|

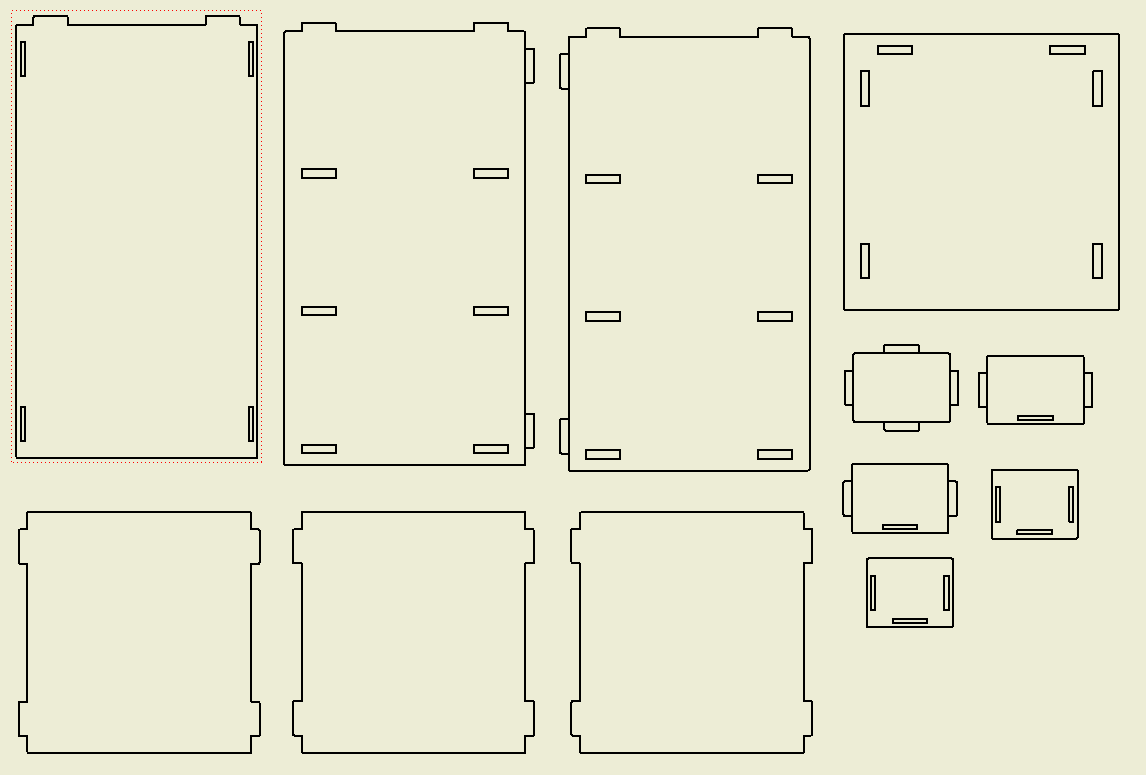

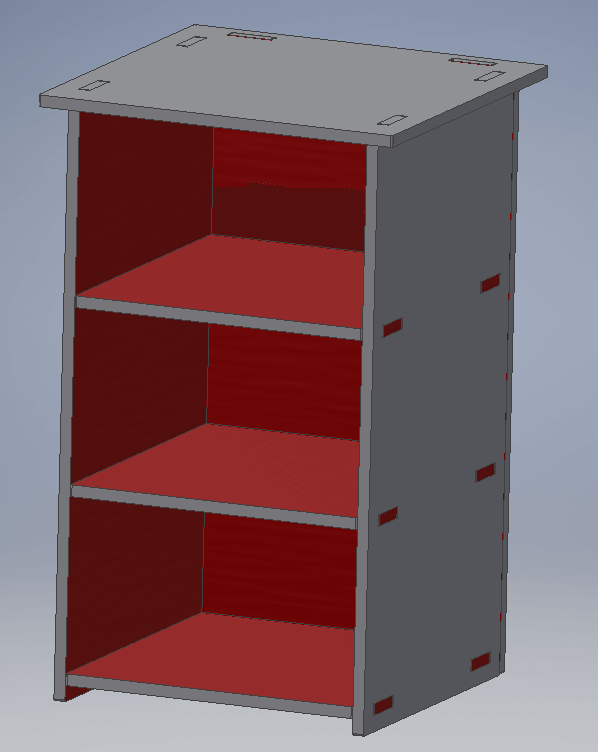

Model Design

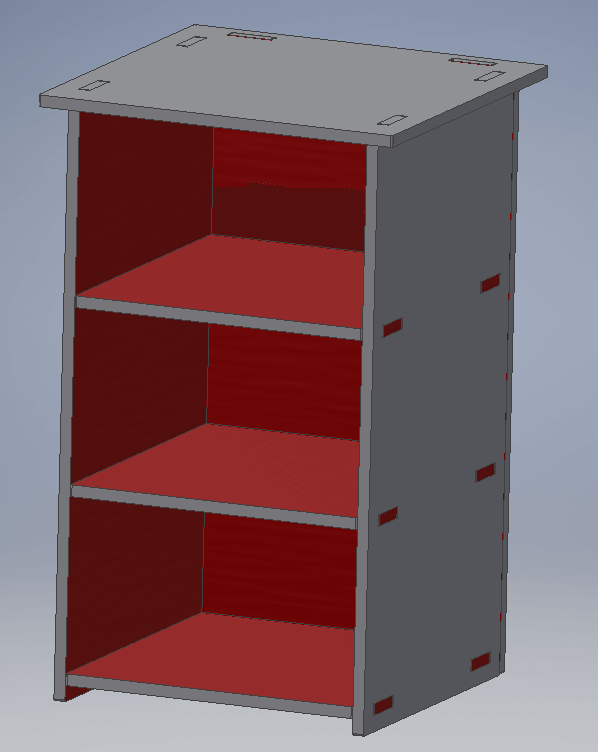

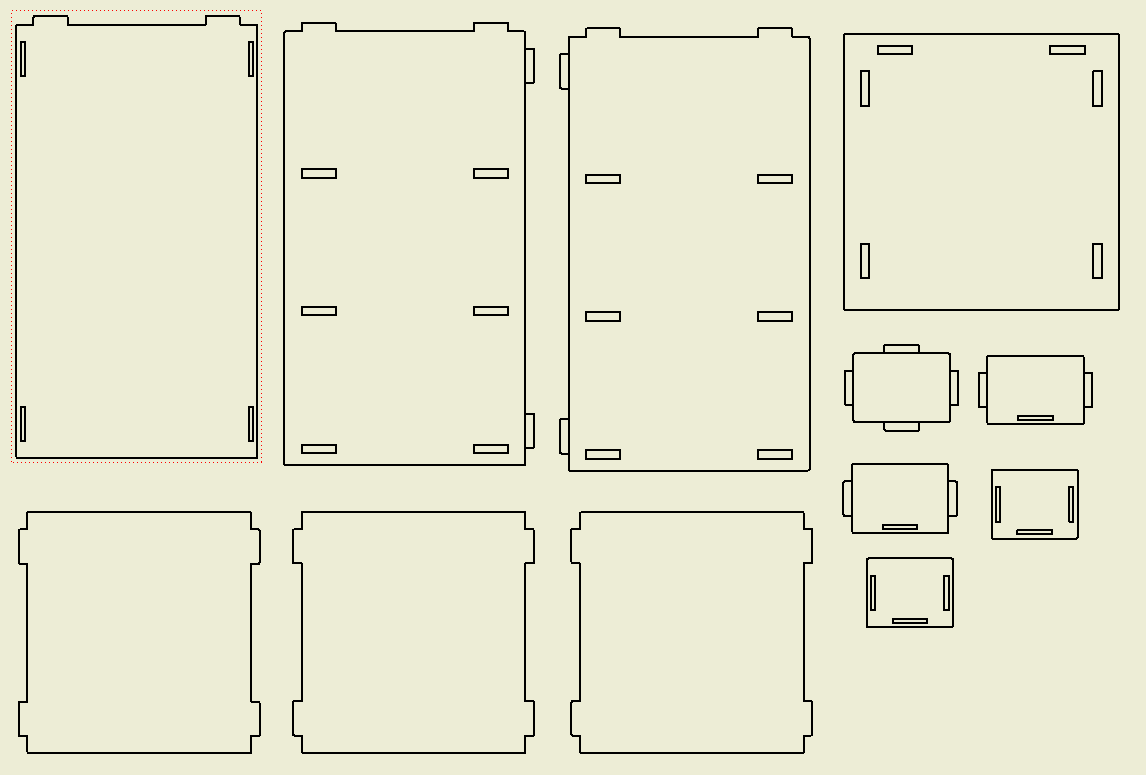

For this week, I'm designing a table for my 3D Printer

I was needing a table with lower slots to keep material cartridge, filament spools and tools. Main dimensions were 400 x 400 mm on top, and aproximatly 650 mm height. The structure

