Week 2

Computer - Aided Design

Objectives

Learning Outcomes

Have I ...

Documentation

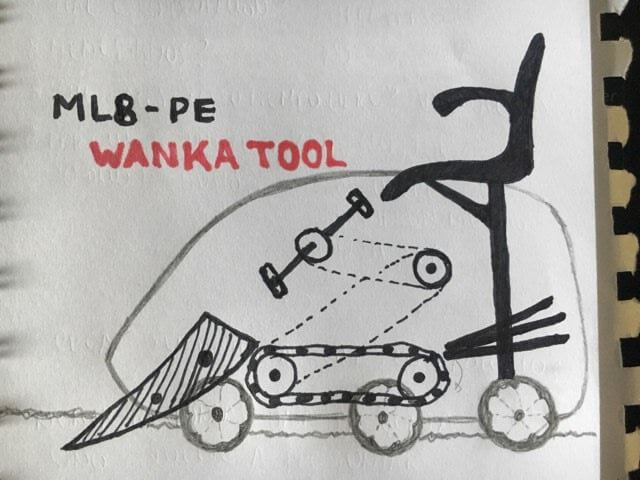

I was tinking about which program use to shape my final project. Finally I decided to use a little book and a sharpie to start to draw.

An idea for the future

I did a sketch about my first idea of project. When I was discovering design world and learning too. I always used a little notebook and a pencil, pen or sharpie to shape mi ideas.

After finishing the sketch of my final project. I decide to use Inventor to design the idea of my final project. I did each part and then I assemble those parts to have an idea of my final project.

