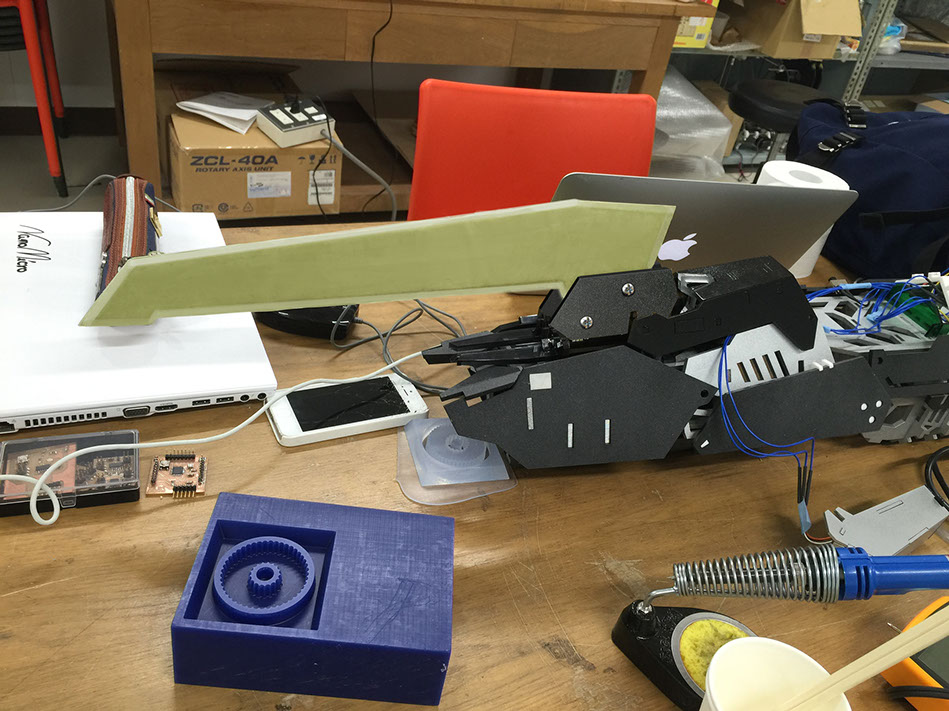

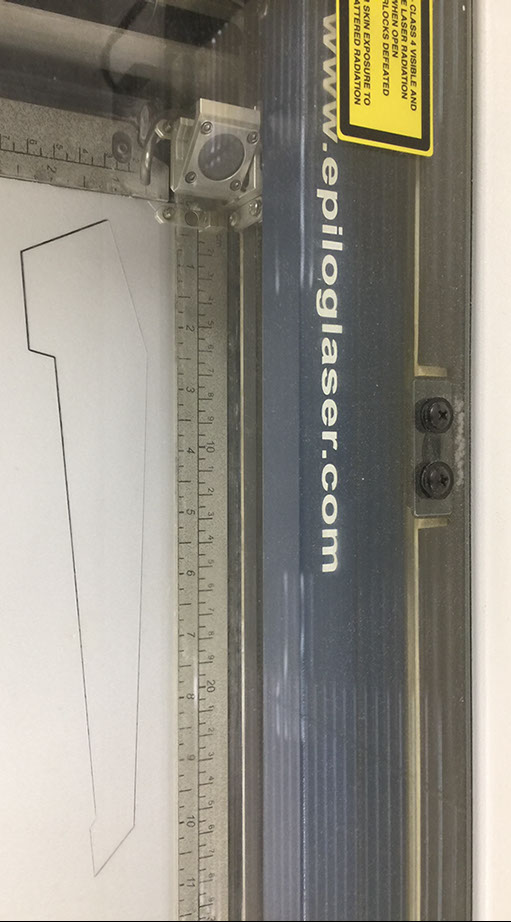

I want to make something like the Wolverine's steel knife. It's doesn't need to use Fab Modules to calculate

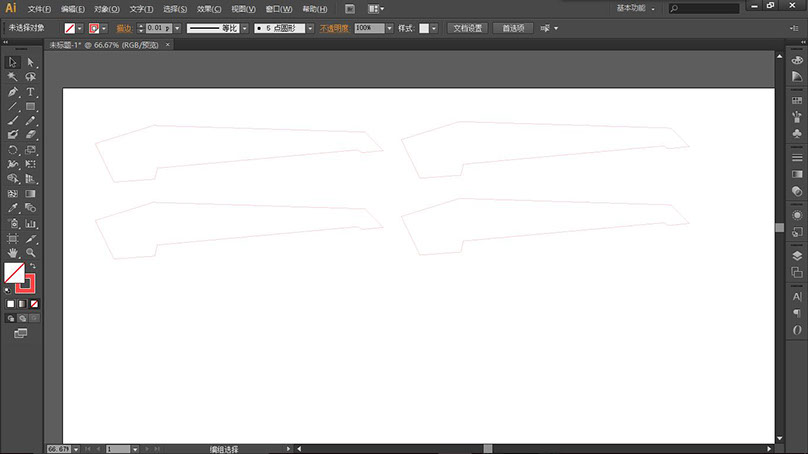

I use 2mm plastic foam board as material.

