Exercise03

Computer Aided Drawing

In this class I learned how to use laser cutter using computer and parametric design.

In specific, I learned to output a drawing from fusion360.

And I also learned to change the number of the sheet thickness depending on the situation.

Output a drawing

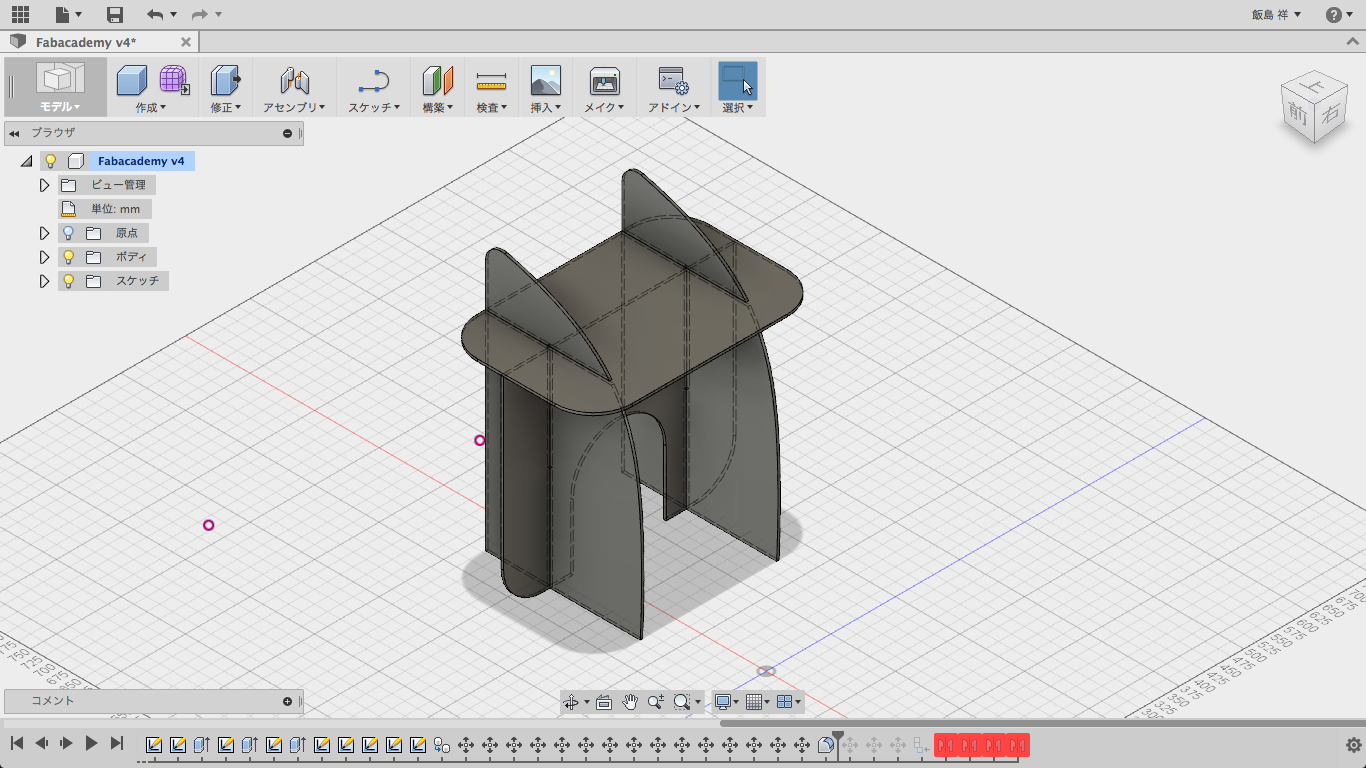

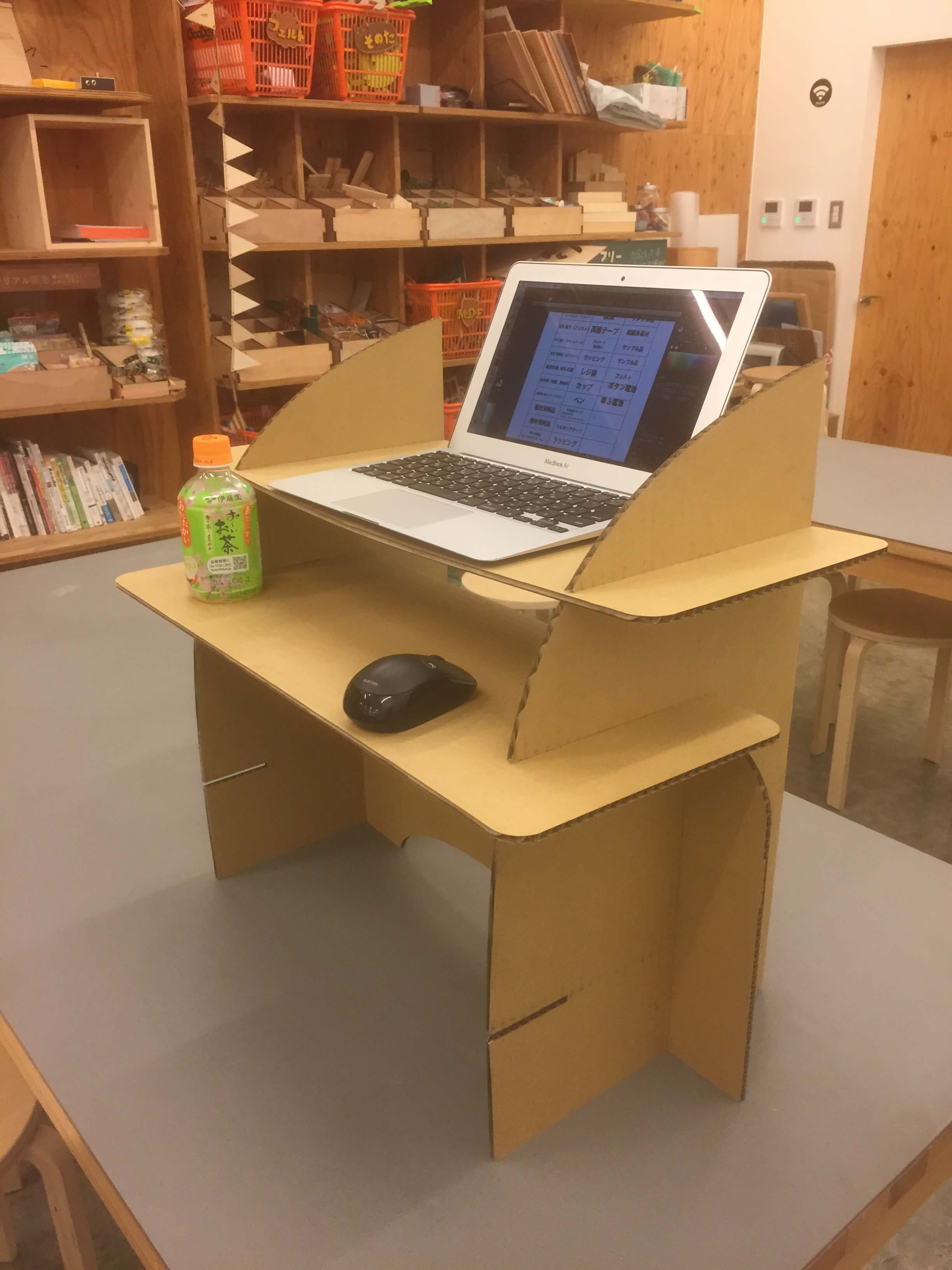

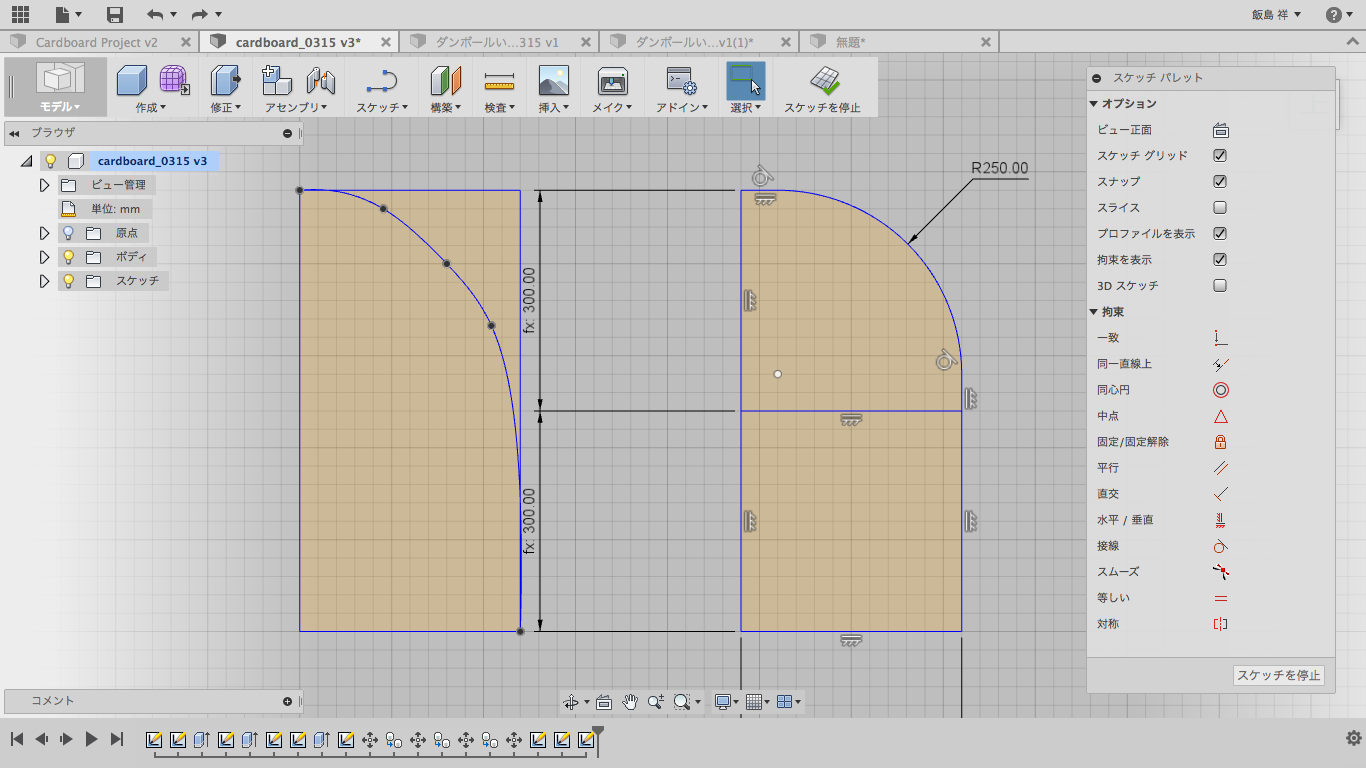

