Exercise07

Data for NC cutting

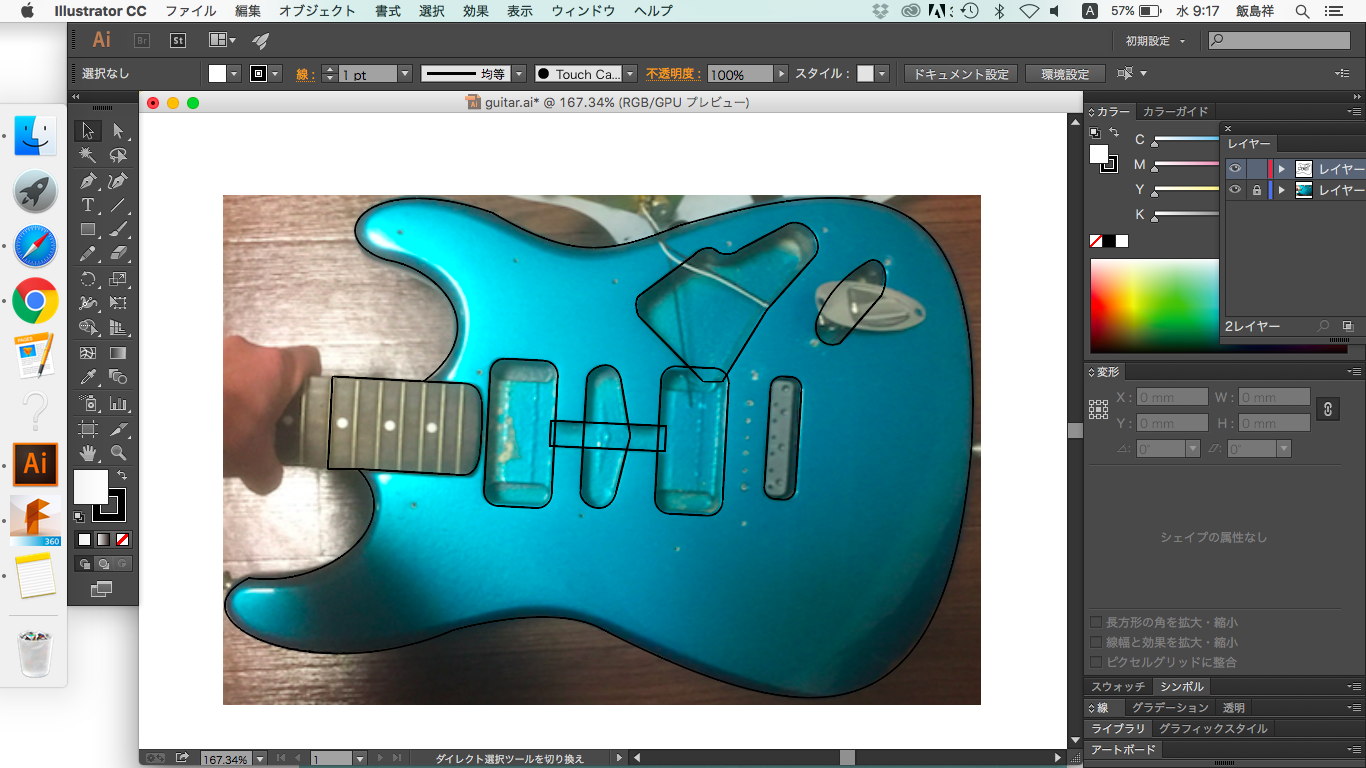

As a homework for this class, I tried making a guitar part.

At first, I took a picture of my guitar which is broken and not used.

Using this data and illustlater, I made outline data and wrote the dxf file.

