Week.12 Molding and Casting

The Player

The idea consisted in reproducing at least one of our Foosball Table Player in the same way Alex Shaub did it for his project.

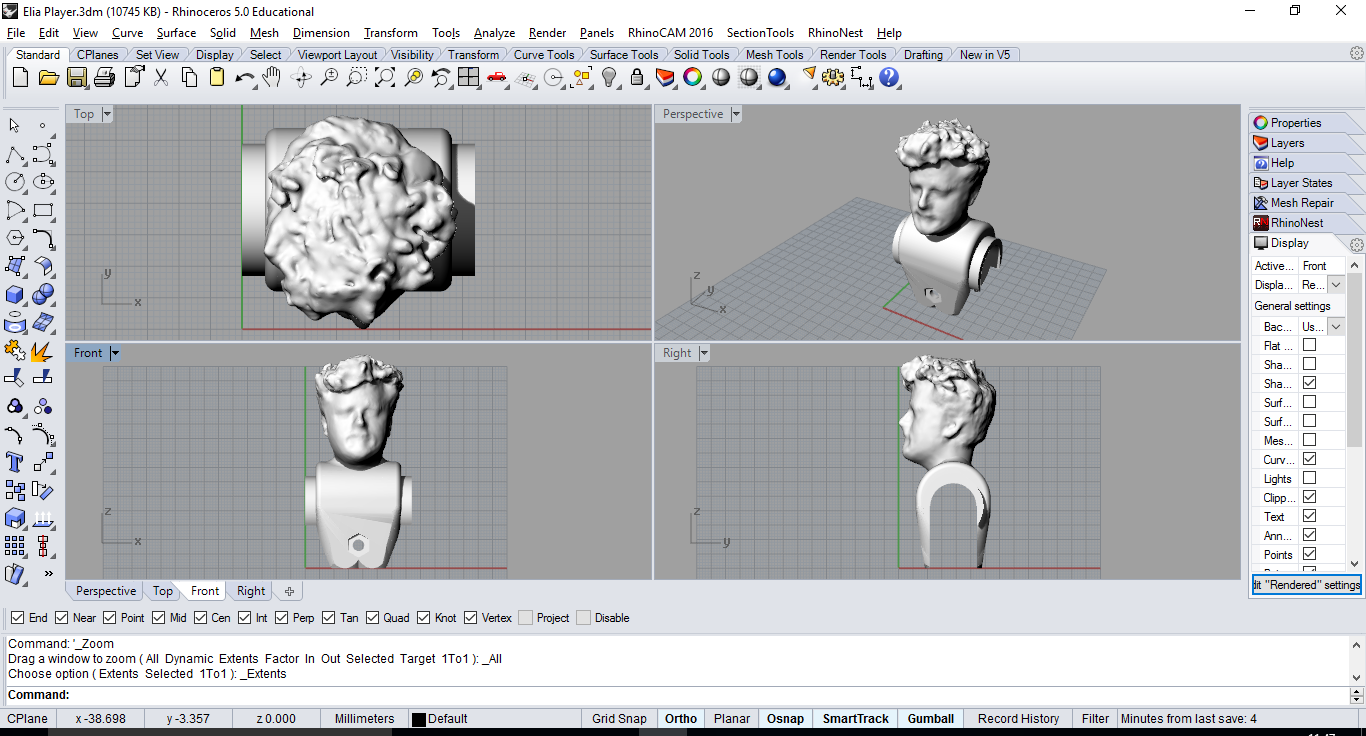

