Week - 12 Molding and Casting(APRIL 20)

ASSIGNMENT

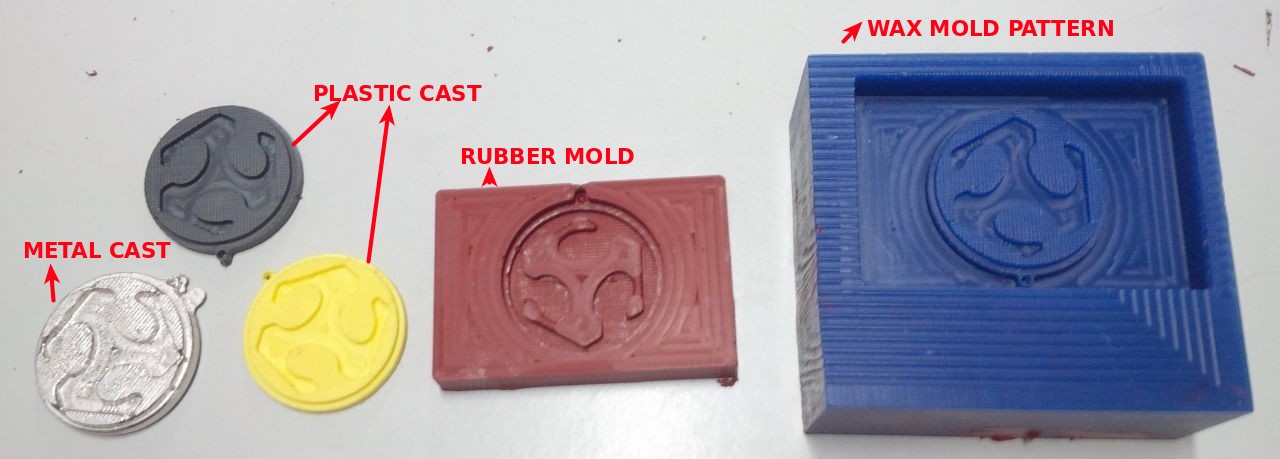

Design a 3D mold, machine it, and cast parts from it,for this assigment I decided to make a fablab logo locket(wish to wear it) .

Designining the mold: I used Solid work to design the mold.I started out by reffering Solid work tutoria,here is the link

I watched some online tutorials on how to use the mold design tools that are built into Solidworks. They seemed to be intended for creating platens with draft angles for plastic injection molding machines. I decided just to design the molds "manually" using SolidWorks. I figured all I would need to do is subtract the part from a block to come up with the mold design. Turns out that I needed to make a mold for a mold. This quickly can become very confusing. I needed to design a machinable wax mold that would create a flexible urethane rubber mold that I could use to cast my desired part.

