- design a machine that includes mechanism+actuation+automation.

- build the mechanical parts and operate it manually

Team

Introduction

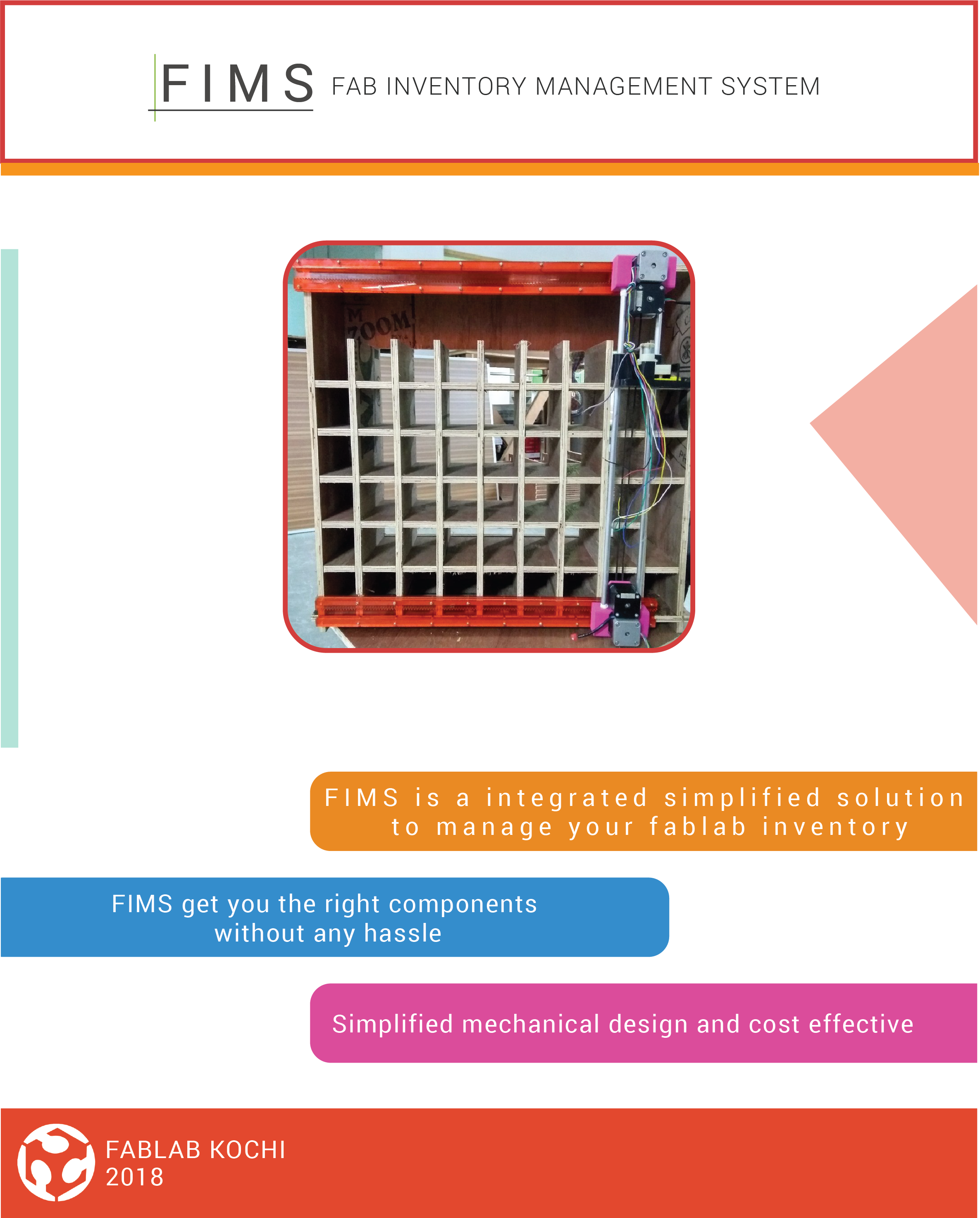

This week's assignment is a team work. All the students of Fablab put their collective effort to build a machine. We decided to make a robot for inventory managemnet.It functions as a easy delivery machine that delivers the required components without hassle when demanded. This week we designed and fabricated various components for the machine. We designed rails and gear and cut them using Laser cutter on Acrylic. We also designed a 60 X 60 rack that holds the inventory.

This week's assignment is a team work. All the students of Fablab contribute their collective effort to build a machine. We decided to make a robot for inventory managemnet in the previous week and we started the designing and machining of the parts for the robot. Then we tested the crucial parts, and its work as we expected. In this week, we need to design the electronics parts. and automate the machine.. We designed rails and gear and cut them using Laser cutter on Acrylic in the previous week. We also designed a 60 X 60 rack that holds the inventory. So all we need to do this week is to design the hardware, assemble them and the automate it.

Design

We designed the structure using Fusion360.