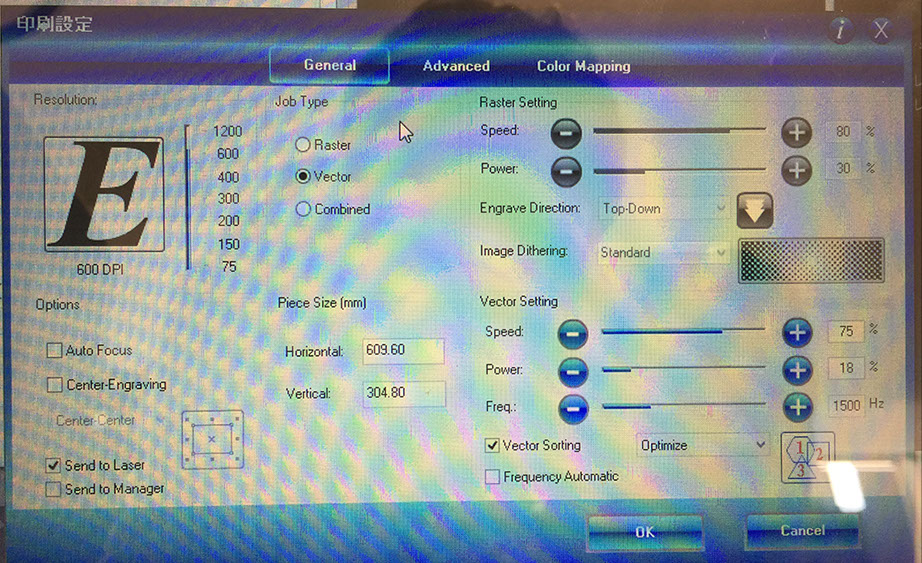

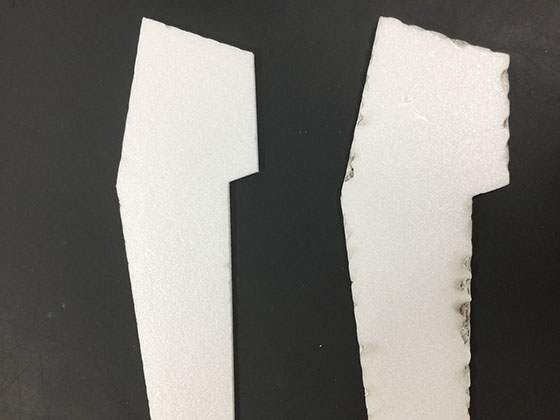

In my first cut, I set the speed as15, power as 18, I got the No. 2 Results, the plastic foam board's back has melted.

So I Improve the speed as 75, then I got the No. 1 Results.