Designing

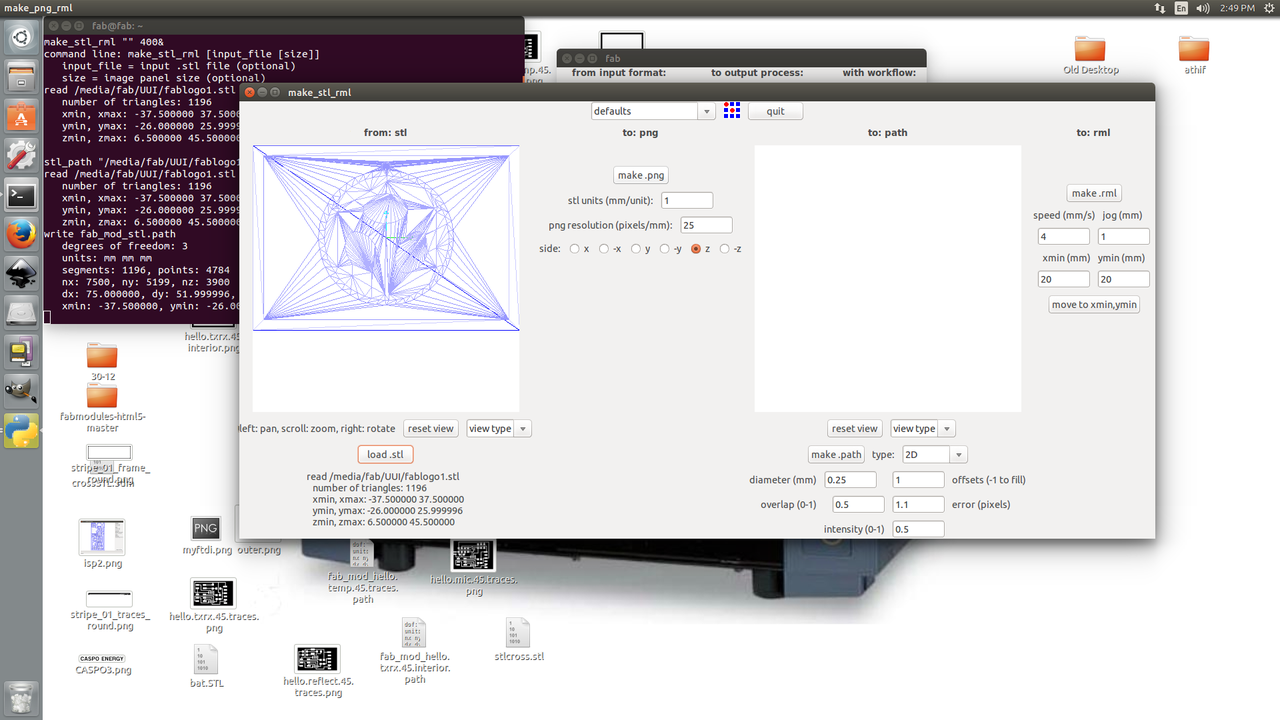

Perspective view of the pattern which i created in solid works and saved as stl file.

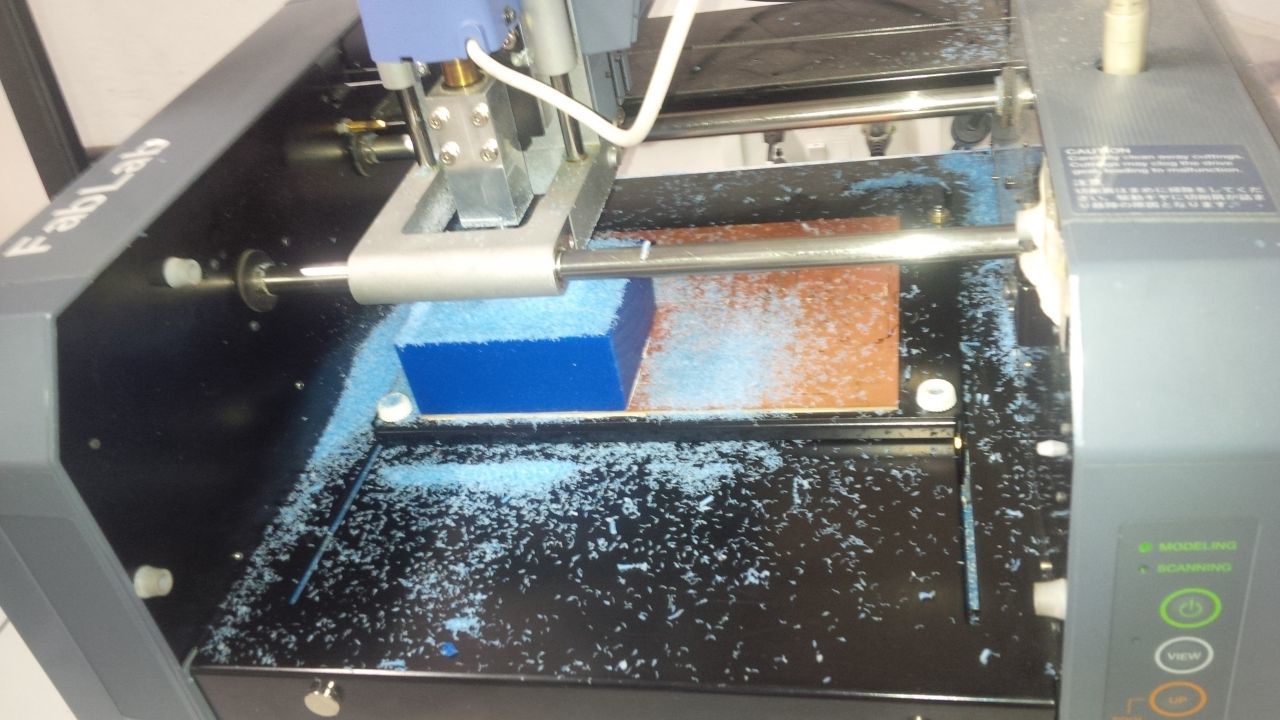

This is what i designed to make a mold for fab academy locket ,With the desired part in mind, SolidWorks used to design the machinable wax molds. This software made possible to visualize my desired locket model wax molds in 3D. Next step was preparing the wax block for the milling,for that gave stl file as input and milled with the Rolonad Modela MDX-20