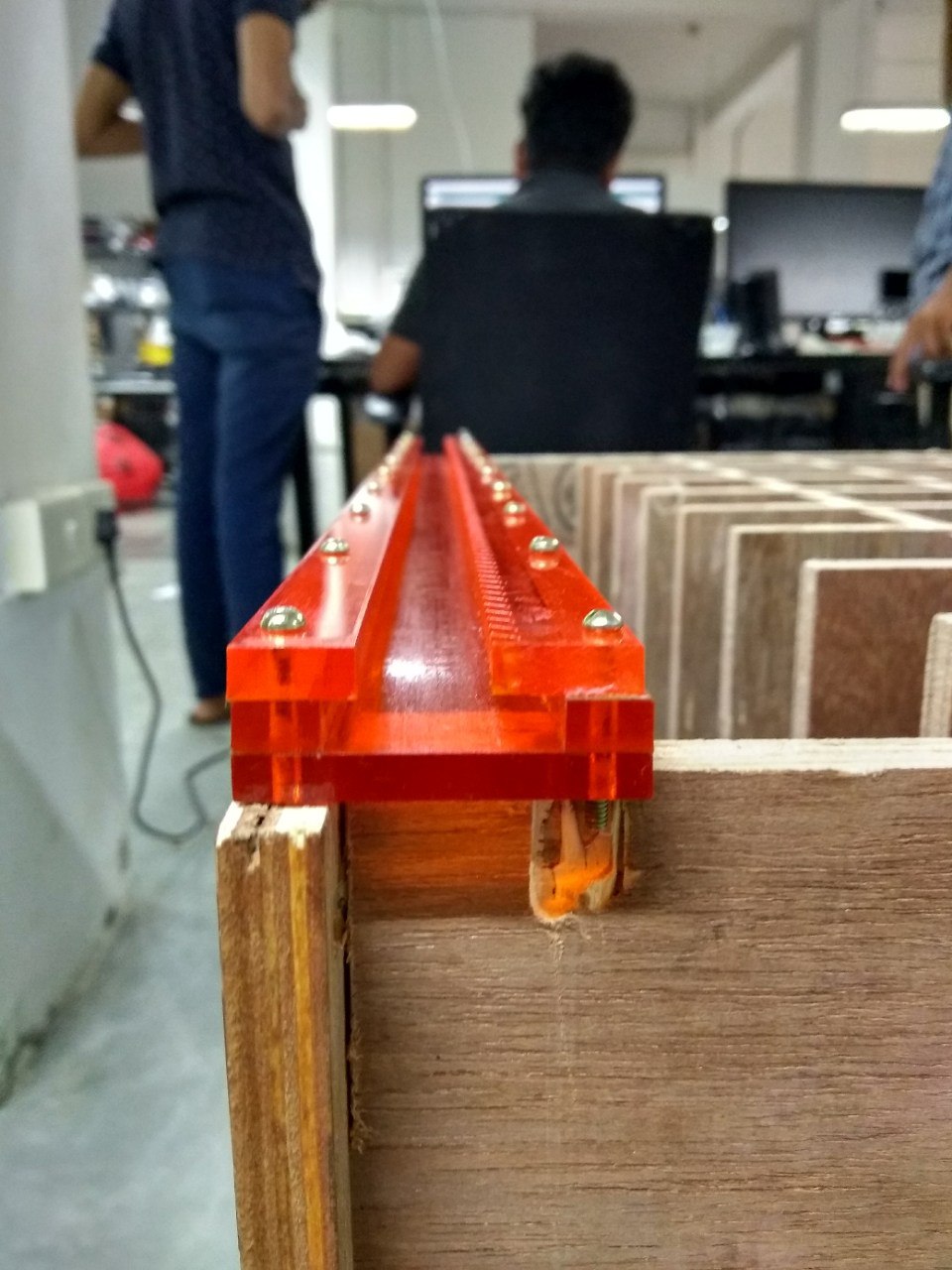

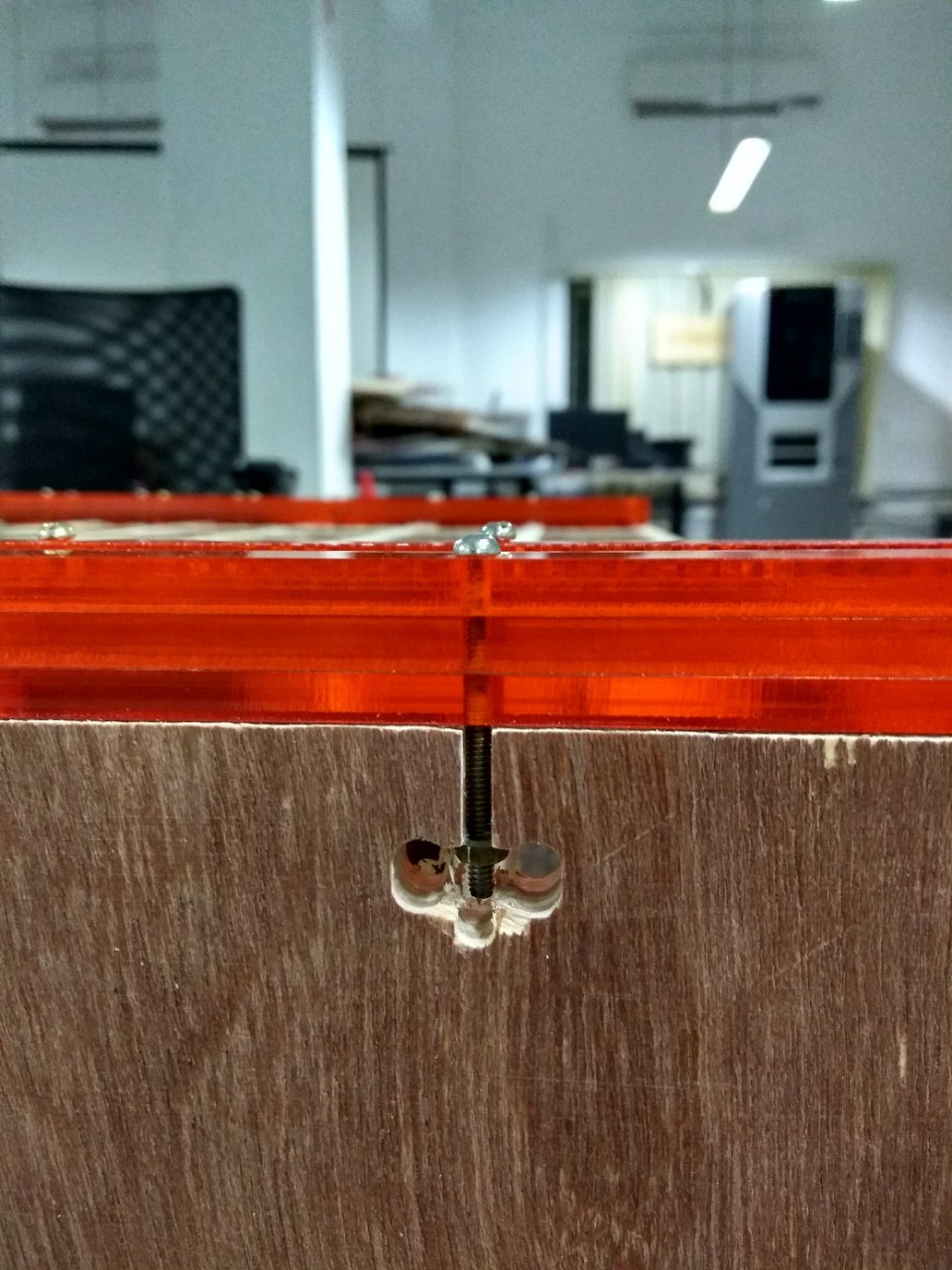

