Week 3 - Computer-Controlled Cutting

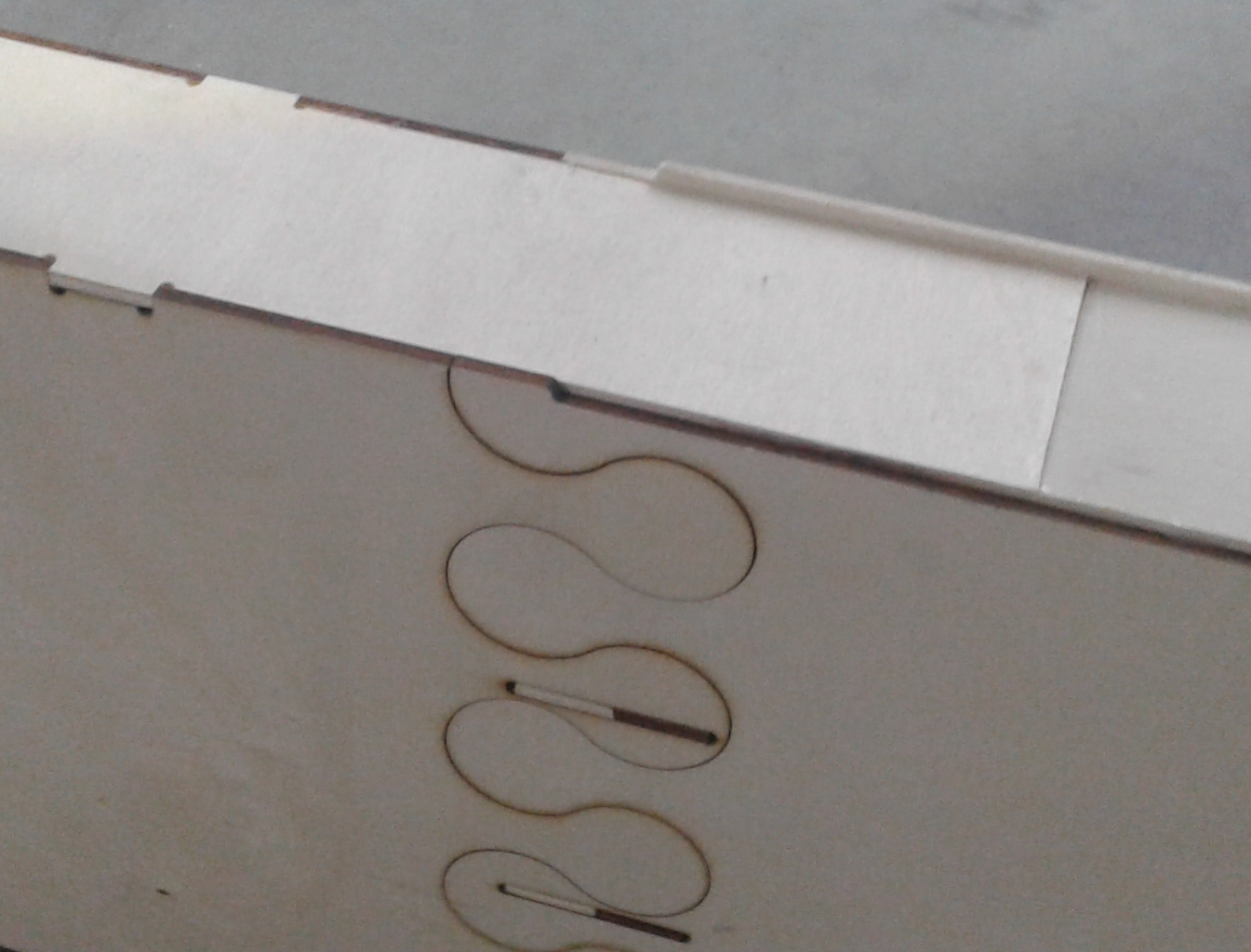

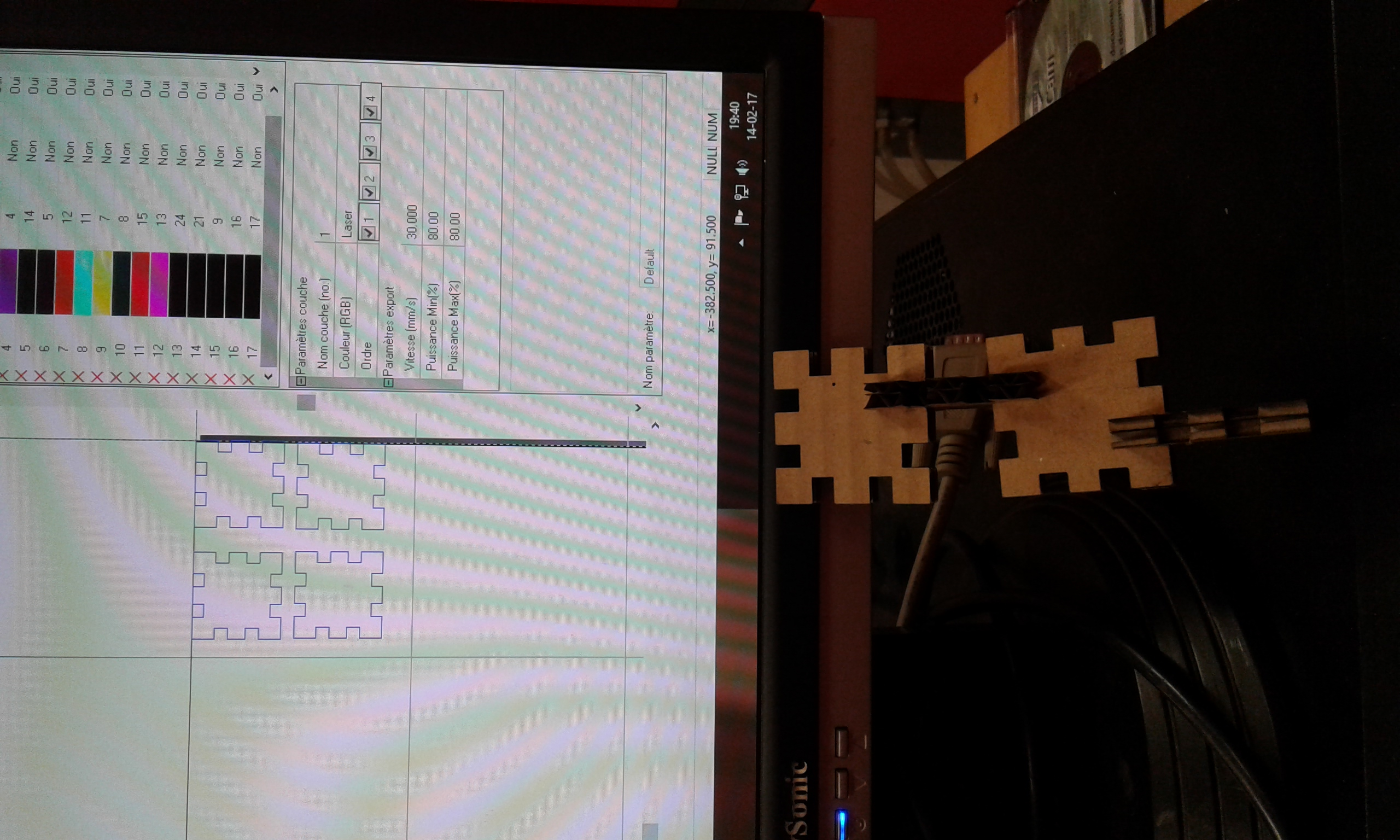

- We make different test with laser

individual assignment:

- Vinylcutter

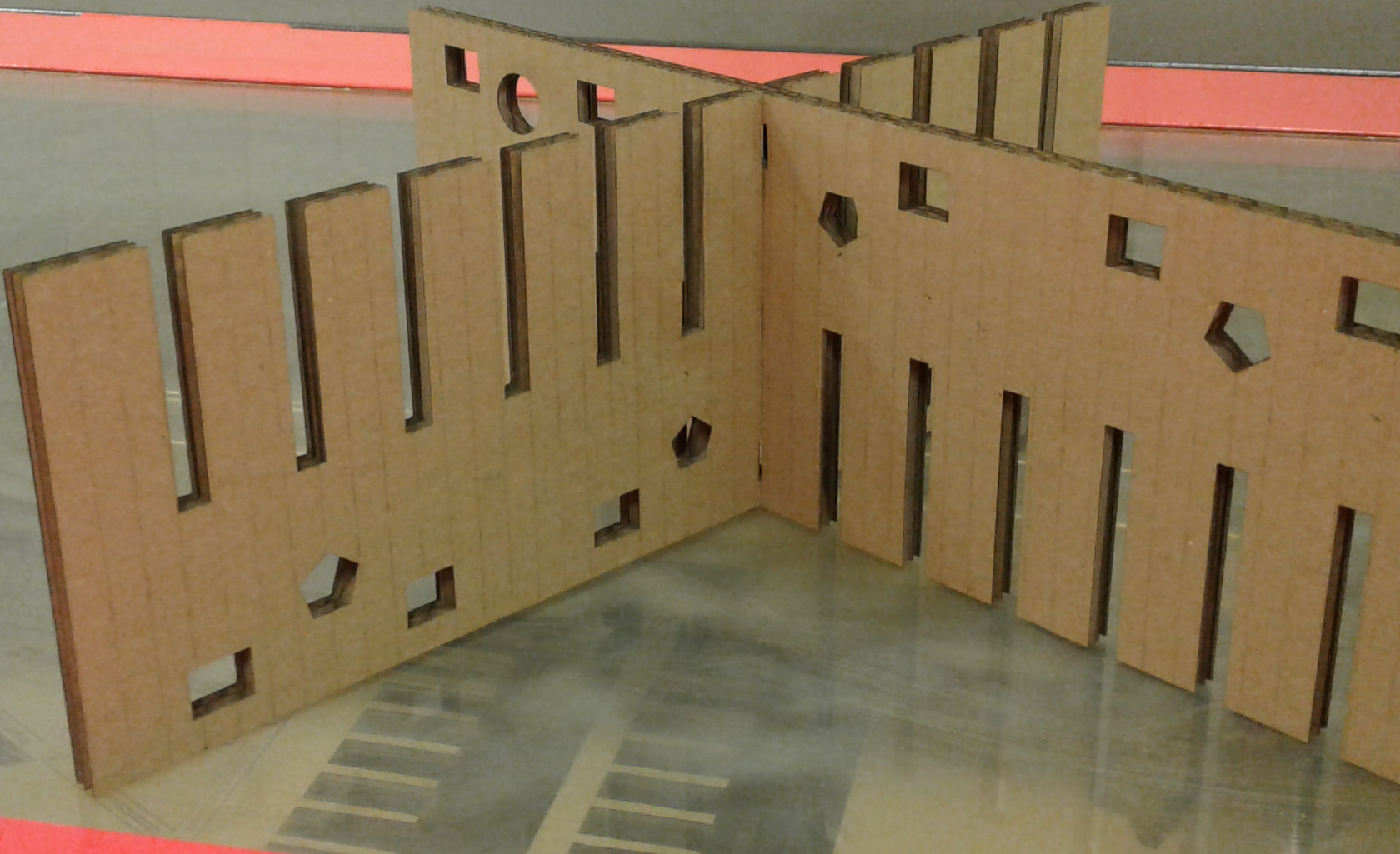

- Design, make, and document a parametric press-fit construction kit, accounting for the lasercutter kerf, which can be assembled in multiple ways

- lasers CNC > Softwares :