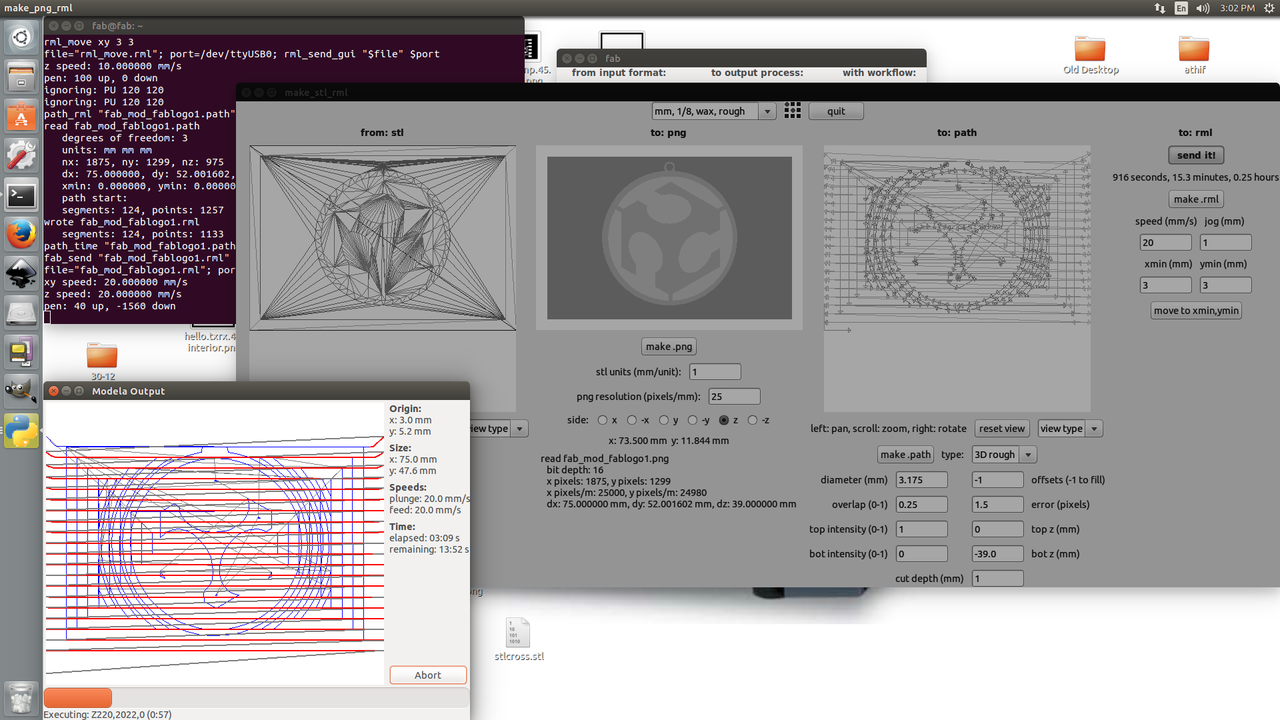

Rough milling

I did a rough cut, and a second finishing job, I used a 1/8 (3.175 mm) ball end mill for the rough cut,used the presets from fab modules for the rough cut with a 1/8 end mill. These presets are actually for a flat end mill, so in my case a little more material was left after the rough cut, since it doesn't take away wax in the corners like a flat end mill would do. so as a finishing job i did a fine milling ,used 1/16(1.6mm) for fine milling.