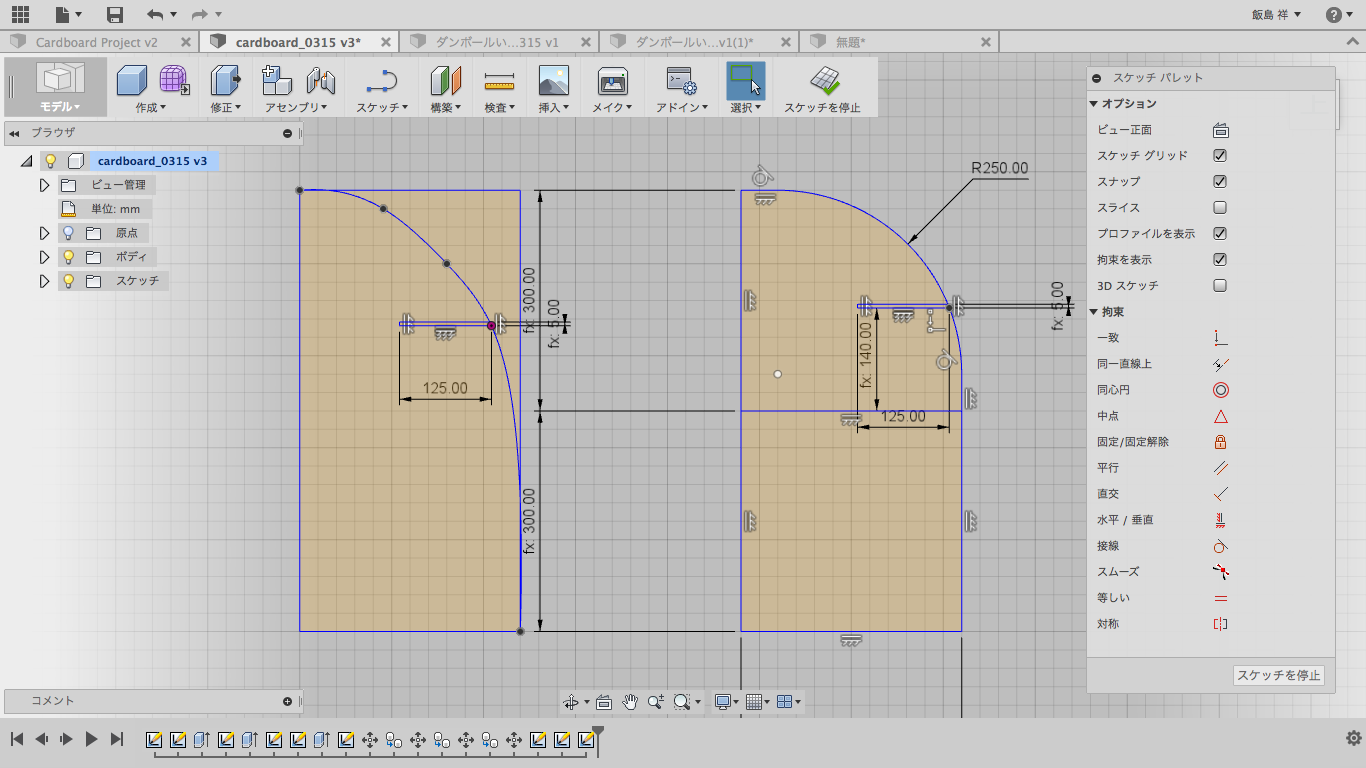

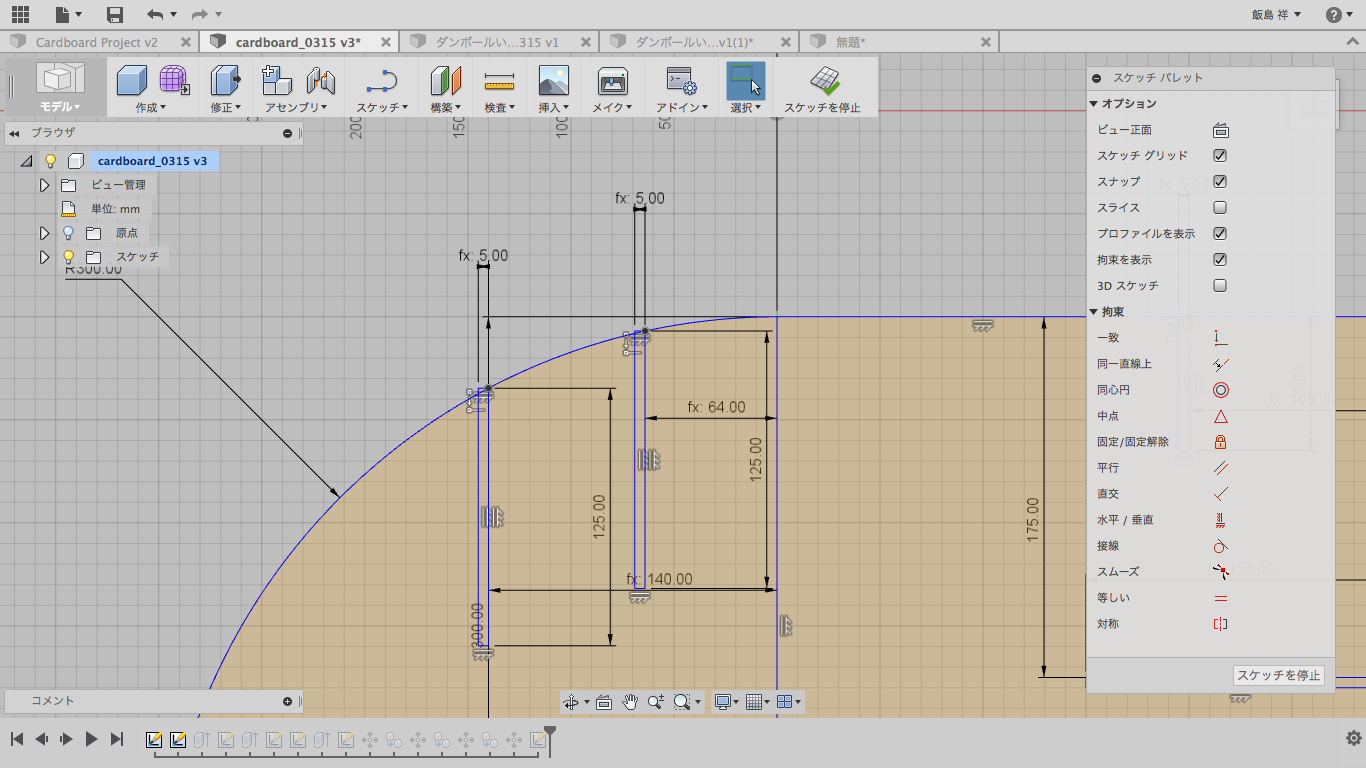

At first, I made this data for this class. This is a desk made of cardboards.