This is me, scanned with Structure Sensor and fixed with Meshmixer

Model 3D

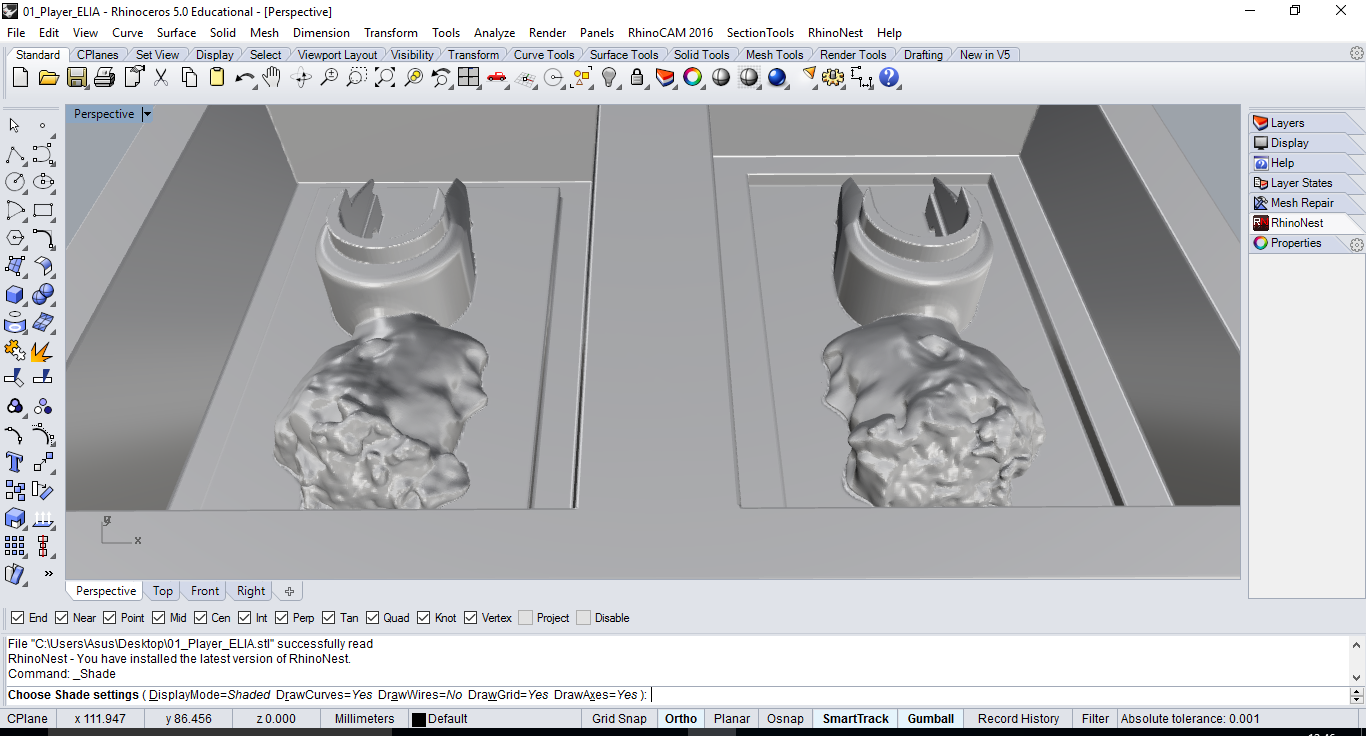

I prepared a box with a 3mm offset all around the geometry and a 3 mm "stair" for the cuttting plane.

