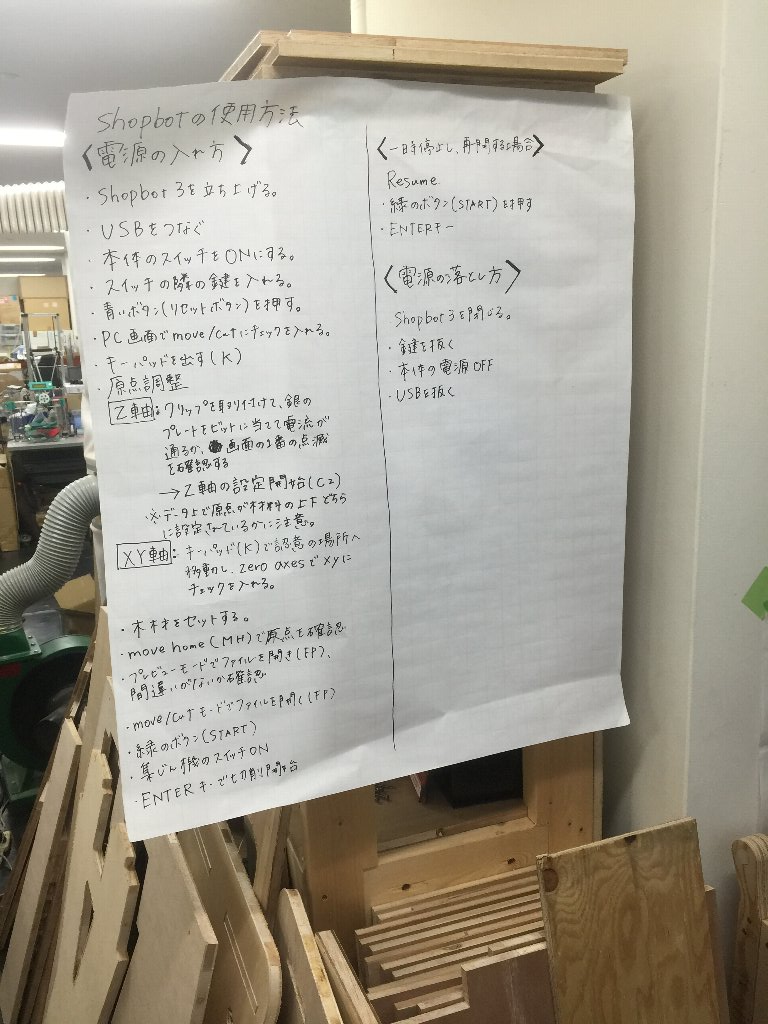

Save the data to Shopbot for PC.