2

1

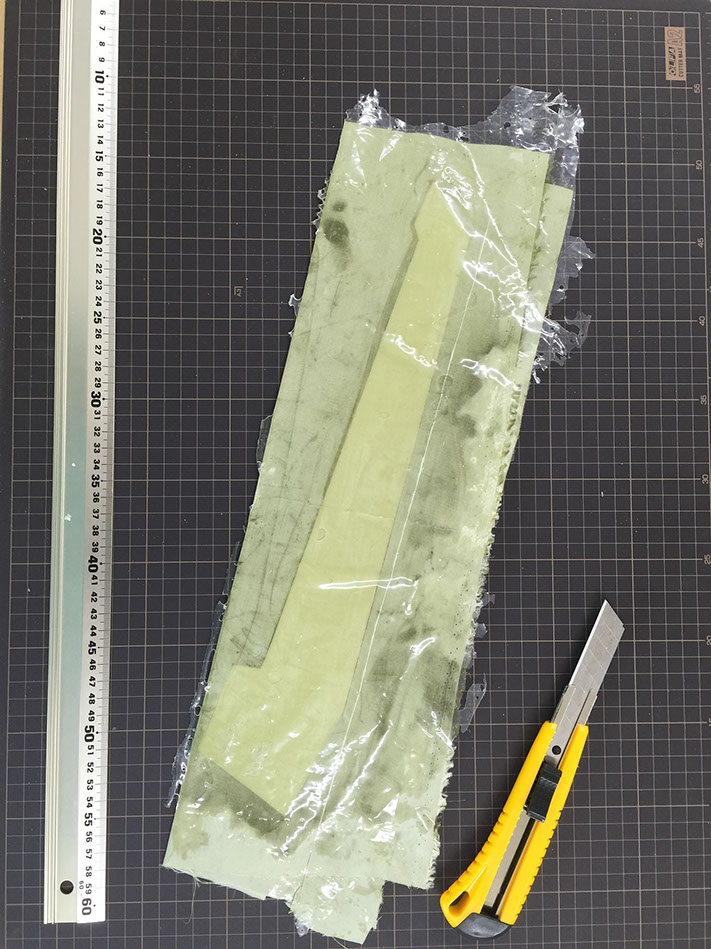

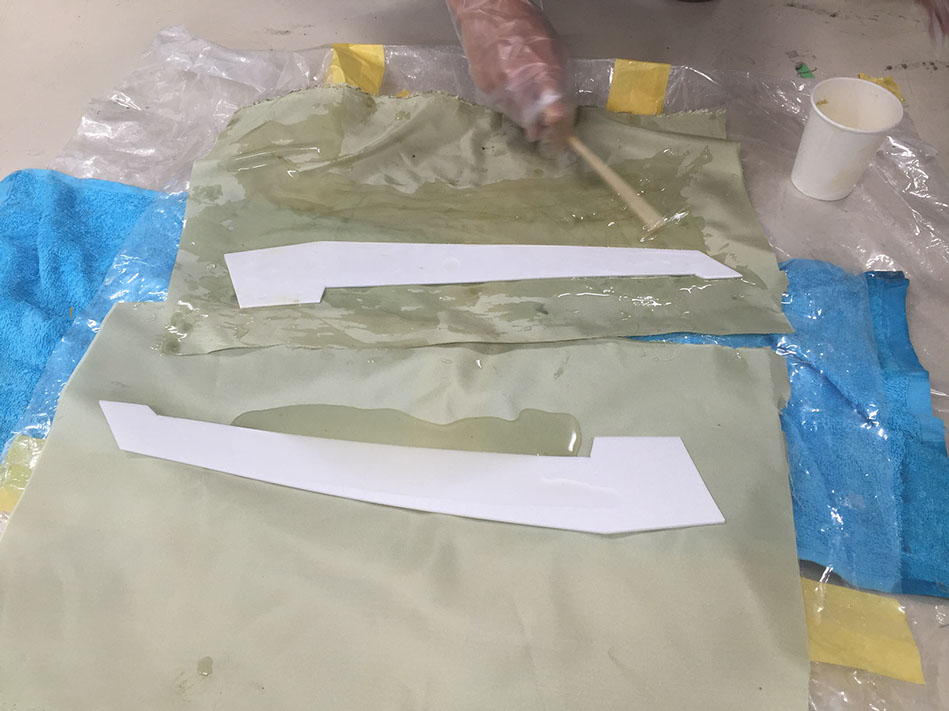

We have 2 kinds of epoxy: main resin and hardner. The ratio of the main and hardner is 5:1.

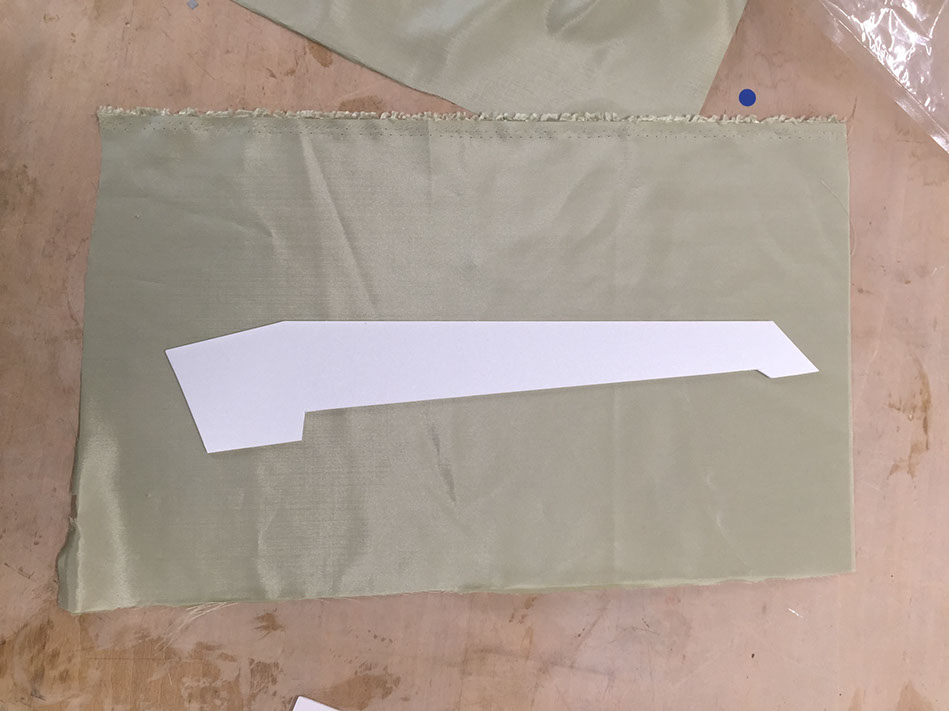

Material and layer

- Towel

- Polyethylene film

- Green chemical fiber

- Foam plastic board (2mm)

- Green chemical fiber

- Polyethylene film

- Towel

Then I put them in a big plastic bag, Use a vacuum to exhaust the air out of the bag.

One day later