must be rigid enough to reduce normal vibrations during work time, to avoid construction problems.I used a 1/8" tool for this assignment.

Comments

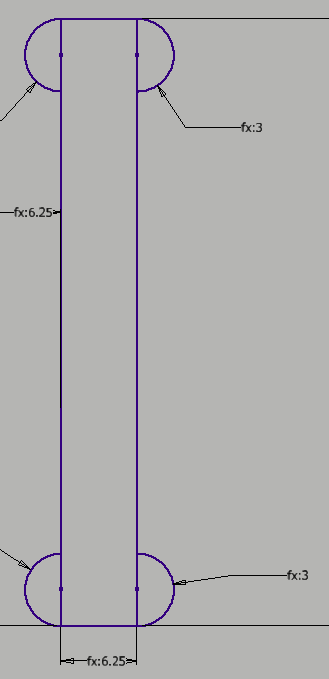

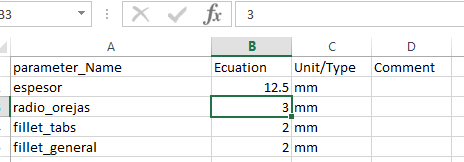

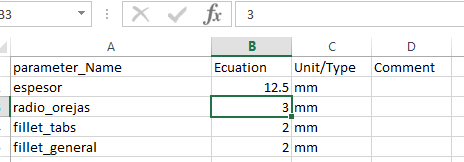

I used Inventor for the design. I made a simple model, but keep it parametric because I didnt know which material thickness we have available at the lab.