Fine milling

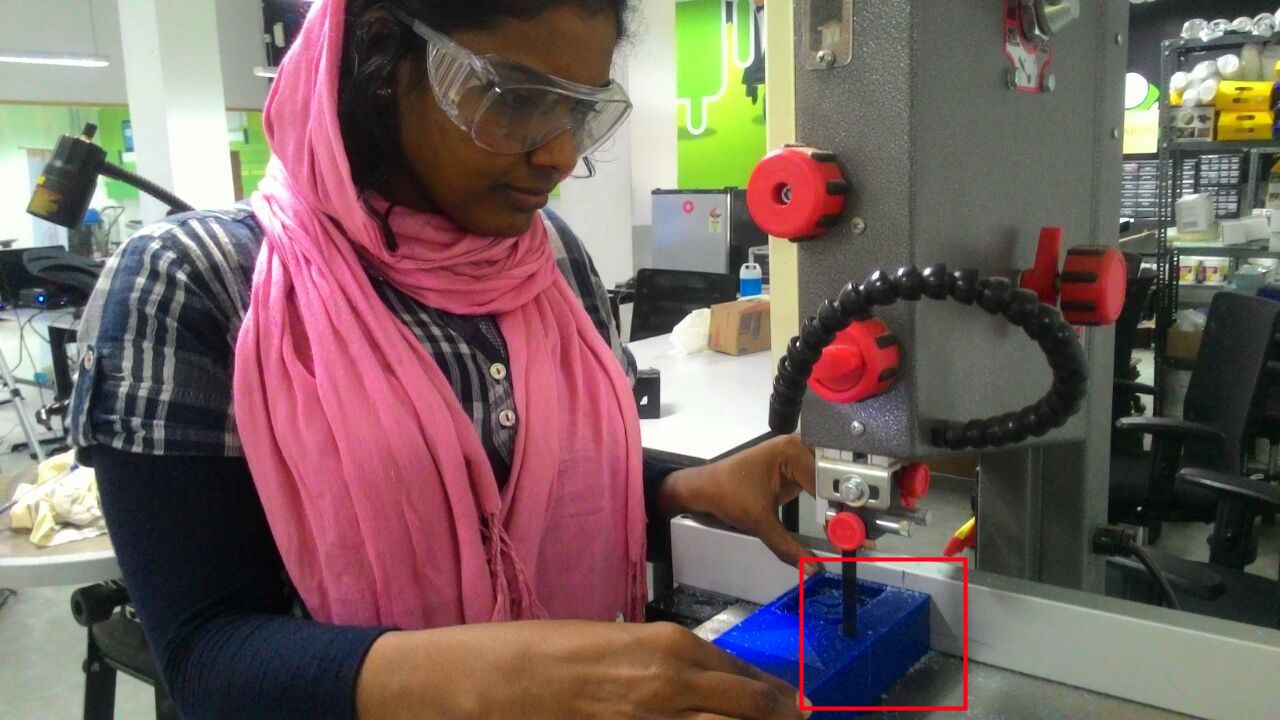

Cutting desired piece of waxmold using bandsaw .

final form of the waxmold

Preparing Rubber mould

Main steps when we are presparing a rubber mold to make a cast of our desired model.

