Ripple Coasters

Files

Process

I've been thinking about waves and interence patterns lately, and i thought it'd be interesting to create some concrete coasters to explore the space.

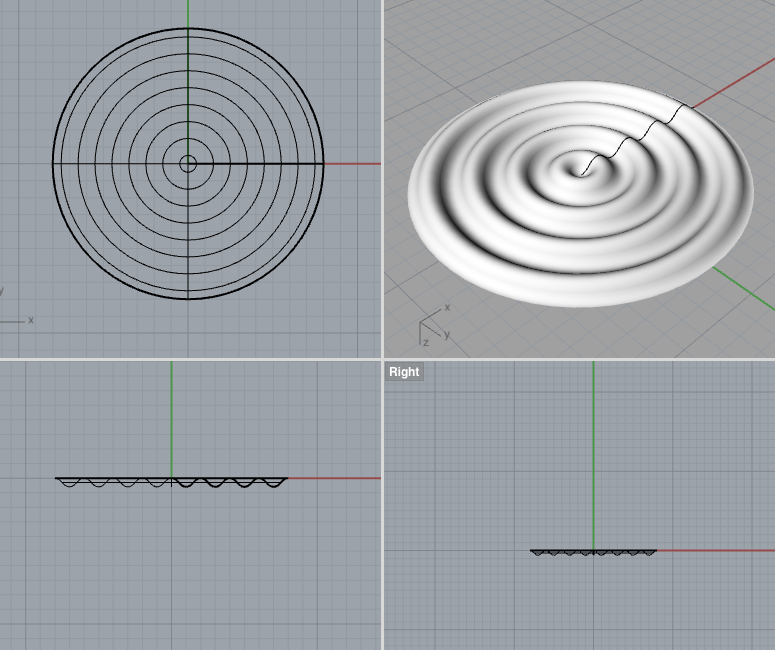

I opened up rhino (a nurbs-based 3d modeling program), drew a sine wave with the bezier tool, and revolved it around a center axis. For a coaster to be useful, it needs to provide a level surface, so i made all the peaks are the same height. A quick survey of the cups around my kitchen determined that the outer diameter of a cup is usually 3.5" or smaller so I scaled the resulting shape to 4" to allow for a comfortable margin.

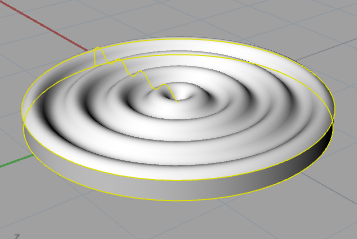

Next, I drew a cylinder and used the ripple surface to split the cylinder giving me two solids. For now I'll only mill one of the halves, but it'd be satisfying to do both parts and see how closely they'd fit together.

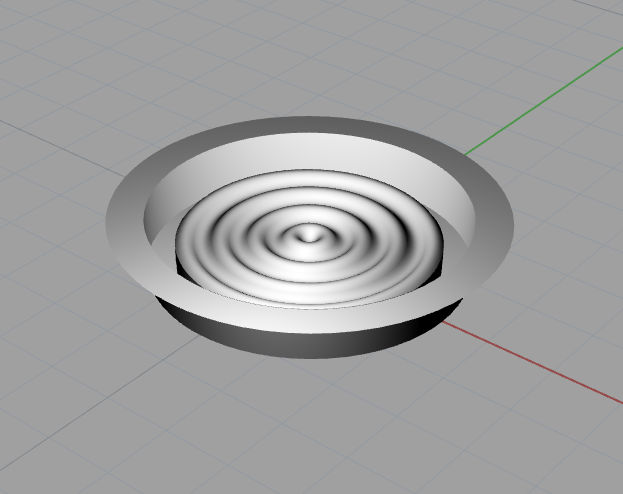

Model a container around the positive coaster shape.

