characterize your lasercutter

We study Fablab Sorbonne lasercutter. It is a Trotec Speedy 100, laser CO2 60 W

To cut a sheet of material, we need to concentrate energy on a very thin part of material.

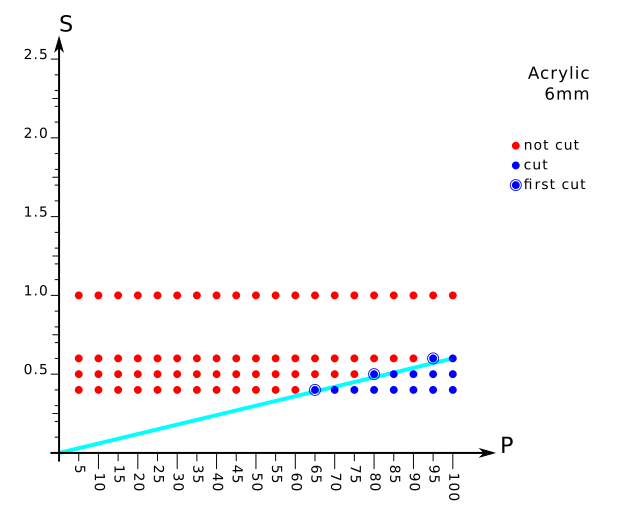

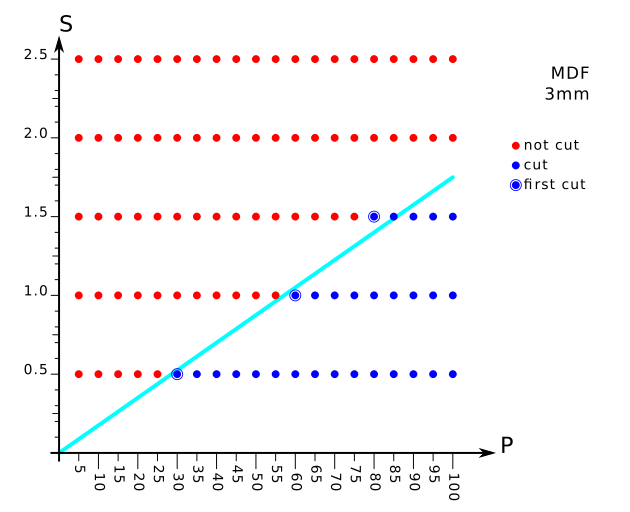

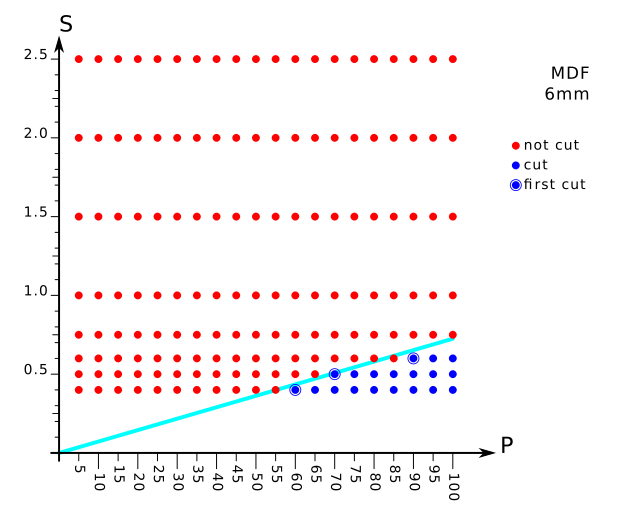

Set up to cut mainly depends on two parameters : power (quantity of energy) and speed(wich determines delay we stay on the same area).

Good parameters to cut depends on materials (type and thickness) and laser cutter characteristics.

Power unit is percent of full power of the machine (60W).

Speed uint is also a percent of the maximum speed on the machine (3.55m/s)

Relation between power and speed

We observed that quantity of energy increase when you increase power and when you decrease speed.

In first approximation, we can search if energy is proportional to power and inversely proportional to speed.

So cut parameters can be a function like :

