We decided to start from same value of laser speed and power (30% of speed and 30W power) and then we empirically changed values relating to cut definition we obtained.

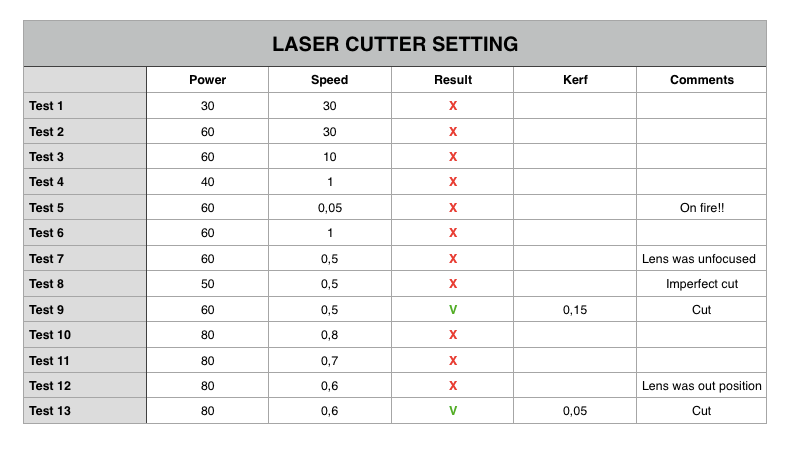

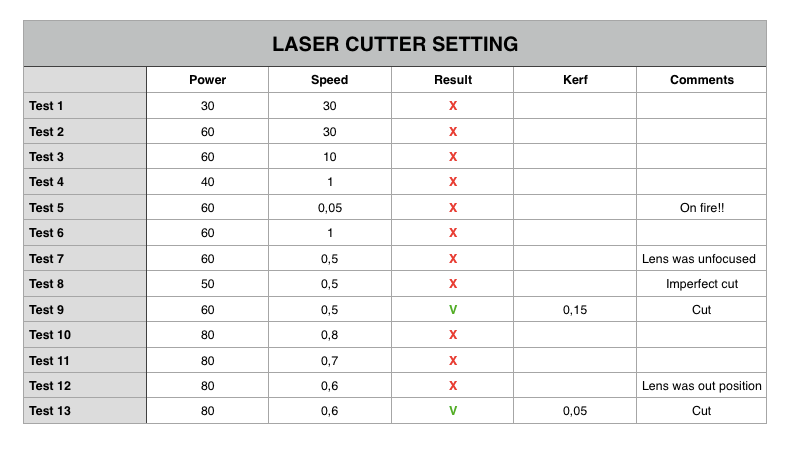

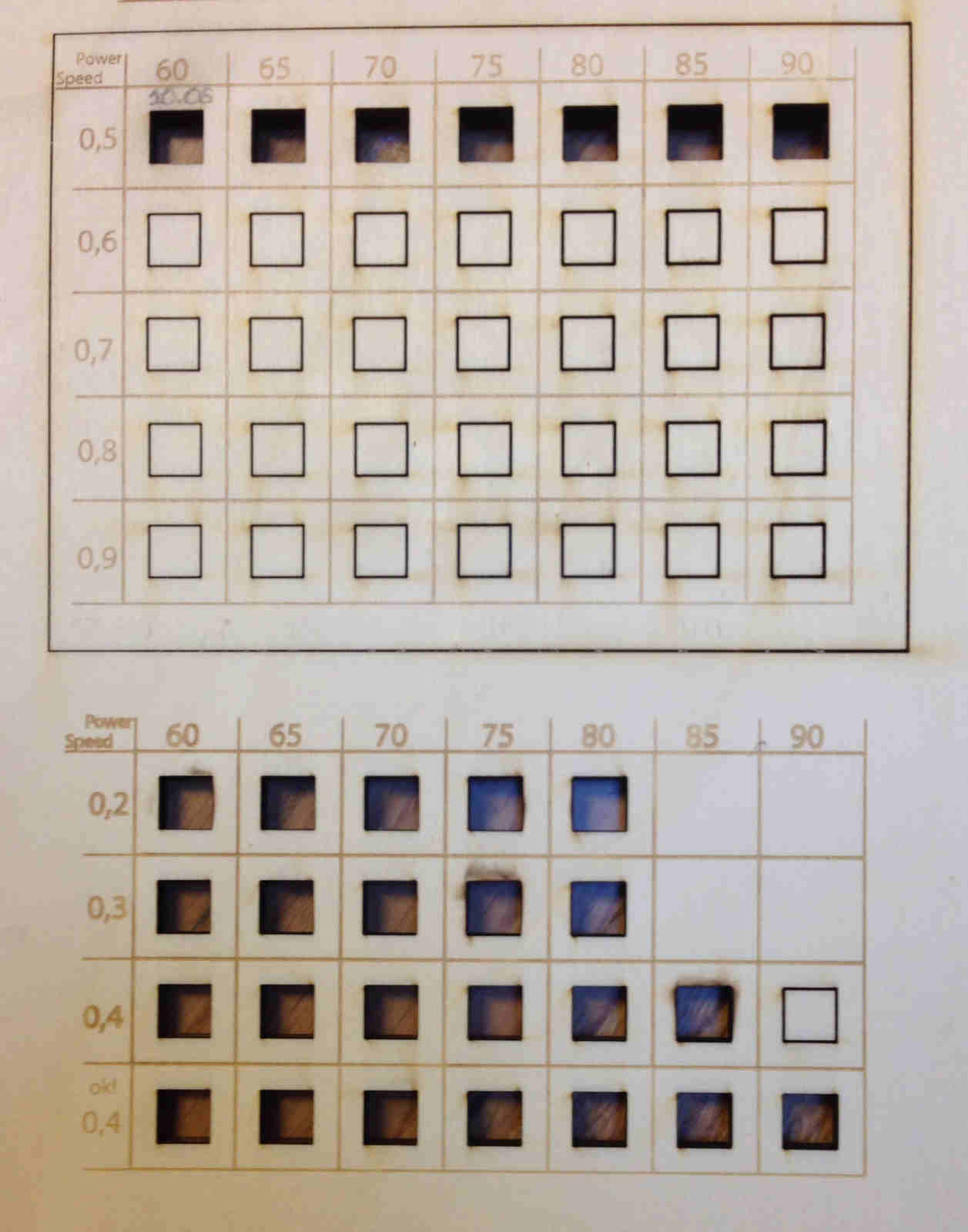

Below there's our test result and summarizing table:

.jpg)

This group work was made by

Silvia Palazzi

Simone Guercio

Chiara Corbo

Alessandro Alonzi

We made test twice because the first attempt was quite unorganized and we ended up with confused results.