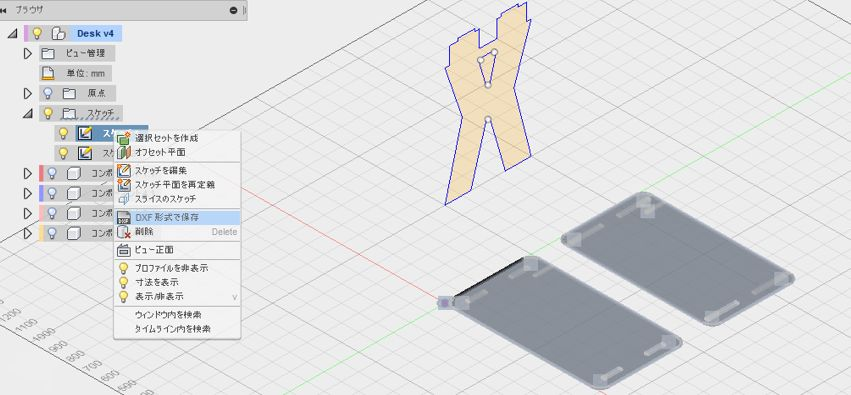

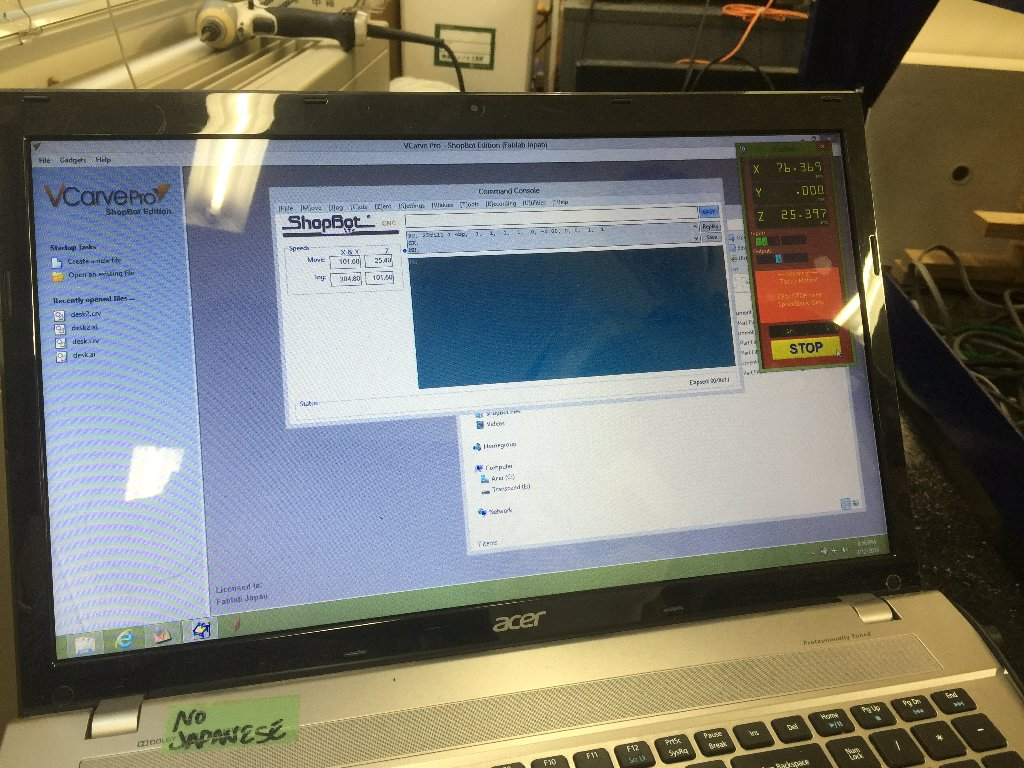

Open the data by "VCarve pro".

This aprication can put setting for excavation.

I input some infomation

Plate size, start point, depth and tabs.