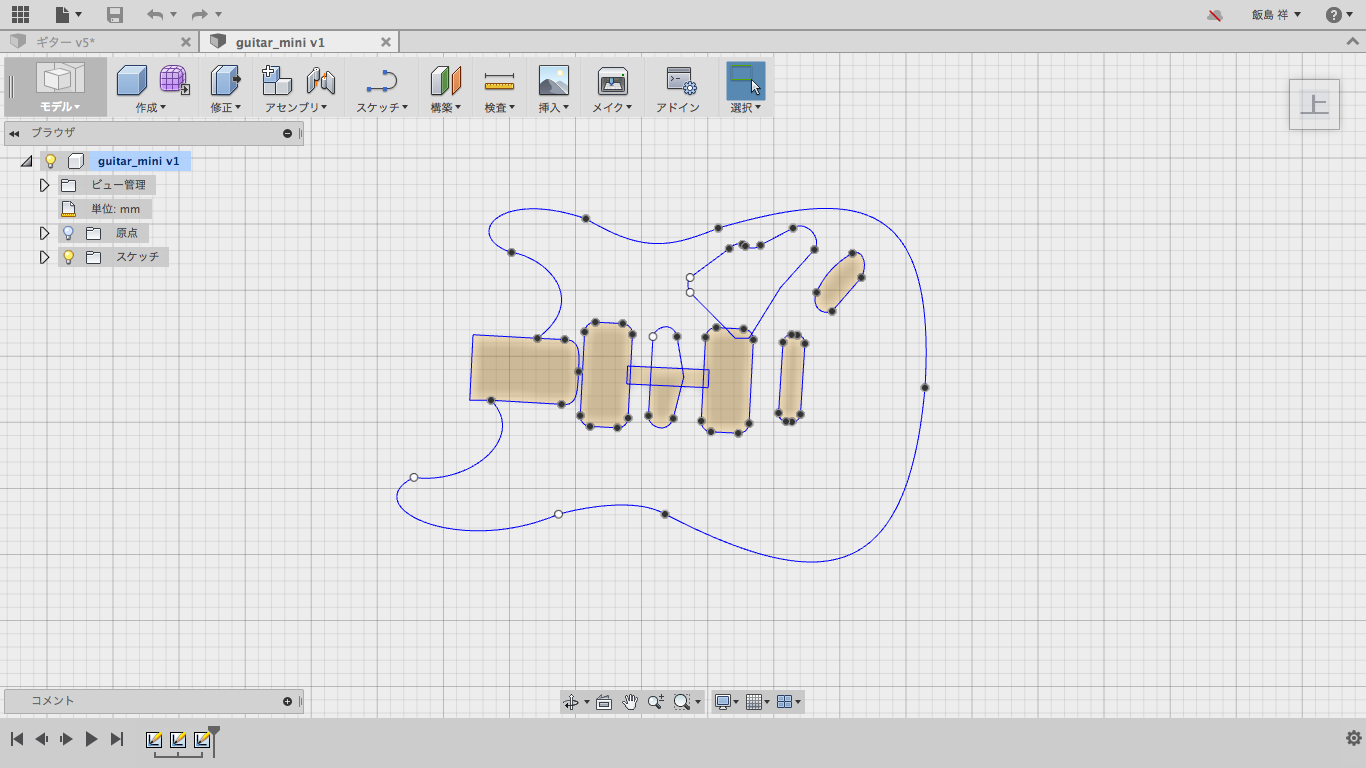

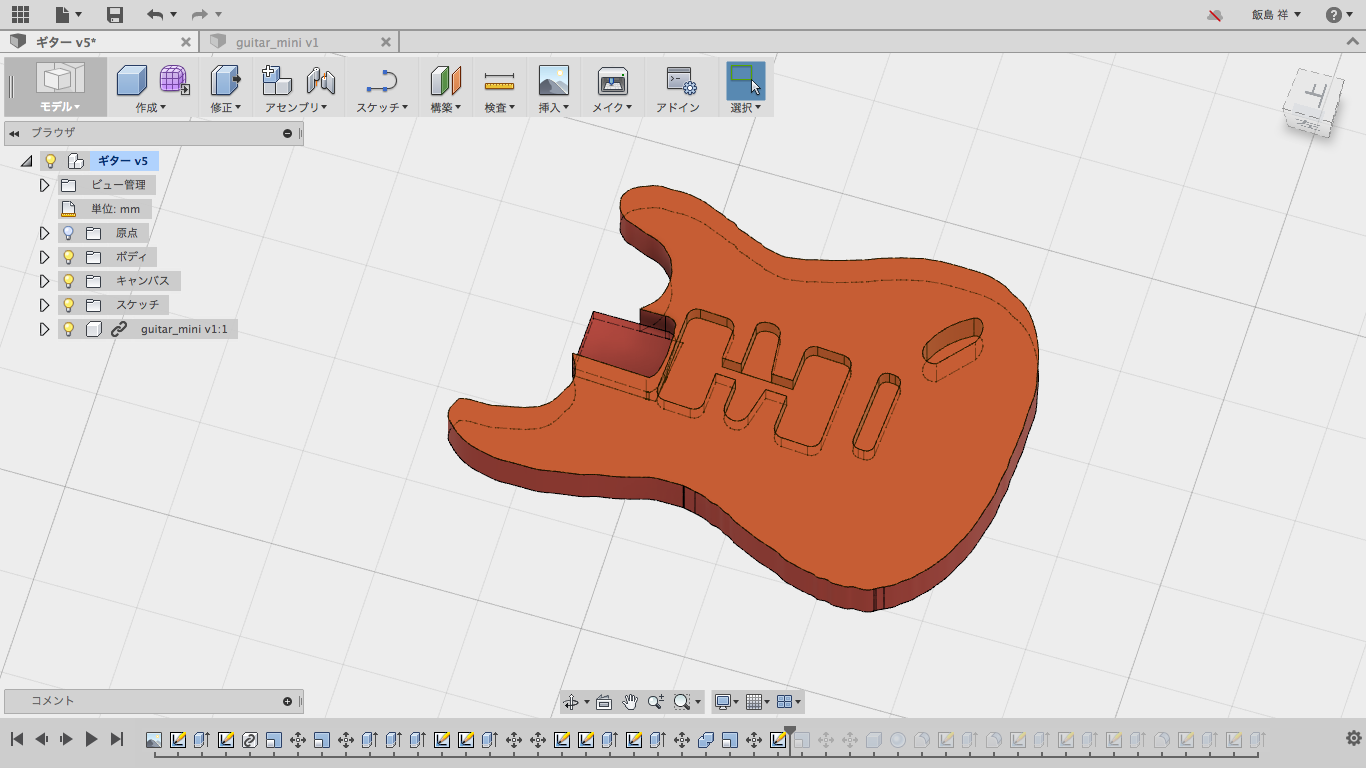

And I open the file using fusion 360.

I pressed the data and made stl file from it.

