Week16 : applications and implications

What will it do?

My proposed solution is intended to evaluated the existing pressure distribution in the foot continously for different gate and posture, without impacting the users daily activities. Secondly this solution also includes a component that would have an offloading mechanism to redistribute the weight based on the long term pressure profile. Ideally the patient would have an

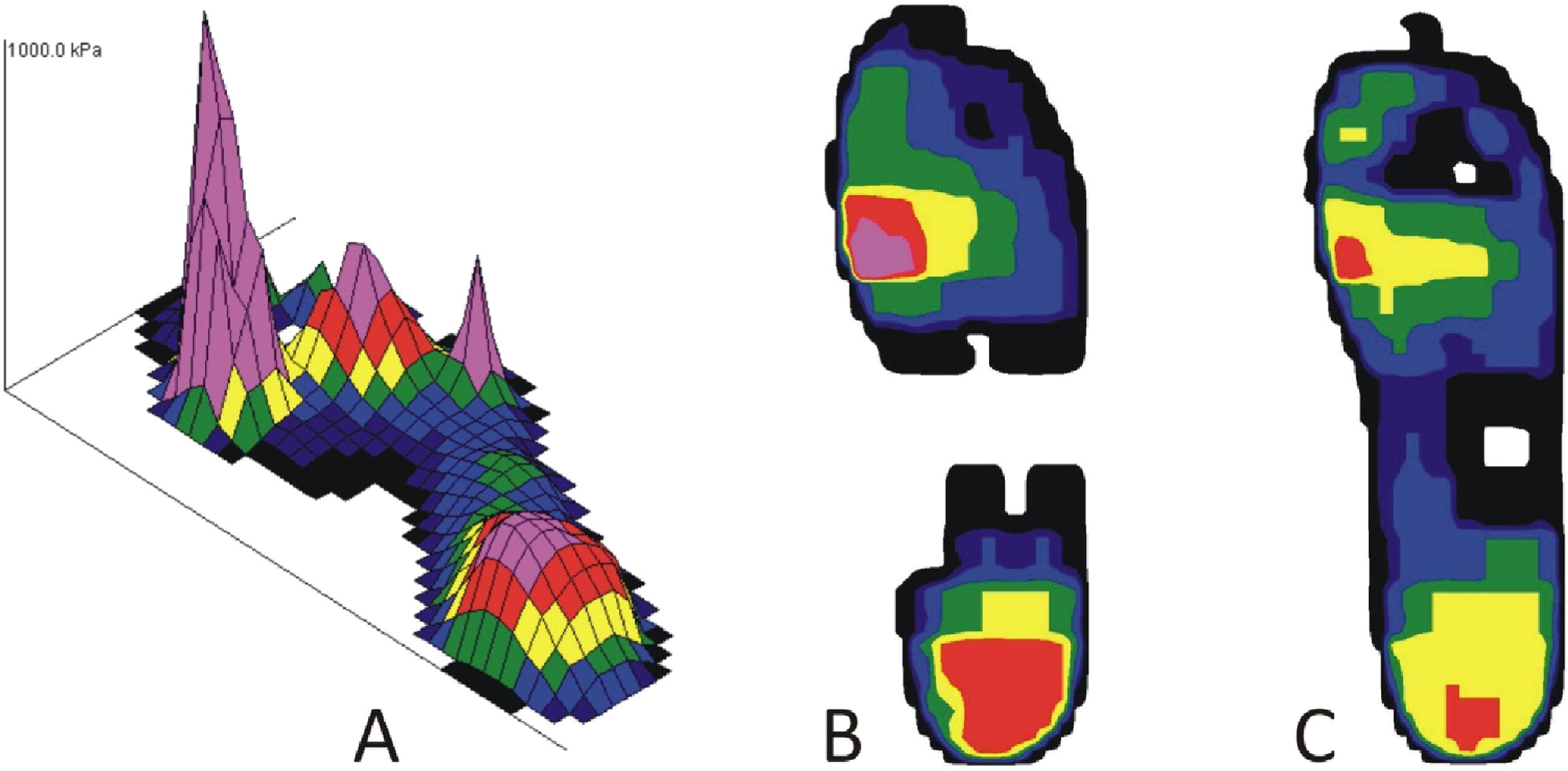

Figure 1: Peak plantar pressure distribution shown for the right foot during(A)barefoot walking.(B)inside the shoe with a flat cushioning insole and.(C)with a custom-made insole being used.Source: Cavanagh, Peter R., and Sicco A. Bus. "Off-loading the diabetic foot for ulcer prevention and healing." Journal of the American Podiatric Medical Association 100.5 (2010): 360-368.

Who's done what beforehand?

For the offloading the golden standard of treatment is the Total Contact Cast (TCC) which achieves a higher level of compliance to treatment.

While Tescan is a leading company in the production of pressure sensing mats and in-soles with high resolution. They are used in many application some off which are not necessarily for diabetic patients but also in gait analysis and foot wear design.

What materials and components will be required?

Where will they come from?

How much will it cost?

What parts and systems will be made?

The main components in this product are the three layers in any foot sole. 1- Outer-Sole : The Outsole would have the offloading elements that would help redistribute the pressure on the foot, are modular and have the potential to be realigned

2- Middle Sole : The Sensing layer with the components for pressure sensing that function as the feedback to the design and provide an insight on how the next iteration of the outer-soles have to be modified.

3- Inner-Sole

Those part would have different function.

What processes will be used?

- Foot 3D Scanning

- Using a 3D modeling software an impression identical to the foot will be created.

- Fine milling to create the custom In-sole layer.

- Electronic Production for Mid-sole sensitive layer micro-controller.

What tasks need to be completed?

What questions need to be answered?

What is the schedule?

- Foot 3D Scanning

- Modeling of customized insole based on the scanned foot.

How will it be evaluated?

- The Fabrication process: This would be evaluated within the fab academy evaluation process.

- The Benefits on Users: If we miraculously overcome the lengthy process of evaluating a health care device, I would say the best way to evaluate the solution i terms of it's benefits to patients is to compare it first with existing offloading techniques mentioned above, obviously it's a long term process. Ideally the sensing layer should also be compared to existing off the shelf ( Applied usually in clinical setup ) high resolution pressure mats. Also we could use the low resolution pressure sensing foot insoles to compare with our solution. But the long term evaluation is best achieved within a clinical setup.