Milling with Monofab SRM-20

I am going to mill my model with a Roland MDX-20 in a block of Wax carving

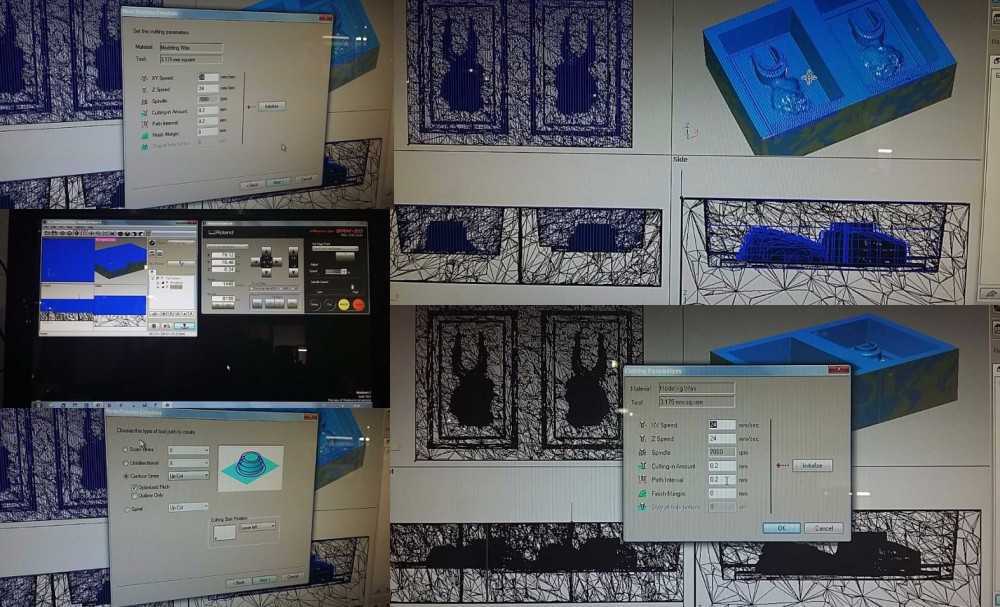

Roughing

First step for milling is do a roughing part.

Milling Machines Settings Tools: 1/8 SE 4FL LONG ALTIN COATED 3.175 mm square XY Speed: 20 mm/sec Z Speed: 20 mm/sec Spindle 7000 rpm Path Interval 0.2 mm Finish Margin 0.0 mm Only along to the Y direction which is faster for my geometry

Finishing

First step for milling is do a roughing part.

Milling Machines Settings Tools: 1/8 SE 4FL LONG ALTIN COATED 0.79mm square for the finishing. cutting Area:Partial XY Speed: 20 mm/sec Z Speed: 20 mm/sec Spindle 7000 rpm Path Interval 0.1 mm Finish Margin 0.0 mm Only along to the X and Y direction which is more precise for my geometry