We won't spend too much time in this explanation because this is NOT A PROPER WAY to make kerf tests.

We decided to start from same value of laser speed and power (30% of speed and 30W power) and then we empirically changed values relating to cut definition we obtained.

Below there's our test result and summarizing table:

.jpg)

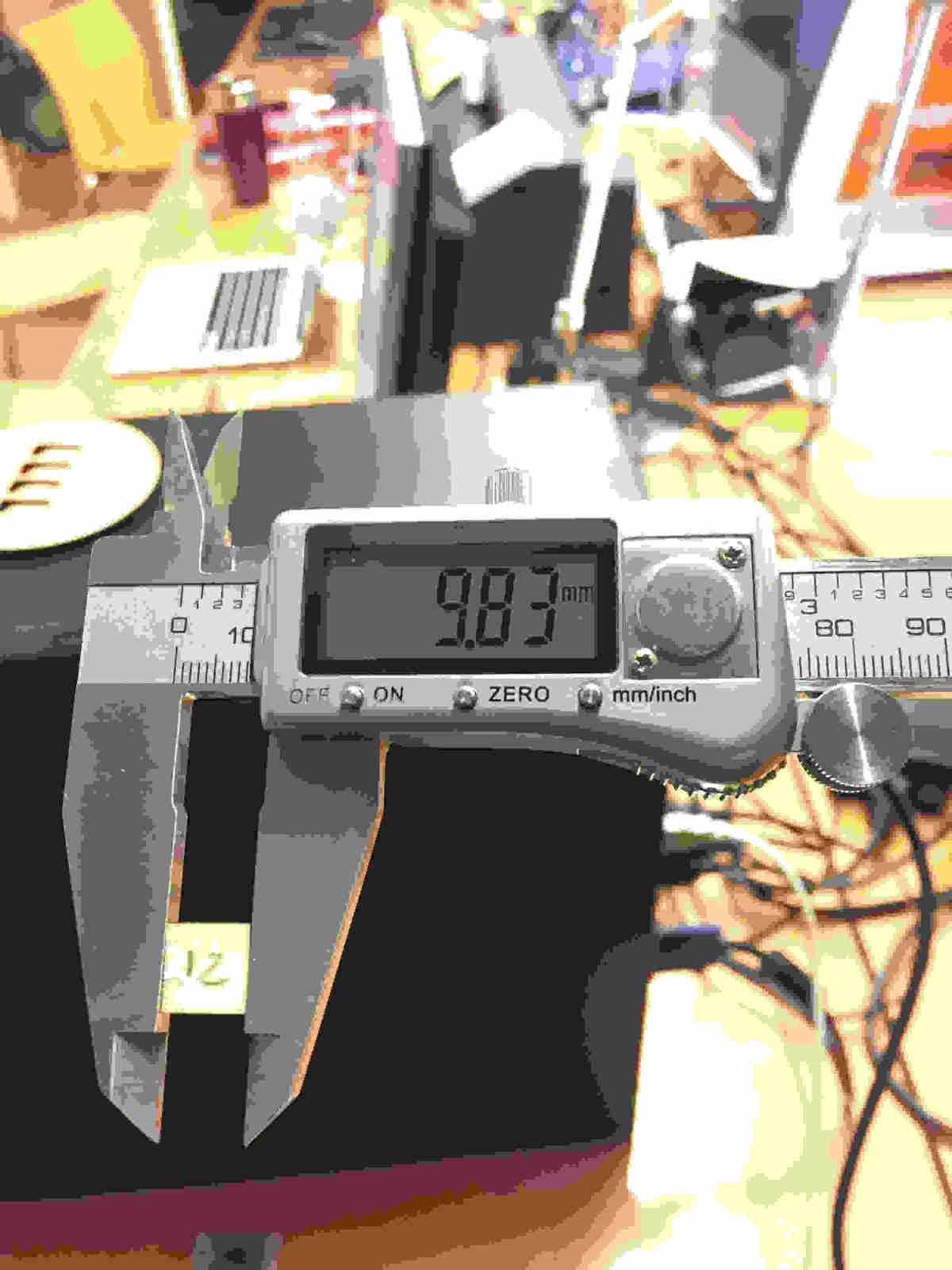

Best results seemed to be with 9th and 13th iteration settings. So we measured squares with calipers to calculate kerf quantity:

To the principles that we had to look for the highest speed and the lowest power values of good cuts with the minimum kerf,

we concluded best setting were 80W and 0.6% speed. We also made a joint example to prove we were right, paying attention

to adding twice kerf to male component dimension and subtracting same quantity to female one.

However we used another plywood panel to do the well-done test and we ended up with slightly different results.