After that there was a problem.I could not prepare the wood thick enough to make the guitar body by the day I use Shopbot.

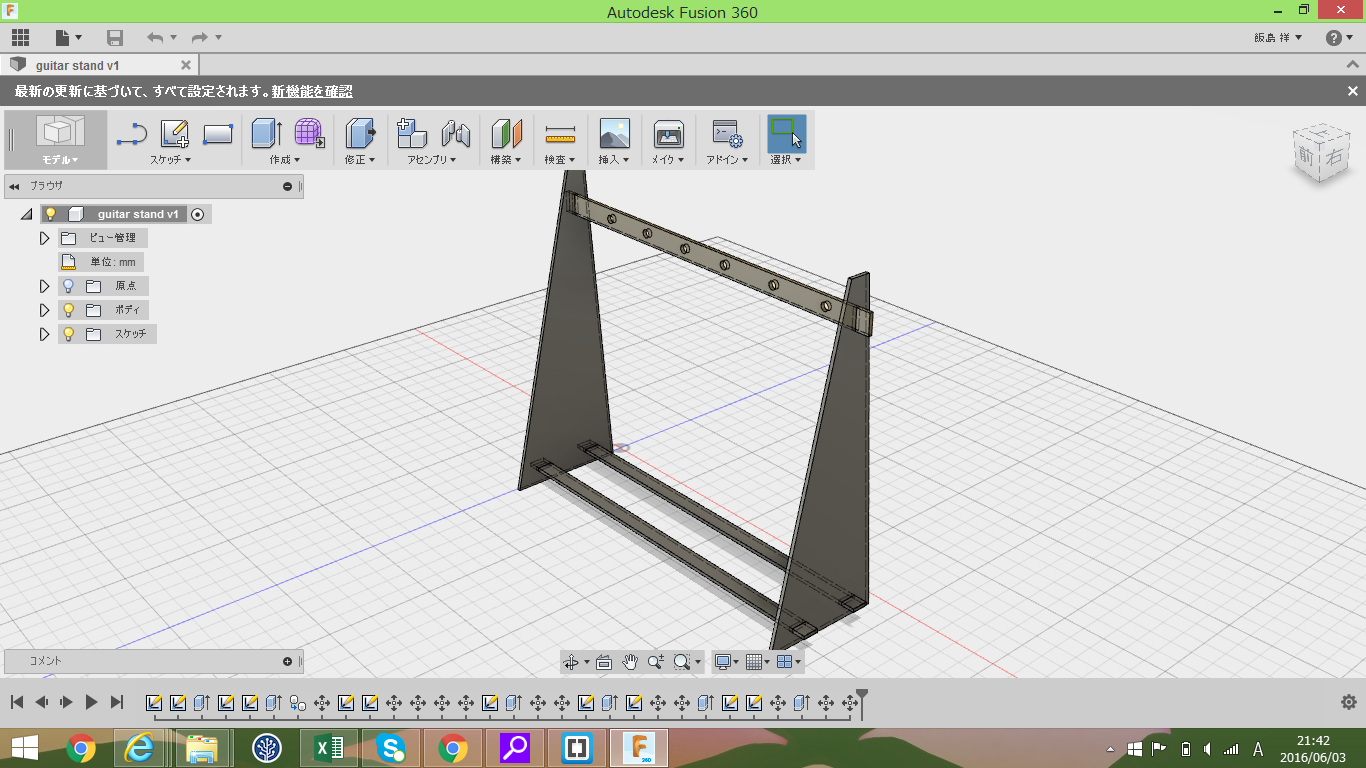

So I changed my plan and decided to make a guitar stand.

