Week.14 Composite

Concept - Aperitive Electronik!

The idea consist to produce a and aperitie dish for finger food and wine glass support

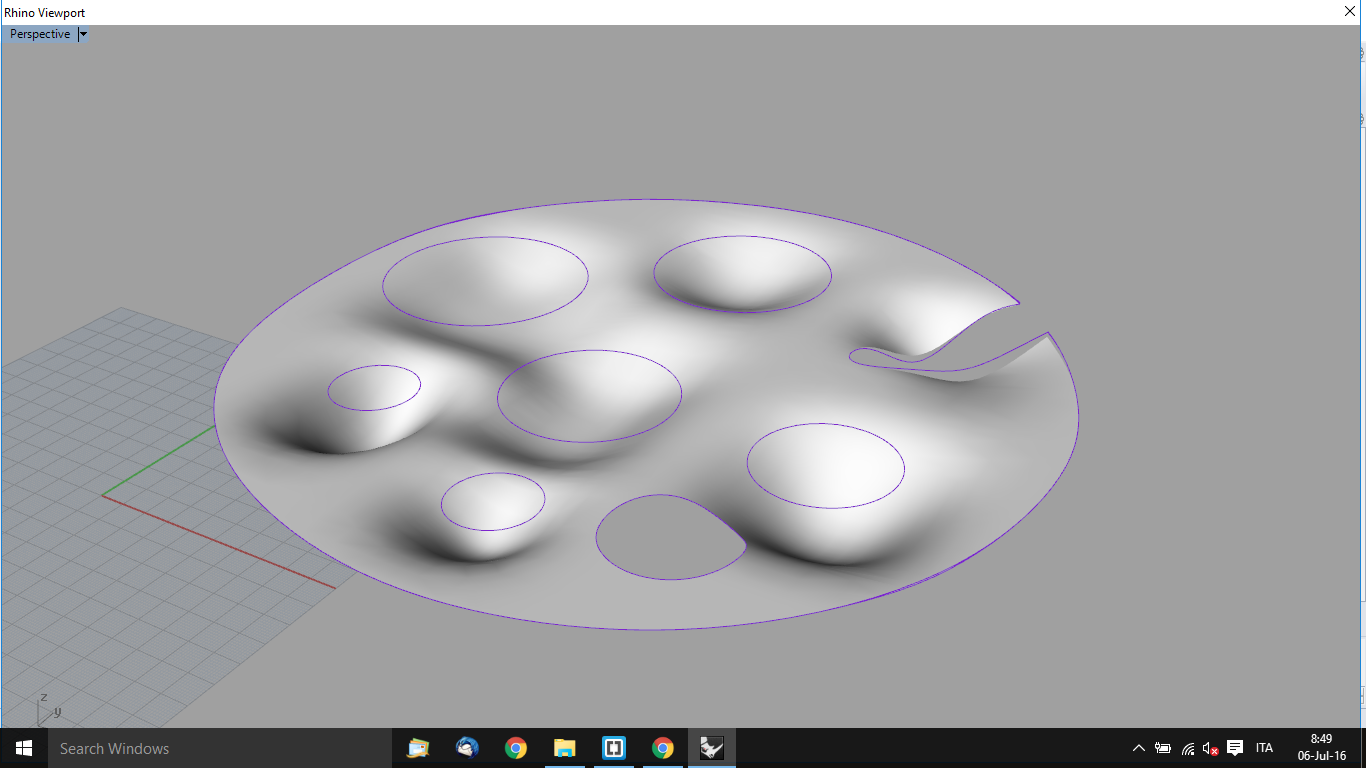

I have designed super simple geometry made by surface that I can mill in a very short time!

I took inspiration by a withe and traslucent color of the resin and from some piece of texitle we have here in the lab. I would like to try to have an withe and opalescent effect like a moon desert!

Concept

In the craters takes place the food, the hole is for thumb and the slot are for stem of the chalice of wine.