Liquid Rubber Moulding :-

PREPARATION

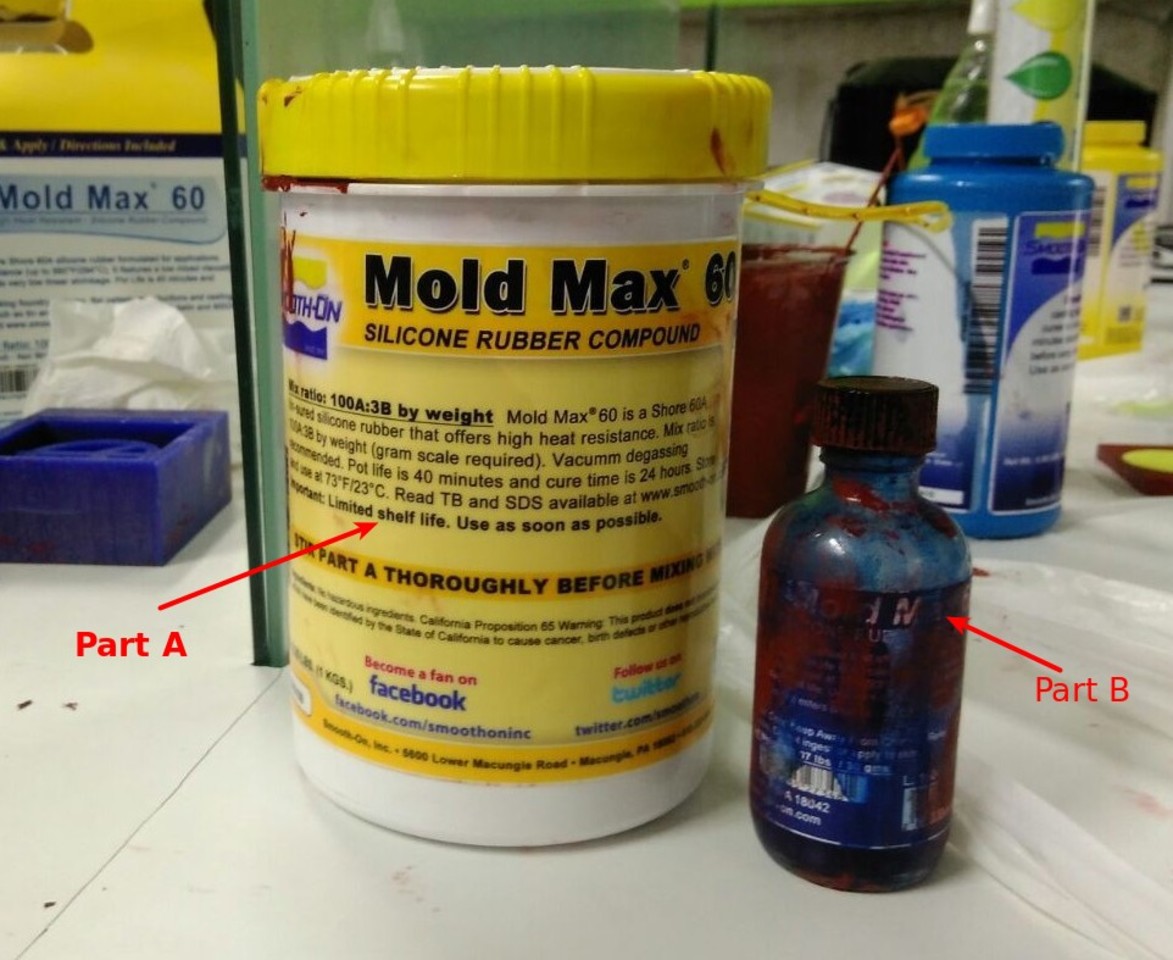

Silicon rubber mold is heat resistant mold,to create this mold used Mold Max 60 high heat resistant silicon rubber compound. .