Finally used 12.5 mm MDF material.

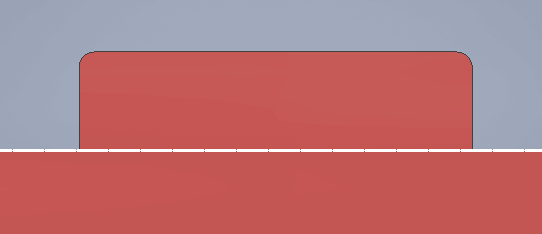

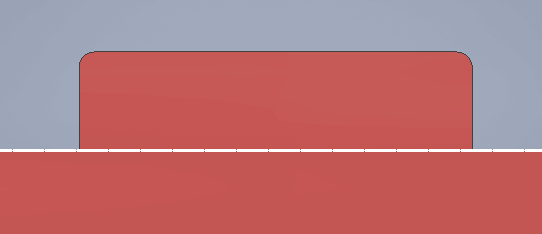

Originally, I made relief ears on each slot, but was noticed the machine software takes care of that.

|

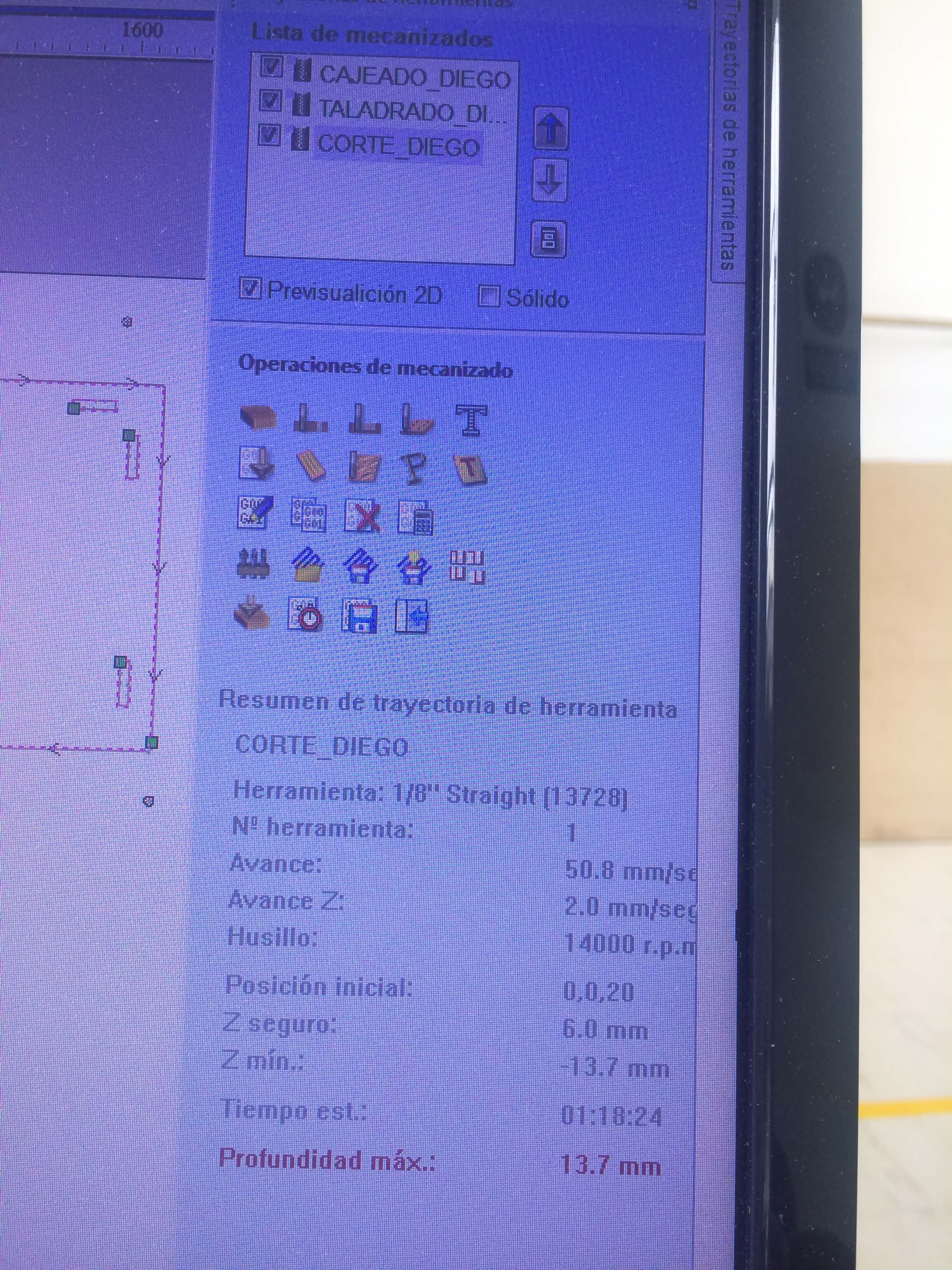

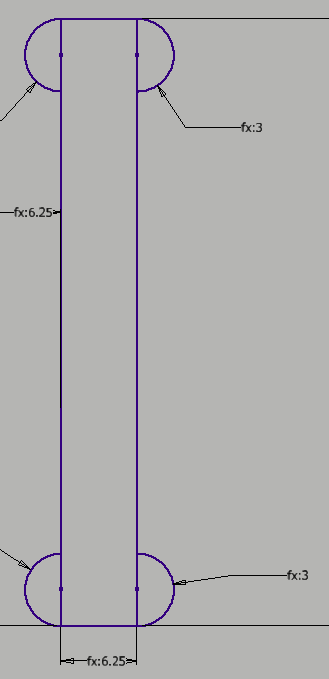

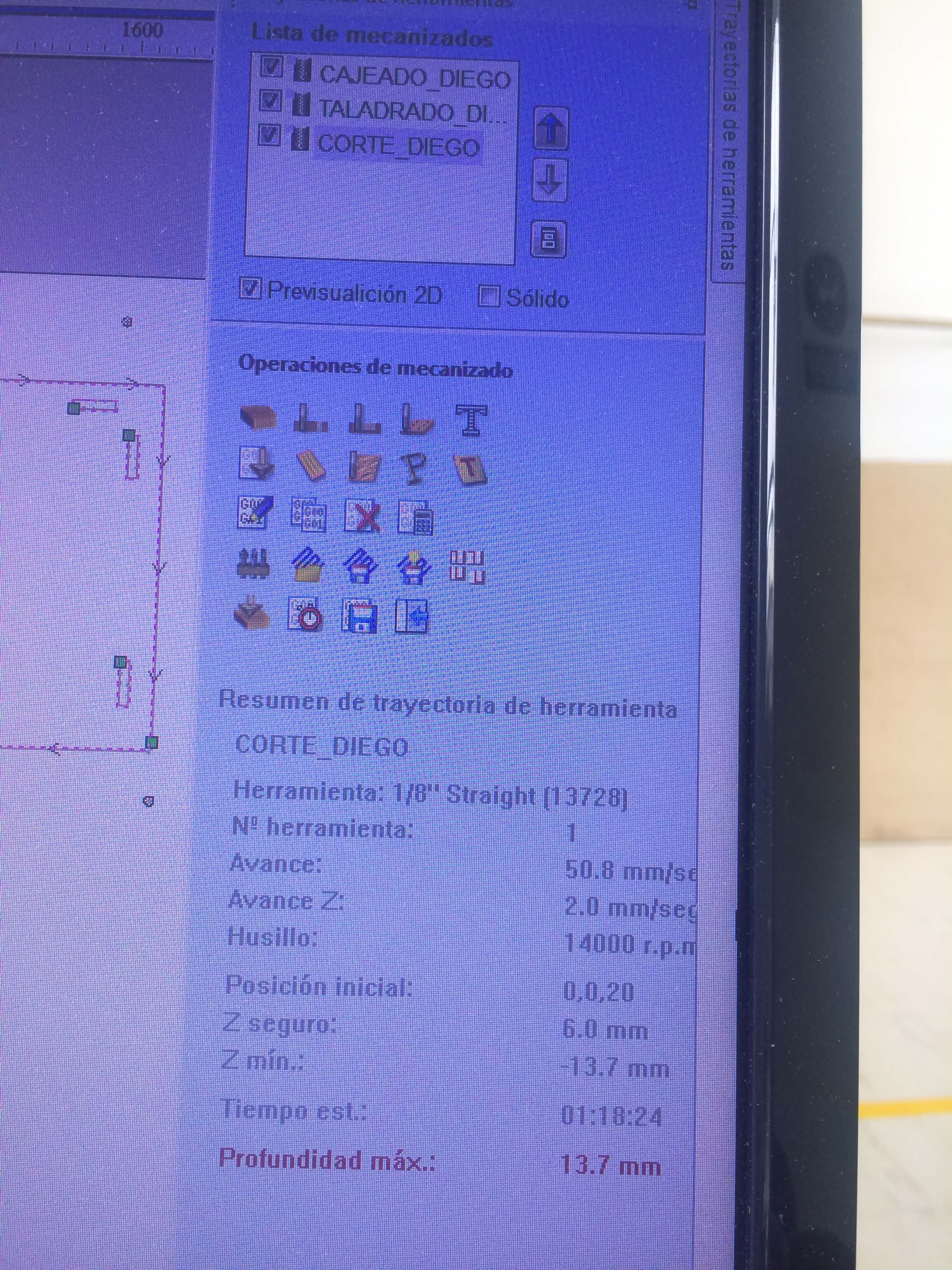

Machine settings

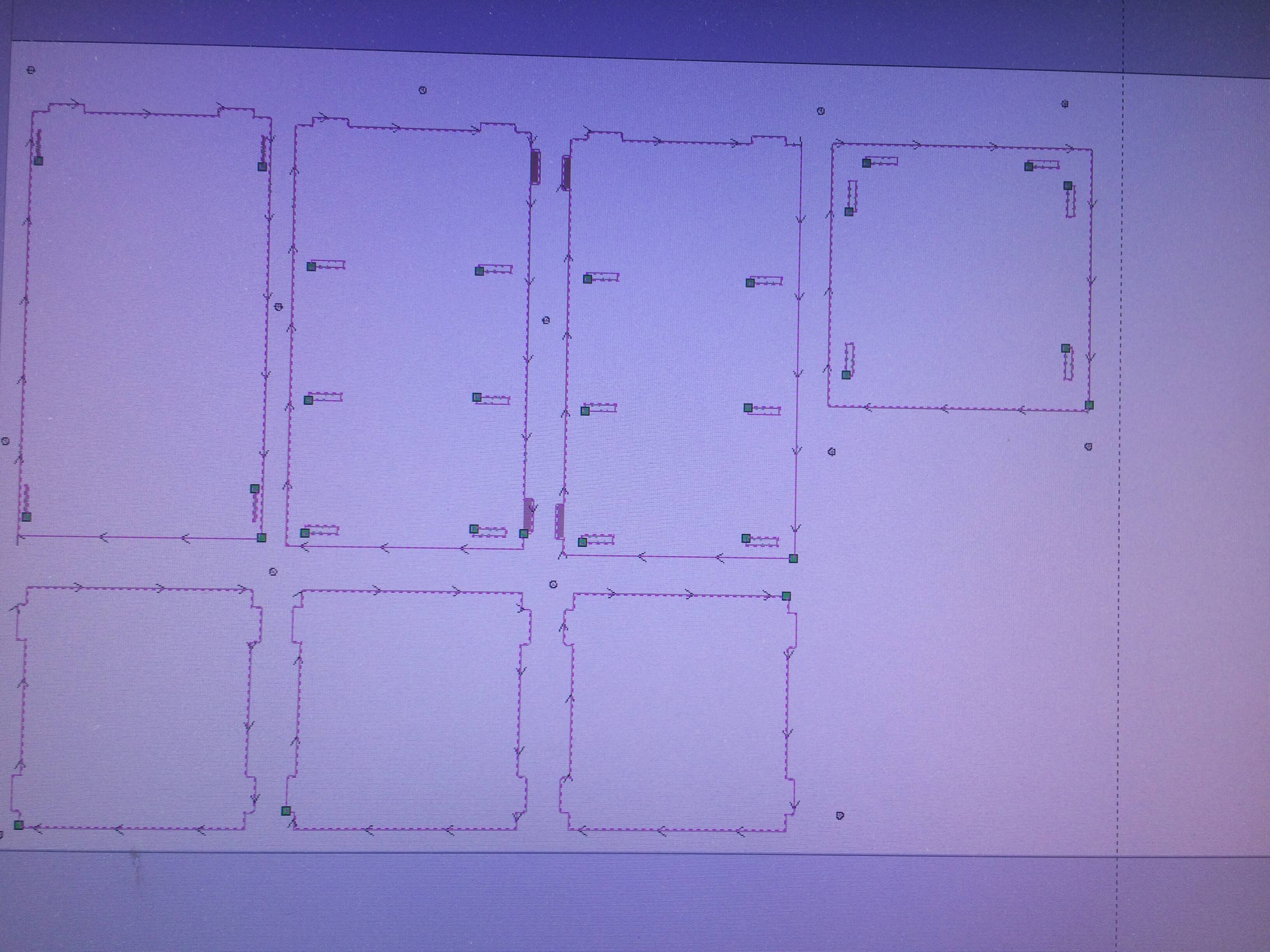

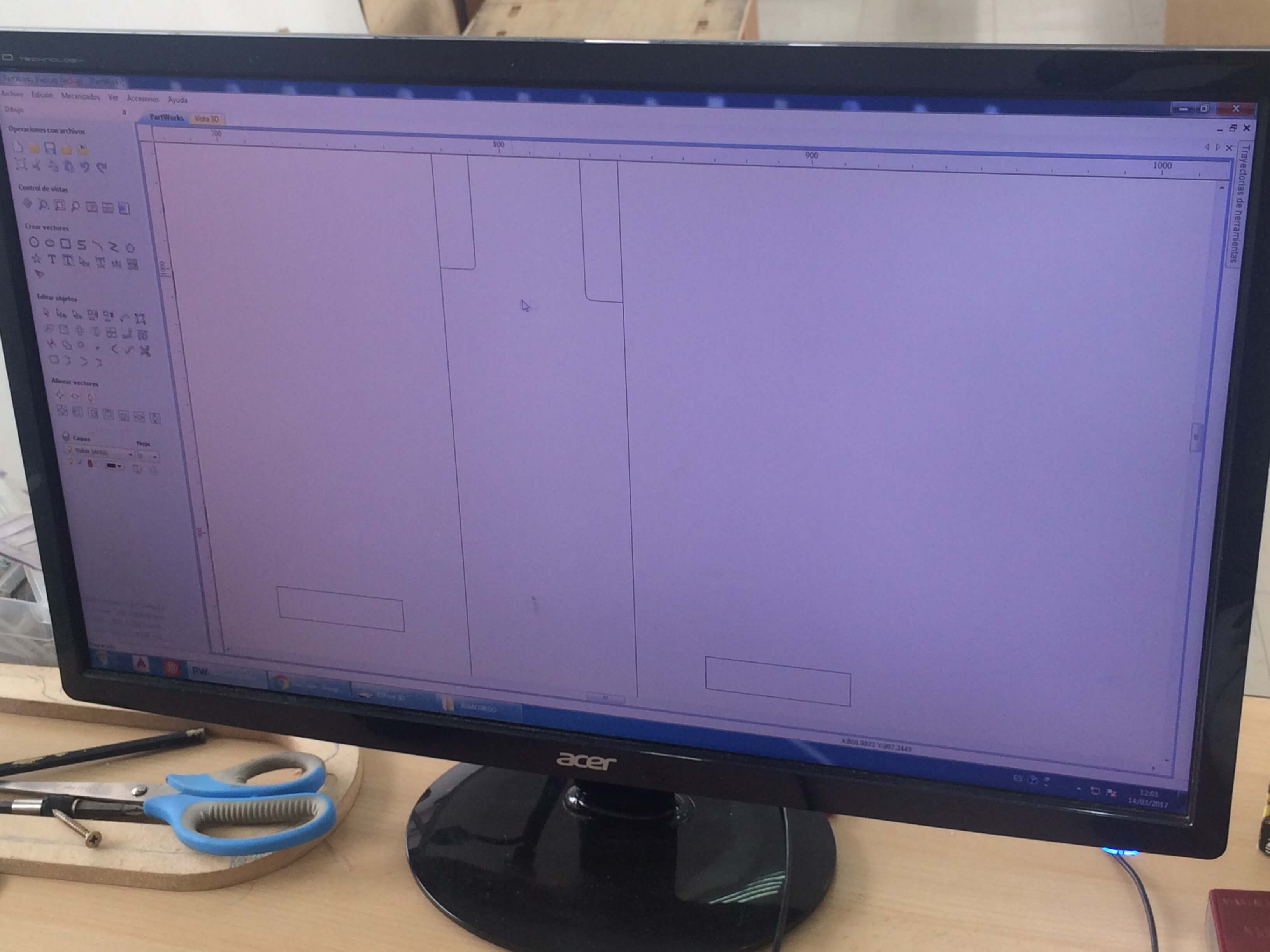