Source 3D Model file Aperitive Electronik

Milling

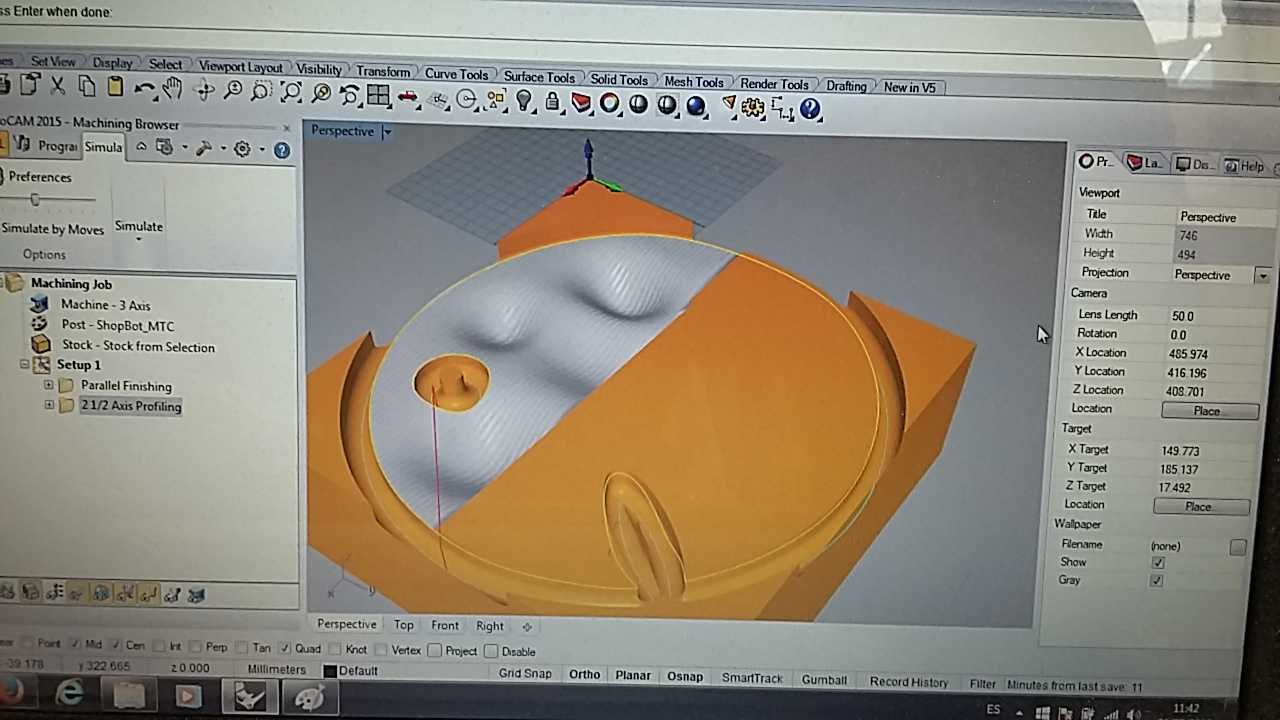

I have created the g-code for Shop Bot by RhinoCAM preparing the mold in a foam 100 mm tall. The model is 300 mm of diameter and 25 mm depth.

g-code parameters Parallel Cut cut depth 15mm spindle 12.000 rpm tool diameter 12mm

Source g-code ShopBot Aperitive Electronik.sbp

Resin Casting

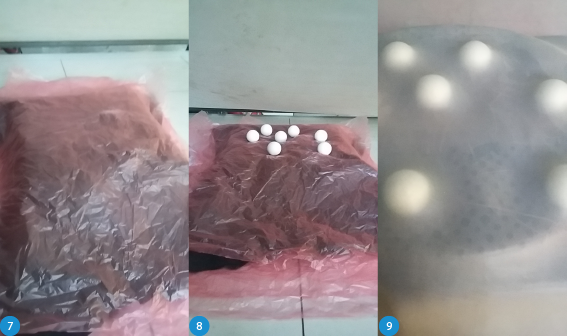

I have prepared the resin mixing the two part.It is very important mix togheter very well the two component of the resin.

The materials

Steps 1 laser the textile unfolded, with short precut 2 prepare the textile fiber 3 prepare the epoxci mixture N.B. Very important mix togheter very well the two component of the resin.

The process

Steps 1 plastic without hole 2 plastic with hole 3 foam over two plastic layer

Step 4 trasparent without hole 5 plastic with hole 6 traspirant textile over two plastic layer

Step 4 trasparent without hole 5 negative shape 6 vacuum for 12h

The result

Copyright © Elia De Tomasi 2016