Guitar stand

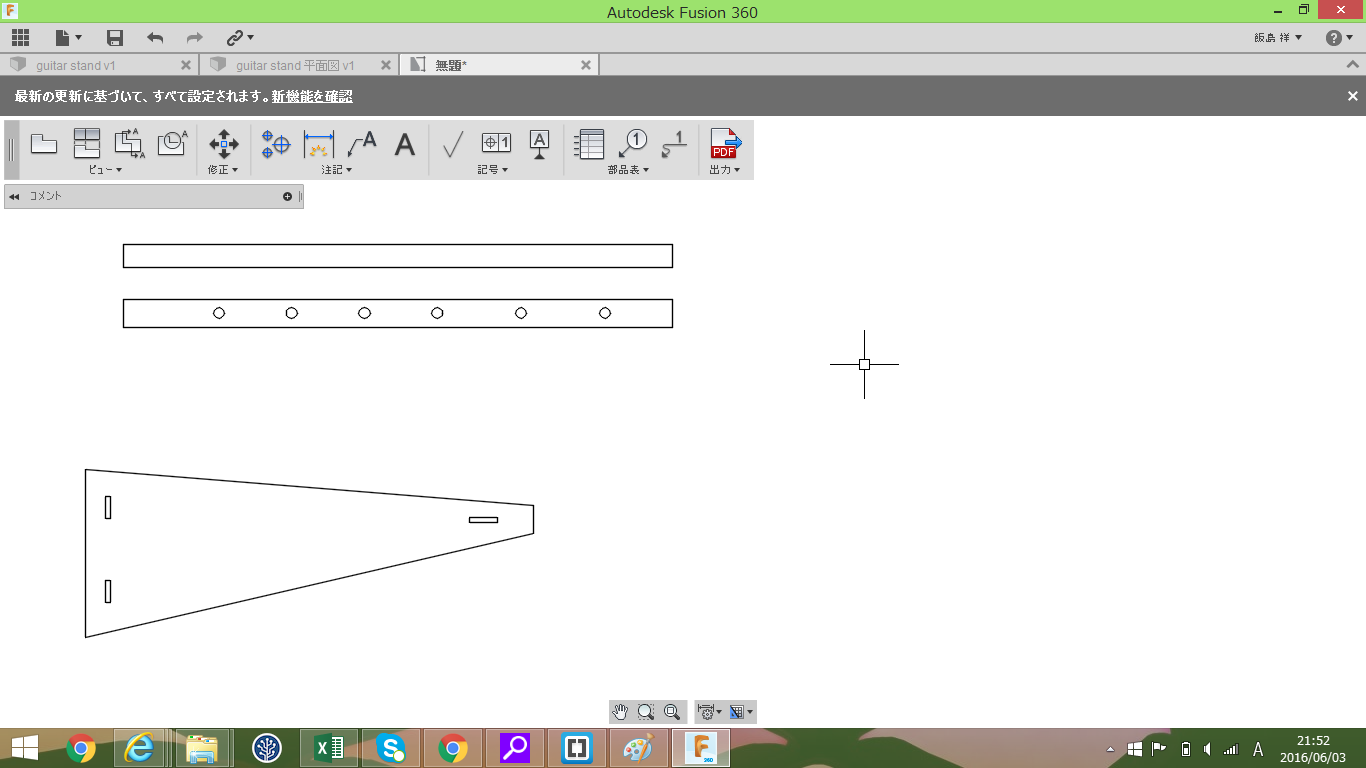

At first I made the modeling data using fusion 360.

After that I changed it into a PDF file as a vector data.

Using this data, I cut the OSB board using Shopbot.

The endmill is for down cutting, and it was a 6mm diameter square endmill.

For cutting, cutting speed was set to move at 30mm per second.

In addition, the feed was set to 3 mill.

You can watch how Shopbot worked from here.

After cutting, the parts looked like these.

After cutting I found that the board under the guitar was so long that I thought it was not strong enough to support the guitar. So I decided to cut the board and change the size of the guitar stand.

That is how I got my own guitar stand!!

download f3d data

download pdf data