Hardware

In this exercise, we will be milling a PCB with a

Carvey mini-mill.

Software

In this execise, we will use

Easel software from Inventables. Easel is an in browser program.

Method 1: Using Easel as the GCODE Creator and sender:

Download or create your trace image.

Easel uses svg files for 2D images. Use Inkscape(or equivalent) vector software to convert

raster image to vector image.

Import svg file to Easel.

Choose the cutting depth((0.015")

CARVE it.

Method 2: Using FabModules as the GCODE Creator and Easel as the Sender:

Create the SVG or PNG image

Open up the file at fabmodules.org and select GCODE as the output.

(As of right now, there is not an ouput for Carvey. I will work on that. In order for the code to work, we need

to make sure the carving area is not under the smart clamp area. We need to change the initialization commands.

I have done these with a simple search and replace from textEdit. I shifted all X and Y coordinates by 1 inch.

I swapped out G0 for the G00 in the code, G1 for G01, and the front header changed.

Save the gcode file.

Edit the gcode file.

Open the gcode in Easel.

Set the proper settings(PCB, 1.7 mm Height. Depth of Cut 0.4 mm

Set up Carvey.

CARVE!

Future Task:Use another GCode sender such as ChiliPeppr.

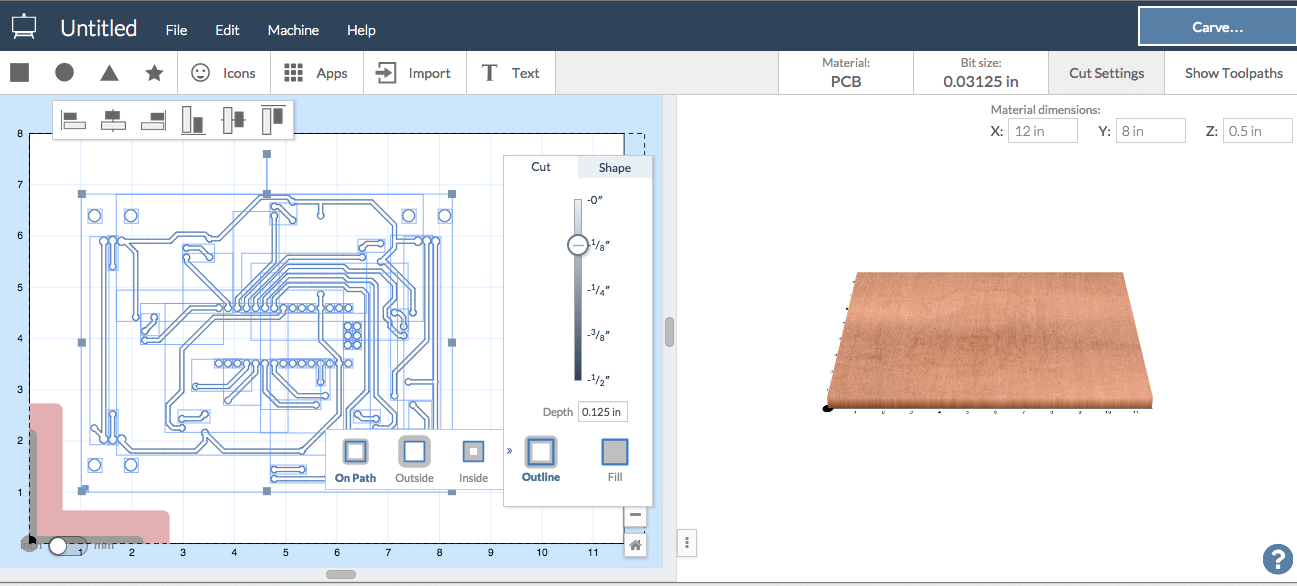

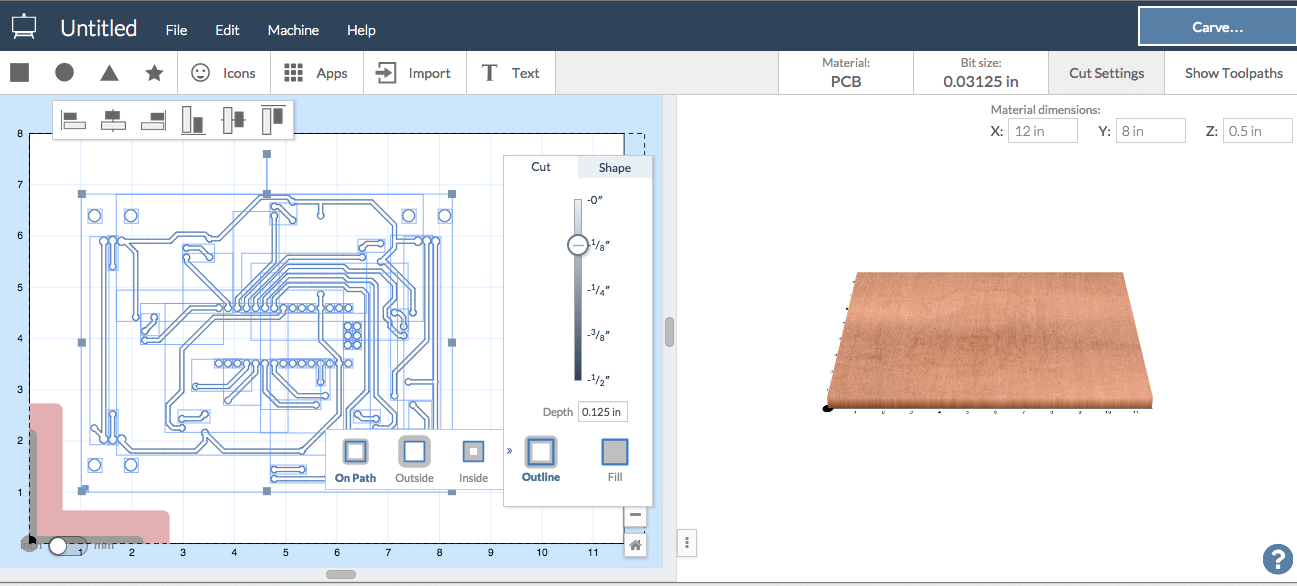

This is the Easel software page. Select the Machine(Carvey). Select the bit size.

Upload an SVG image.

This is the board after importing an image. Select Outline in the table. Select Carve.

I have not had great cuts using the Outline. I prefer using FabModules to do this.

The Fill cuts(removes everything but the trace) looks nice when done.

Reflection

The software(Easel) is simple to use. It is easy to import an image and cut it. It is easy to

import in circuit boards.

The Carvey should have no problem being used with FabModules. Will investigate during the session on

precision milling in two weeks.

The other thing I need to work on is designing the circuit. I have used some of the software, but I should

get more experience laying out the board.

This is the Easel software page. Select the Machine(Carvey). Select the bit size.

Upload an SVG image.

This is the Easel software page. Select the Machine(Carvey). Select the bit size.

Upload an SVG image.