What will it do?

I work in a traditional ceramic workshop and my finally project is a ceramic 3D printing with recycle ceramic materials

I use two type of ceramic dust and water with natural binder, Whit to join the different ceramic dust.

I make a different process to make a prototype faster on ceramic with the precision of a CNC machine.

I explore different options for take a new system of 3D printing in ceramic whit an concept in a machine in which the size

of printing is not a problem very important.

Who's done what beforehand?

The best form to make a faster prototype on ceramic is apply in the 3D print.

I take with reference the 3D ceramic printing the IAAC (Barcelona - Spain)

IAAC

The different projects of the CTTC easy ceramic Fab Lab (Limoges - France). In this Fab Lab I found information of great help

CTTC

What materials and components will be required?

- Motors

- Guides

- head

- Extruder

- Natural binder

- Ceramic powder

- Steel rod and Threaded rod

- Sharp Sensor

- Square tube

Where will they come from?

The electronics components use of the fab lab components and the structure of the machine

I design and make whit fab machines, and the ceramics materials I have ceramic workshop

whit my family.

How much will it cost?

To do it we take recycling ceramic material plus natural binder. The recycling ceramic

material is a compost of two types of ceramic powder; the first is when you sand the imperfection

of the pieces and the second one is the fail pieces that you take of the first burn.

Of the natural binder, we buy this to all production in the ceramic workshop.

What parts and systems will be made?

In the first part, we collaborate about the modular CNC; in this machine, we can join the controlling part of this machine.

I need design the extrude to de natural binder.

Make the correct performance analysis to my composites the ceramic powder and natural binder.

What processes will be used?

- CNC electronics boards

- 3D printing

- Laser cutting

- Output Devices

- Input Devices

- Mechanical desing

What tasks need to be completed?

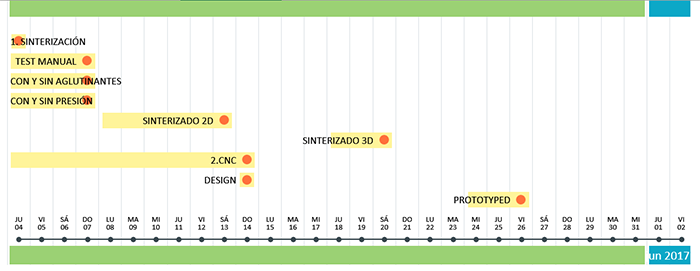

1. Manual test

1.1 Water + bender

1.2 Compression test

1.3 Join in two dimensions

1.4 Join in three dimensions

2. Link the system with cnc

2.1 Fluid control

2.2 Extruder design

2.3 Machine control

What questions need to be answered?

Can I make a faster prototype on ceramic?

Is possible to join these materials?

Can I make 3D models using these composites?

Is it possible to exemplify the powder ceramic with natural binder?

What is the schedule?

In the next link we can take my the time line of my final project

Time line

How will it be evaluated?

The principal purpose is make product whit them get better the process of the familiarly.

The functionality and the concept, I think is the most important items to my evaluation.