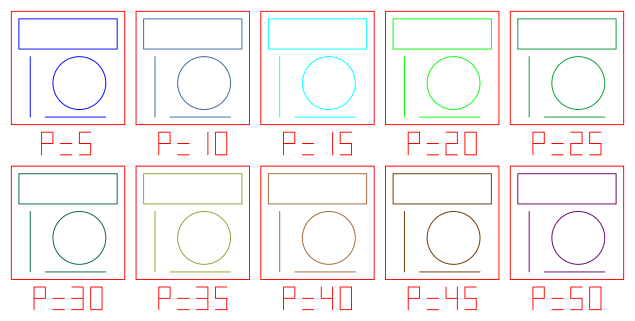

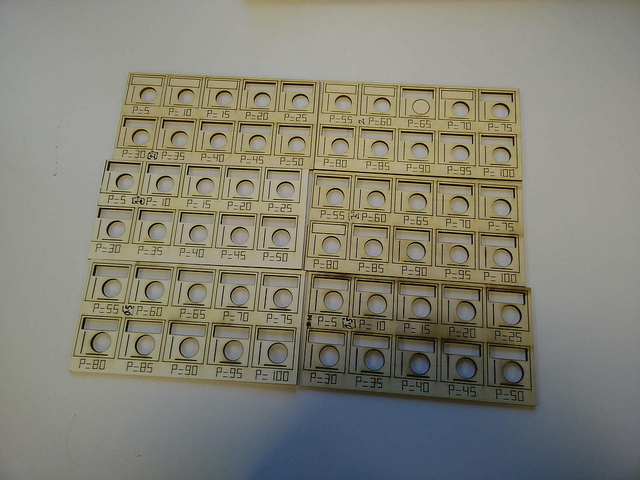

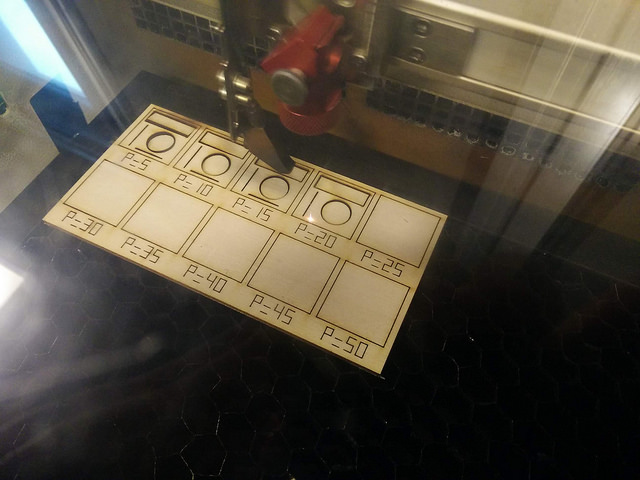

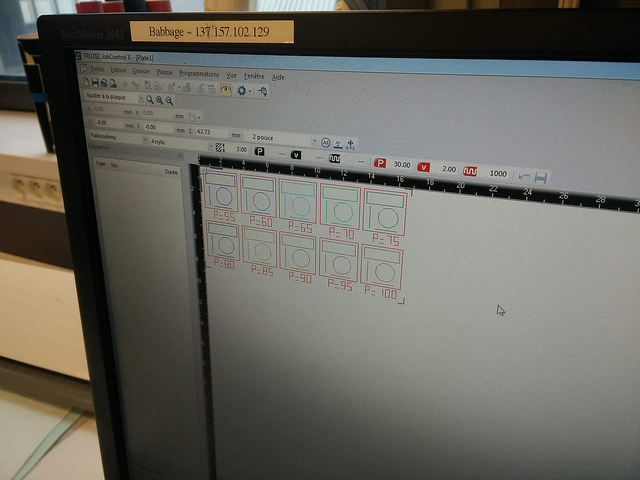

Firstly, we have made a file with two shapes : rectangle and circle and two lines vertical and horizontal.

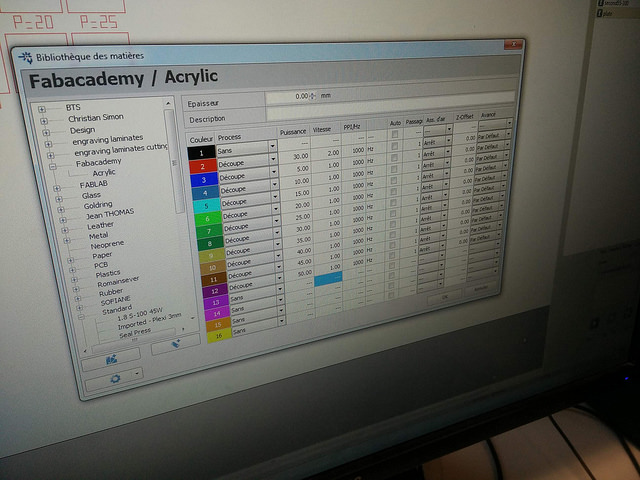

To test different power in the same time, we used Trotec colors.

First results

Linearity

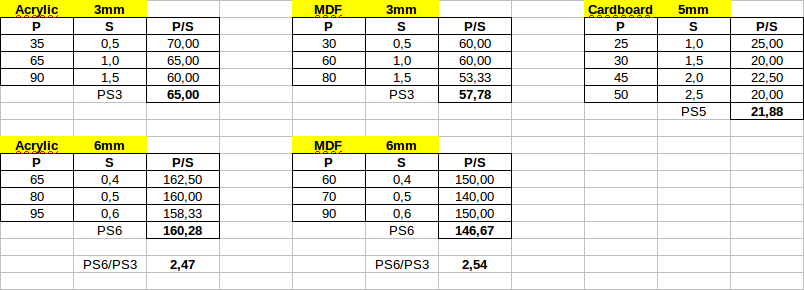

Results of P/S show that linearity is acceptable.

Another interesting result is that when we compare P/S for 3mm and 6mm, we can say that power we need to cut is not proportional to thickness

because P/S for 6mm is 2.5 higher than P/S for 3mm. But the result is equal for acrylic and MDF.

There shoud be a law we have to find by testing different thickness.

Measuring kerf

it's very difficult to measure precisely the kerf, even with a digital caliper, because kerf is so thin that small variations,

hundreths of a milimetre, exists between jobs.

On MDF, we found an increase of 0.08 mm difference from the original file length.

So, the cutout has a possible increase of 0.1 mm and the remaining shape has a possible decrease of 0.1mm.

We found that this value is similar on 3mm and 6mm of MDF.

With acrylic, we found similar results with the caliper.