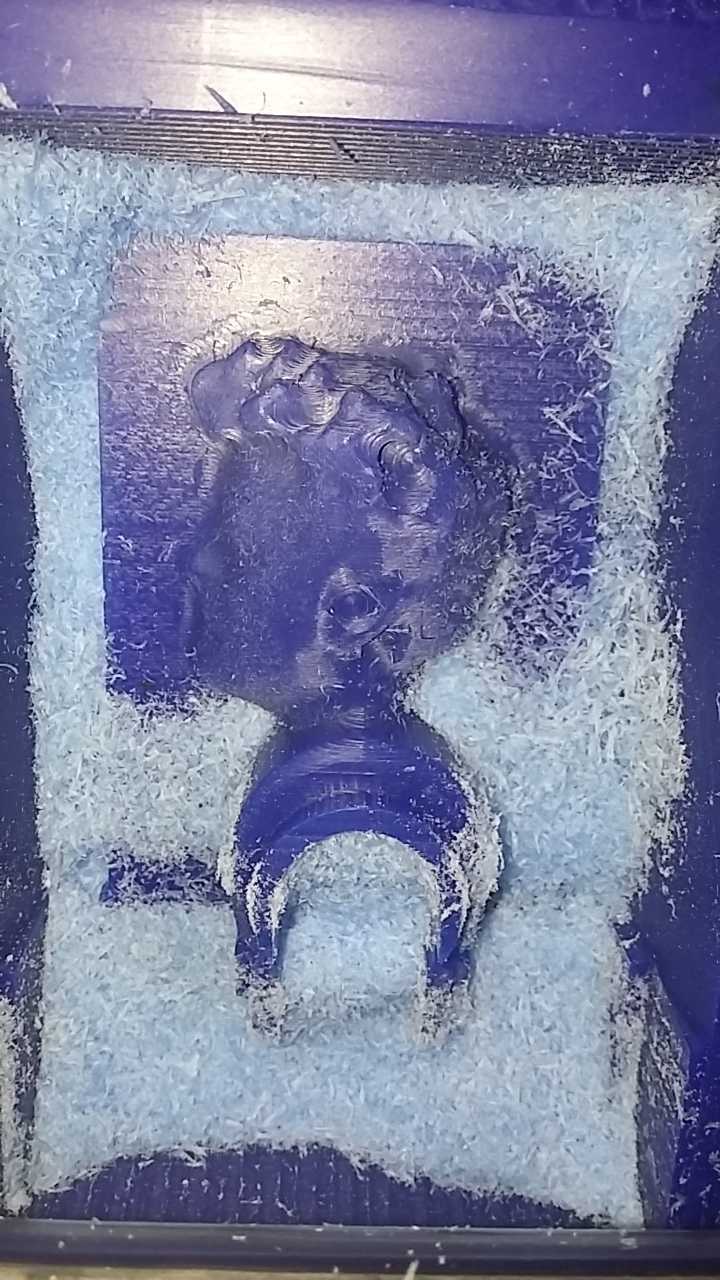

The Rolamnd SMR20 milling the wax model

The Rolamnd SMR20 milling the wax model

Preparation of the Silicone Mold

For the silicone mold I am going to use the

FormSil 25 Pro /1kg Set.FormSil 25 Pro is tin-curable silicone rubber to create durable molds. Can be cast or be thickened with a thickener to a thixotropic mass for brush-up molds. Time of approximately 1 hour and a curing time of 5 hours. White