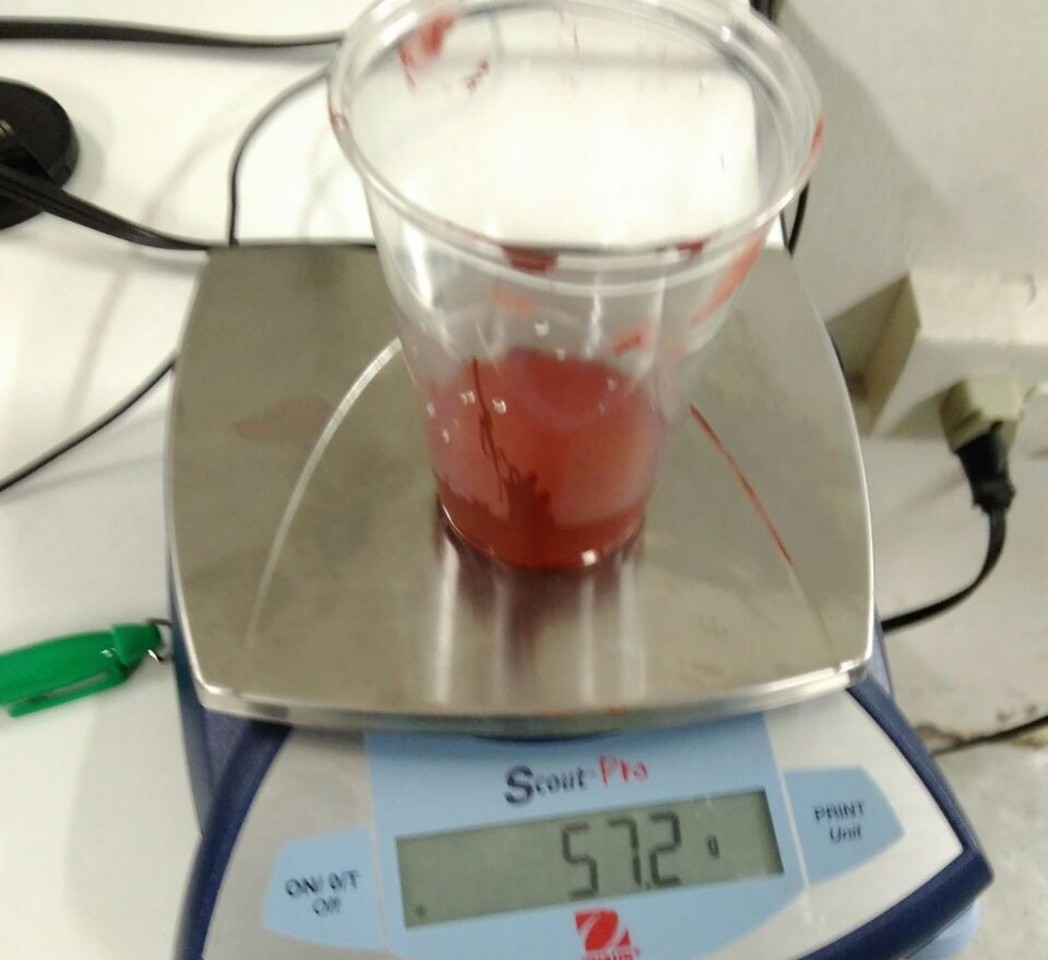

MEASURING & MIXING

First off all i wanted to know volume of the vax mold,for that filled the mold with water,after it got completely filled,transffered same amount of water in to a glass and marked the volume level using a skech pen. then take silicon rubber till that mark.there are two parts A and B,The ratio to be mixed is 100A to 3B by weight.

Now i know the exact volume of required mold cavity ,filled part A till the marked level and measured the wait using load cell.After that mixed Part B(3:100),that means 3 percentage of part A weight,the stirred thouroghly before it get hardened.