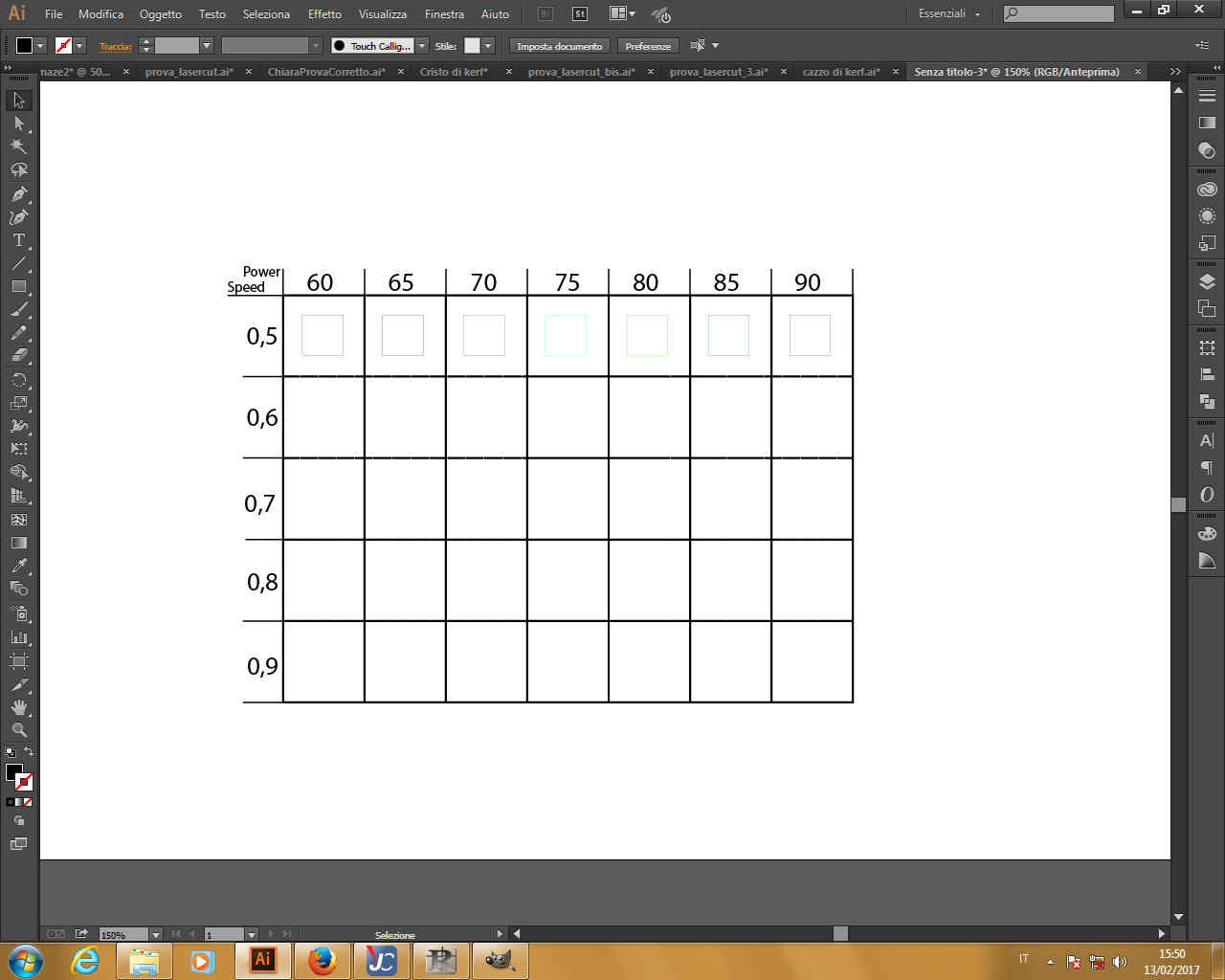

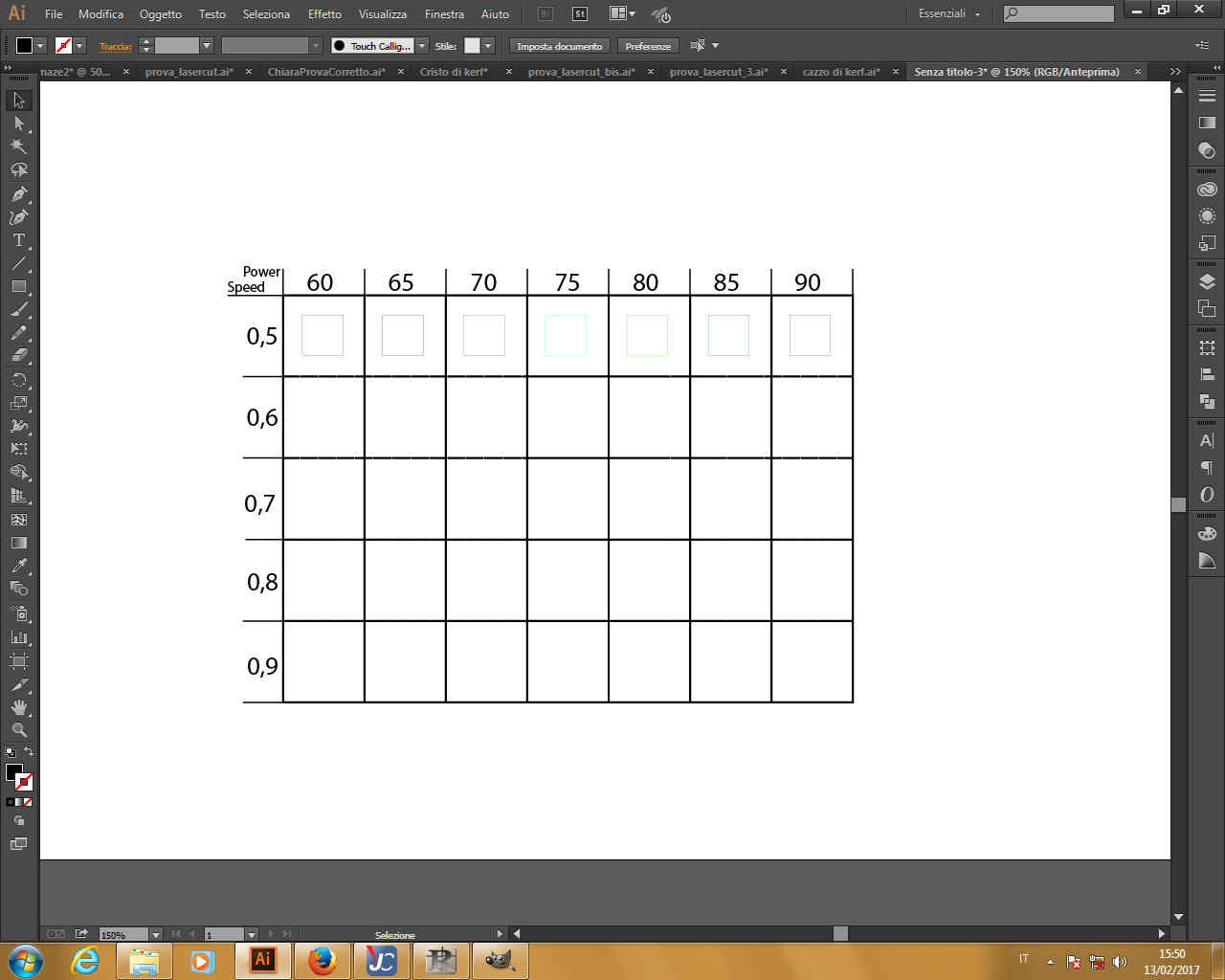

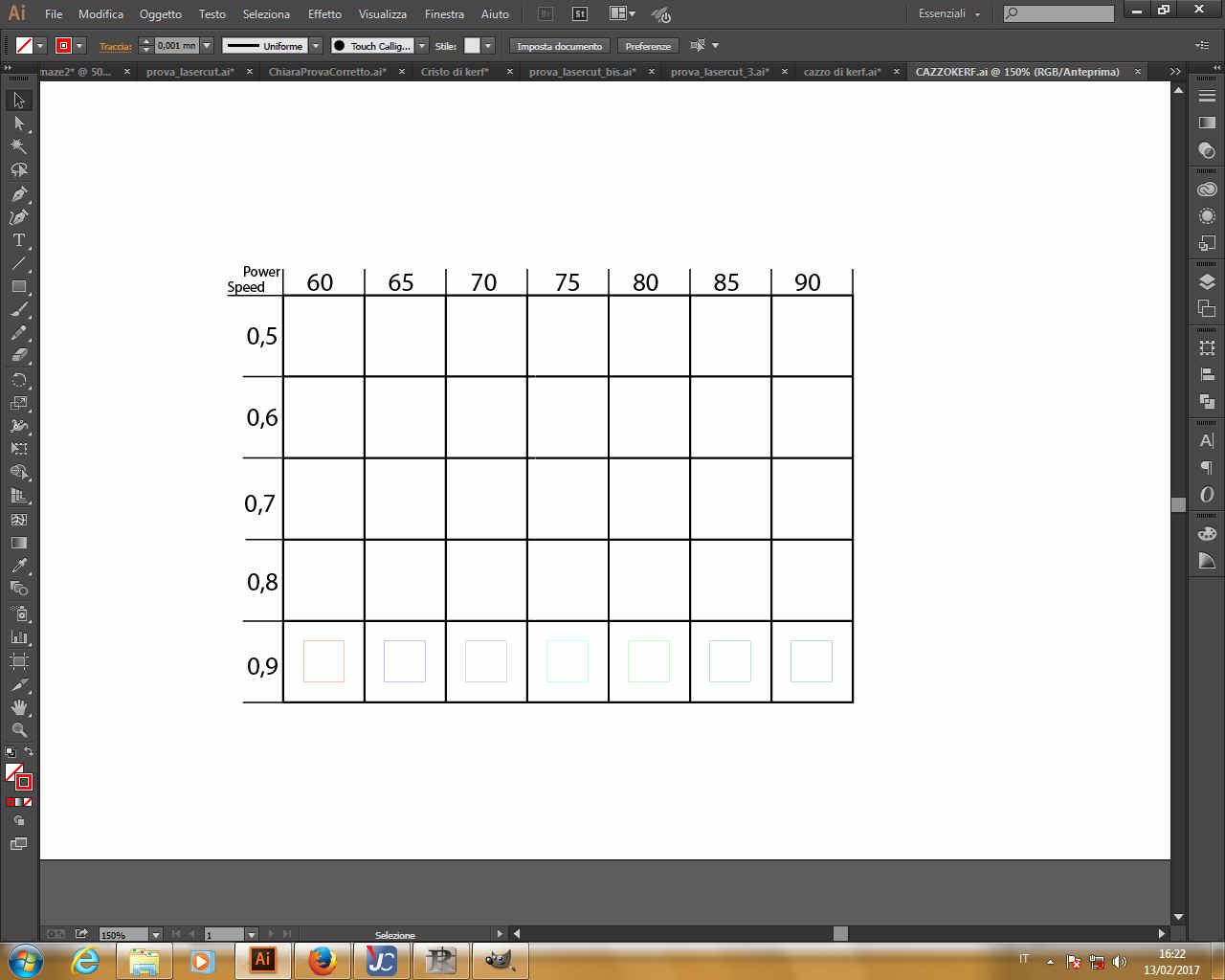

To do this test we first built a table with [60-90]W power and [0.5-0.9]% speed ranges on Illustrator:

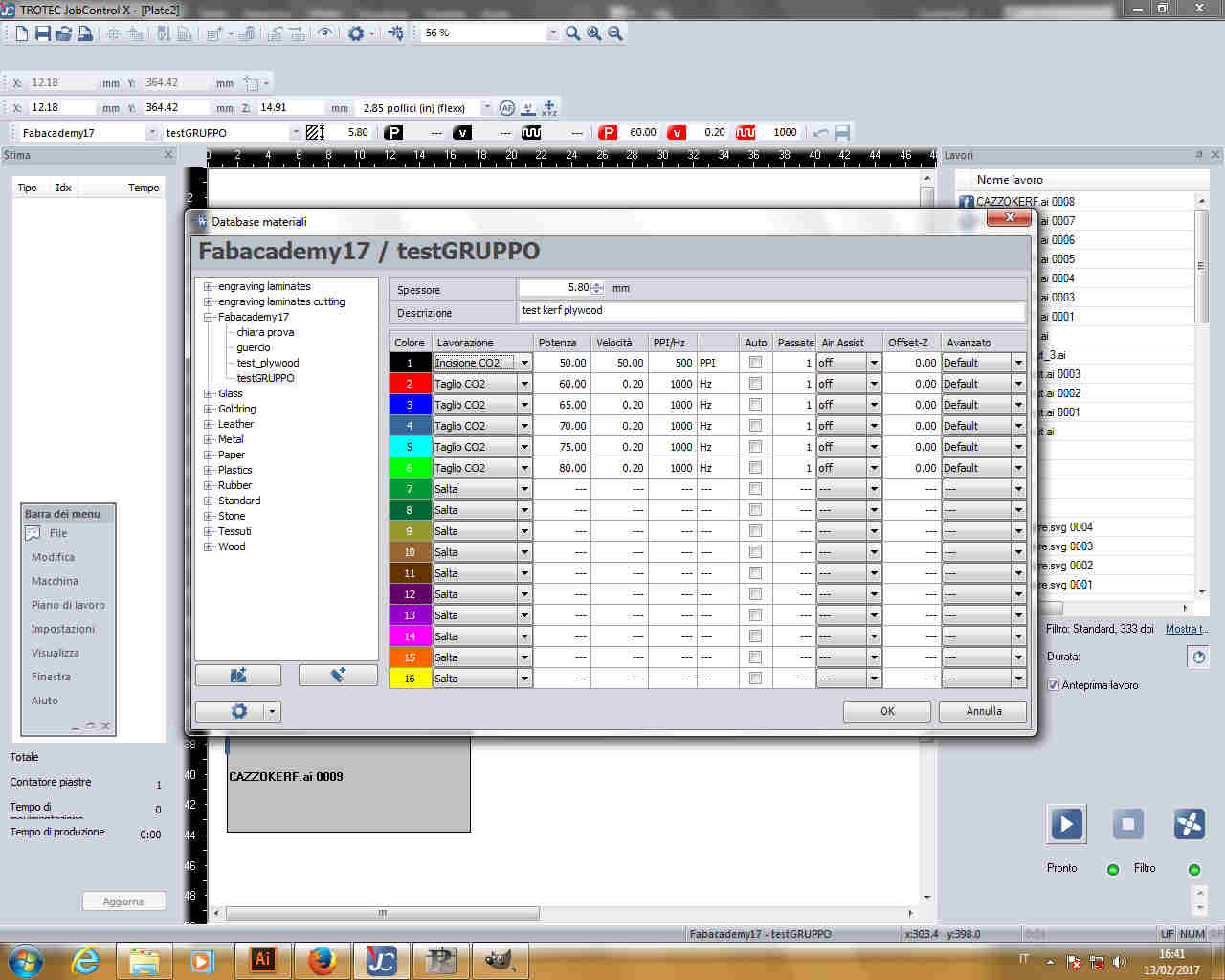

As you can see we put a 10x10 square in each cell changing their trace RGB values according to those Job Control

-our laser cutter software-could accept.