- Inskape 2017 a free software for 2D designs used in parametric way

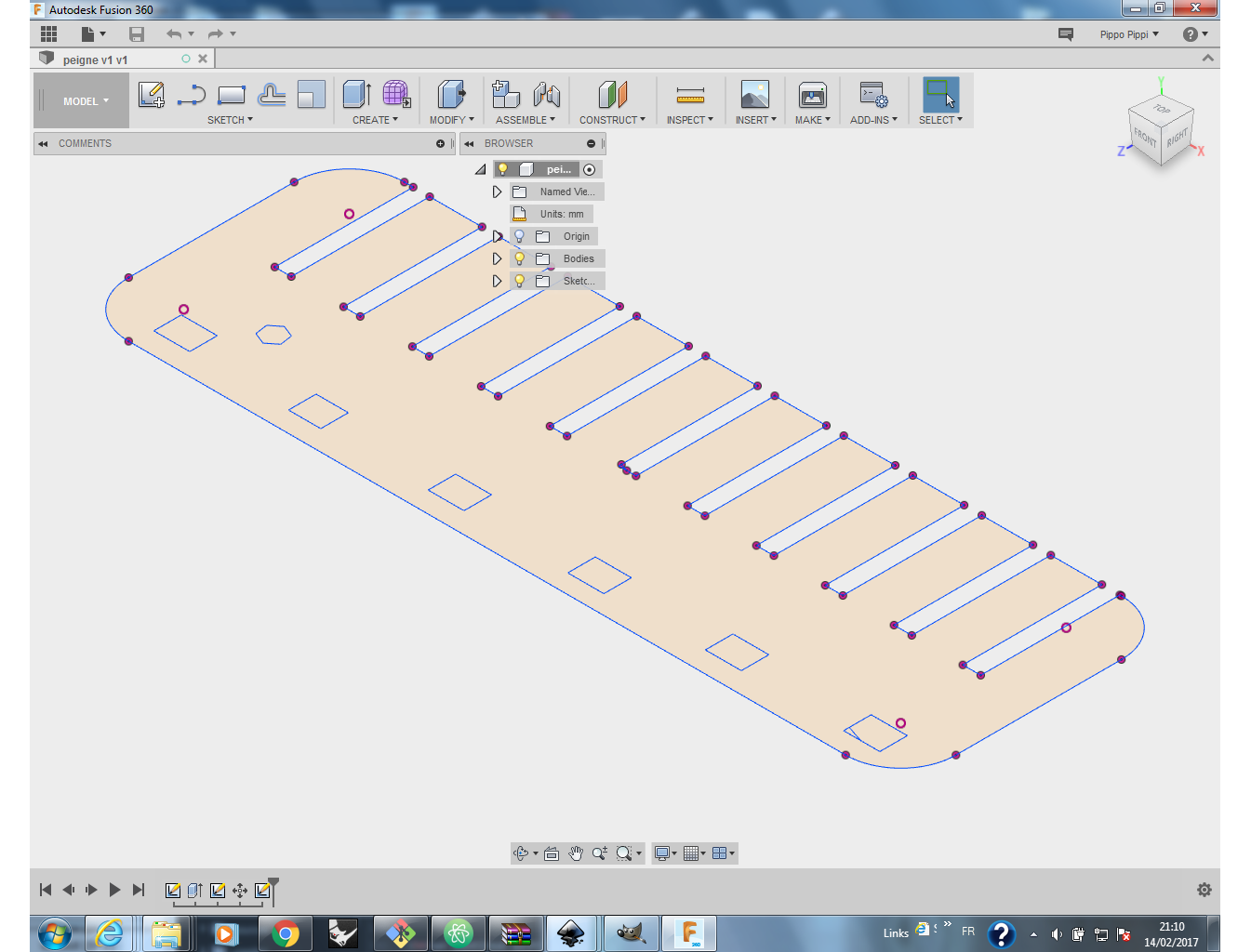

- Fusion 360 a 2D 3D CAD CAM parametrica TOO

- CyborgCyborg machine use a low level soft to control the step motor of the laser