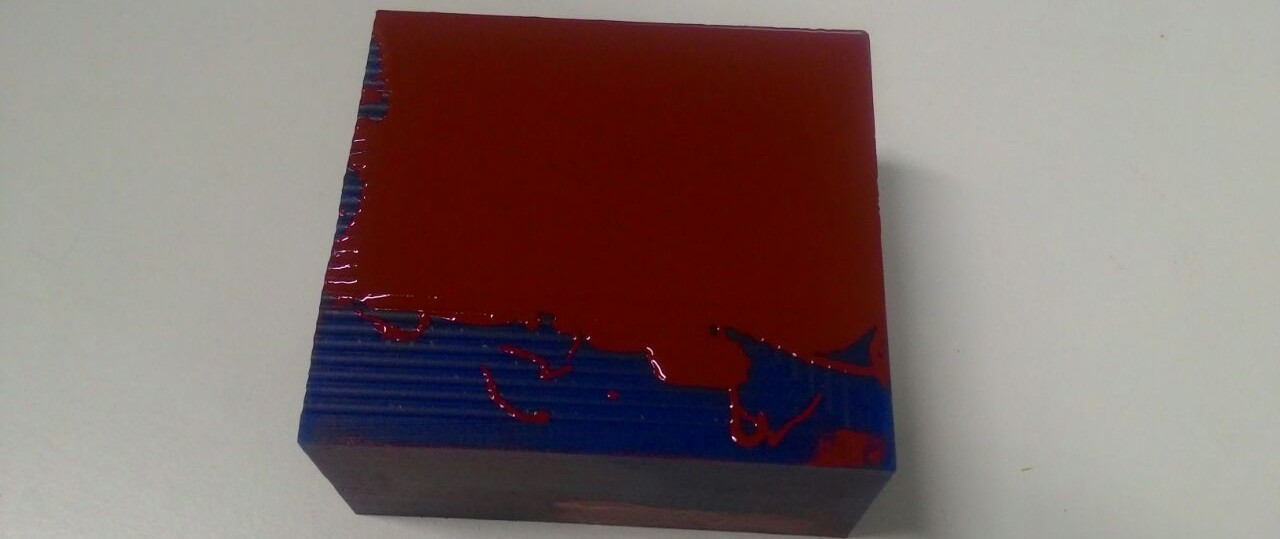

POURING, CURING & PERFORMANCE

After stirring,next step was pouring to Wax mold,used Toungh depresser,

Full Curing time =24 hours,here it took 17 hours to cure

Casting-Plastic and Metal Products

Plastic Locket Casting

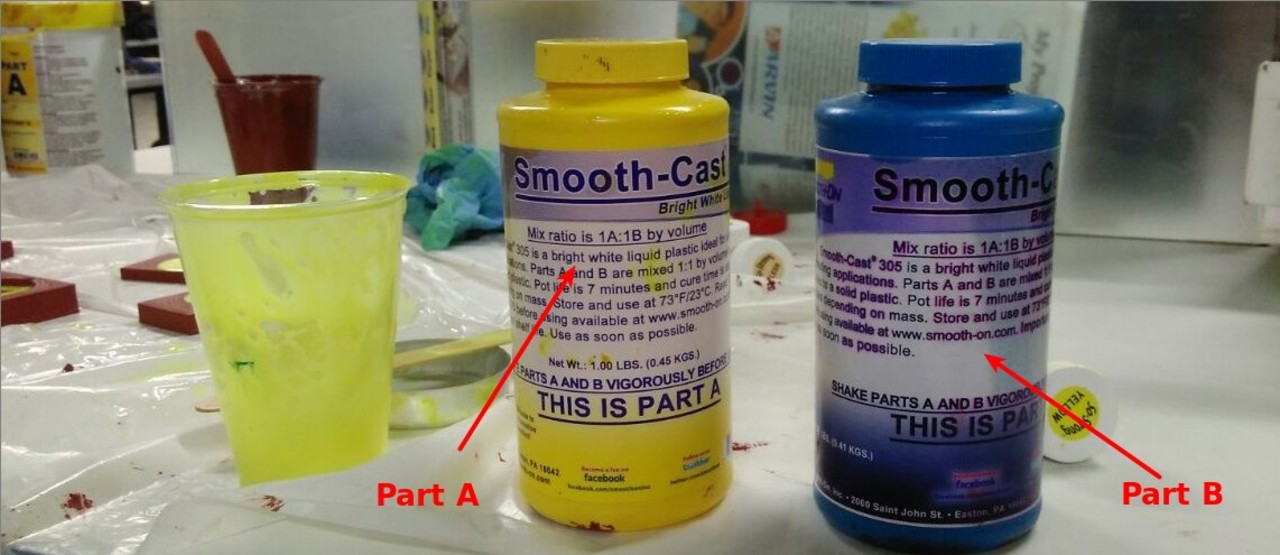

To make a plastic locket used Smooth cast-305 liquid plastic (Part A,Part B ) mixed 1:1 ratio,added yellow stainer (1 drop) to get yellow colour locket,

poured to mold,curing time just 30 minuts.

