Project Designing

The project design is devided into:

- CAD Design

- PCBs Design

CAD Design

I used Solidworks for designing all the project CAD files.

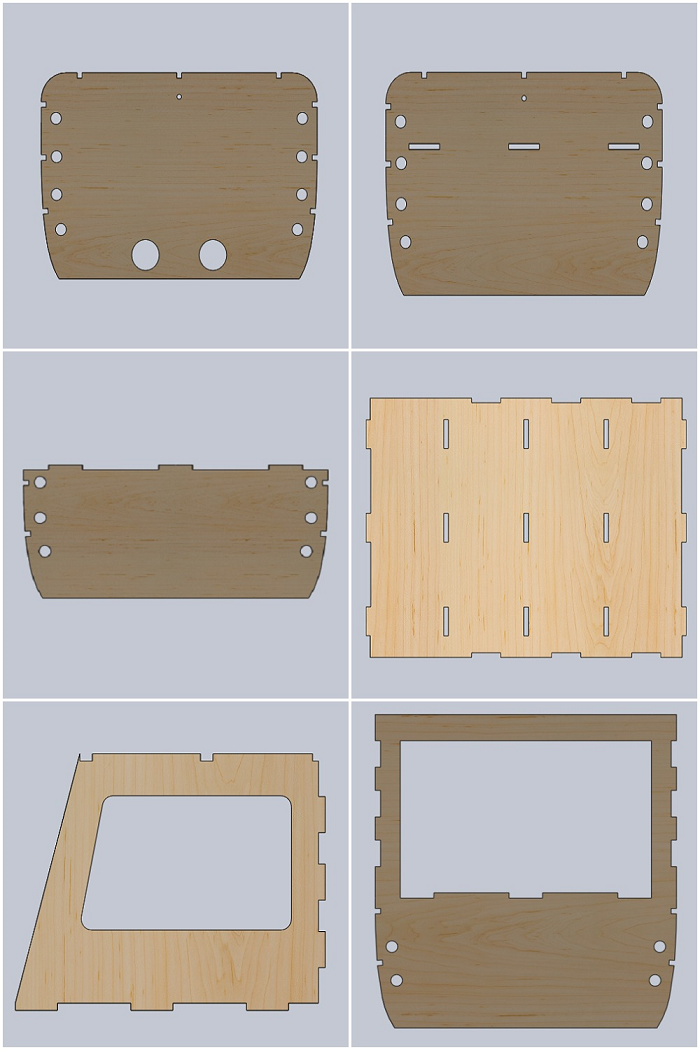

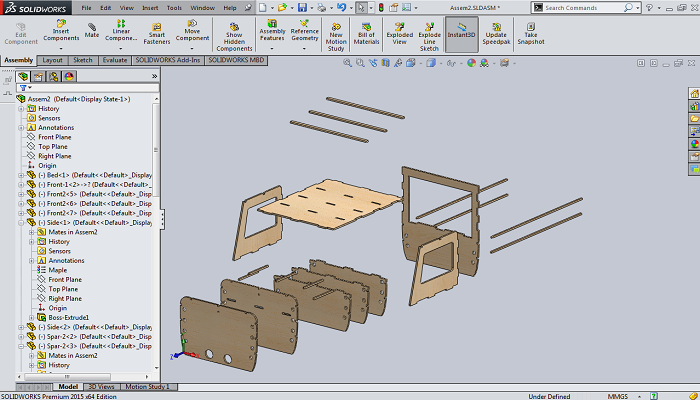

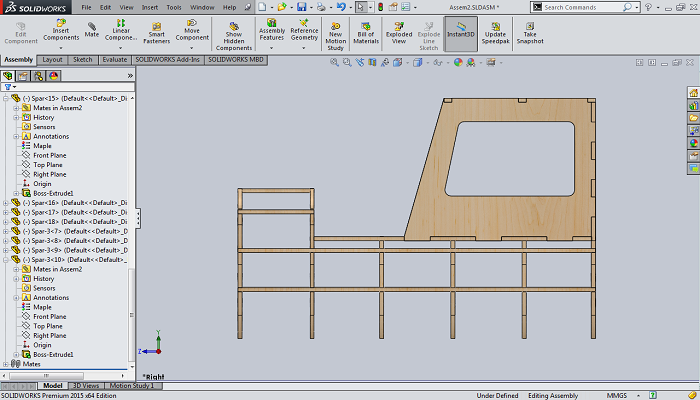

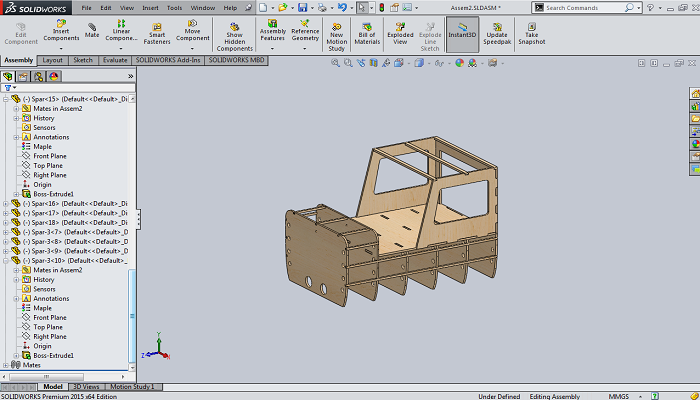

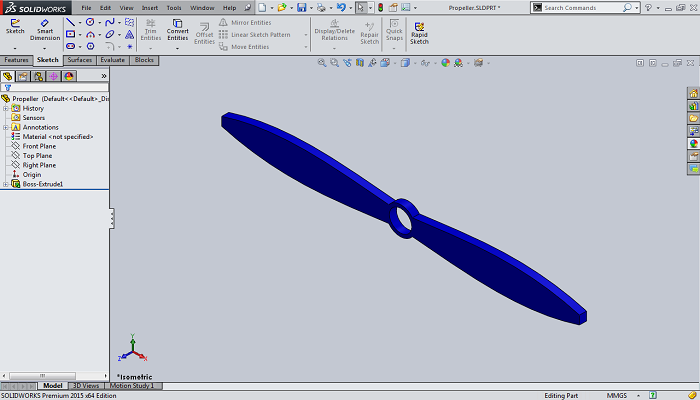

1- The Shell and Propeller

One of the main objective of the project is to be easy to assemble, so I design the shell to be assembled as a press fit kit.

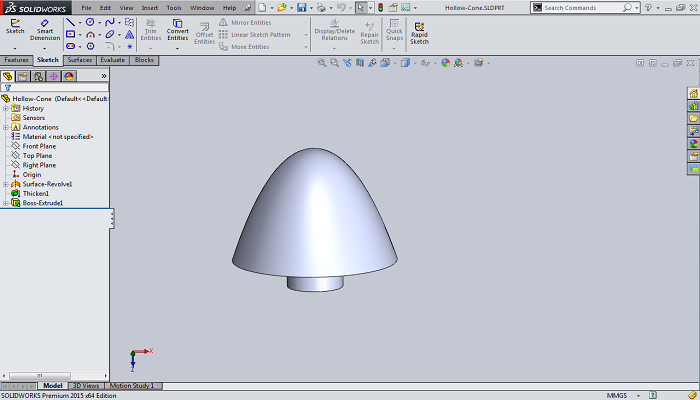

2- The Cone Nose

First I was palnning to 3d print the nose so I made this design, but I found out it will take about(200 gm) of PLA and will be printed in (13 hrs).