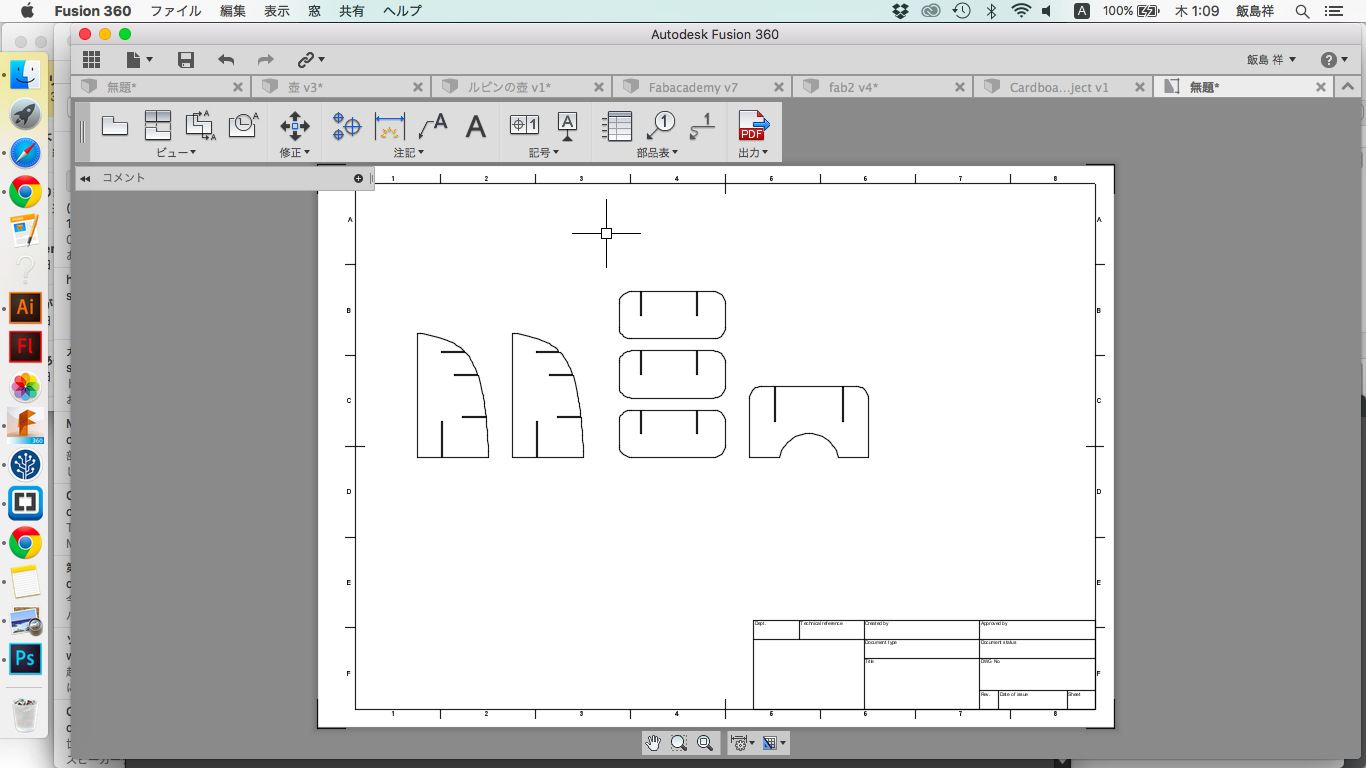

After that I chose a command to output a drawing

That is how I output a drawing for lase cutting.

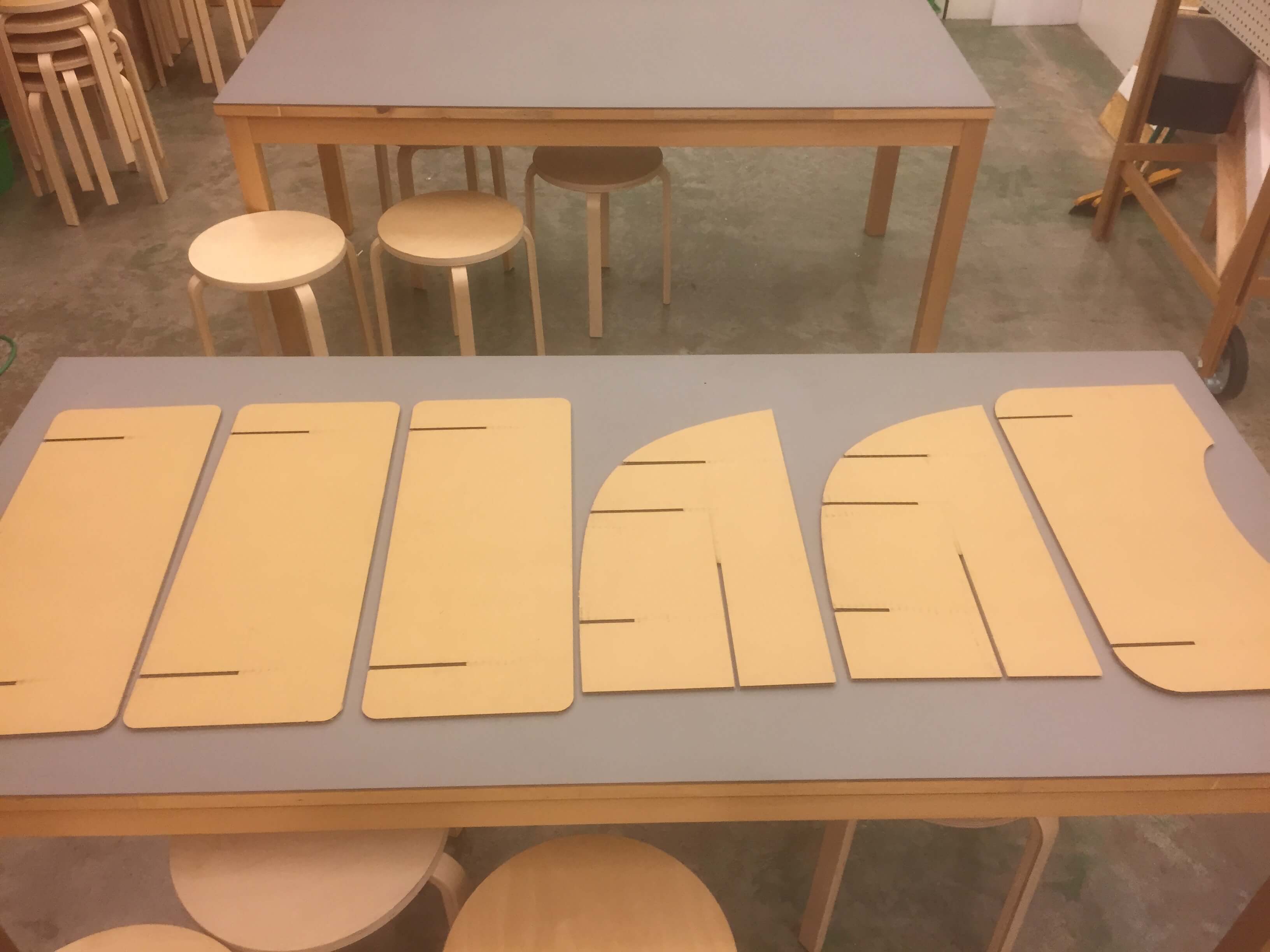

These are parts I made of cardboard using laser cutter.