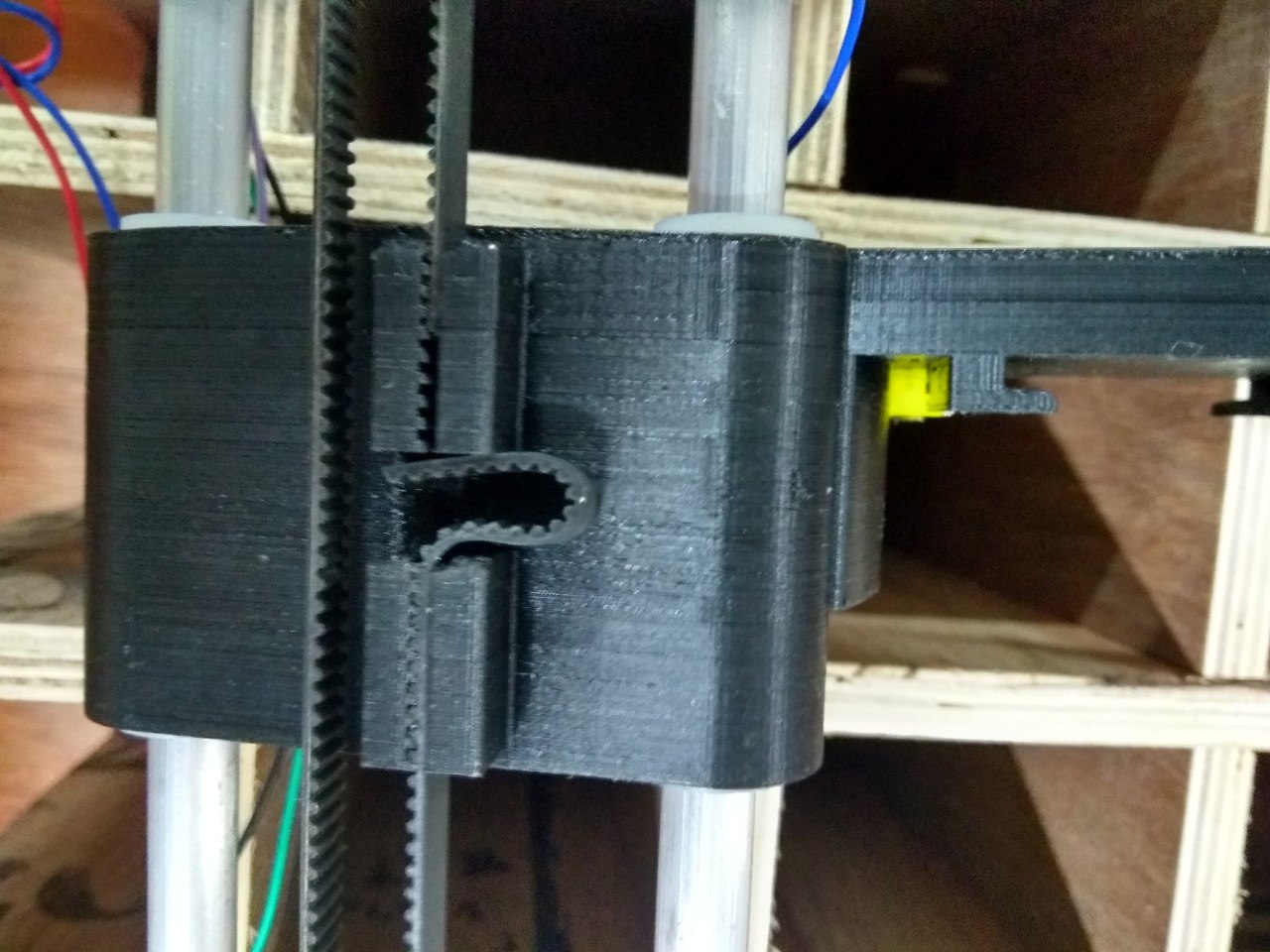

Rail Prototype