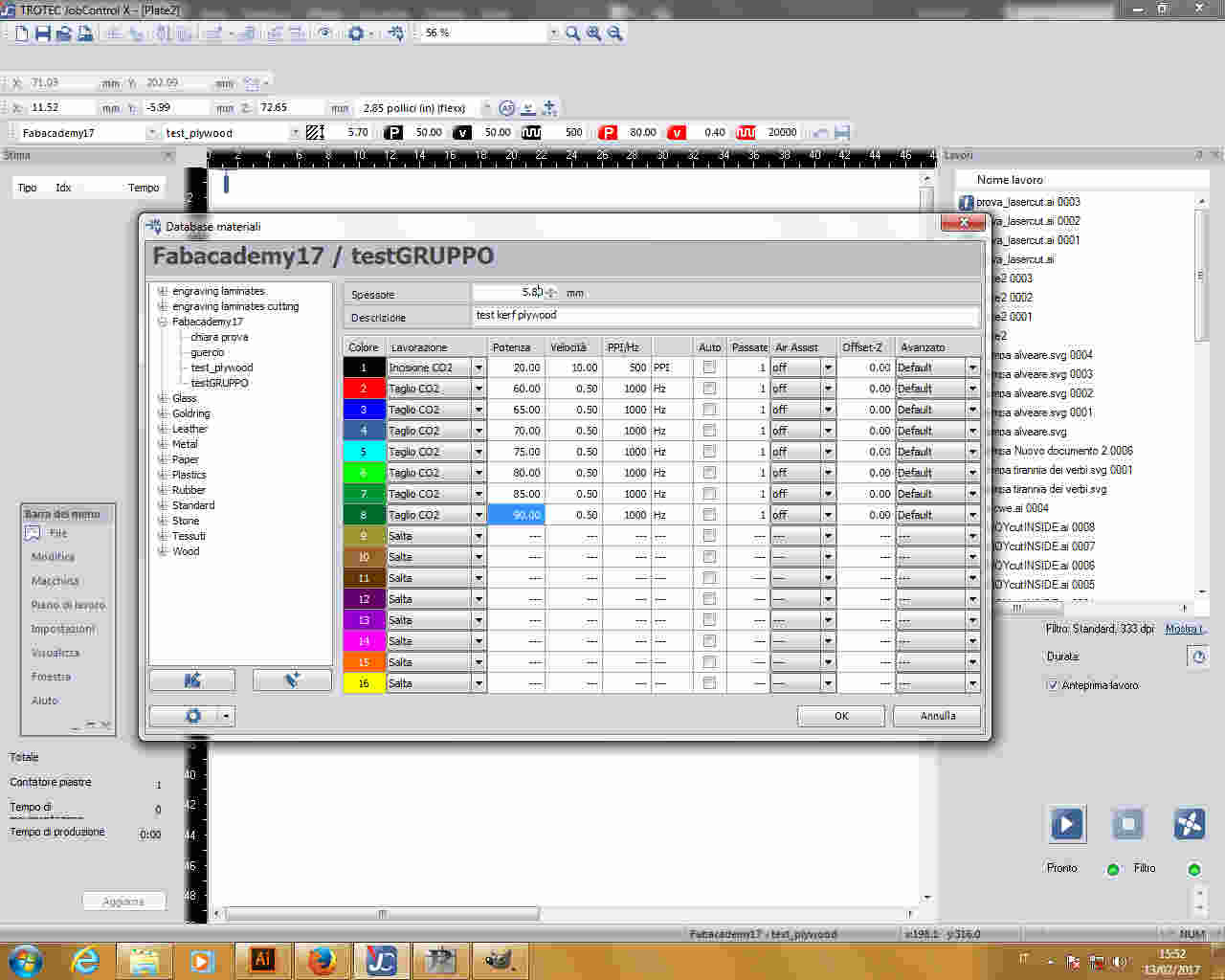

The idea was to send every time seven squares at the same speed but with different power values.

Then, following steps should have suit same principle with higher speeds.

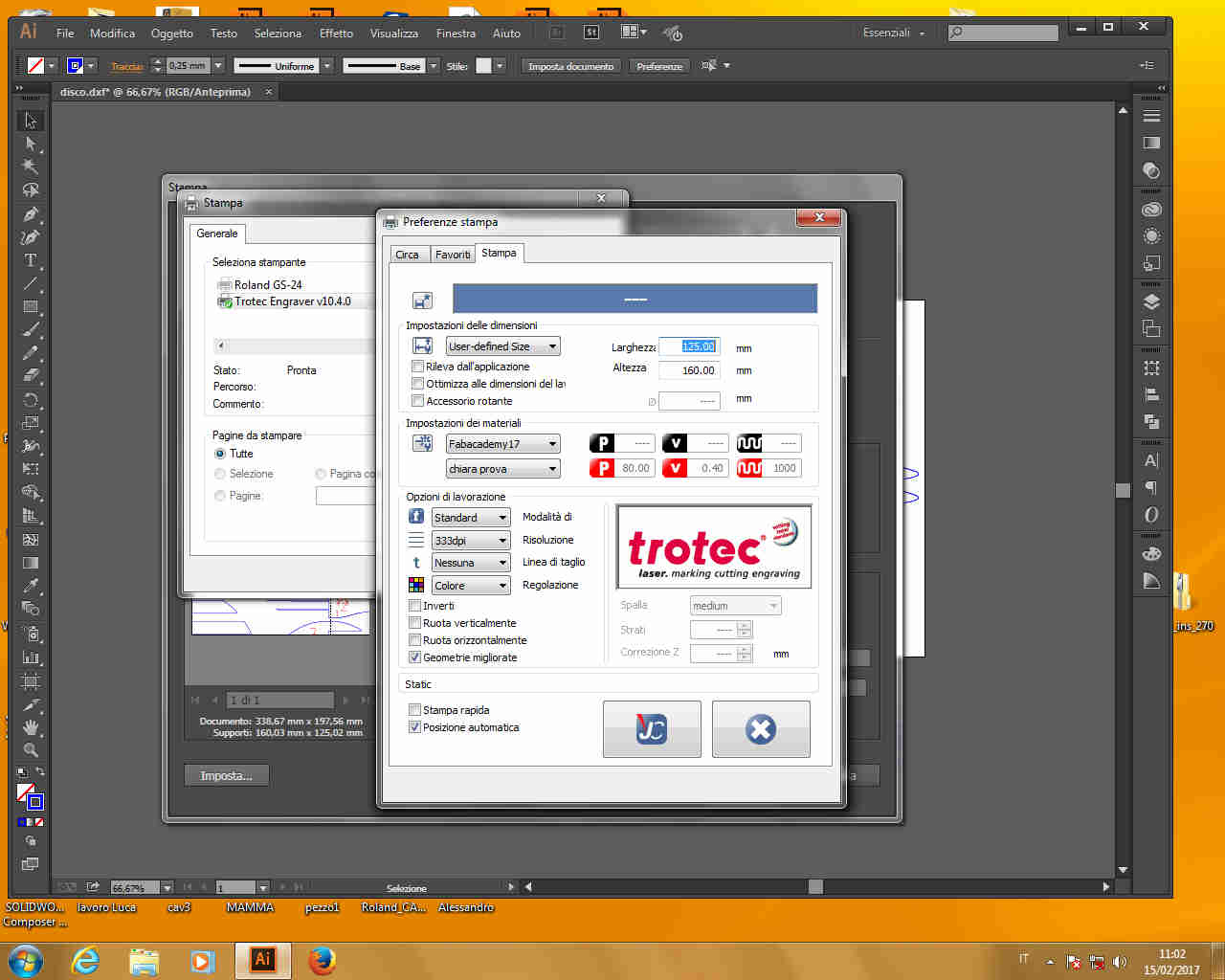

Absentmindedly we forgot to change speed on Job Control material setting window so we restarted a new table.

