Back to main page

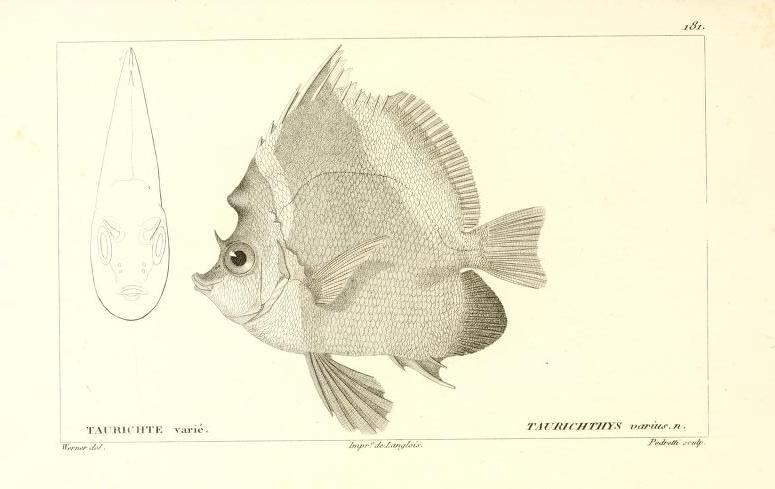

I'll use fusion 360 in Sculting Mode to produce a fish as this one:

using some of the technices I learned designing a shoo in this video: Fusion 360 Lezione 12 - Esercitazione Tsplines

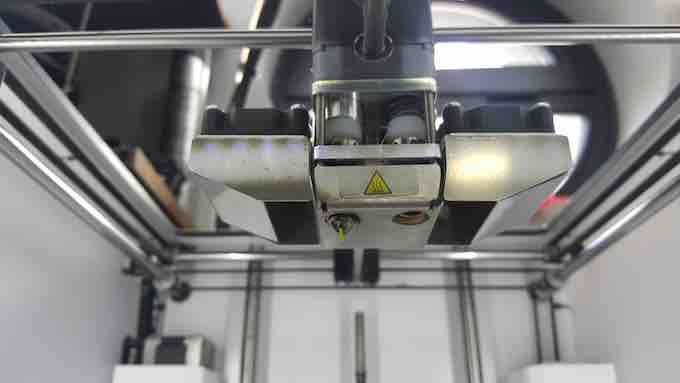

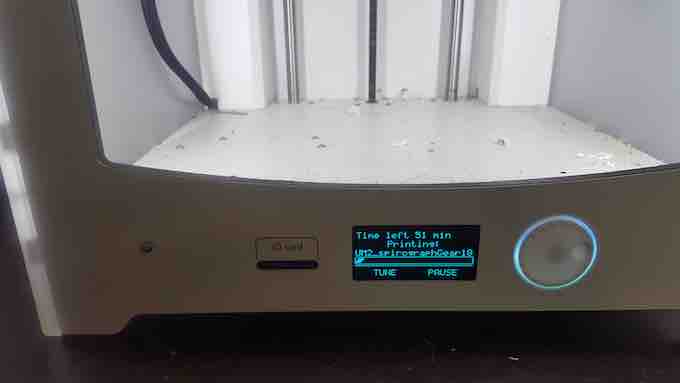

The Lab printer is a Ultimaker 2+

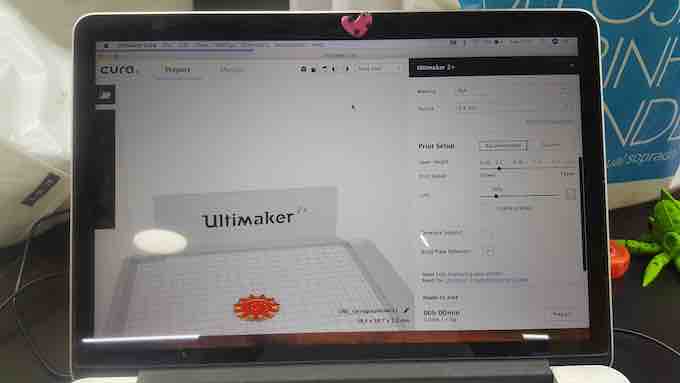

needed to instal Cura

and the process to print was:

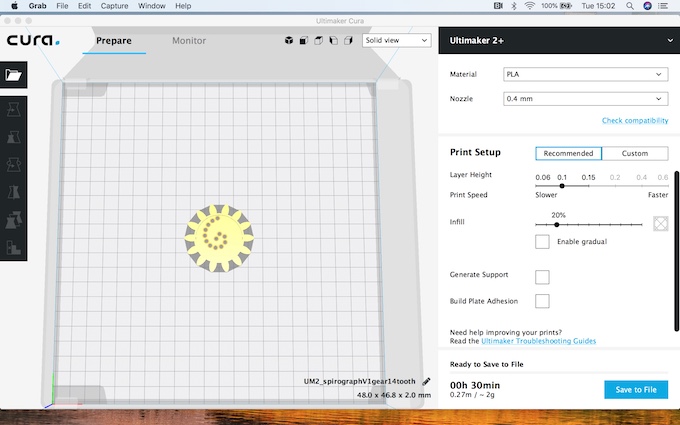

and this are the first prints to know how to operate the machine

configuration for the first prints...

finaly some objects to play with Geometry...

---------------------------- (-).(o) -----------------------

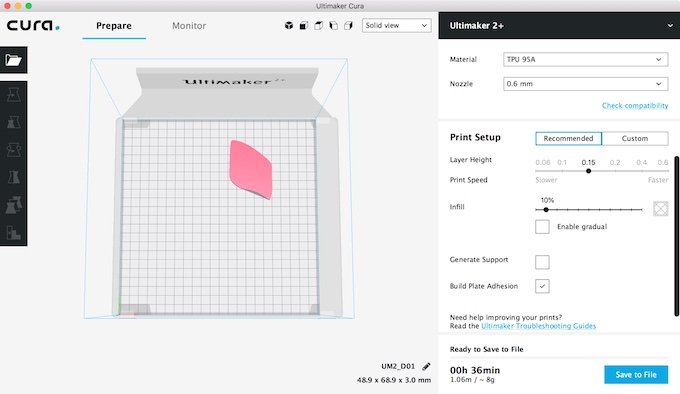

I'll try the Flexible Filamente using larger NOOZLE, to evaluate both the material and the viability of such product

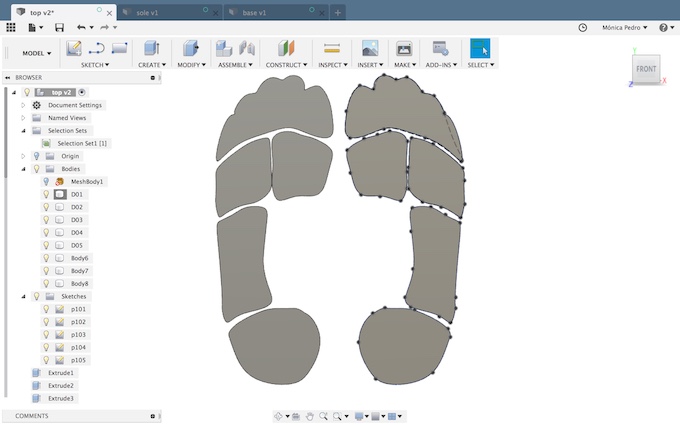

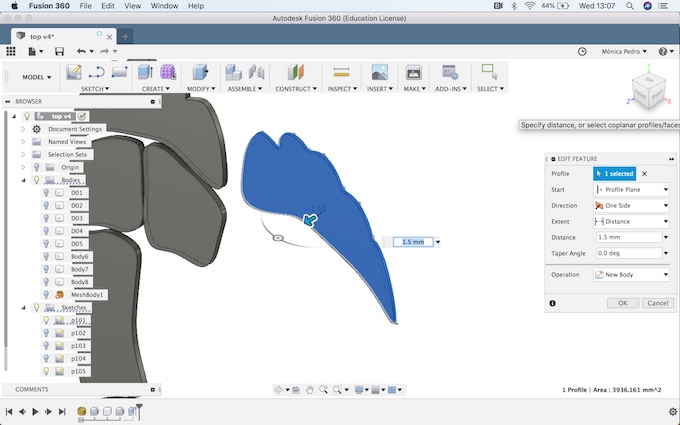

I'd decied to design a ergonomic modular sole so that the Printer tests would be quiker ;-)

Thikness of the sole: 3mm

steps:

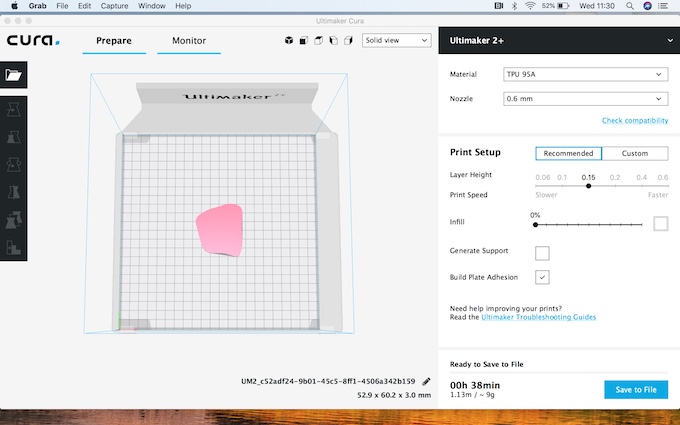

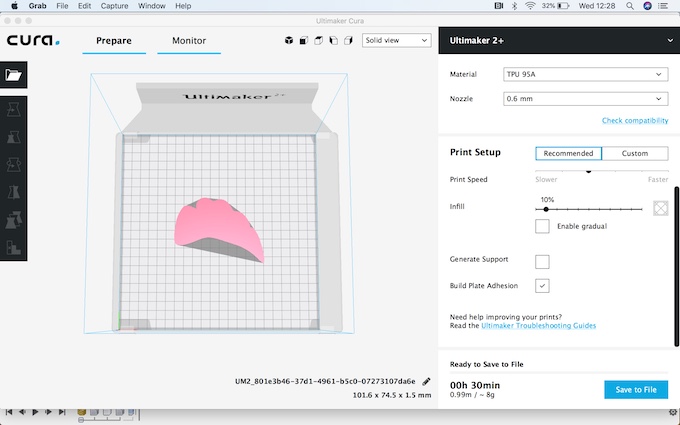

Configuring CURA for the new material

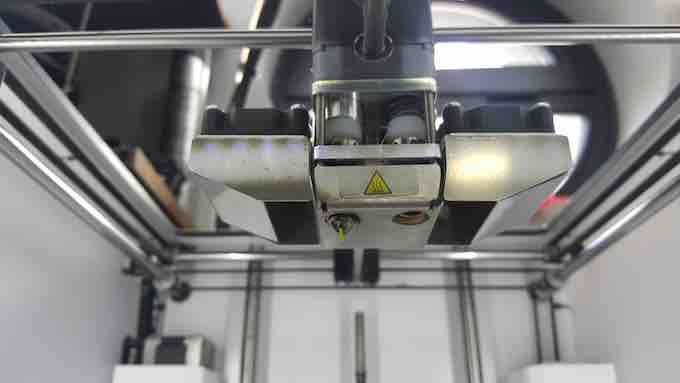

When printing.....

Final print... its not very bad, but NOT GOOD for the purpose...because it's not flexible and soft enought to give a "no Shoo sense"

I'll try a print without Infil...INFILL = 0

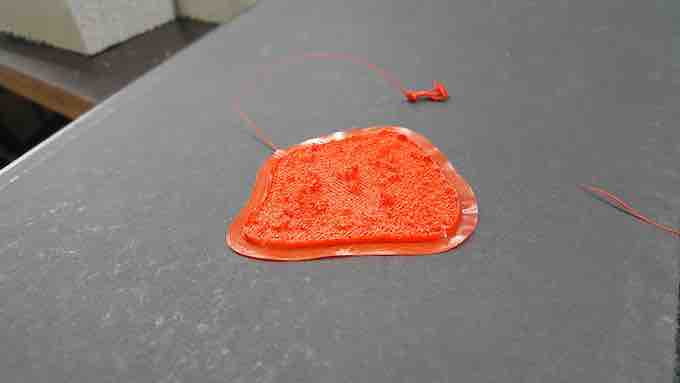

and the Printing becomes quite strange....