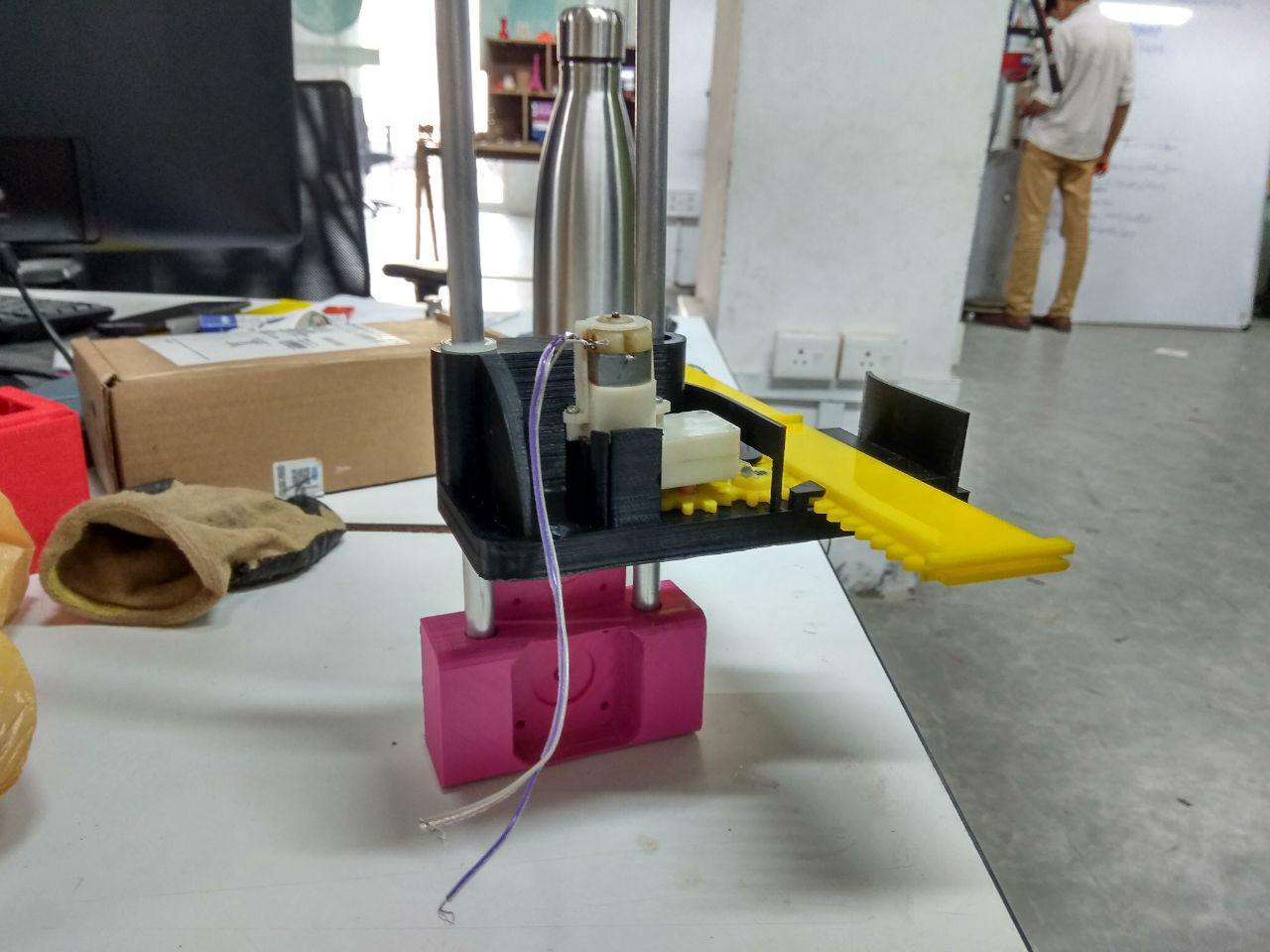

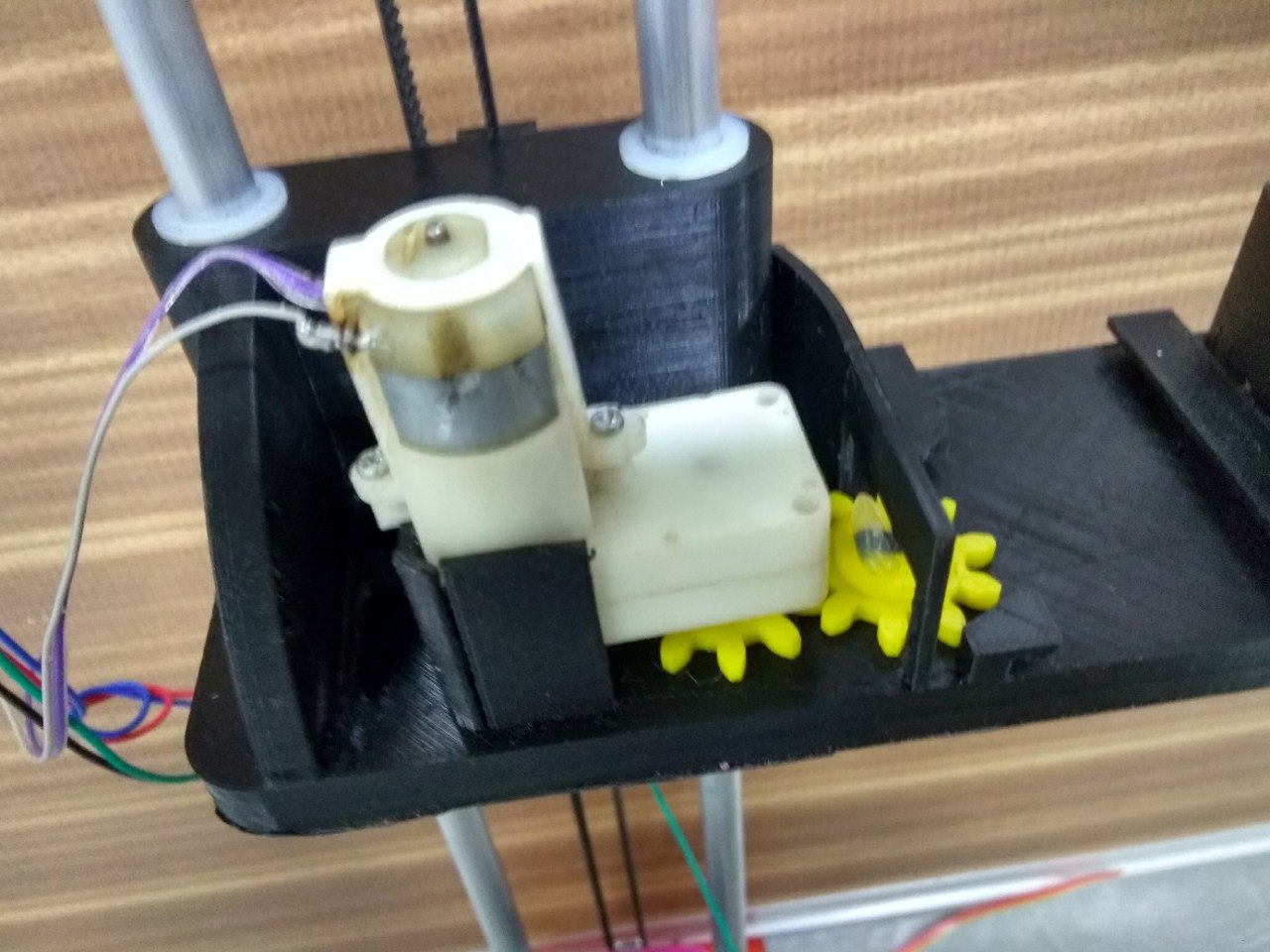

