Composites

Task: | design and make a 3D mold (~ft2), and produce a fiber composite part in it

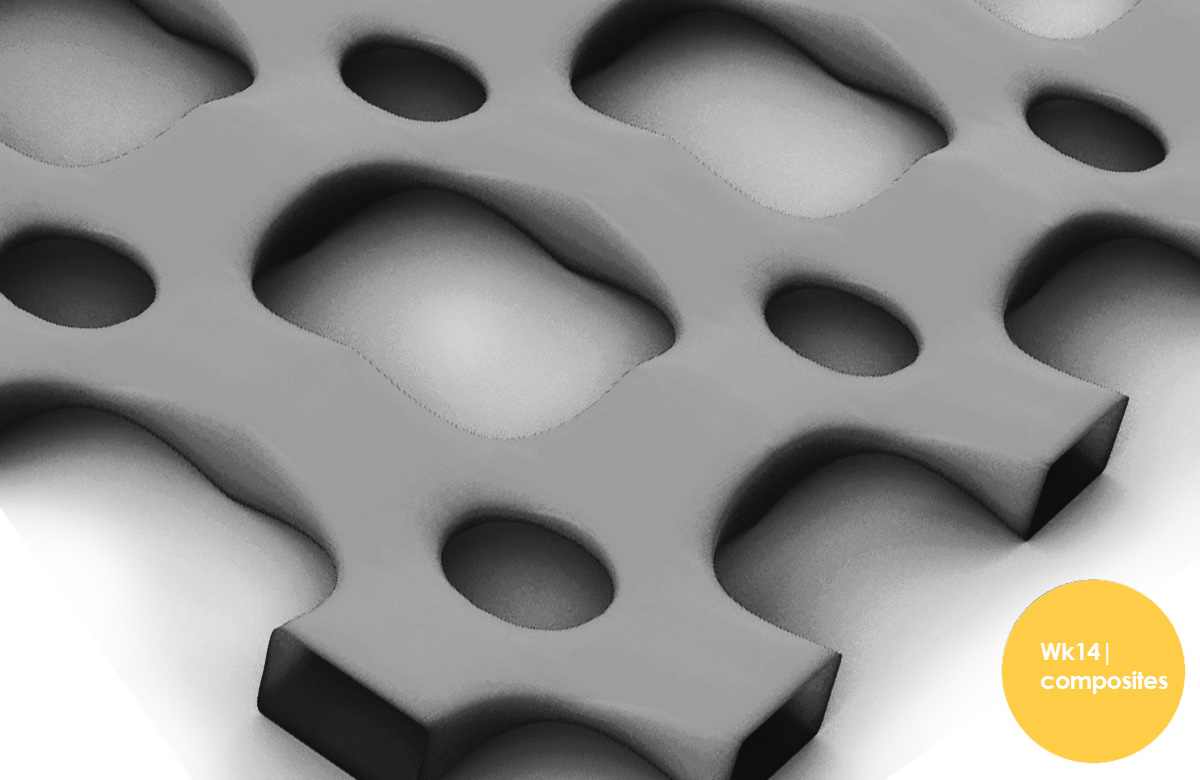

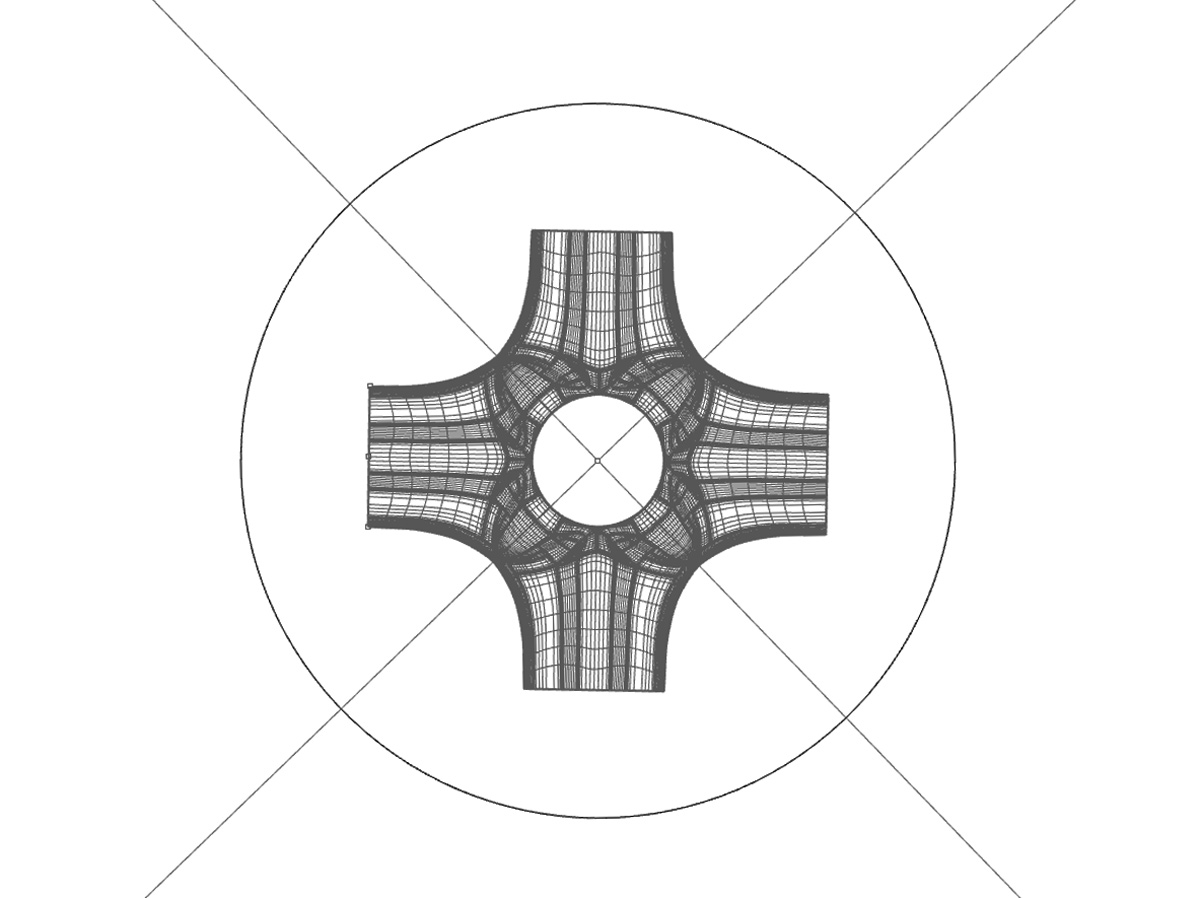

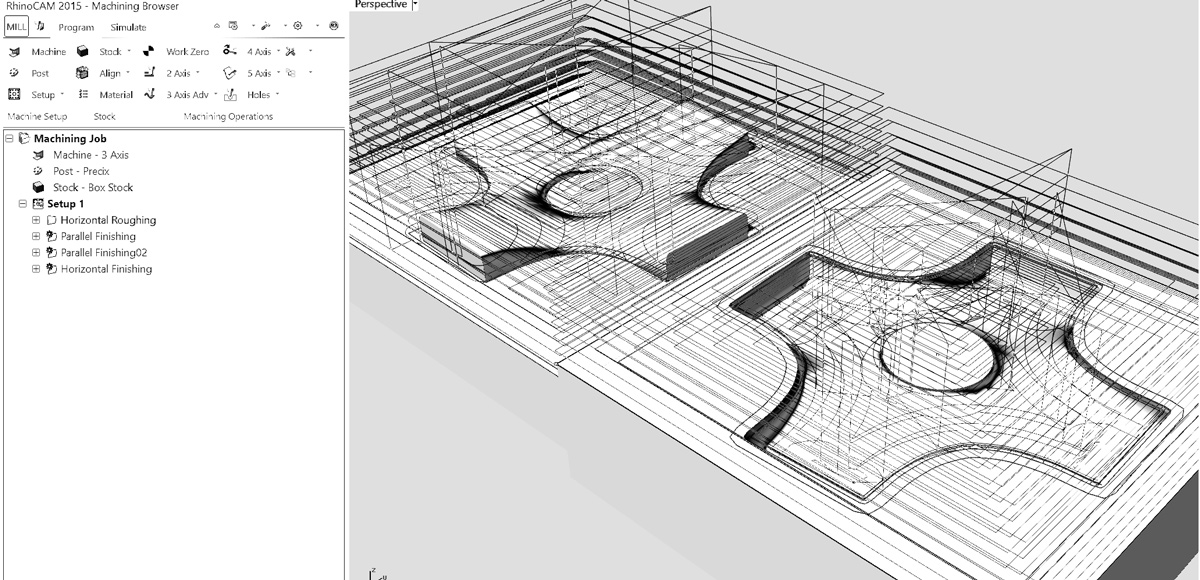

This week i got to understand rhinocam for 3 axis milling. I created a kangaroo definition in grasshopper3d and post modified it with T-Splines. The design is a symetrical manifold system (such as those of Erwin Hauer) which could be used at different scales for different reasons; especially if used as a system of many. In my case i wanted to create one compnent which could eventually be used as a glowing light.