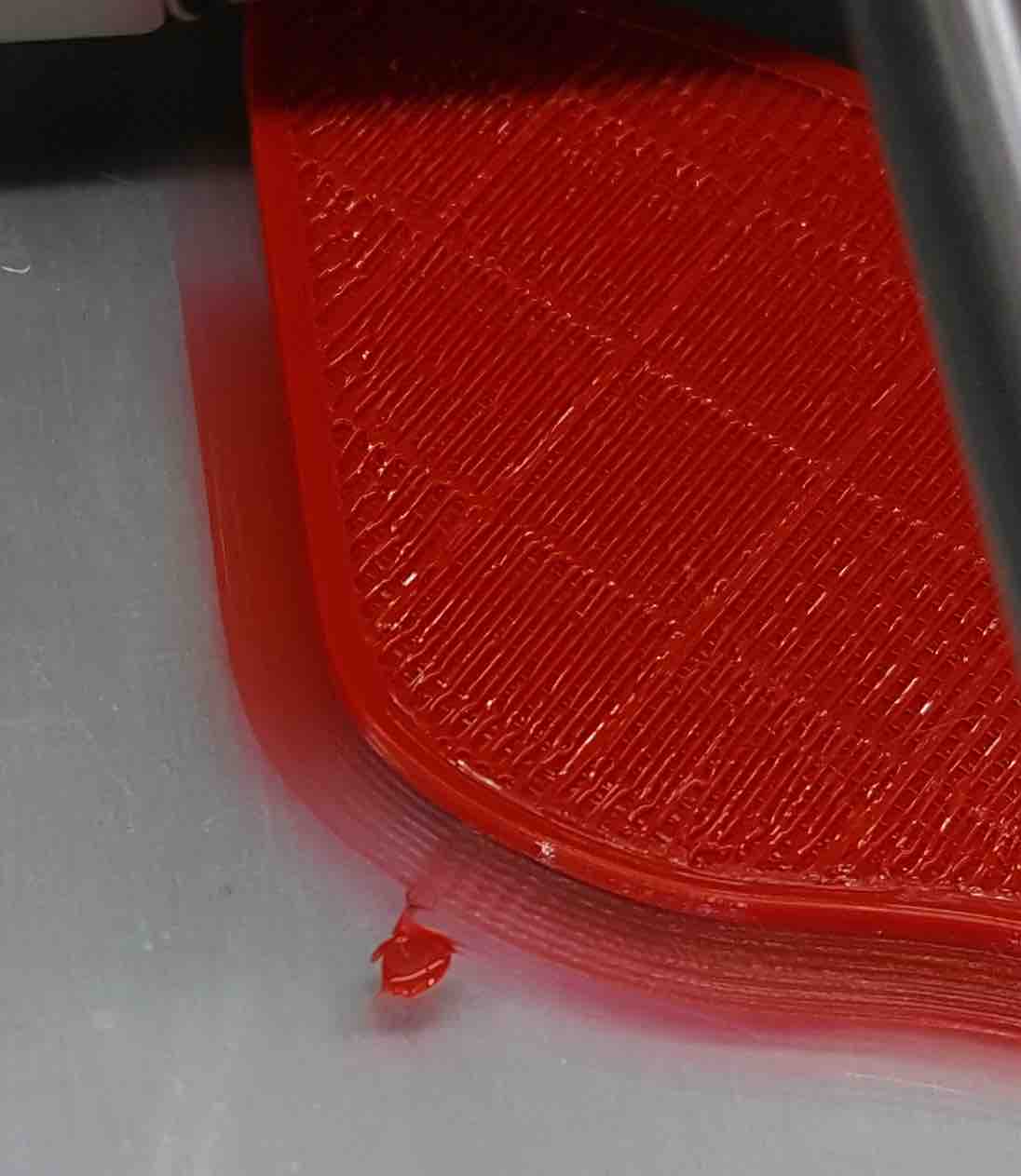

Look fuzy... but it has its qualities.. flexible... soft

I'll try with lower thikness of the sole...EXTRUDE = 1.5mm

sent it to Cura

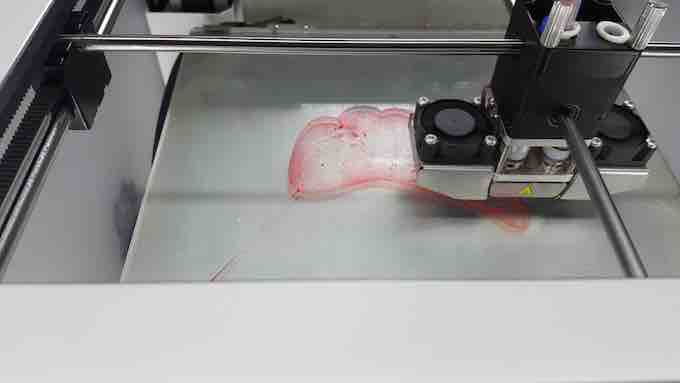

and then this was happening in the printer

the BAD RESULT

group assignment

test the design rules for your 3D printer(s)

individual assignment