3D printed End-Effector

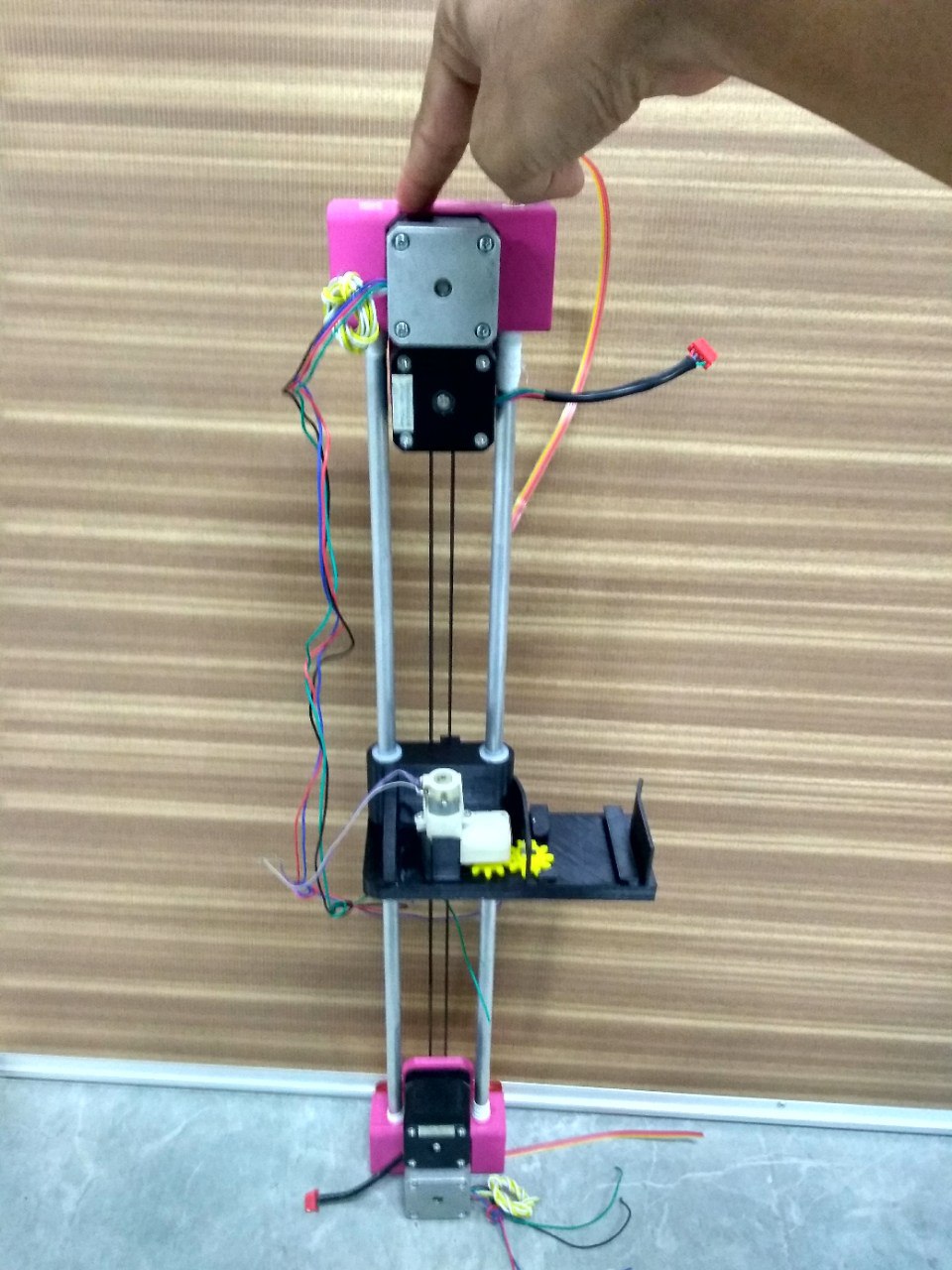

vertical rail

Demo

- actuate and automate your machine.

