Week

8 : computer-controlled machining

Source:

Wikipedia

Group

project:† test runout, alignment, speeds, feeds, and

toolpaths for your machine. I am responsible for this section this week (First

task hereafter)

Individual project: ††make (design+mill+assemble) something big

First

task: truly learn what Fusion 360

can do for me! Researching and exploiting Fusion software capacity led me to :

Fusion 360 CAM tutorial for CNC beginners from Evan and Katlyn website (visit here).

There I learned the way of thinking in Fusion and how to approach the task at

hand here. There, they recommend making a CNC carved figurine called Kevin (CAD

process). I went on creating my own version of the happy face and called it:

Larry. My plan was to use the design on molding and casting week.

This turned out to be a wise decision, I was able to

learn the CAM way of doing things, followed by machine control process up to

the final carving itself, being the CNC steps itself. The tutorial ignored

voluntarily the CAD step, but since I was to build something BIG here, I

resorted to apply myself first with Larry and then move forward to the CAM

process itself. This cost me some time delay but overall proved to be highly

fruitful! Find below a picture of Larry into design phase.

But this step (the design) is really preliminary to

the real task at hand here, assisted by the machine, lets create the

manufacture data needed to fetch a CNC machine so that Larry can emerge in real

life. To do so, I followed the tutorial into phases: Select medium we are going

to use, select the appropriate tools and define a sequence of toolpaths. This

is when, for me, a paradox into making something really begins: removing

sequentially matters to produce not by addition but by subtraction medium so

Larry can emerge. I went on with sequentially, as suggested into tutorial:

circular (eyes), 2D pocket (smile), adaptive to create a working space,

parallel horizontal, parallel vertical to smooth the surface basically and a

final pass in contour mode to ease into removing the shape out of medium.

†

†

Then it's only a matter to generate, here in Fusion

360, the G-Code and try it on the CNC machine. As I mentioned before, Larry is

to be used for the molding and casting week, therefore, I opt to carve Larry

right away into a wax block. The results are shown hereafter.

Of particular interest here,

operating parameters experimented with where:

This appropriation of the

technics yields good results and turned out to be very instructive. Now onto

the main task at hand this week:

The

Bartop Arcade Cabinet!

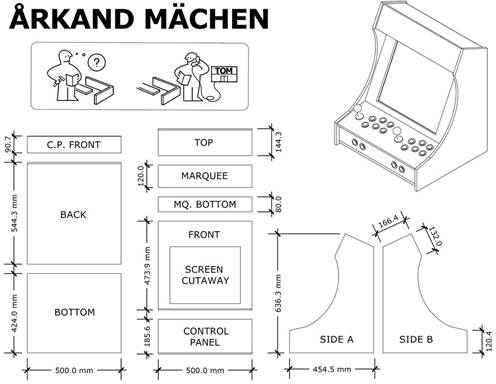

I have based my build, influenced a lot by the

HolBrook Tech website. There, a teacher like myself, details the step he had to

follow so that a class he's teaching to can build from raw materials and

electronics, a fully functional bartop arcade. The details of his adventure are

can be found here.

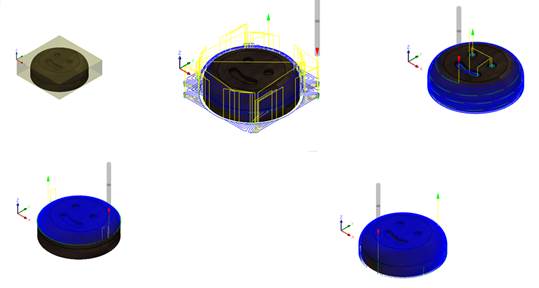

From the original website, the

cabinet is built from hand cutting the pieces, I used Fusion 360 to reproduce

the design and compile the G-code to be used by the CNC to cut out the panels.

At

first, my lack of experience leads me to build a single file flat file

containing all the parts and organized in a way to fit on 24 by 48 inches MDF panel.

Two mistakes here: the CNC we have access to, is 24 by 36 inches capacity, a

single file does not permit an easy reorganization of the different

bodies.†

Results?

Start over and over, until you get a functional folder of all the organized

into sheets files!

Tedious

is the word that comes to mind, Ultimately, I managed to produce after several

iterations (12 versions) files that fit my medium and are easily manageable.

With

one CNC machine, several need for it, time shared access and uses others then

for the make something big week lead me to decide to postpone the cutting for a

later time, when the CNC will be available for me to machine the cabinet

itself, all the openings and carved designs it needs in one single session. So

currently completion of the cutting phase is halted, I plan on returning to it

ASAP, after all, a lot has to happen before I can play retro game on my retro

bartop arcadeÖ maybe during April break? HAHAHAHA letís see!!!

†

Update:

I finally got to cut out on

the CNC my bar top arcade!! And no, I did not get to play and road test the

arcade during Aprilís brake, wait April, there was a brake in April ?????

†