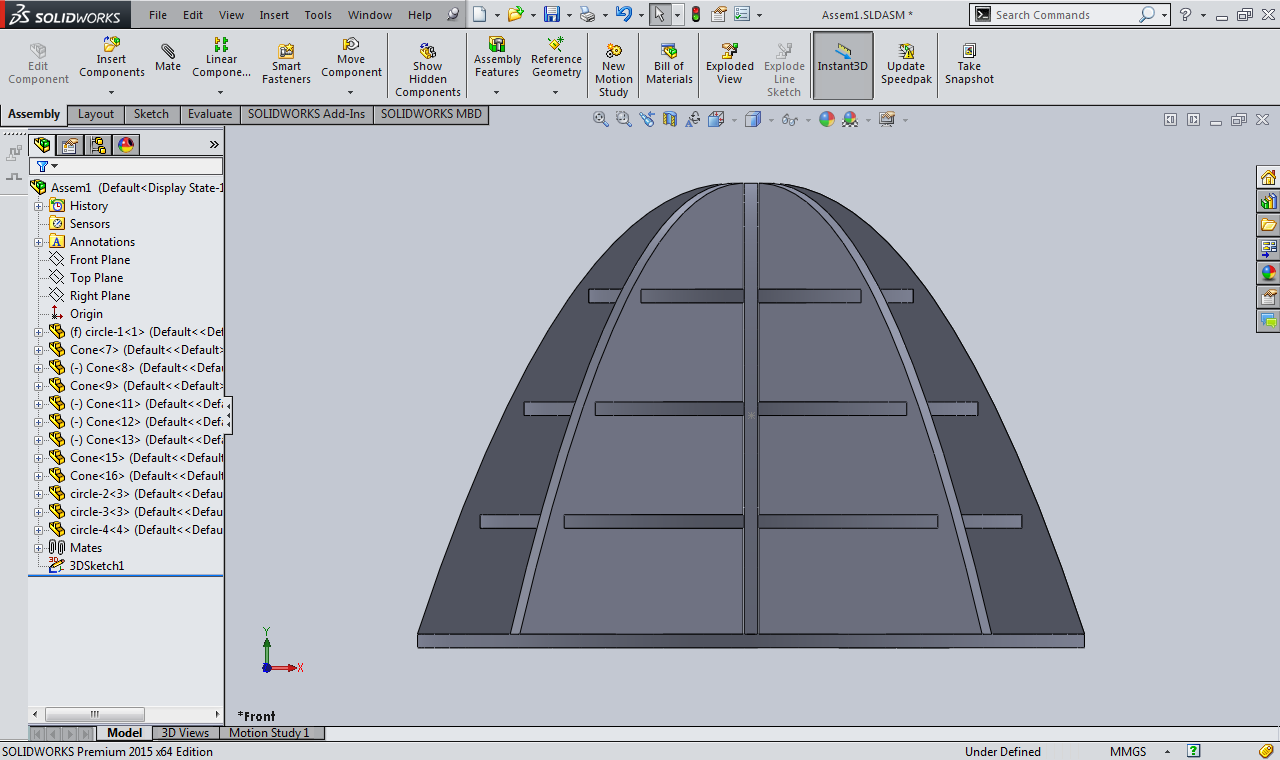

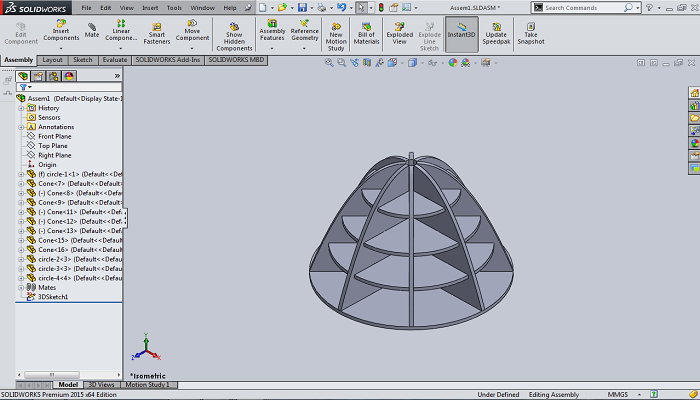

Then I redesigned the nose to be laser cut and be assembled using the press fit technique.

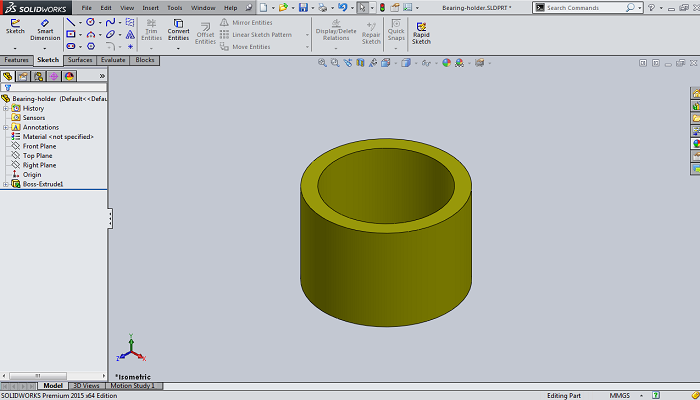

3- Mounted Ball Bearing

The mounted will be made from PLA using 3D printer. The ball bearing will be mounted inside it, and the propeller will be mounted from outside