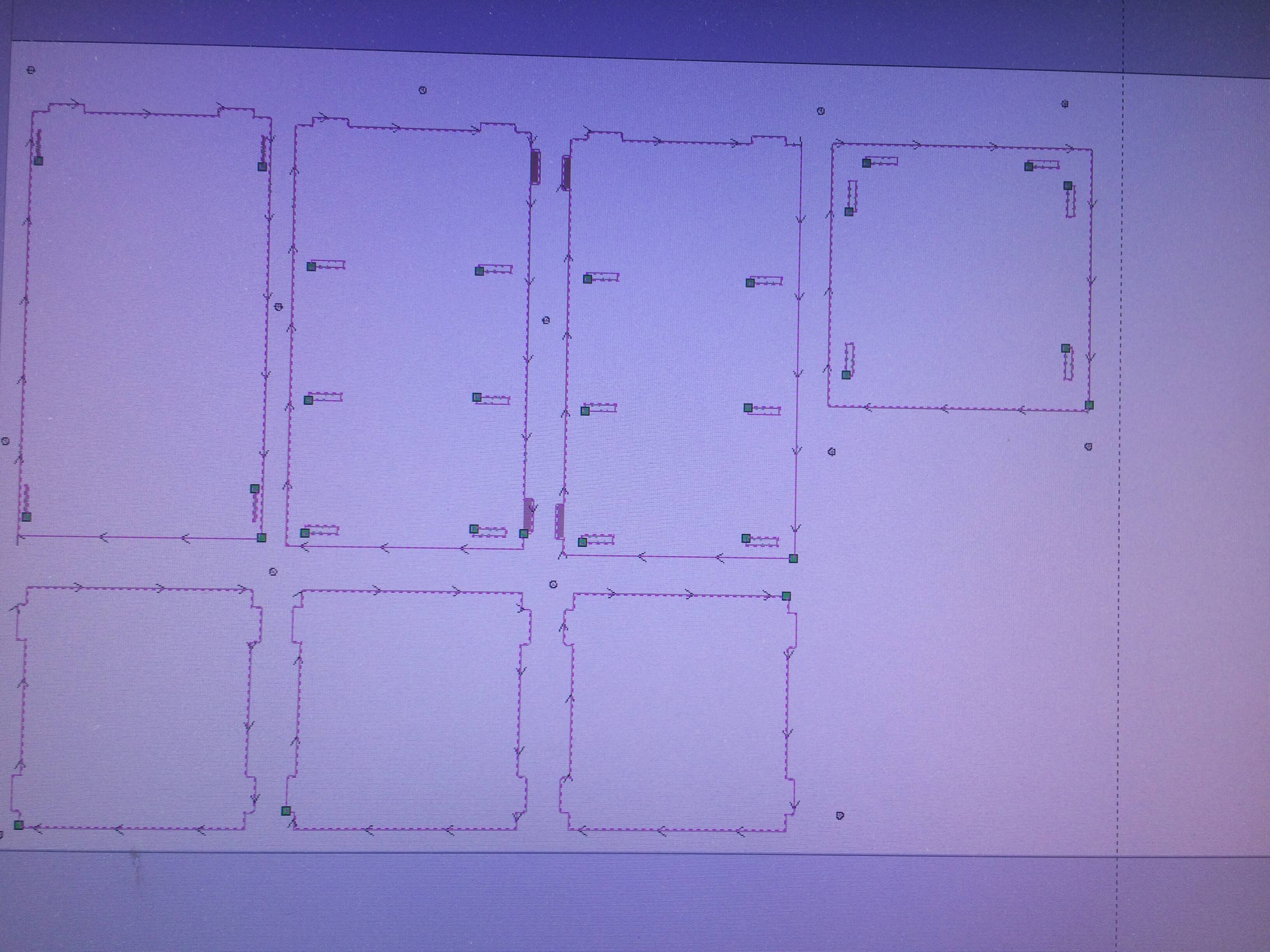

Made my pieces distribution and loaded to the Shopbot. We set the machine parameters and guide bolts to fix material on the machine.

Comments

Have some issues with tabs that where half thickness. The software could not process naturally and a sub routine have to be added manually to avoid problems.

As said before, I remove the slot's relief ears to be added in this part, but we forgot to do that.