Error: cut with same speed:

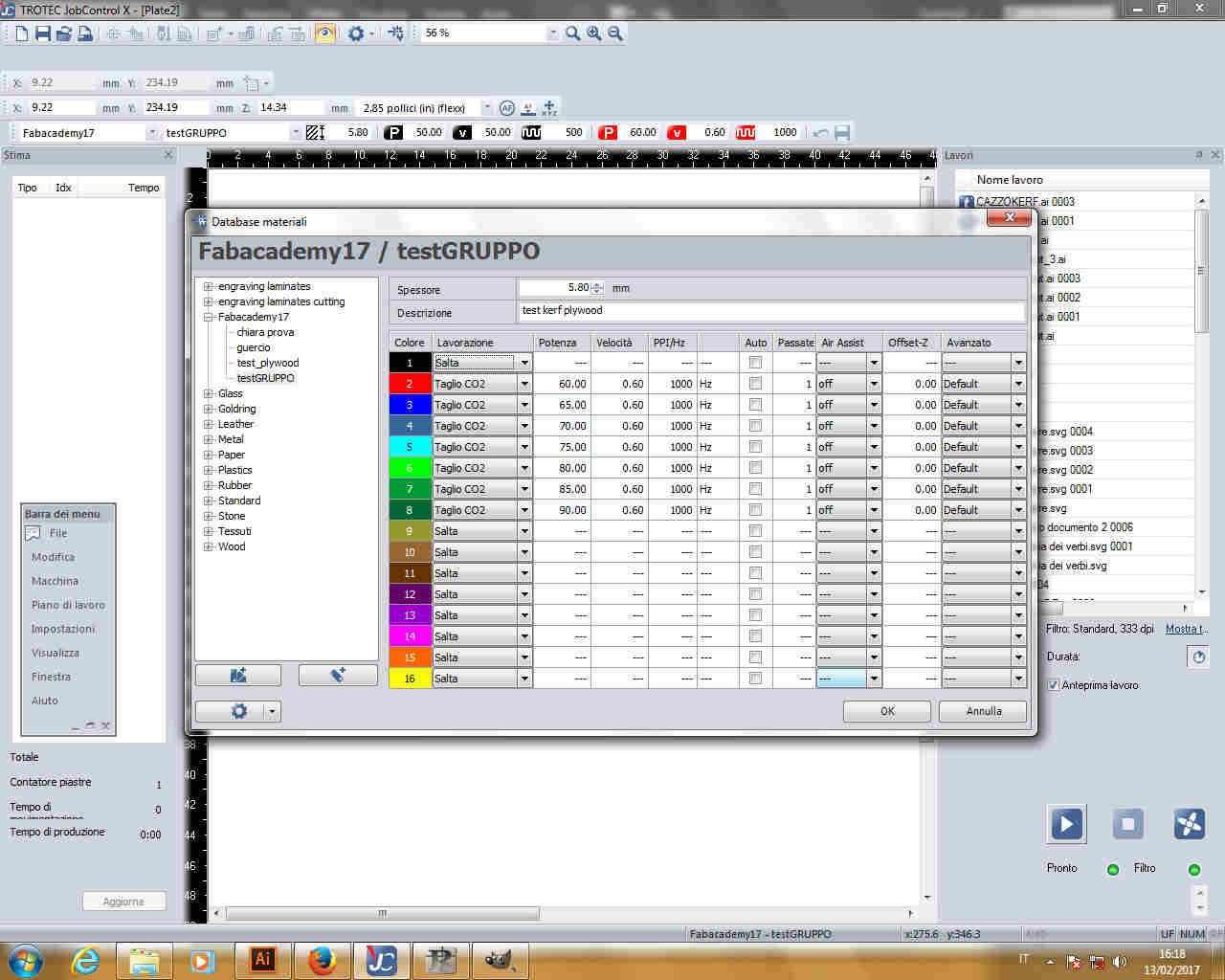

New table: error fixing by changing speed also on Job Control:

NB: table lines were engraved with (0,0,0)RGB just during first step, for the net we set

skip to that voice on Job Control.