- 123D Gaget to make toys

Group assignment

We had to use four lasers at our disposal

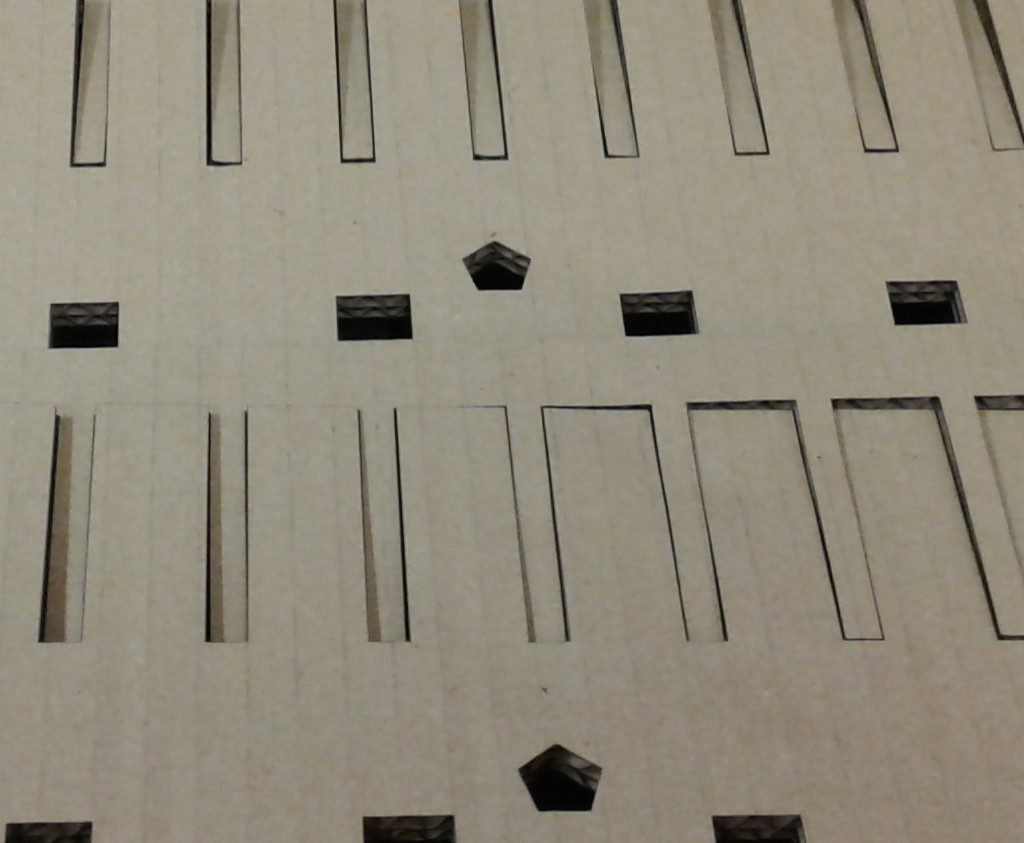

We have seen the different kerf values

Interesting

KERF

I use a https://www.hypertherm.com/hypertherm/hyintensity/hyintensity-fiber-laser-hfl010/ when i work in my company WWW.meetalconcept.com the advantage the kerf compensation is automatic like a CNC

Designing the press-fit kit

I design with inkskape the idea after with fuse360 the joint and we cut with laser