The parameter is 80W power:23 speed:0.5 freq:1000 hz.

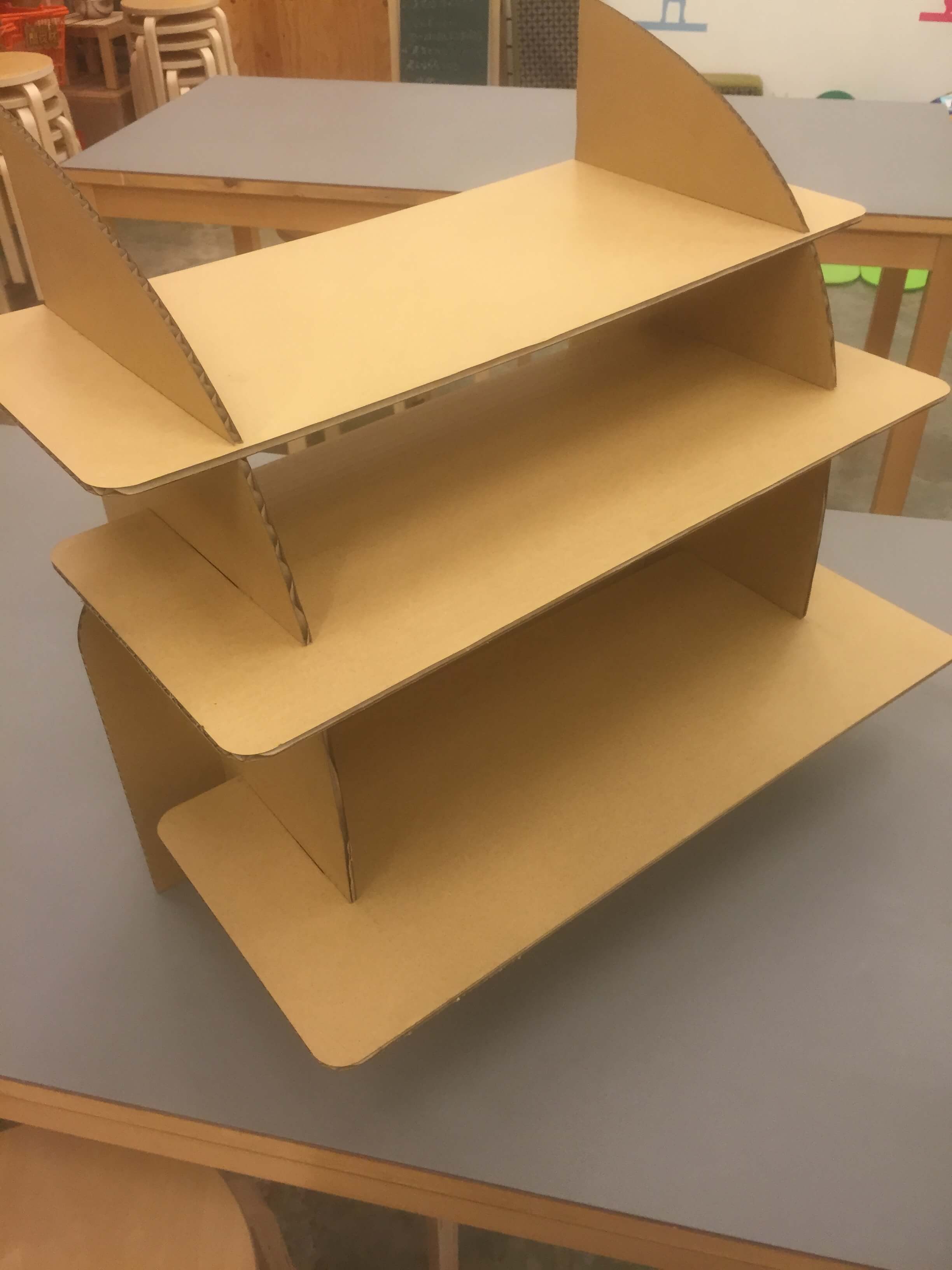

After combining them, this product looks like this.

Not only that, you can insert some cardboard and cordinate how it looks.

These are same parts and reversible.