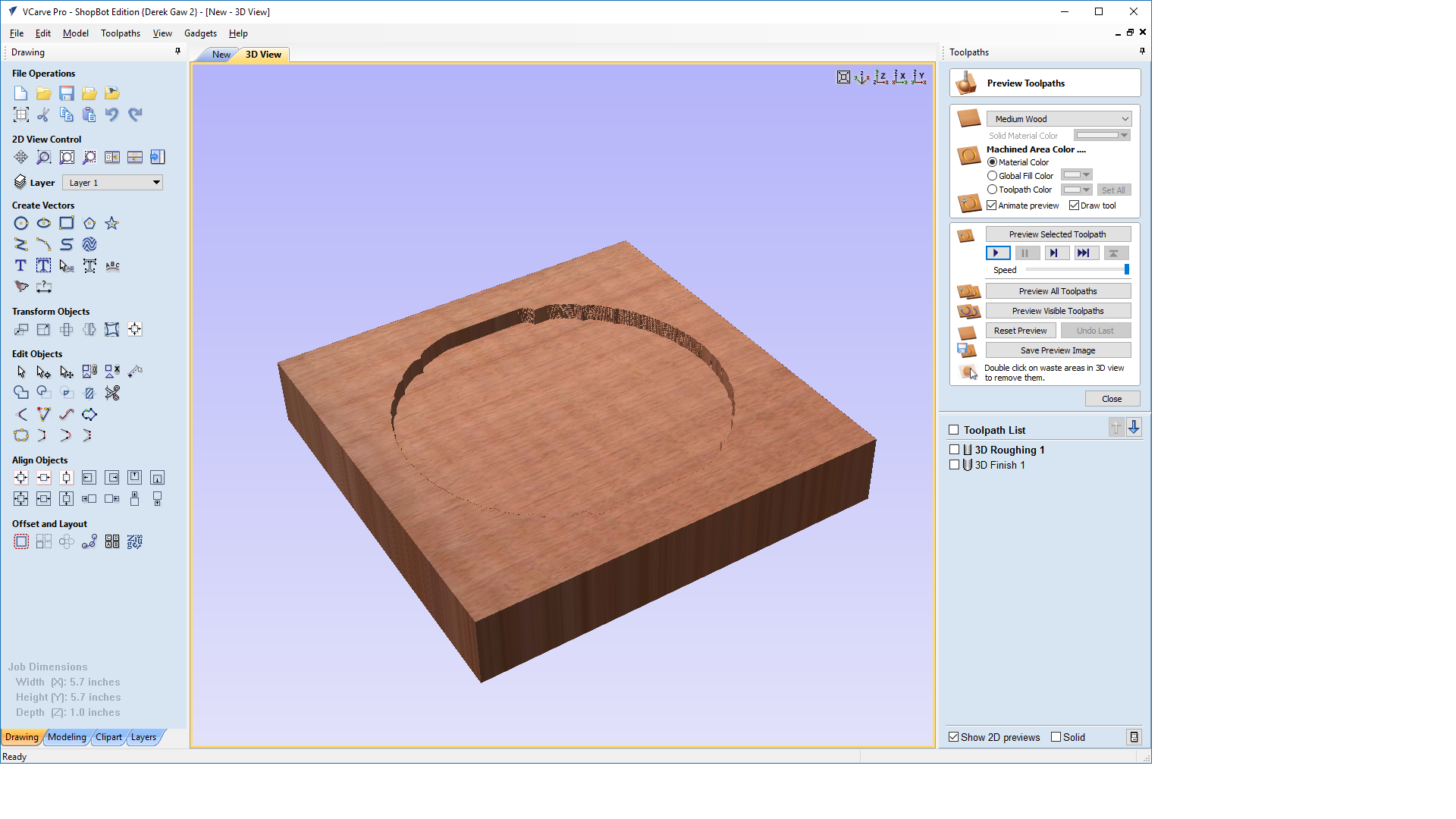

VCarve Roughing toolpath with a 3/8" diameter clearing bit.

VCarve Roughing toolpath preview.