PCBs Design

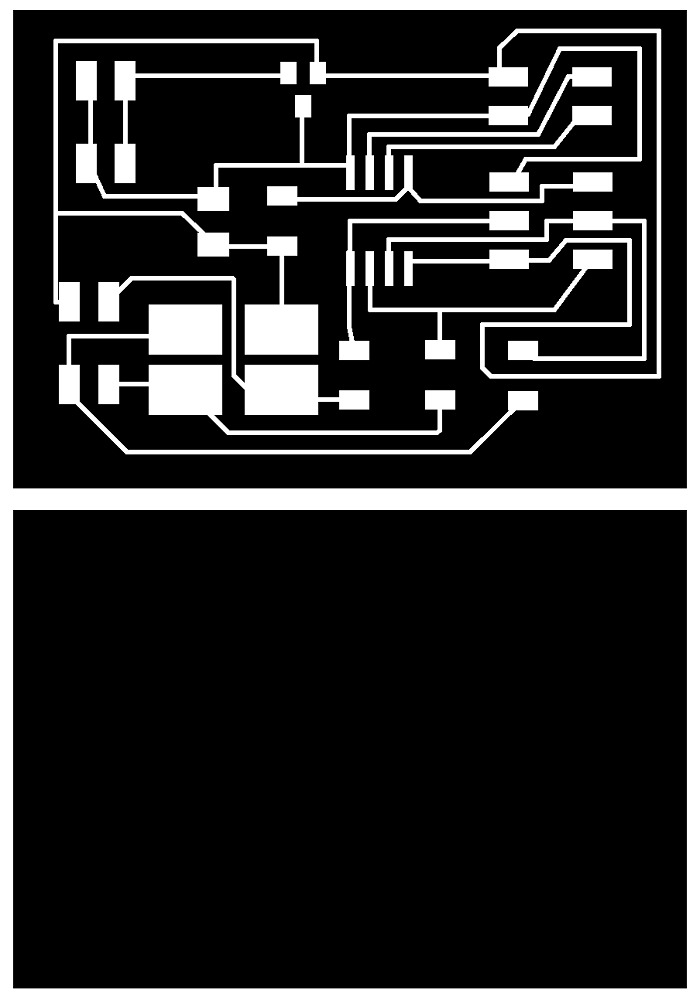

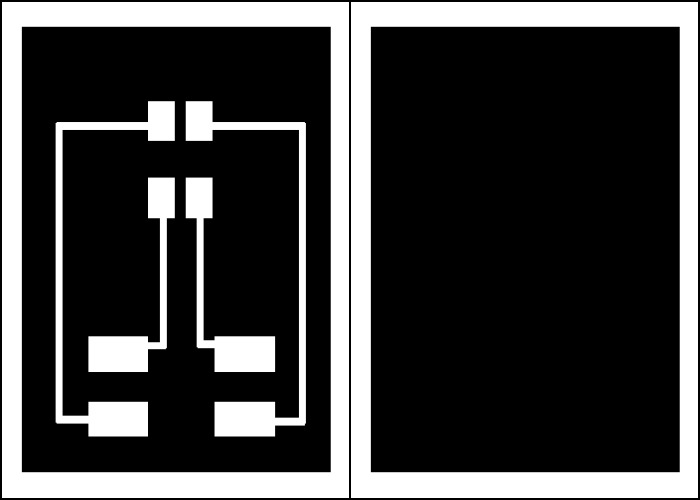

1- Bridge PCB

I wanted to add some light effects to the bed so I start from Niel's board hello.RGB.45 , and used Eagle to modify it to design my bridge board.

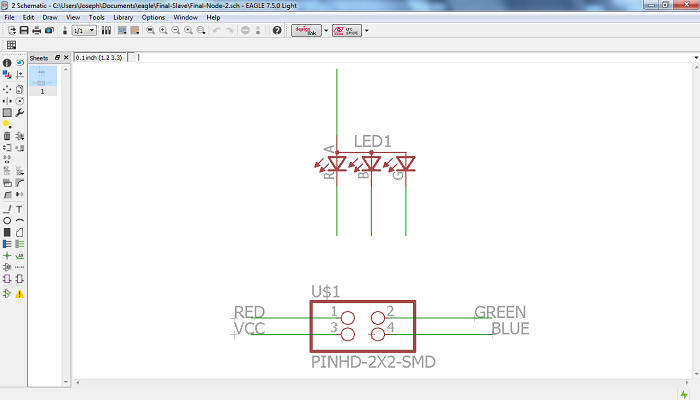

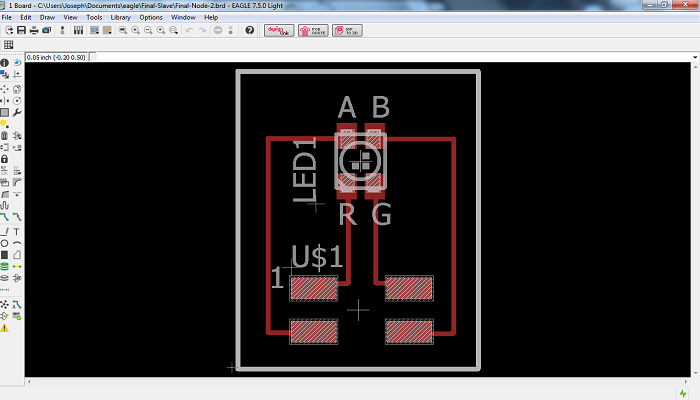

2- Node PCB

Then I designed this node board to take signals from bridge board.

Files

This work by Joseph Gourgy is licensed under a Creative Commons Attribution-NonCommercial 4.0 International License.