FormSil 25 Pro

FormSil 25 Pro

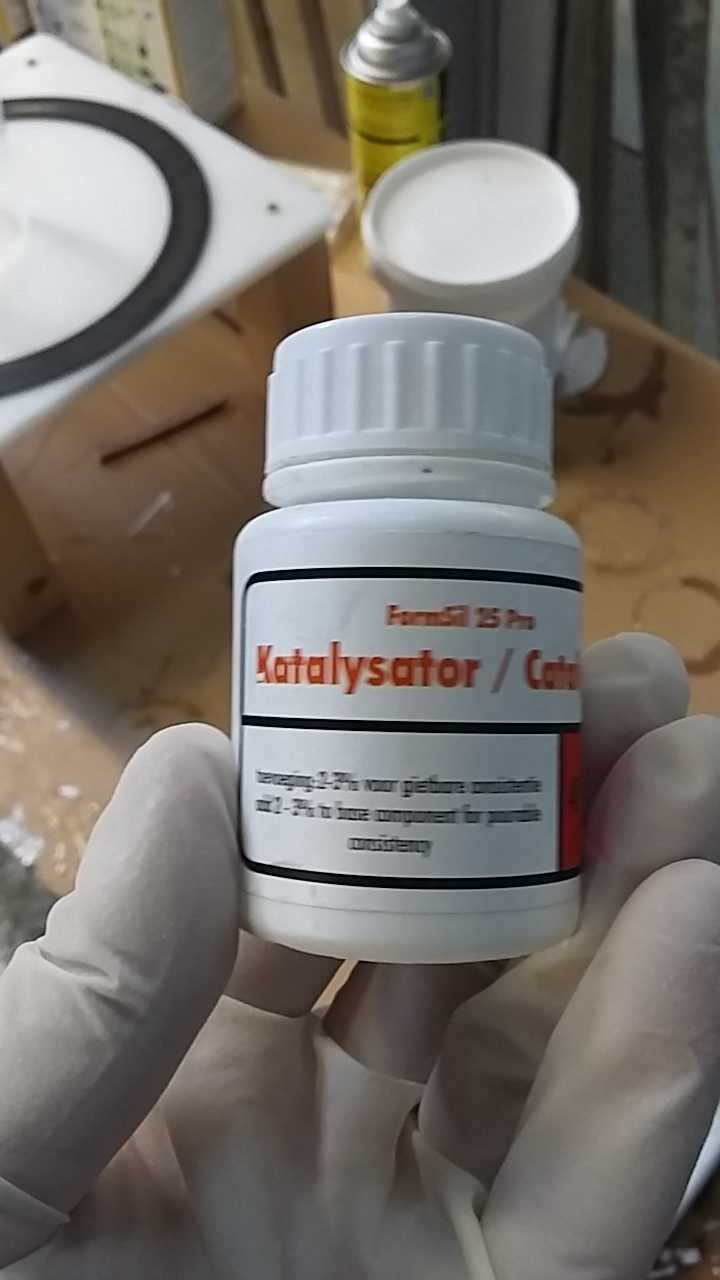

Catalizator

Catalizator

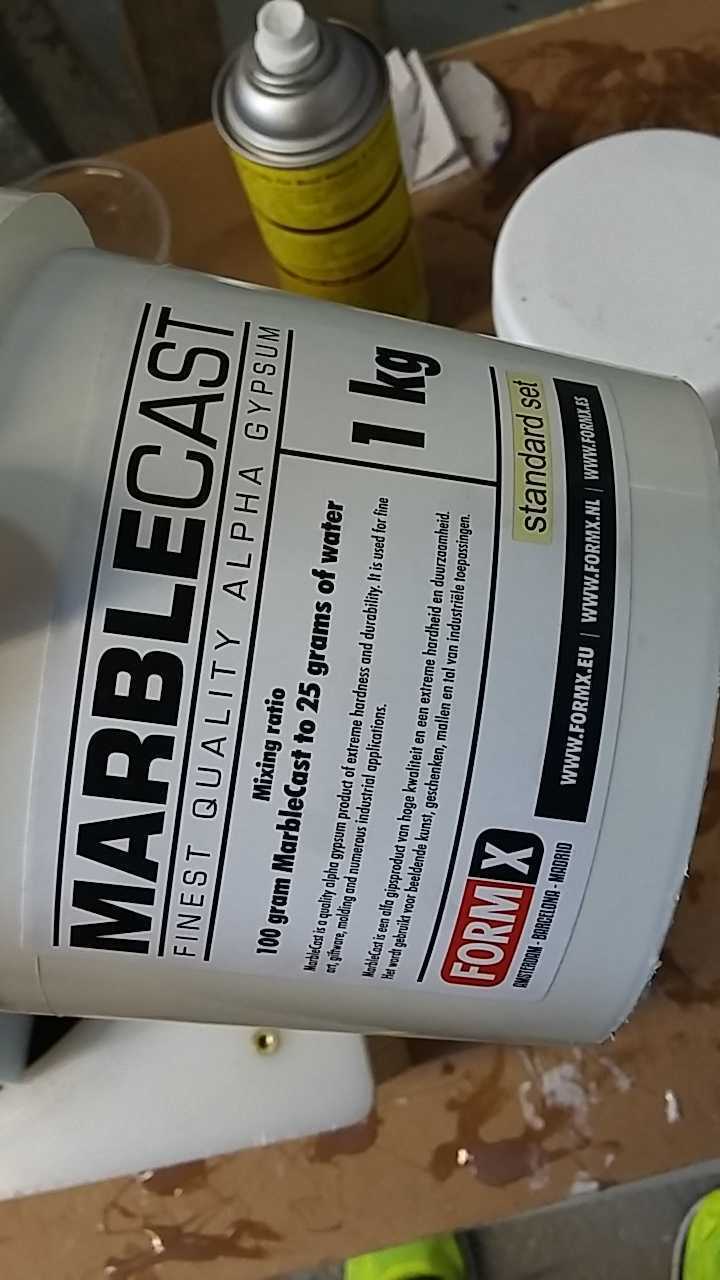

for the final casting I decided to use the MarbleCast Standard MarbleCast alpha crystaline gypsum standard setting.