- document the group project and your individual contribution

Team

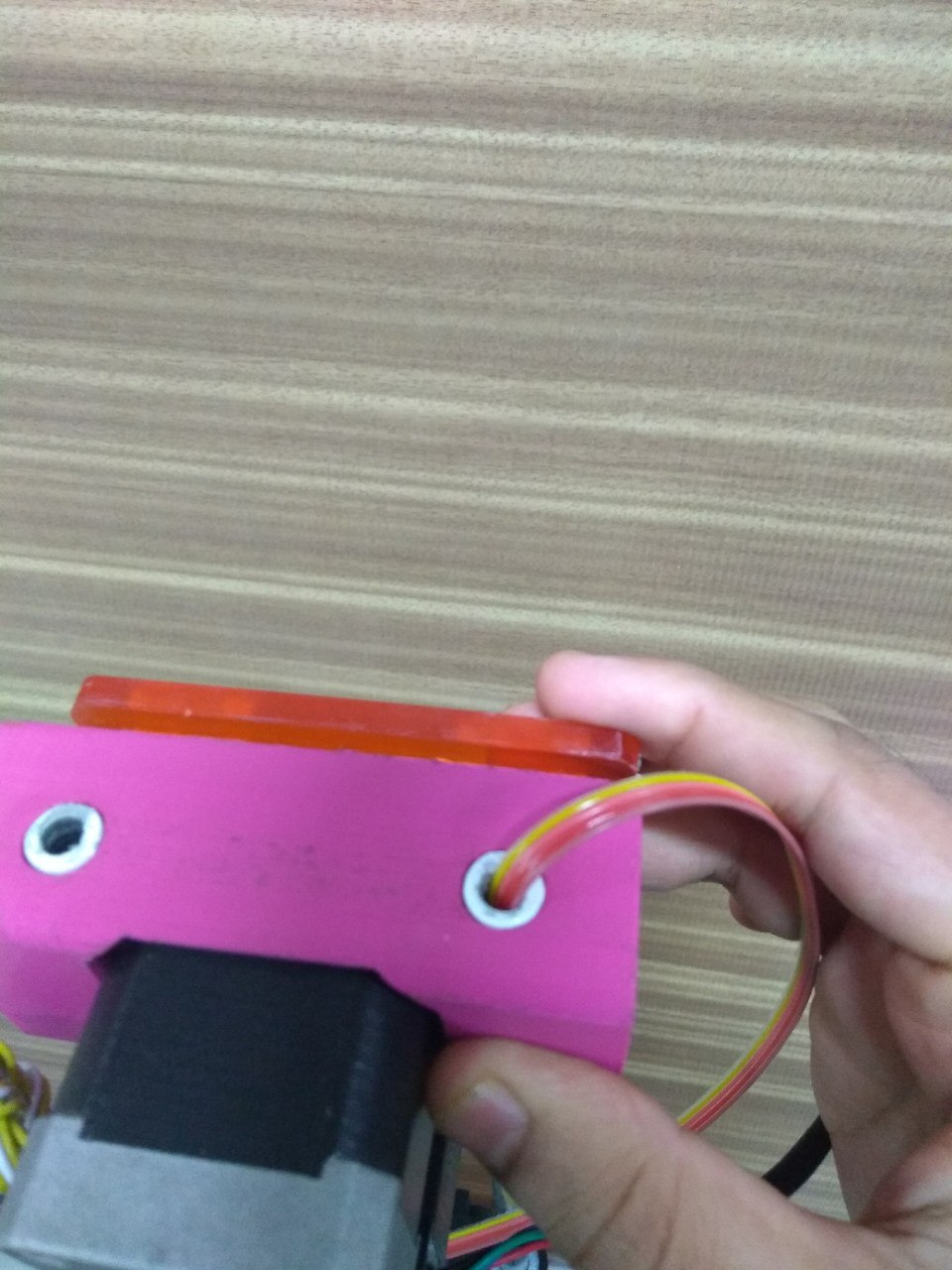

Assembling the Mechanical parts

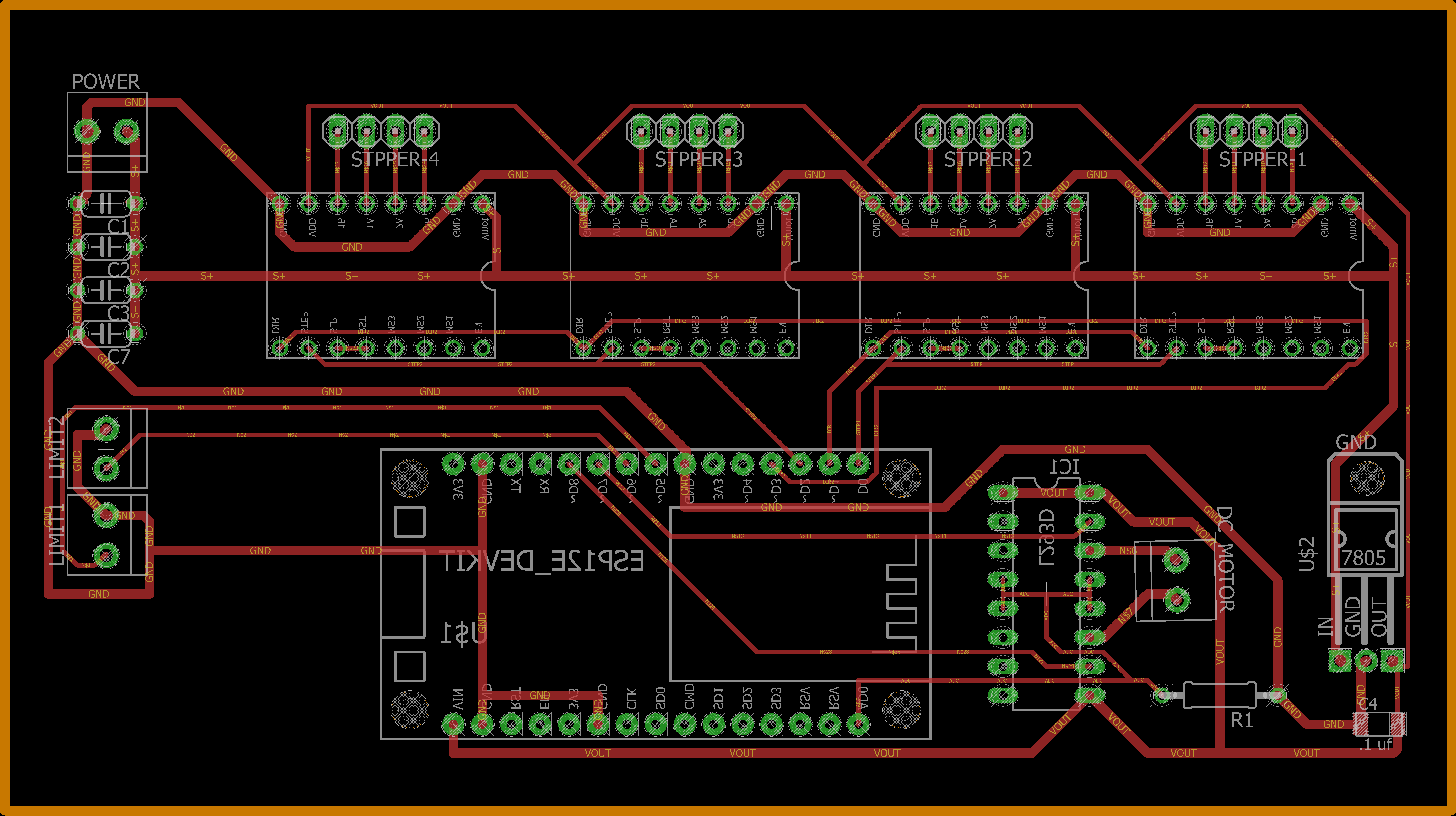

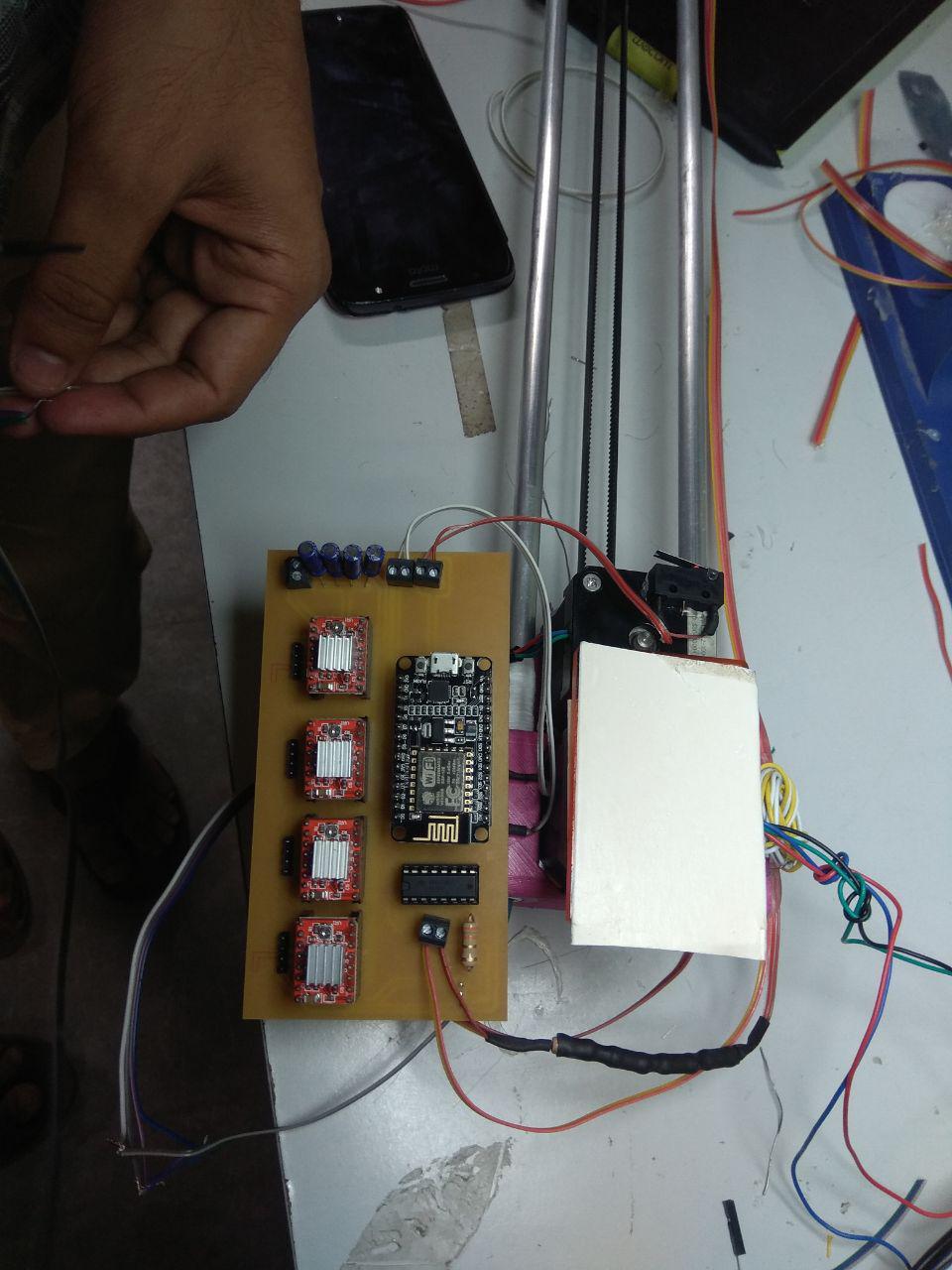

PCB

Here we used NodeMCU as a main MCU and we used polulu Setepper motor driver with that , we also deisgned PCB our own.

Soldering

Machine Used.

- Shop Bot

- Laser Cutter

- Modella PCB milling

- Soldering Station

- 3D printer

Demo Video