|form finding with kangaroo3d

|3 axis milling

|keyshot render

1. Modelling

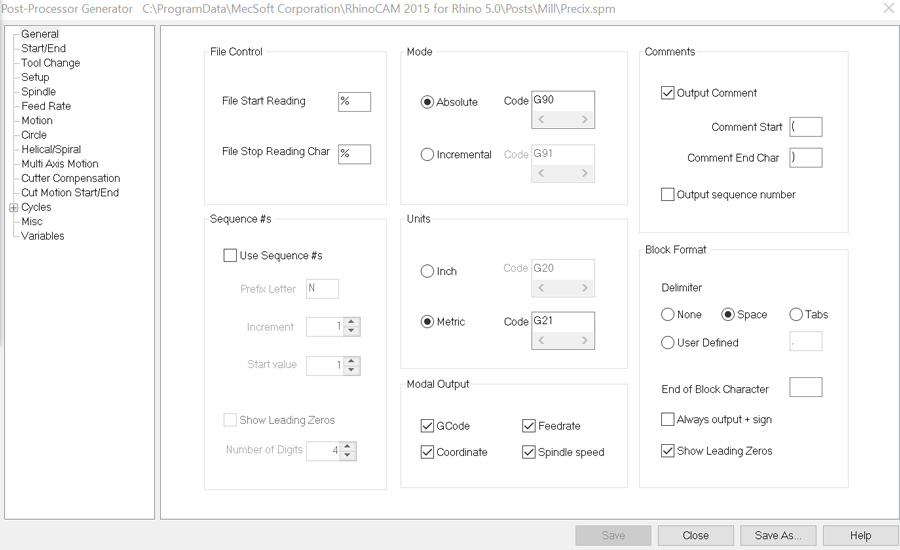

