* Design and make a 3D mold (~ft2), and produce a fiber composite part in it.

Assignment:

* Design and make a 3D mold (~ft2), and produce a fiber composite part in it.

I have been thinking for a long time in getting a tool case for all my electronics staff, so for this assignment I decided to do it!

I made the model in Solidworks:

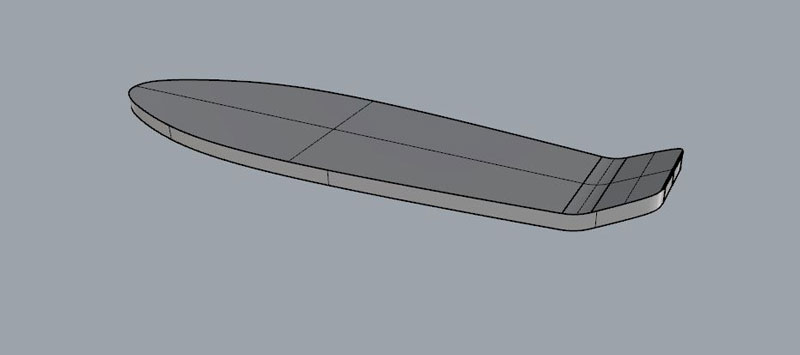

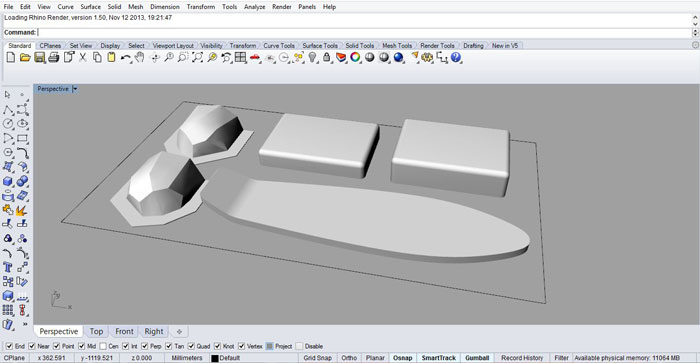

We made the model of the skateboard in Rhino:

We shared the milling file with Cit and Andreas so I exported the model as an stl file and inported it in Rhino.

I wanted to test with different finishes, I used as fiber the Burlap, after this layer I put a layer of a journal from barcelona:

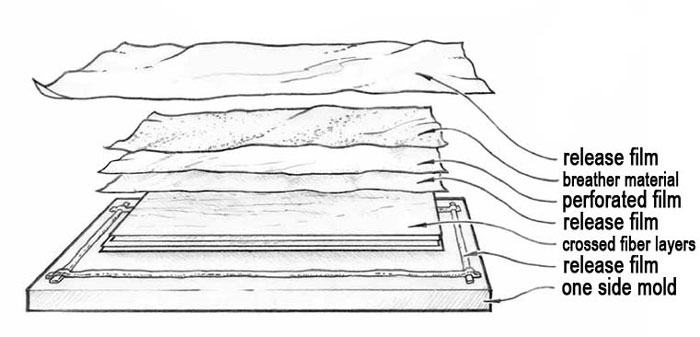

LAYERS:

MATERIALS:

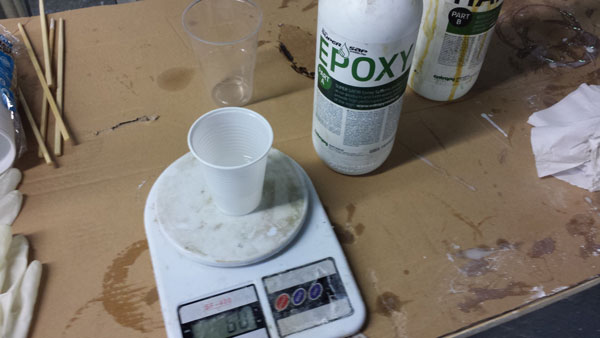

Part A (100):

Part B (47):

VACUUM:

I have put the test in the vacuum for about 8hs:

I liked it!