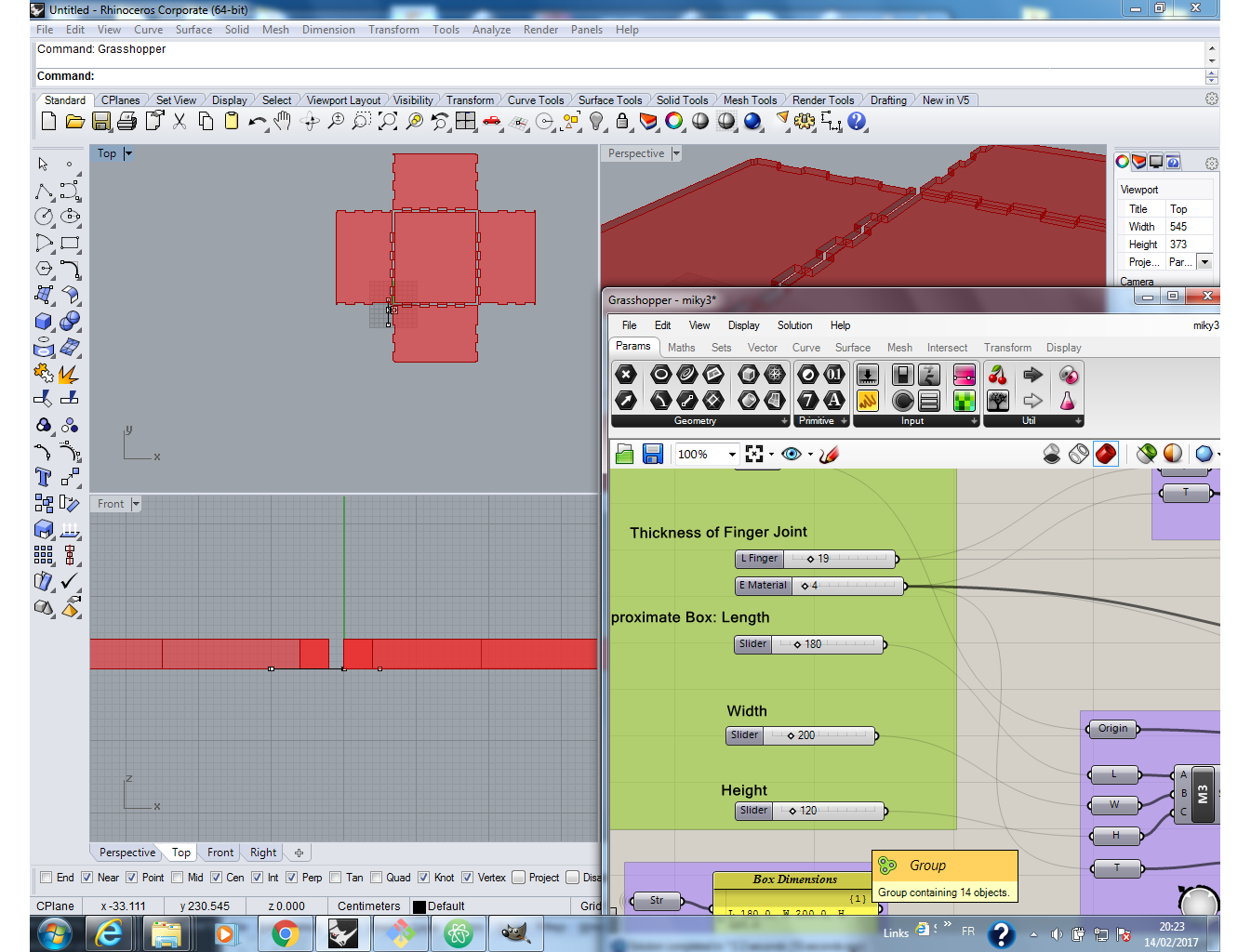

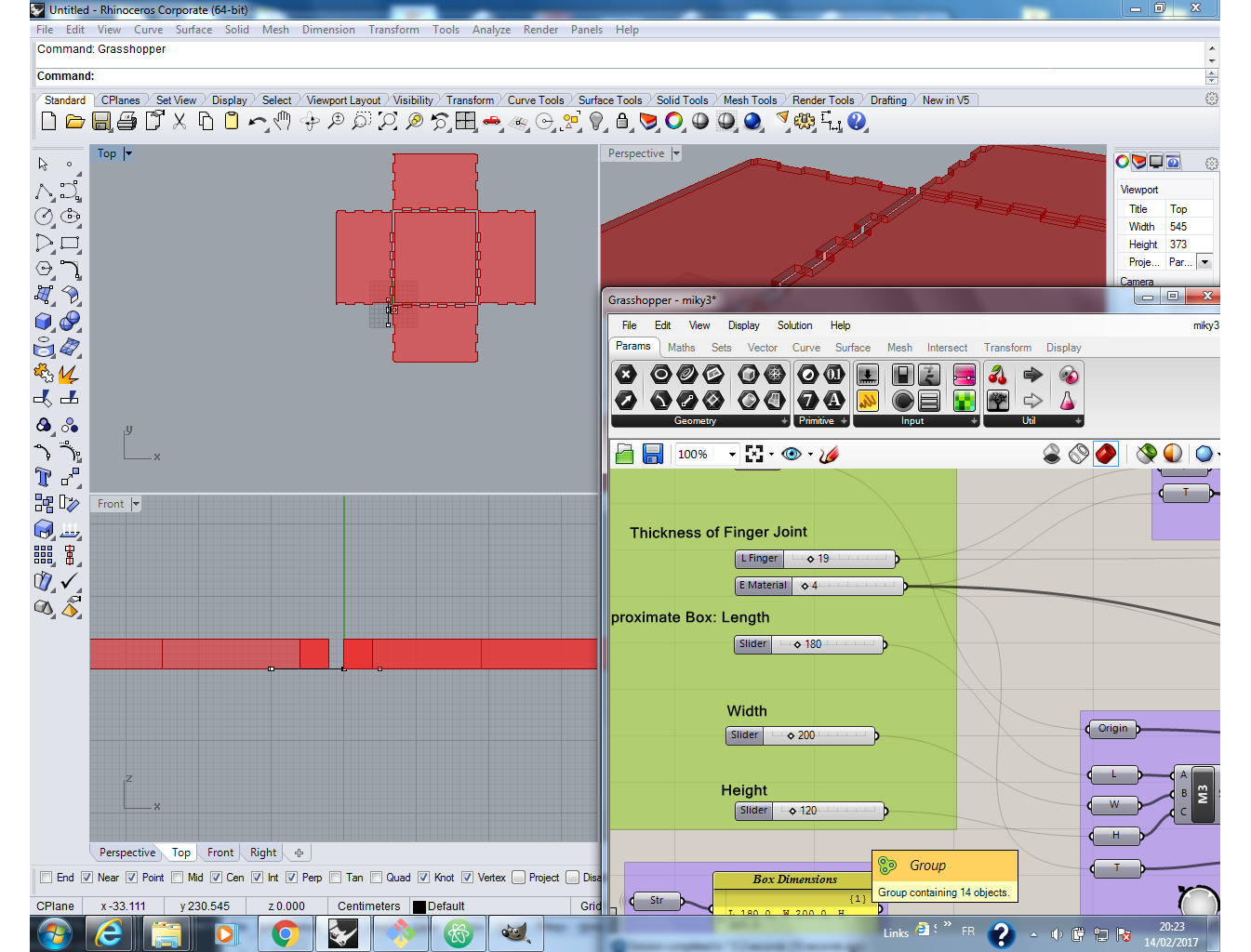

I make a overdose of tutorial to use grasshopper to make something of usefull

I have find in a official site of autodesk a grasshoopper spaghetti to make box with joint

is very usefull tomake the structor of my final project

after 4 hours of brainstorming with Jeremi and Victor i have understood

i try to modify to make joint with a 5axis cnc machine

i think that joint with circle is good becouse we can use with cnc.