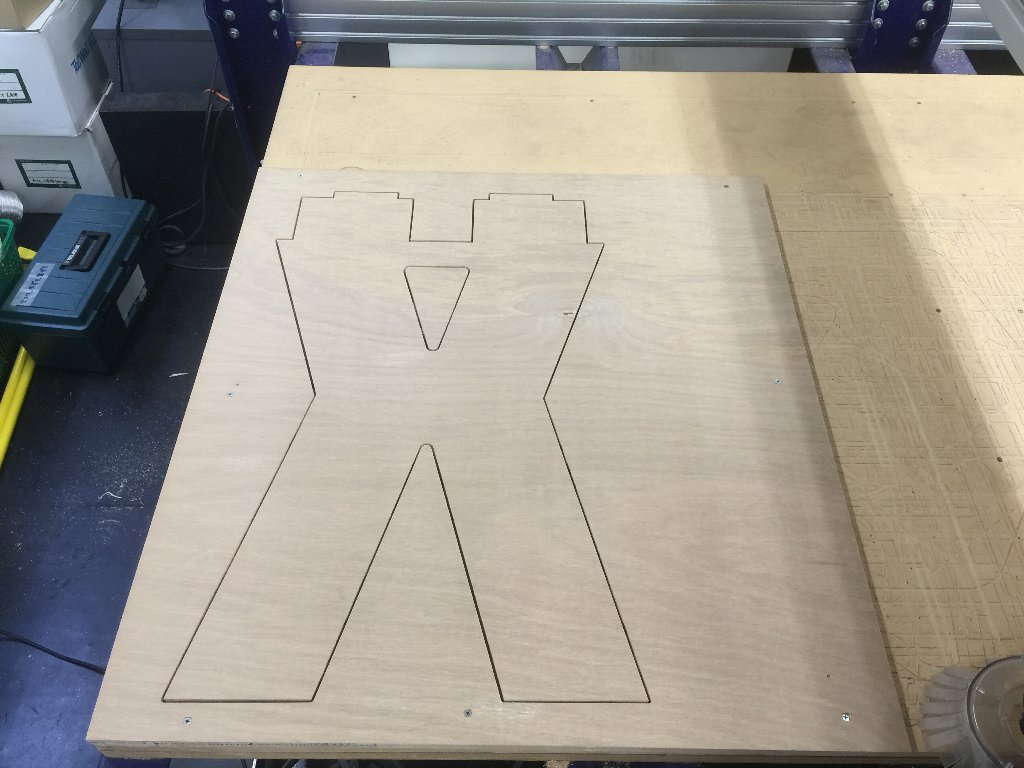

Made holes to fix the board.

These are small holes outside.

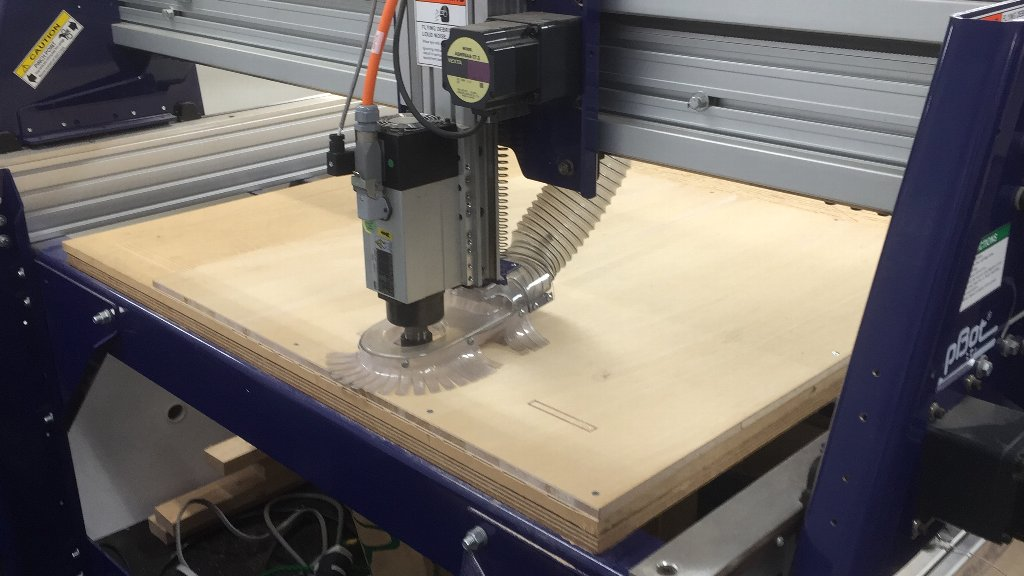

Important!

Tab and fix the board need for excavation.

Shopbot use mill. If you havn't make Tabs. some parts will blow.

if it hit to guys, you injured.

Excavated items

It has created a cable inlet.

But Mill was digging inside. Uncut area was remained.

I guess it need to make slitly large hole.

Setting of thick is 15mm.

The part of connectivity were cut by this value.

It was not able to insert to this hole.

When you create a structure to fit the plate, it is better to set a large cut width about 1mm.

Finished product

Power board can be put in desk.

Reference