|

|

|

Milling

My vid for milling

|

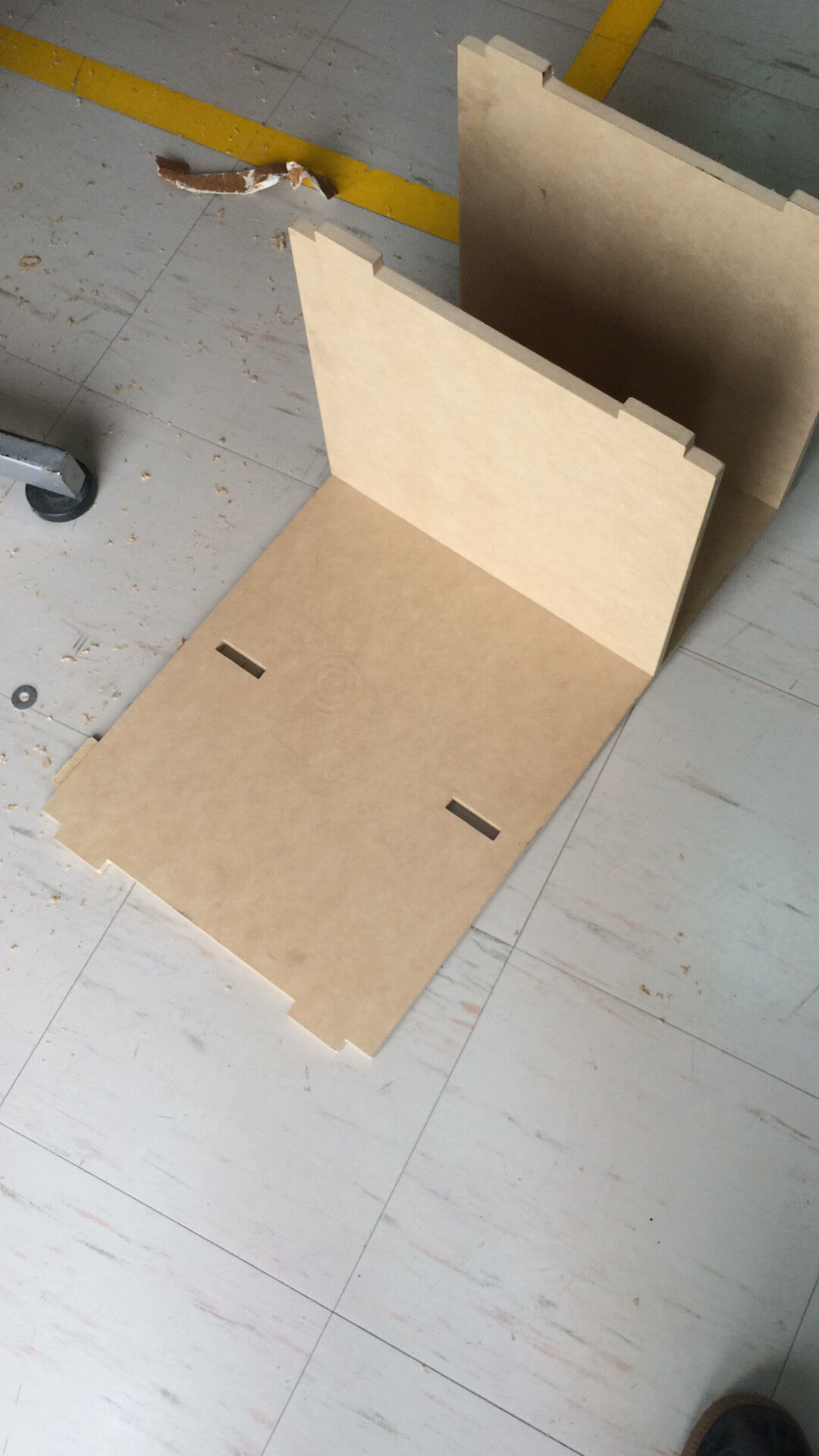

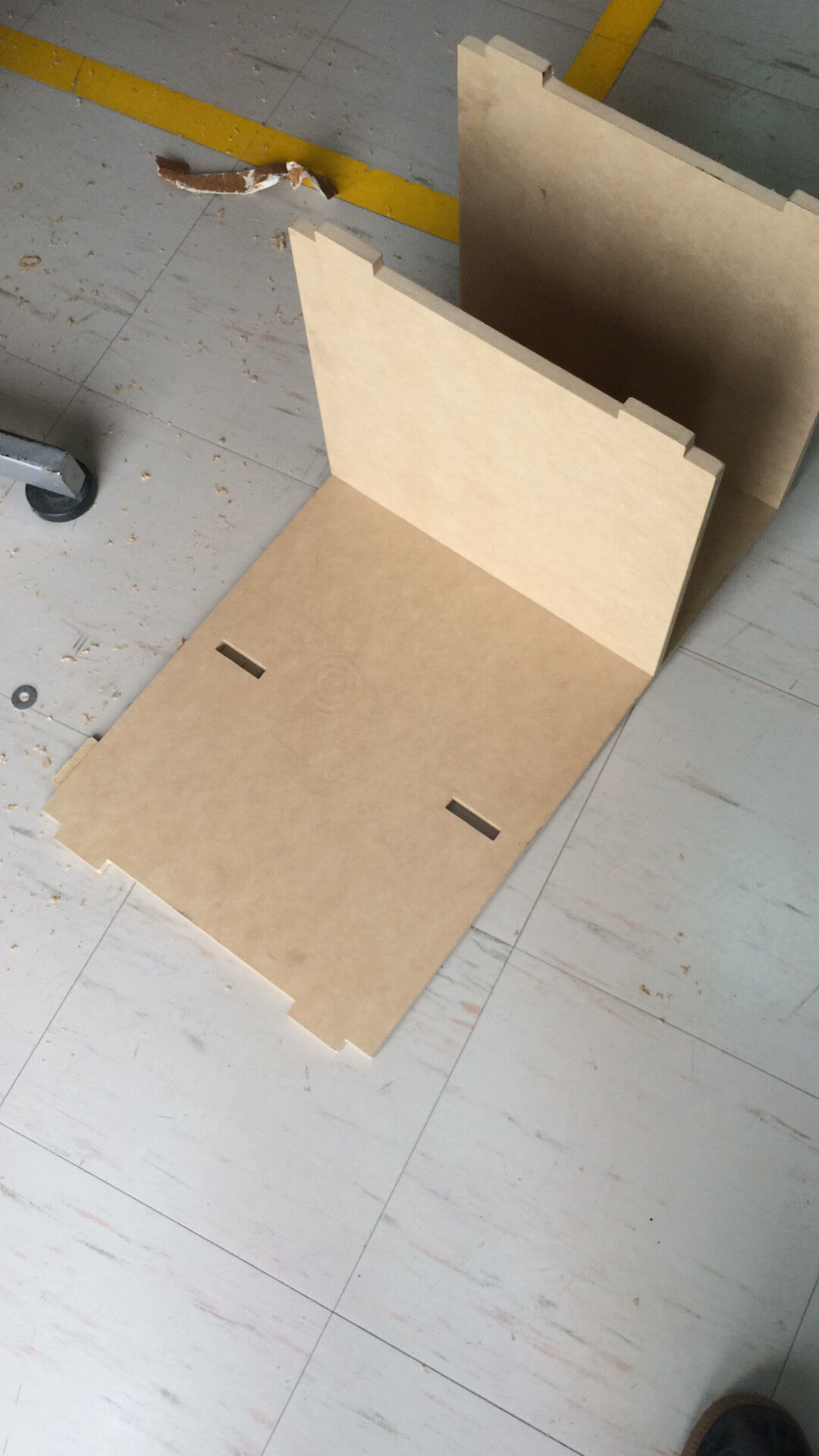

Assembly

Finally the Avengers assembled!

Comments

I thought would have problems without slot reliefs, but in the end it was really smooth

|

|