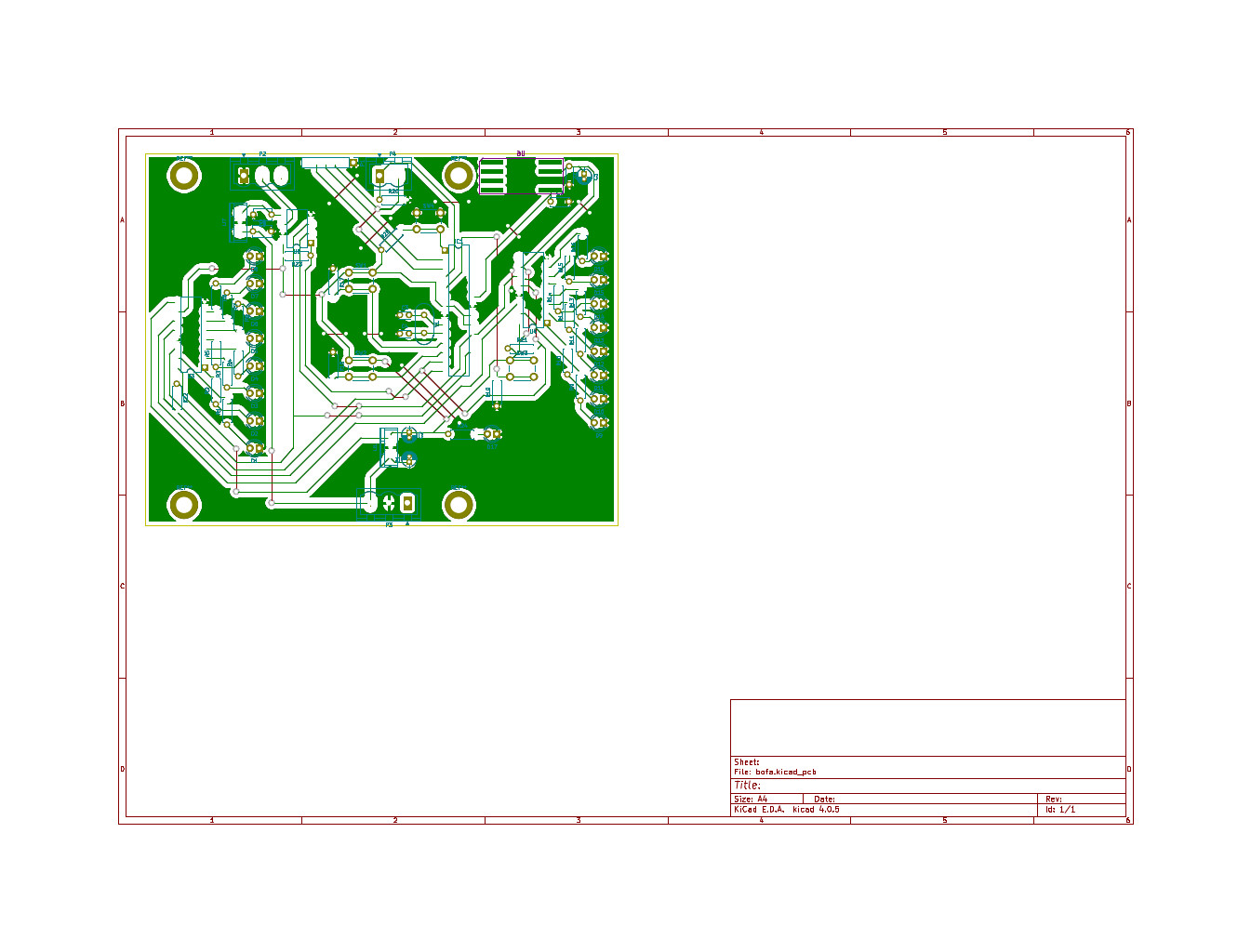

We have designed a arduino board to test if it is possible to use a stiker like a mask for acid etching