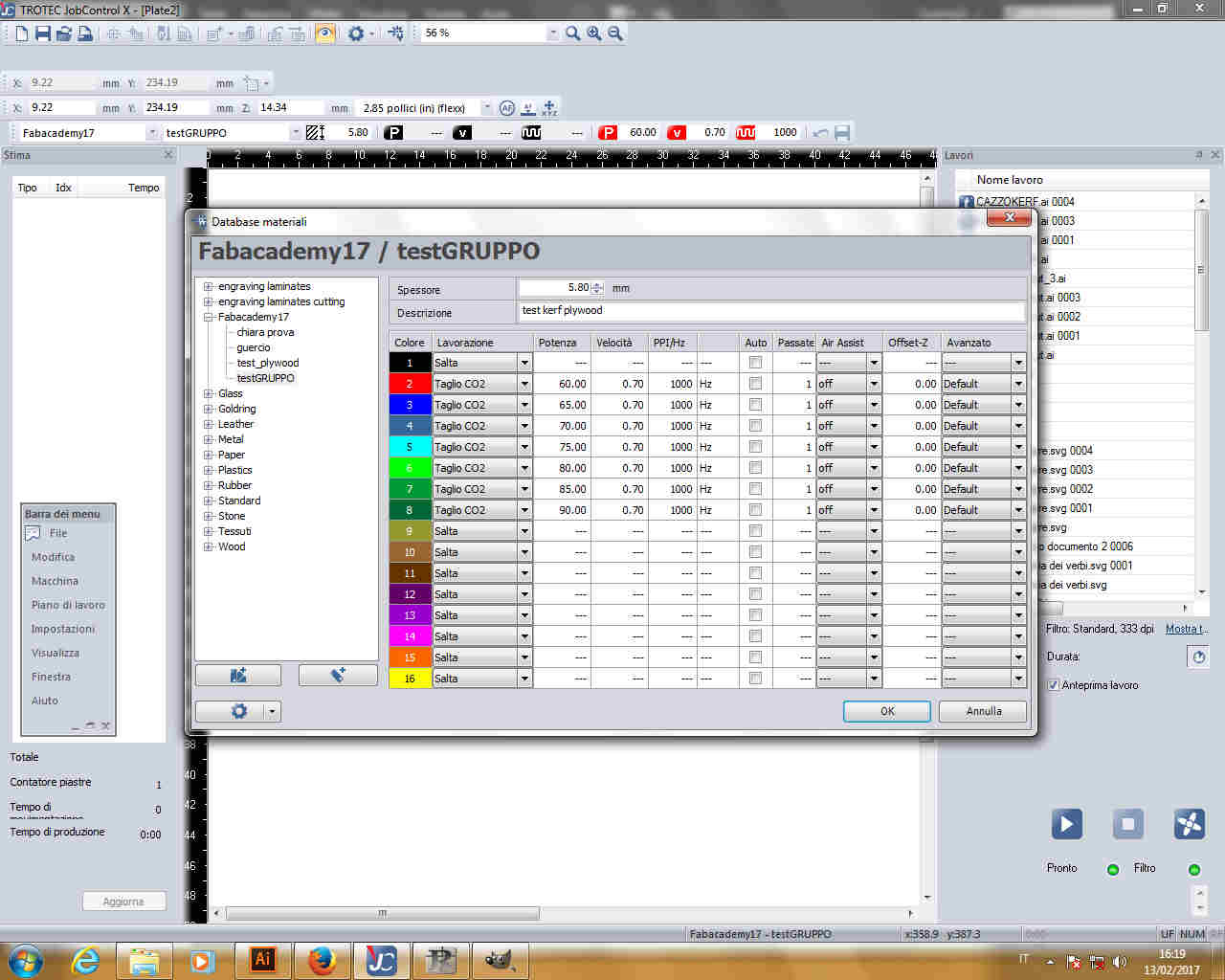

We saw that best cuts had all 0.5% speed:

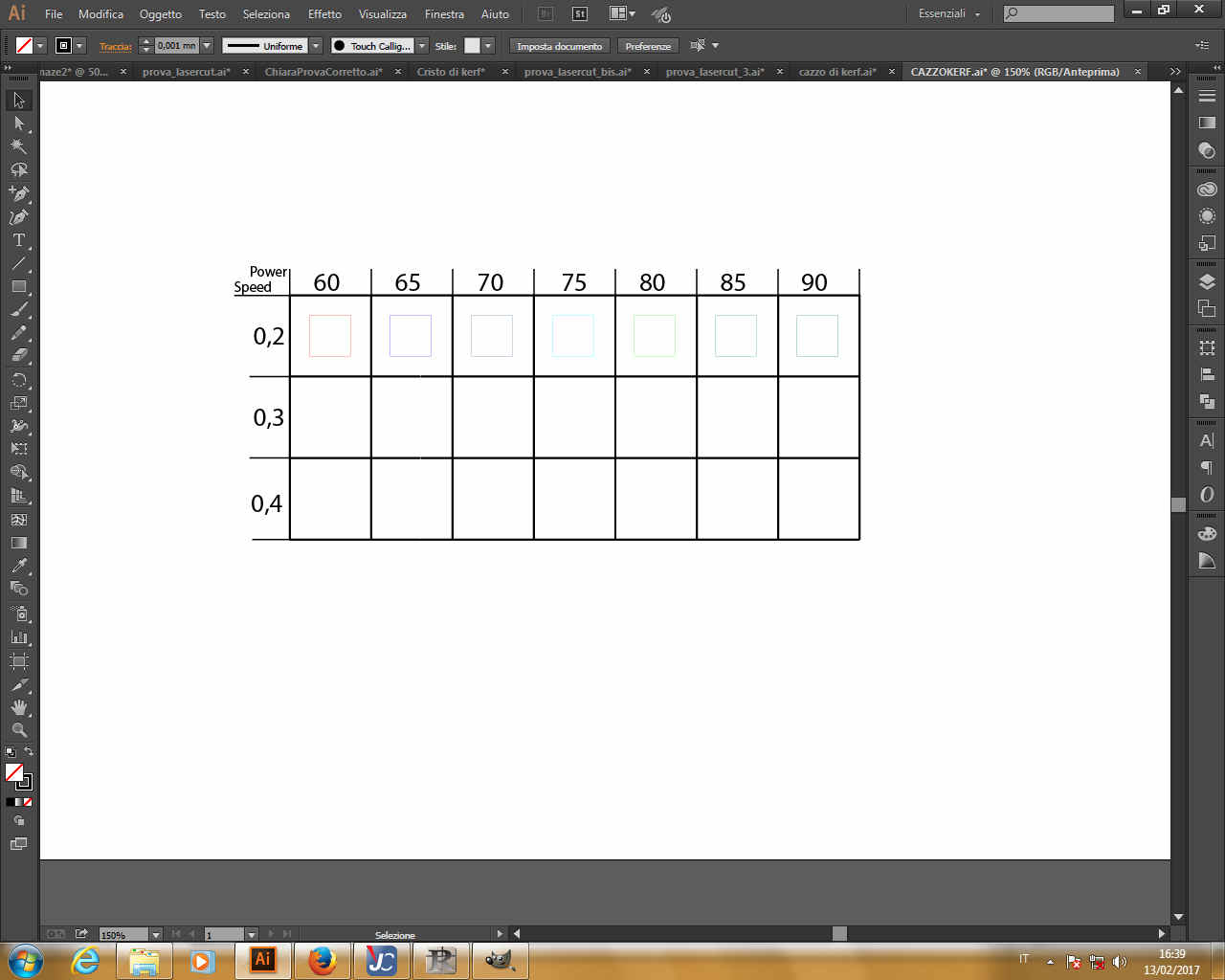

Therefore we decided to built a new table with lower levels of speed to see if we could have a better

cut than the one with [60W power-0.5% speed].

Now we had to rember both to change speed values on Job Control as previously and also workspace

area while exporting the littler table from Illustrator.

The result we gained was the following:

Total result came out like this:

According to previous principle of seeking the lowest power, the highest speed and minimum kerf we chose:

Different results showed up not to depend on our faults but also in plywood panels quality: in fact, when we then worked separately on our parametric designs, each of us had to test kerf again because setting found didn't work properly for joints.

Therefore, due to the fact that panels were quite bend, to calipers different results for the same cut and to lack of experience, we ended up our method of kerf testing revealed ambiguous and rectifiable, so we will repeat tests in different way to find the right (or maybe the least wrong) one.