2. Rhinocam

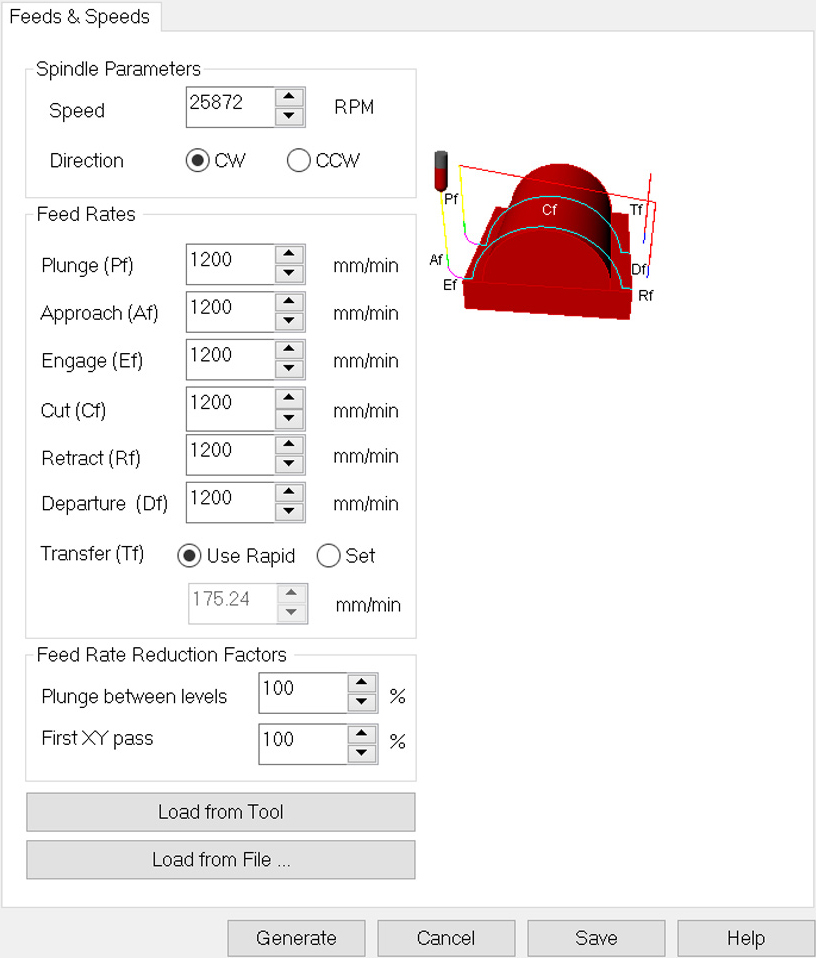

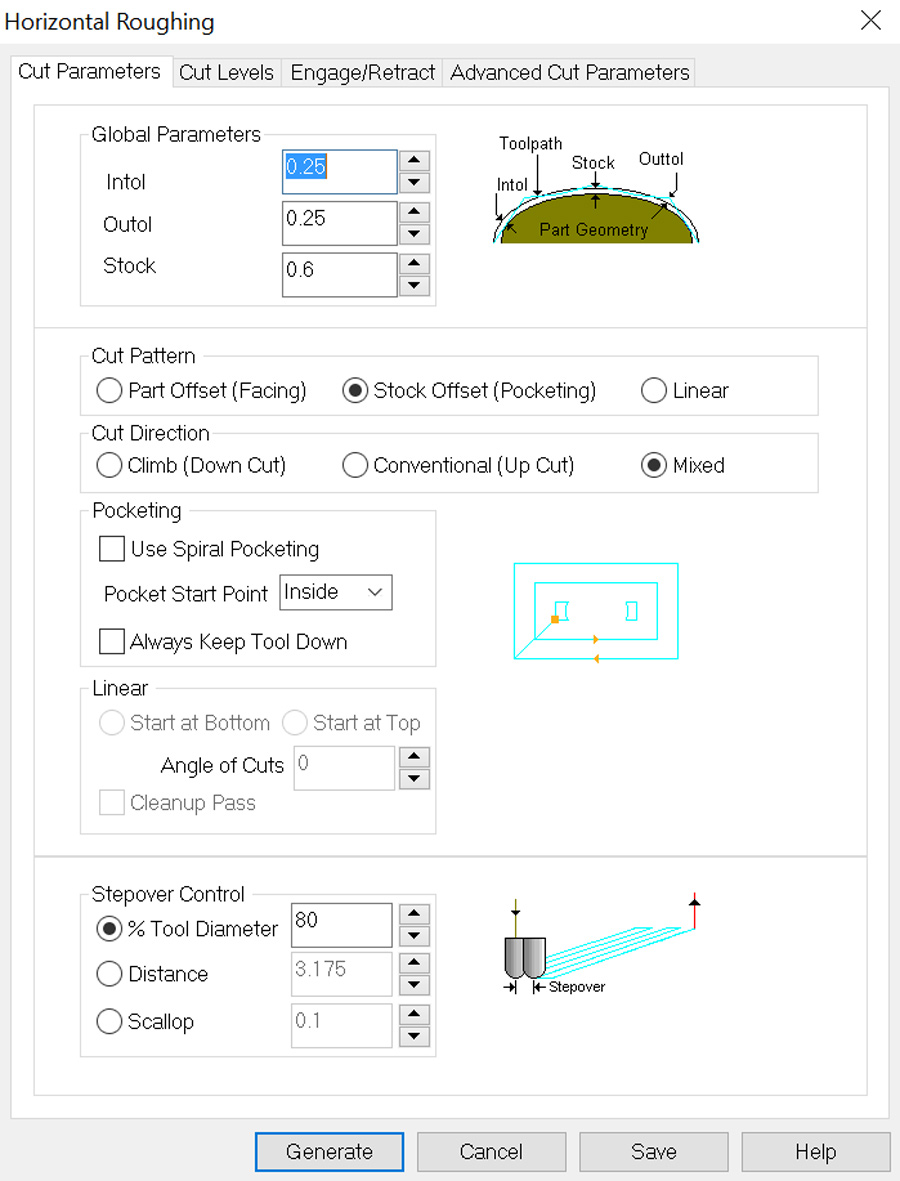