I have used a vinyl cutter to make a stiker for the friend of planet park

we create stiker on the frigidaire for cocacola

we continue with test

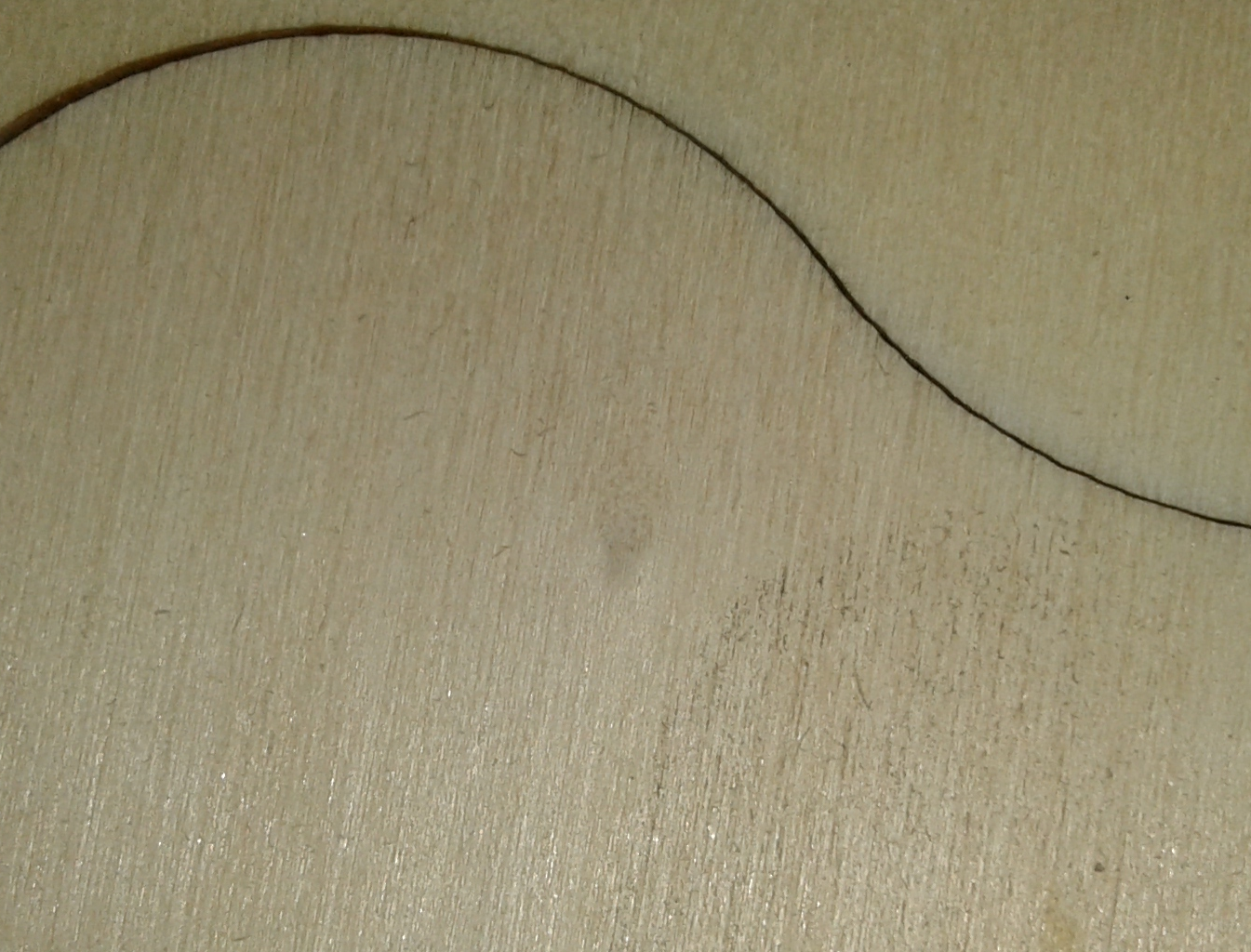

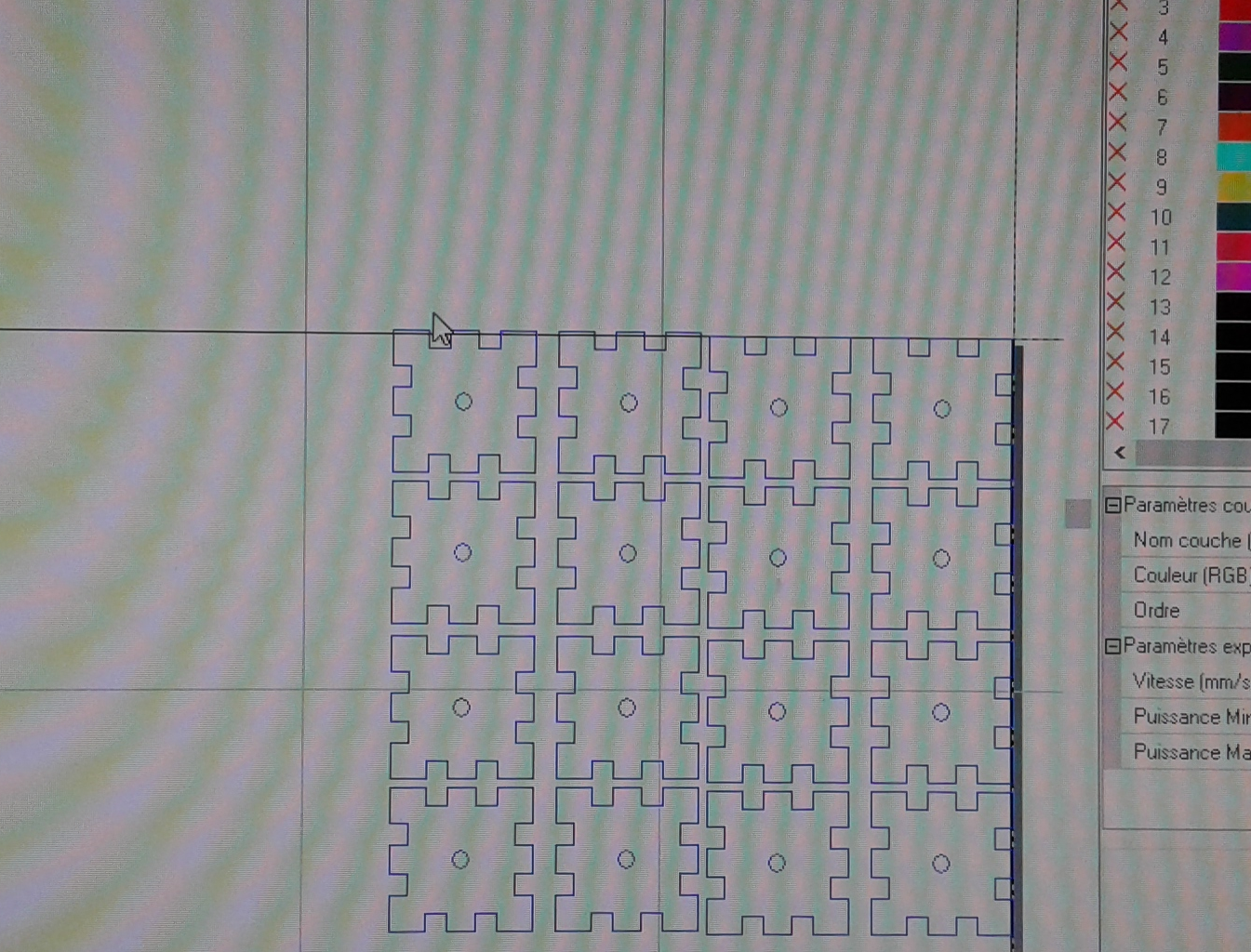