- Plaster / water ratio: 100/25 to 100/30

- Soaking time: 30 sec

- Mechanical mixing time: 1 min

- Beginning of set: 10 min

- End of set: 13 min

- Hardening time: 30 min

Catalizator, to add in a proportion of 3%/ 5%

Catalizator, to add in a proportion of 3%/ 5%

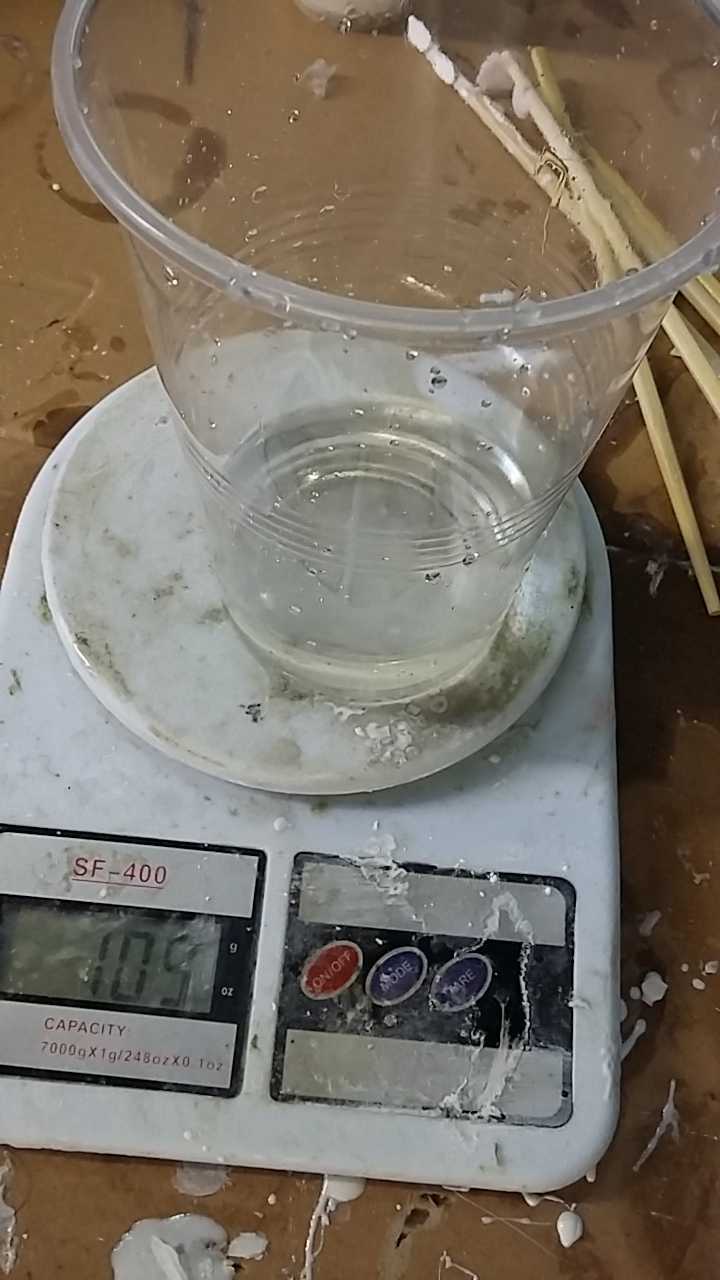