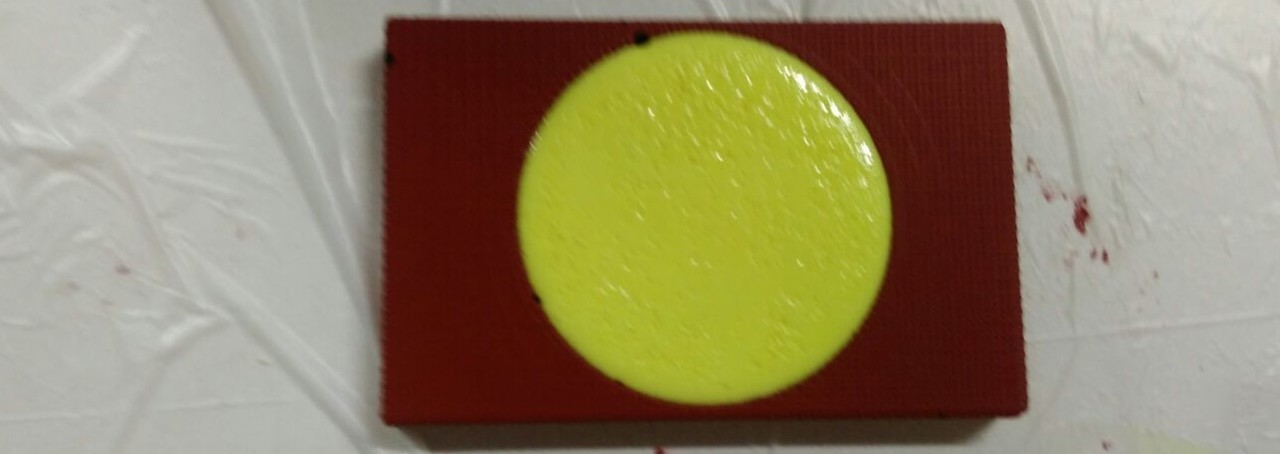

Final product-Plastic locket

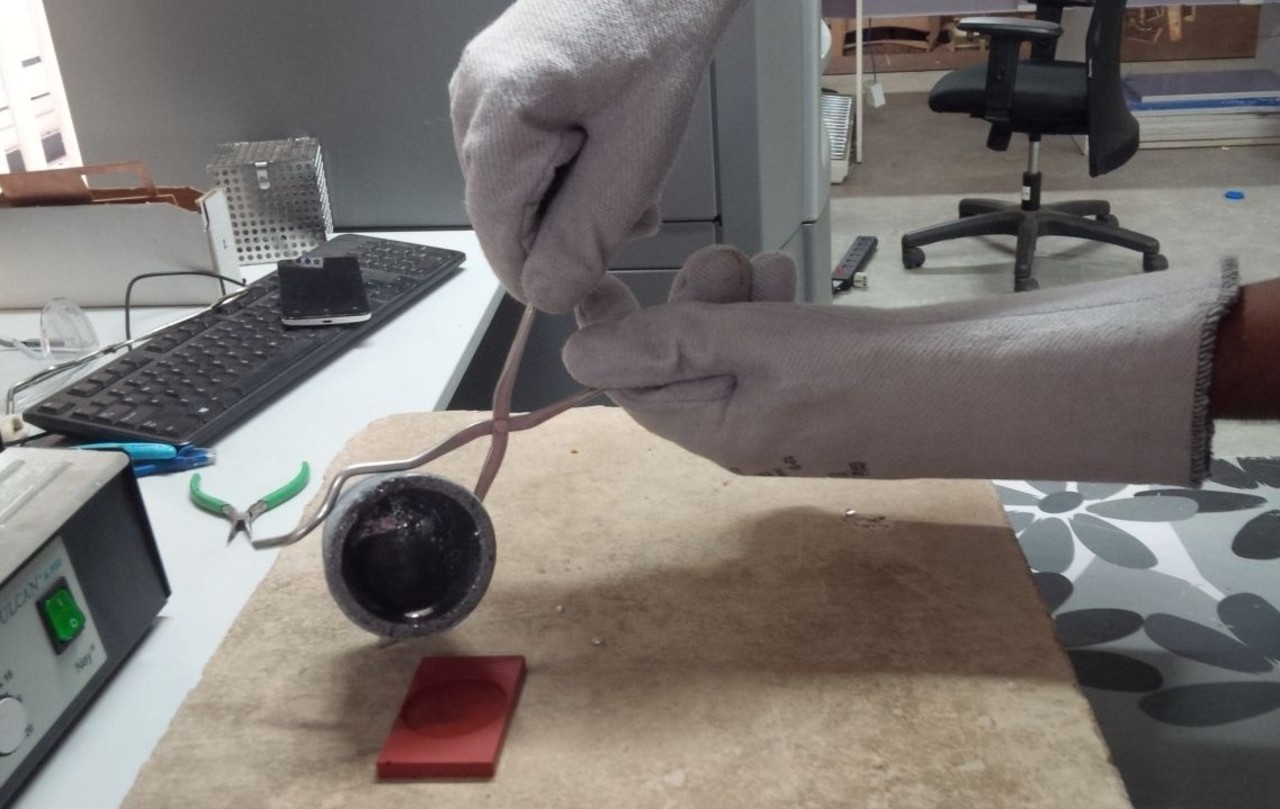

Metal locket Casting

To make a metal locket used

- Lead as meterial

- Furnace (set temperature 500 F,because Lead melting point is 500 F)

- leather gloves

- goggles in case of splashing

- big tweezers to pick out from furnace

Lead Bar

Furnace

Temperature setting.

Pouring melted meterial to Heat resistant silicon Rubber mold

Curing process,took less than 2 minut .

Final plastic locket.