we cut wood using laser round interlock joint useful in cnc

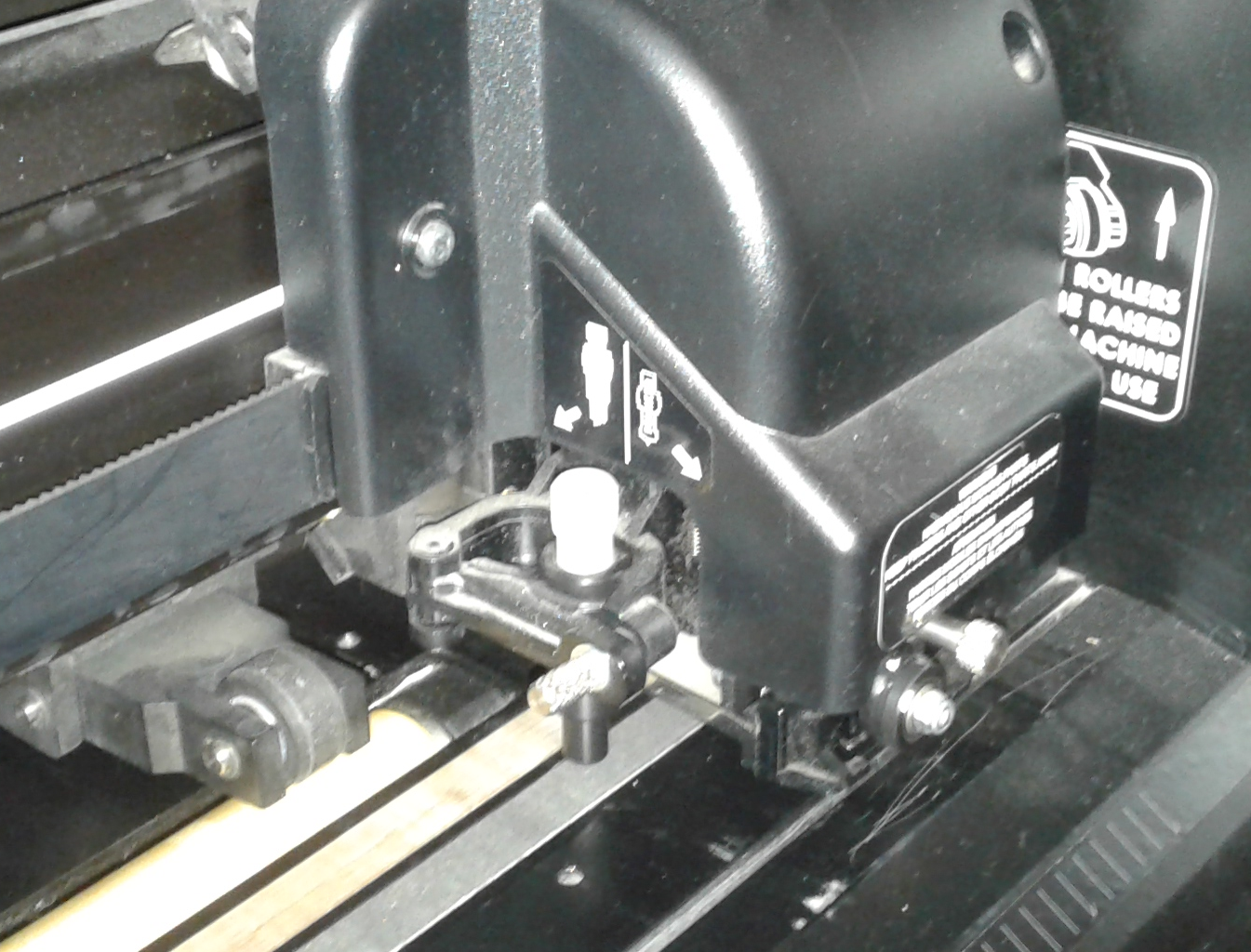

you can see the cutting head of vinyl cutter SUMMA

we make other stiker and I add photo in future