Mesure how many Marble castin mix you need by a glass of water volume

Mesure how many Marble castin mix you need by a glass of water volume

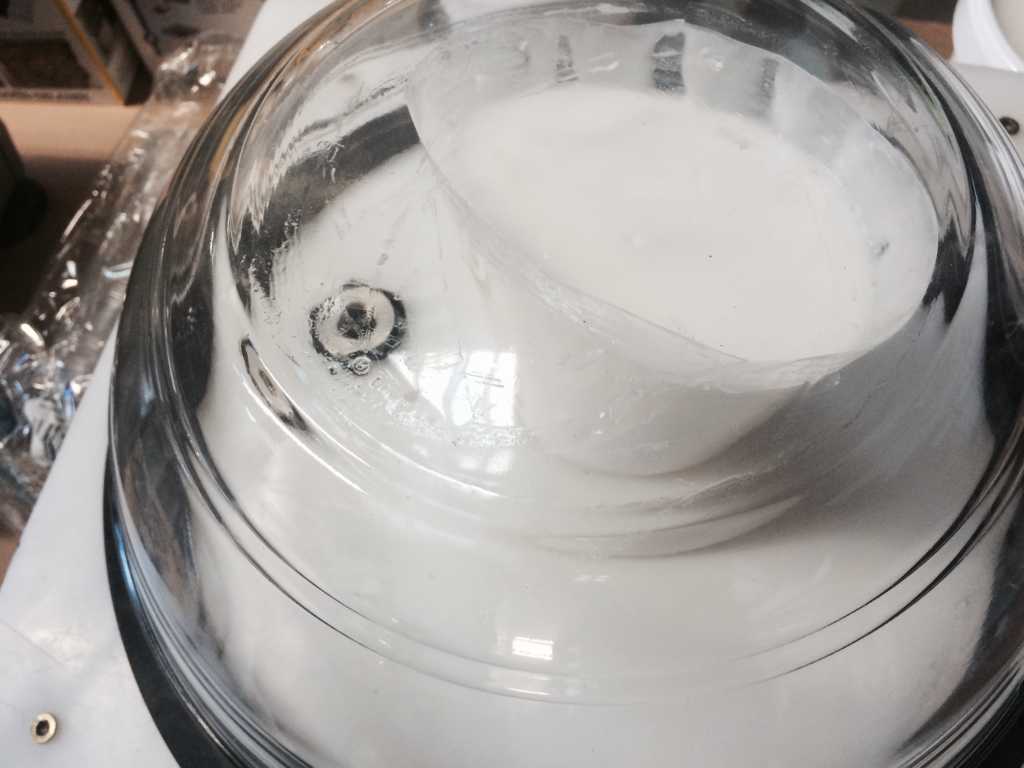

Vacuu to eliminate all bouble in the mix

Vacuu to eliminate all bouble in the mix

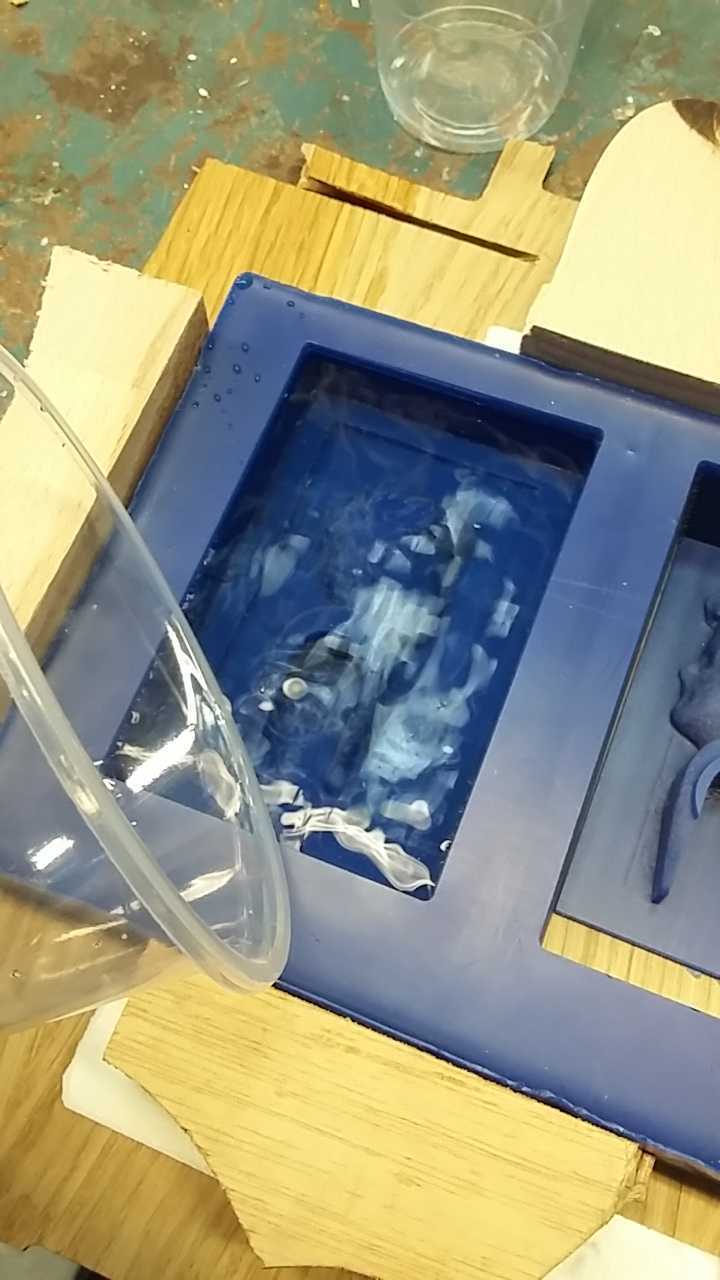

pour from above to prevent the formation of bubbles