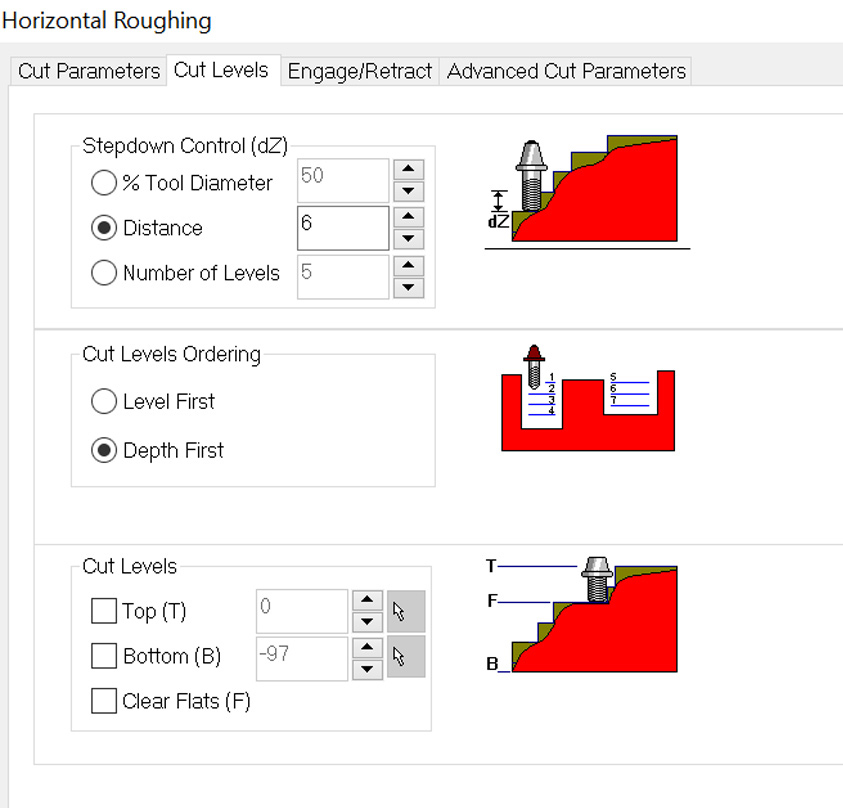

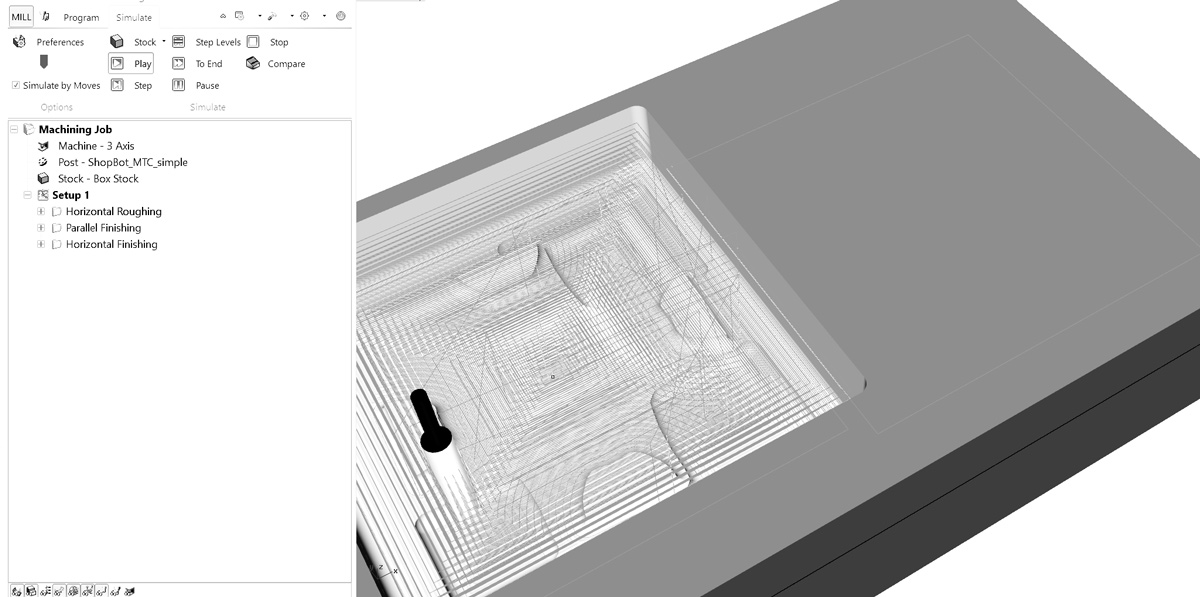

These were the important settings used for Roughing:

(this was used for both)

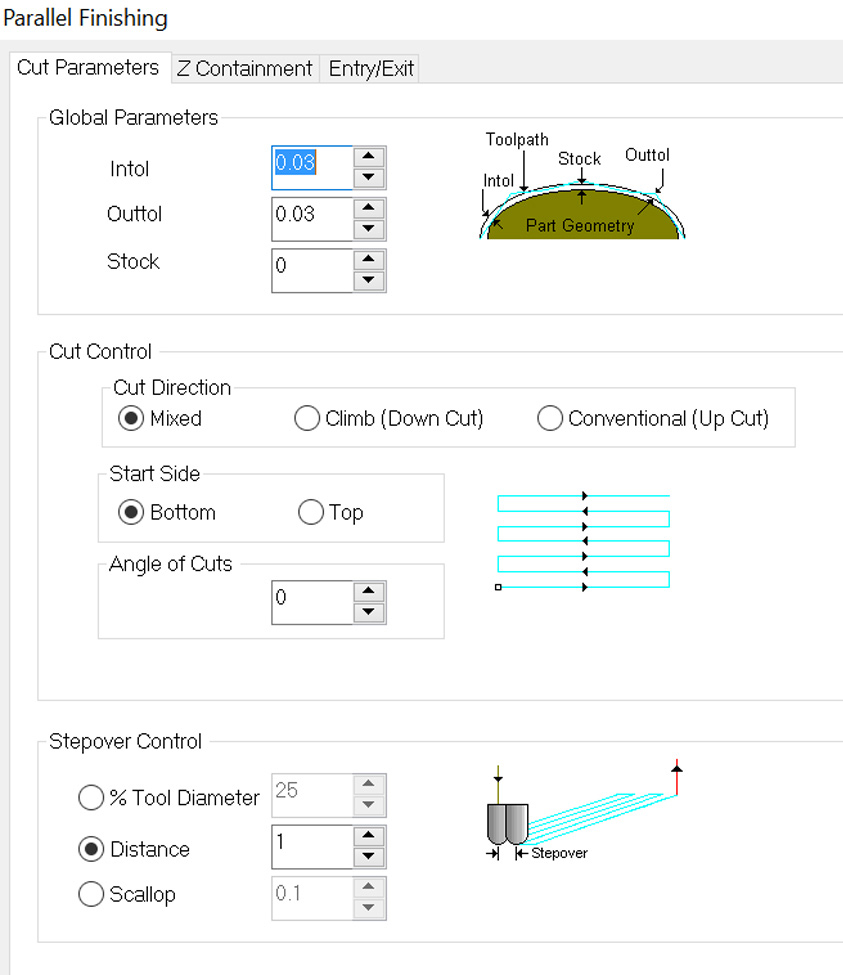

and these were the ones for finishing:

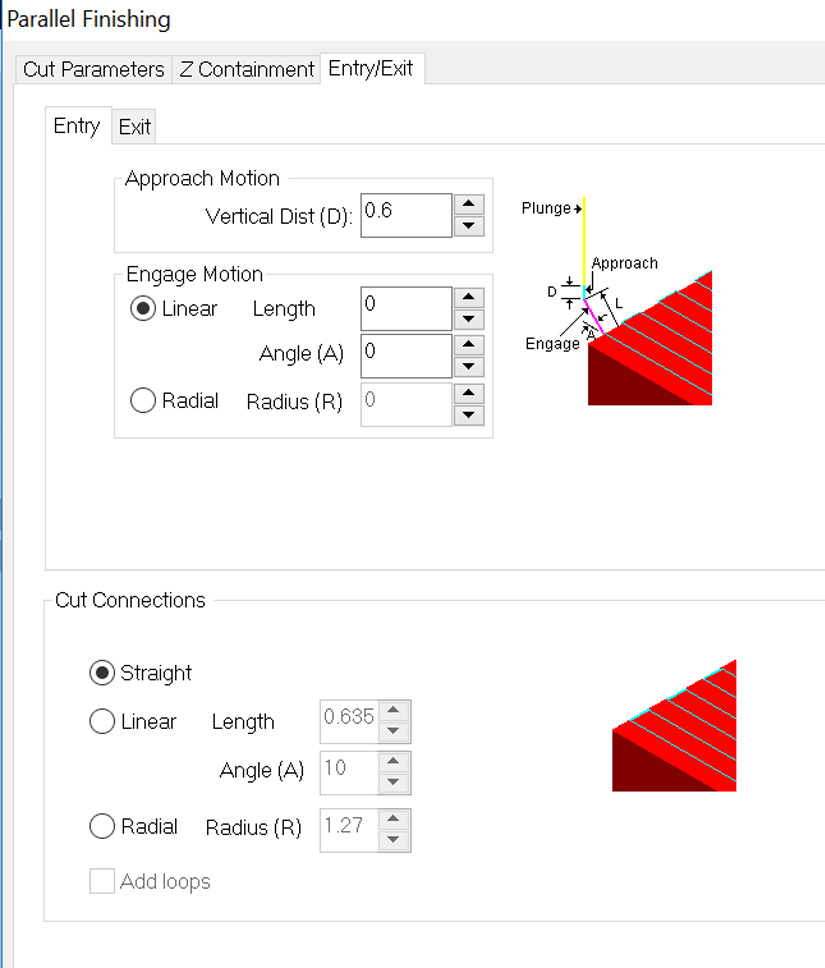

when exporting g code make sure all units are metric:

A two piece mold was created to keep the integrity of the shape. This was done by making an offset of the positive mold to ensure that the fabrics keep their shape. This was possible because the positive mesh was seamless and therefore could use weaverbird offset in grasshopper3d to simply create an offset of 2mm (space of fabric with resin)

3. Precix

increase feedrate to 6000 in gcode. Press tab to switch on controllers. Change bit to 12mm d. Set home by zeroing x,y,x. If you happen to loose your home when changing bit. Once bit is chaged go on random point(say g-47) place bit there then go to the relative 0 point as your z point.

4. Composites

>Secure blue foam mold onto table/ flat surface using adhesive tack and apply a layer of mold release wax.

>To prepare epoxy follow the ratio of mix below. This will require weighing of each mix by placing paper cup onto weighing machine for precise measurement:

Mix A (Resin): 50 Percent

Mix A (Hardener): 50 percent

>When mixing epoxy mix, stir gently to prevent forming of bubbles-make sure to mix well.

>Next, prepare all composite layers at the side of molding area. This is done so as to prevent confusion during setting of layers.

>place layers on 3d mould followed by non porous plastic film and negative mold.

>place in compression machine and leave for 8hours plus. If you do not have such a machine; you can use a one of these Vacuum packs (check inventory for more info)

In this composite too much resin was placed and not enough layers of fabric therefore there was not enough compression and creases were made.

|Brief MIT

|Lecture Neil Gershelfeld

|Download all files from repository