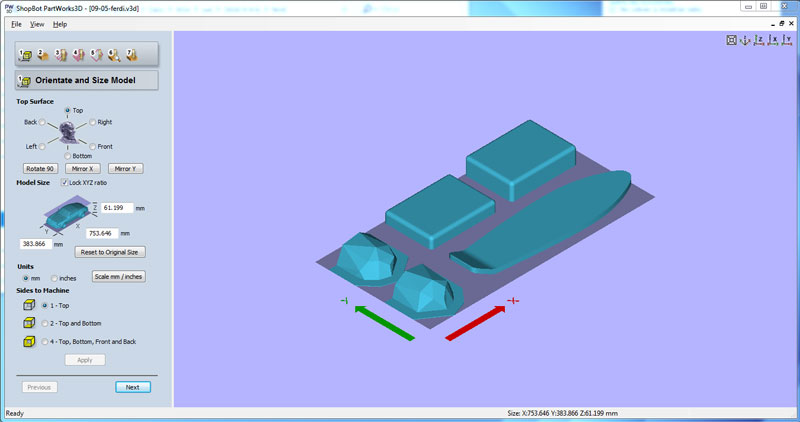

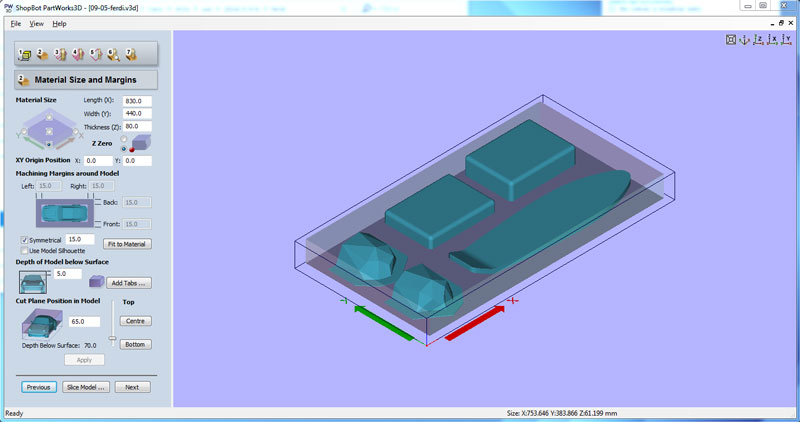

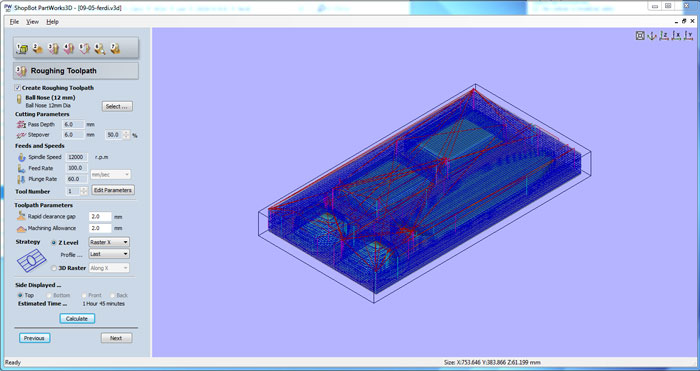

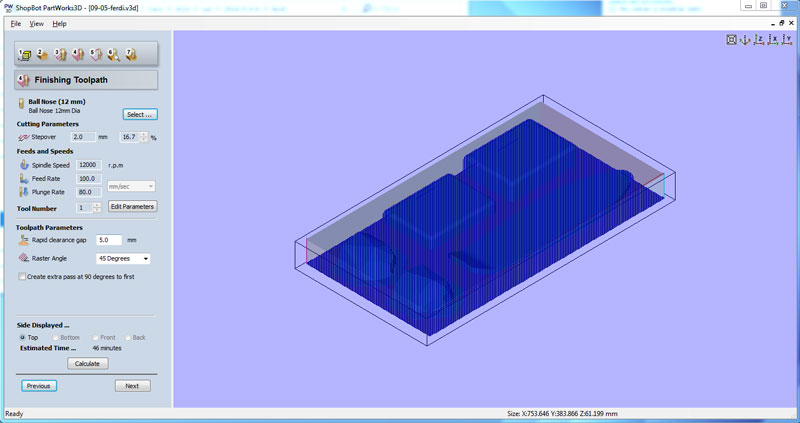

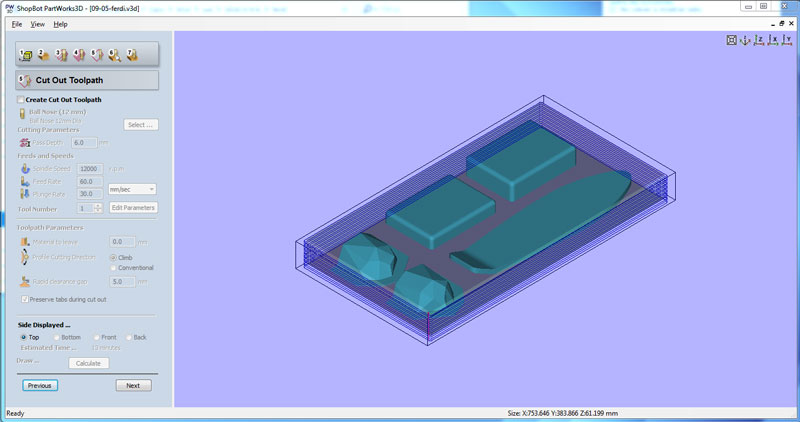

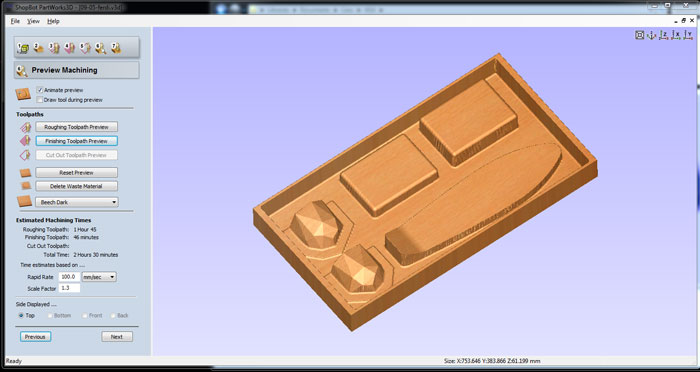

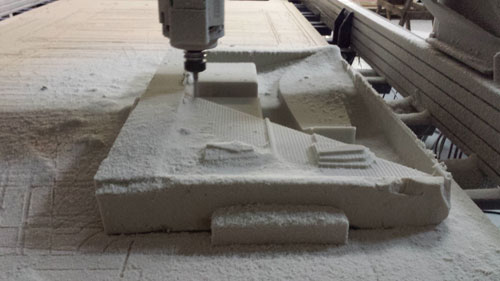

For generating the G-code we used Partworks3d software:

Values that we used:

We looked for a piece of foam for all of us:

composites from carovignoli on Vimeo.

Once I had the mold made I was able to do the composites, so I repeated the process for the test:

LAYERS:

In the layer 03 I finally used a white fabric instead of the burlap because I wanted a different finish.

FINALLY!