pour from above to prevent the formation of bubbles

![]() Silicone for negative mould

Silicone for negative mould

![]() Silicone for negative mould

Silicone for negative mould

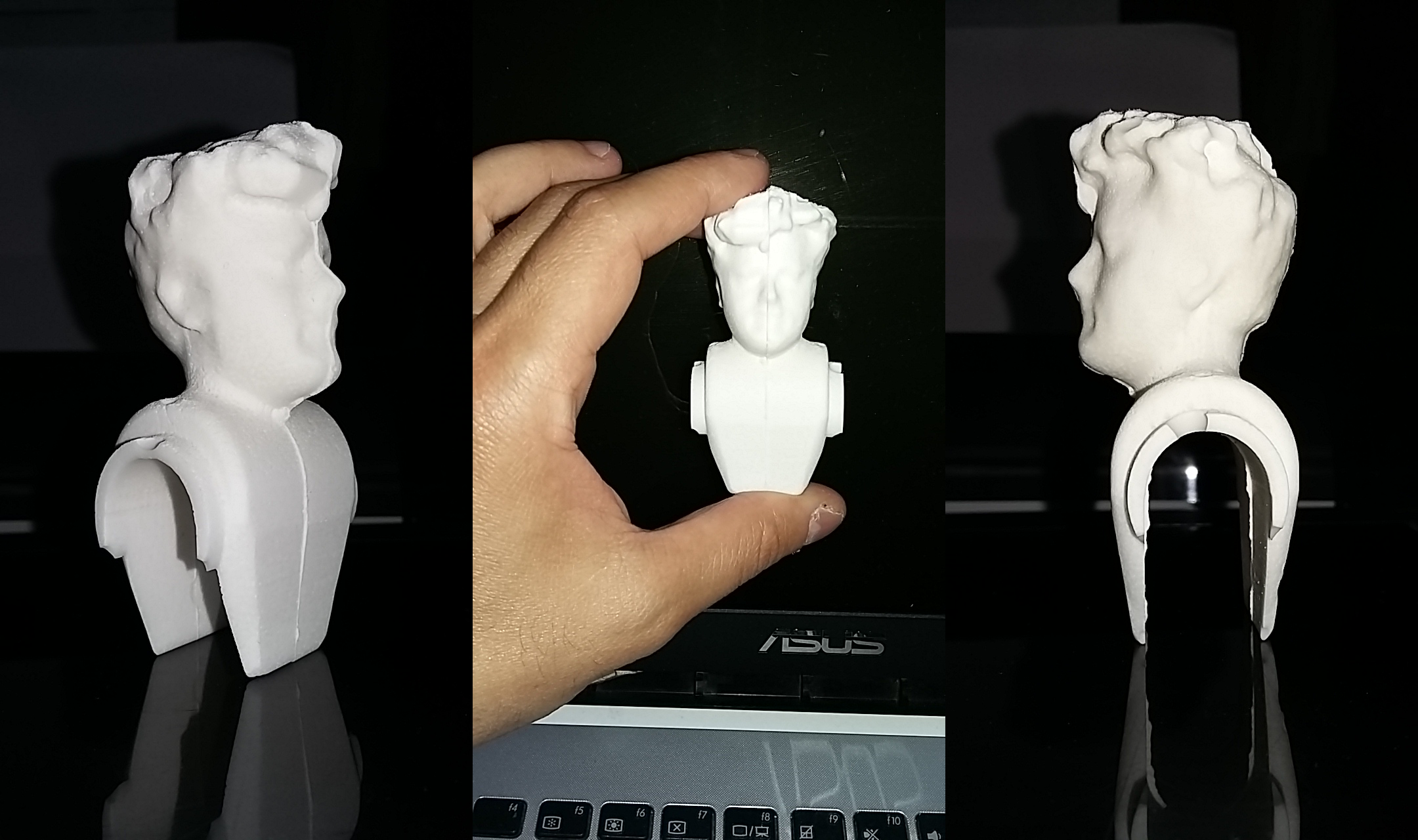

The Result

Marble Casting

Marble Casting

Source 3D Model

Elia Player MeC.stl

Copyright © Elia De Tomasi 2016