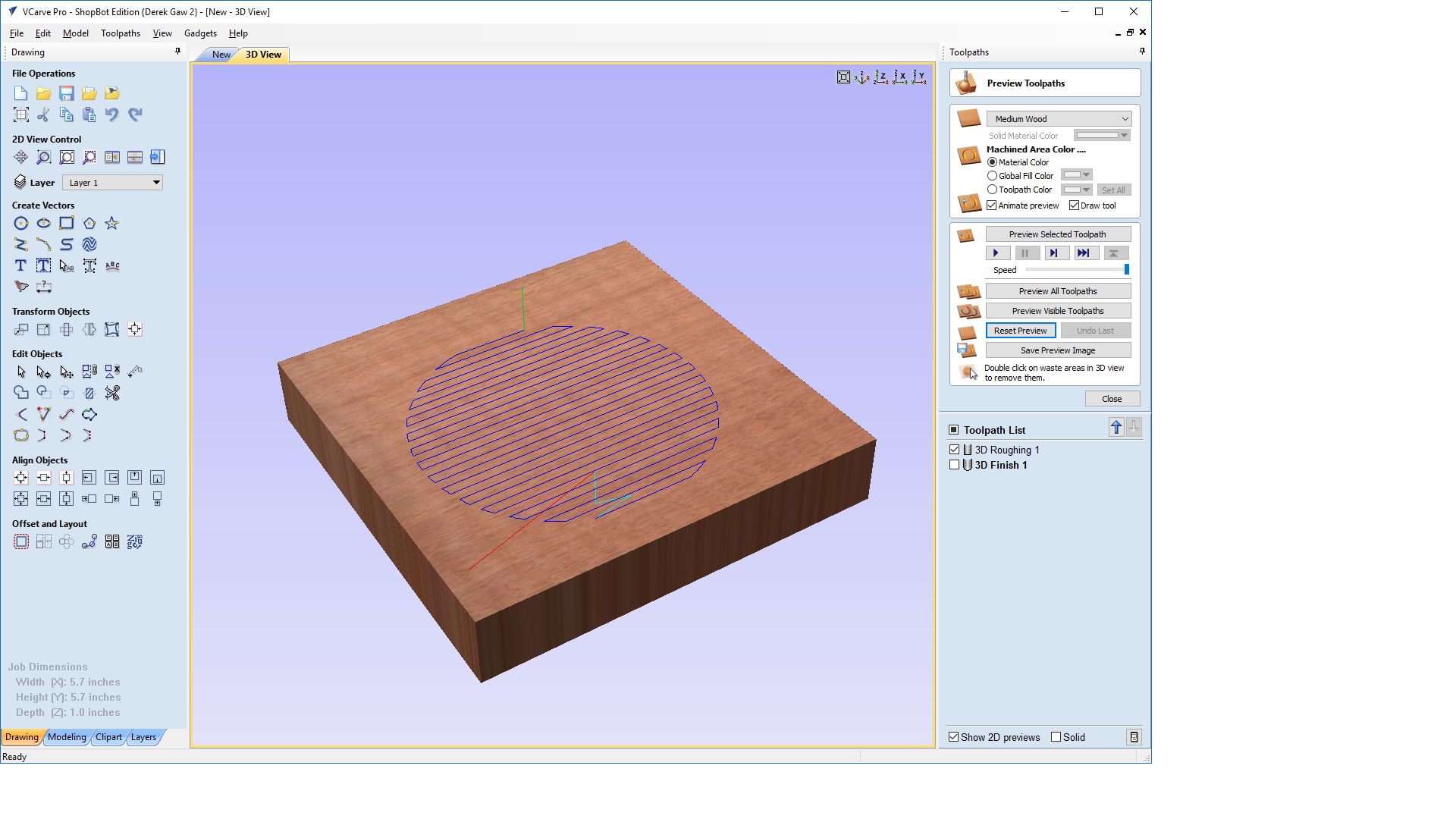

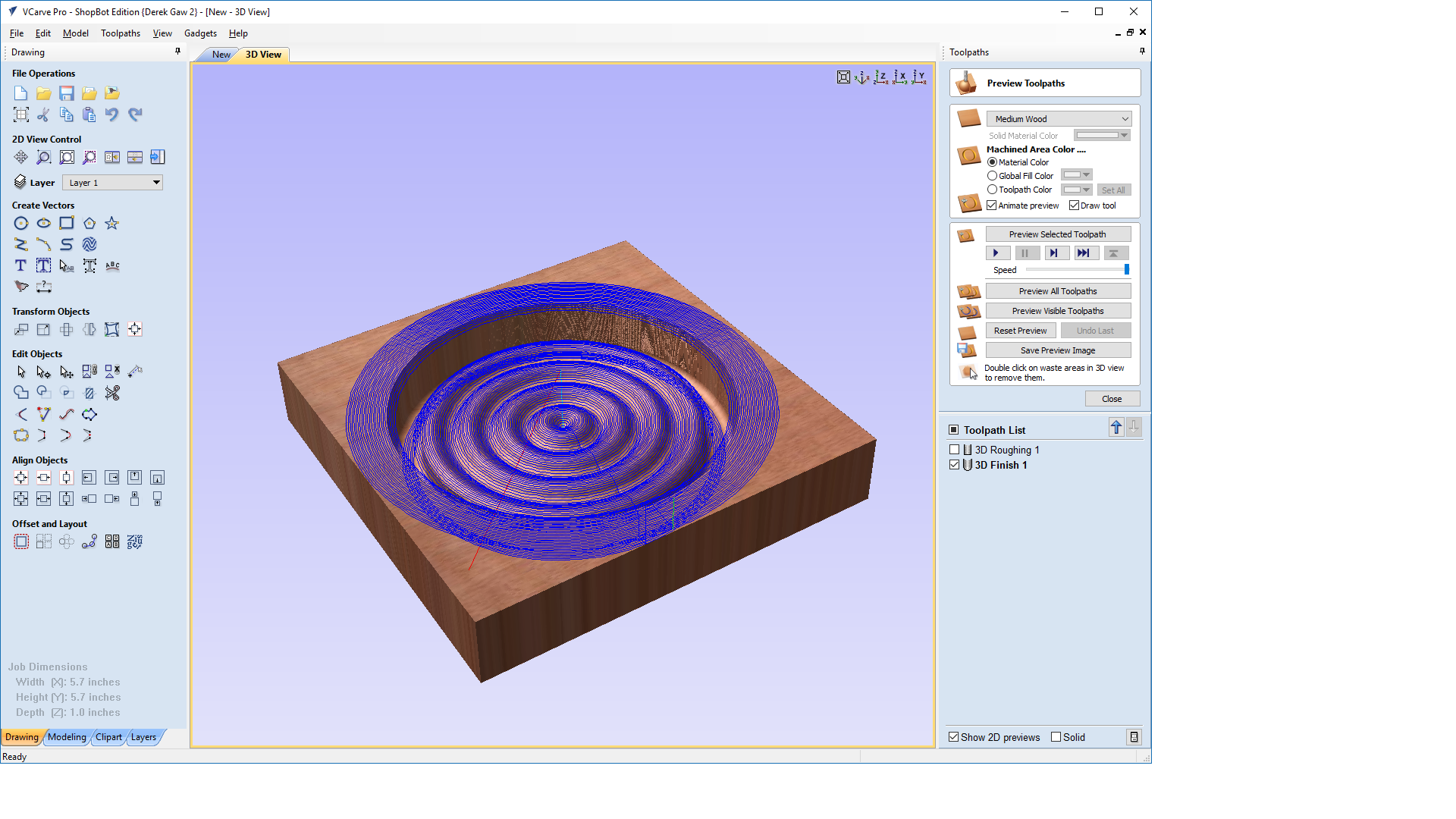

VCarve Finishing toolpath with a 1/4" diameter ballnose bit.

Action shot of the mould being milled from 1" ultralite MDF.

Cleaned up mould, ready for casting a negative.

TBD: Cast a negative so that I can use that to cast a positive.