Parametric design

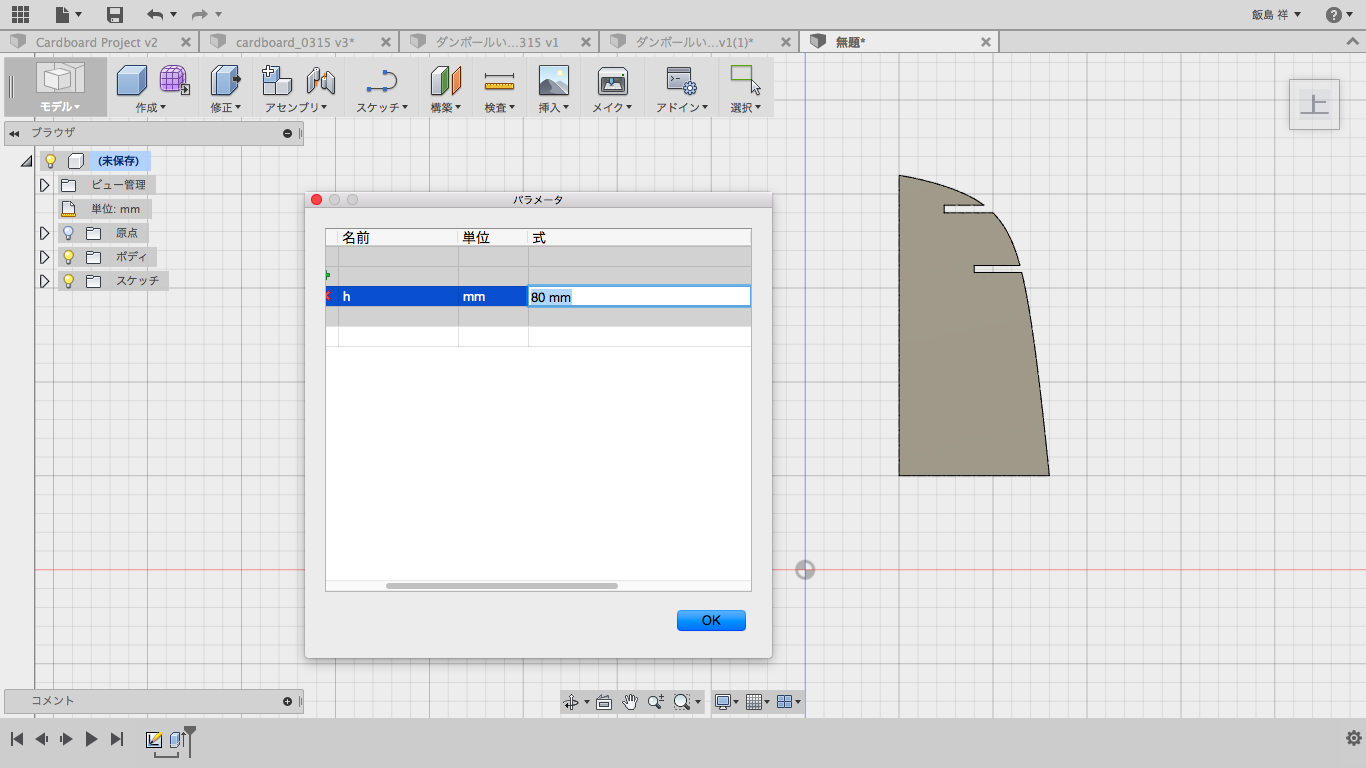

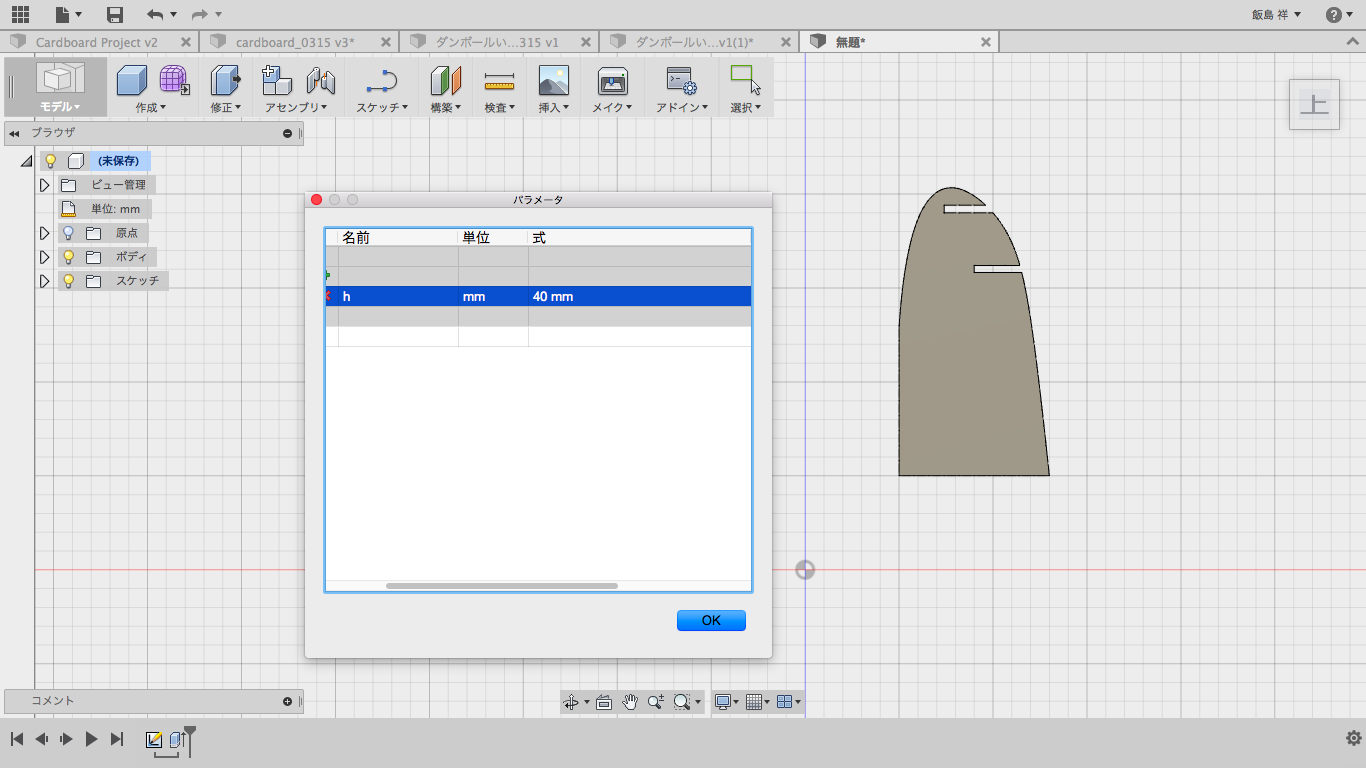

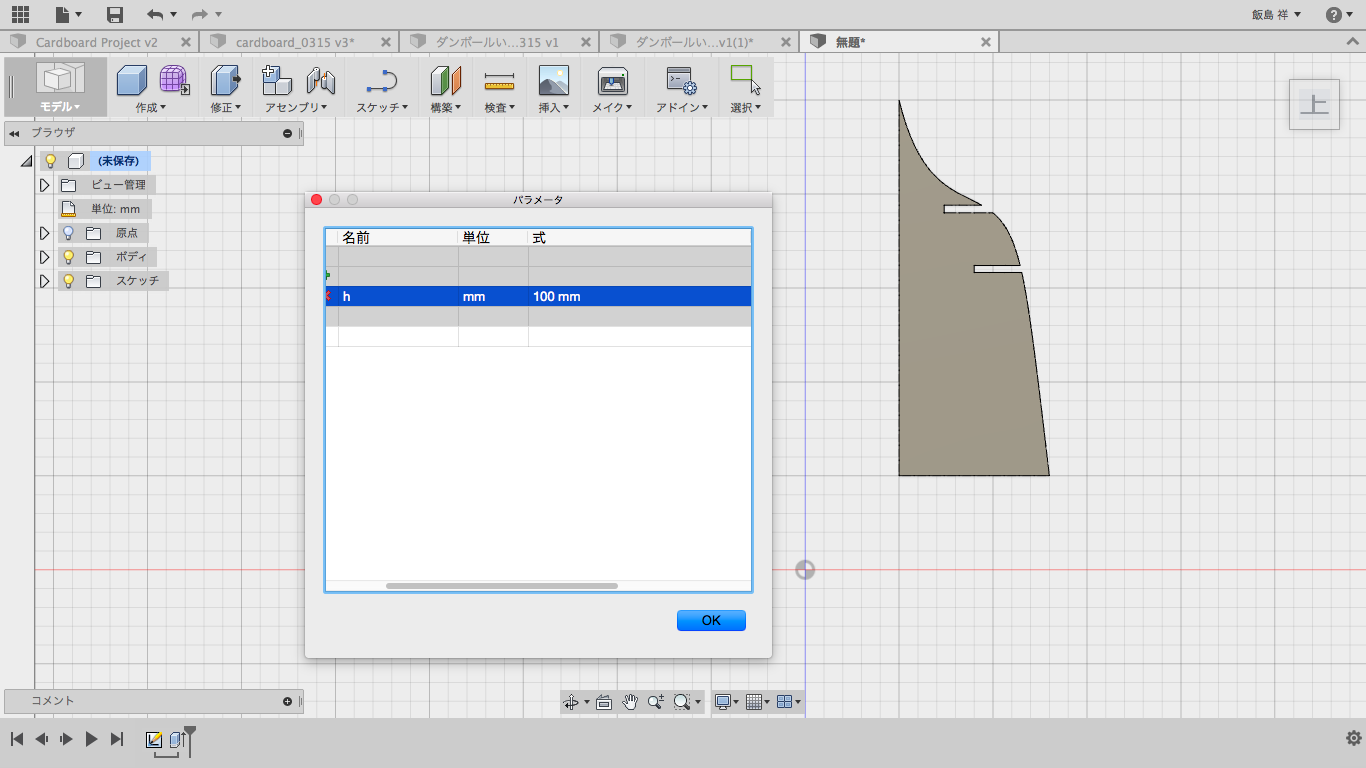

But this data can't be changed easily.In order to change how it looks, I need to make new data.

And I decided to make this using parametric data.

For example, if you plot the dot without any information about distance, the figure of the design changes as you change the other parameter.

That is why I did not use the left one this time.

For the first time the data is made of only information about distance, the data can be changed correctly according to parameter.

Now I could design the desk which we can change hight and the place of the plate so easily!

download ai files

Cutting machine

I belong to a nano micro medical engineering labolatory, and I cut the sheet like the logo of our labolatory.I used graphtech CE6000-60 for a cutting machine.

download ai files download jpeg files