Design of my final project idea

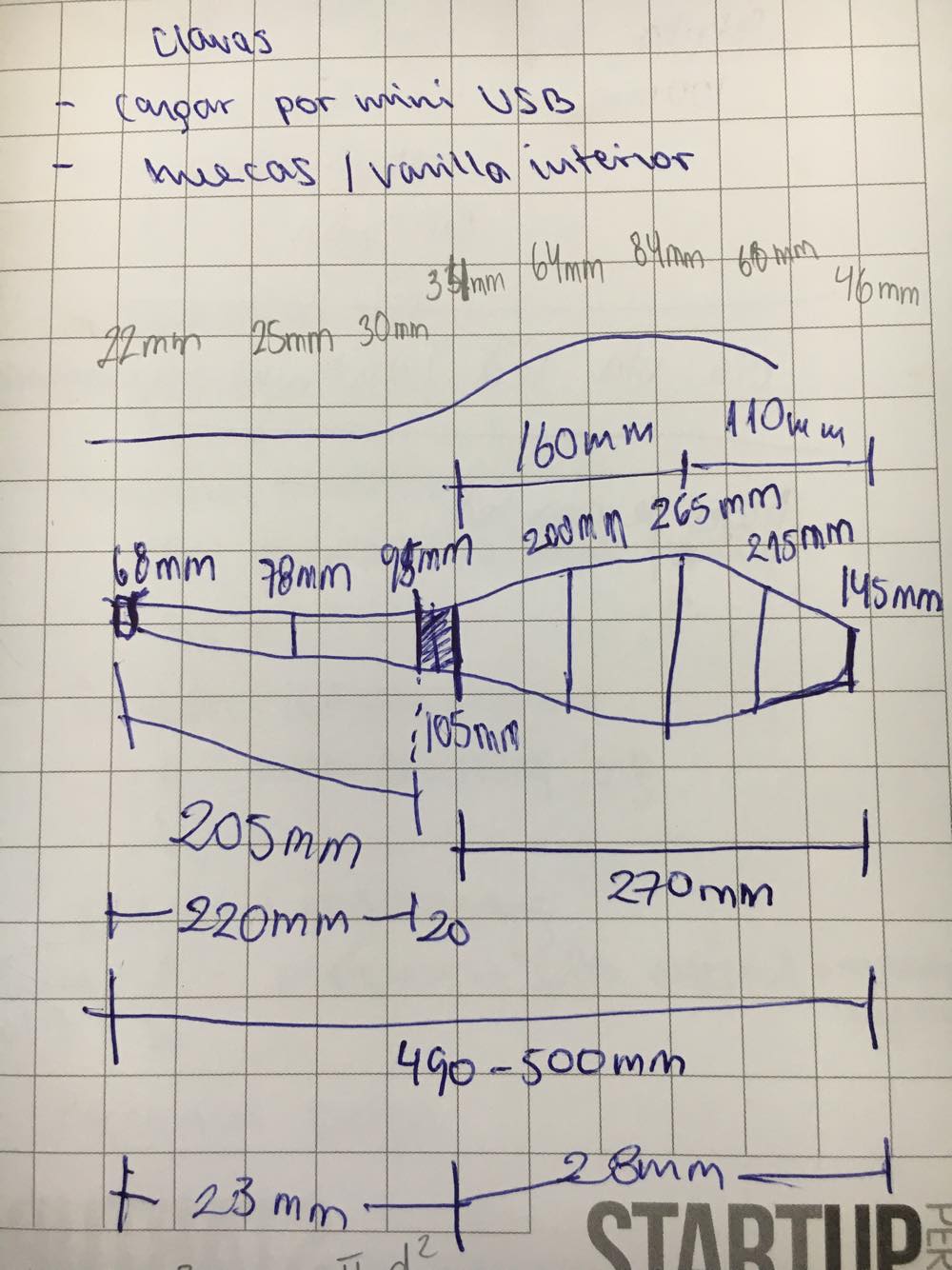

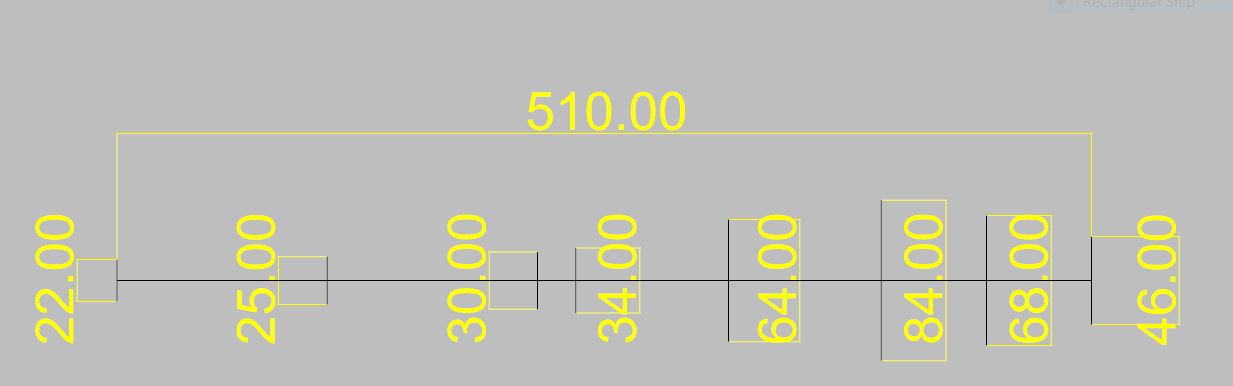

I asked to my friend Agnideva to take measurement of his juggling club. I use a notebook to take notes and a measuring tape. Now, using Rhinoceros I am going to design 2D and 3D parts to manufacture my final project.

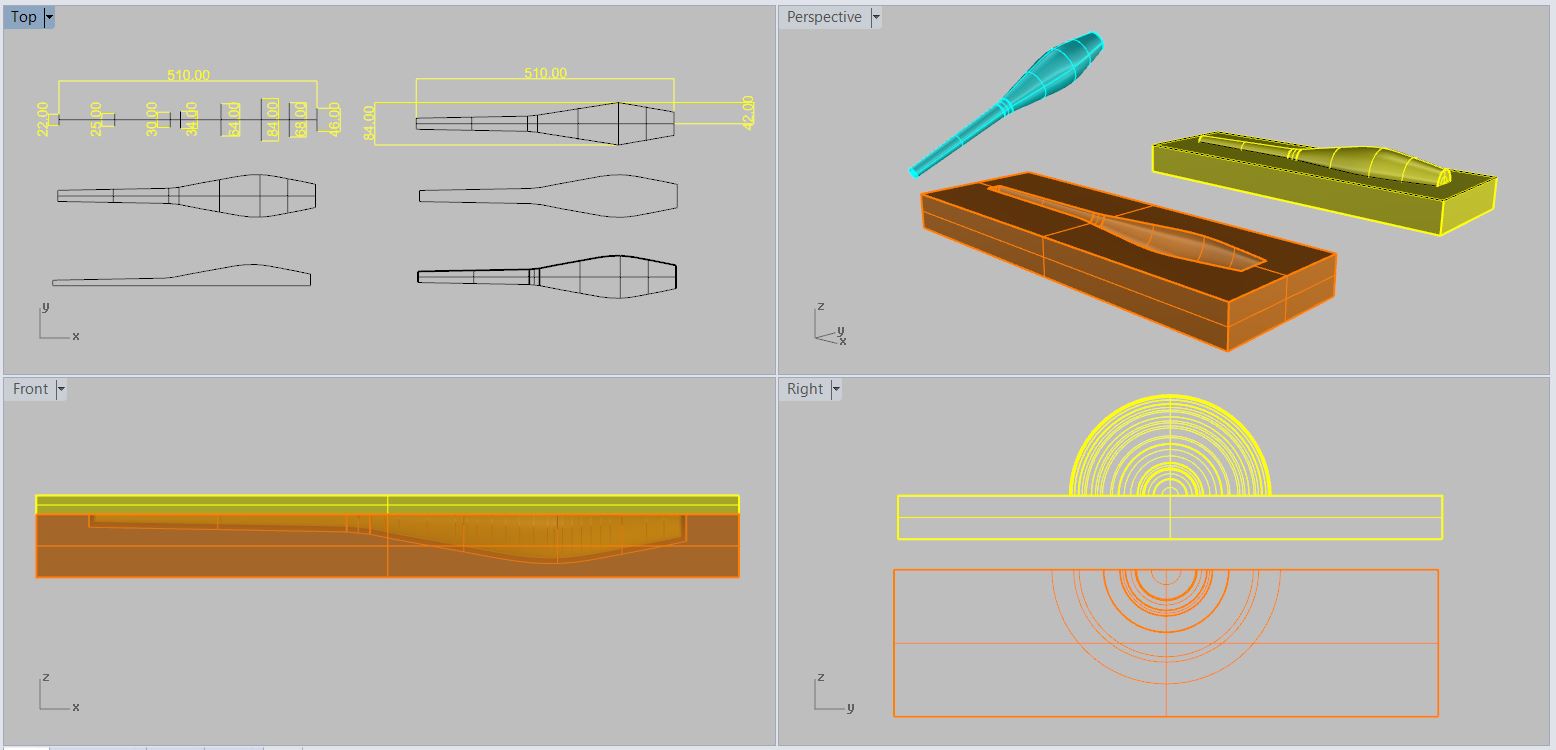

Designing 2D

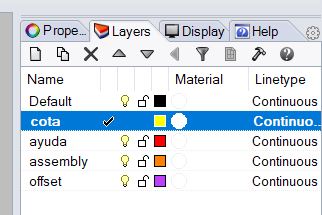

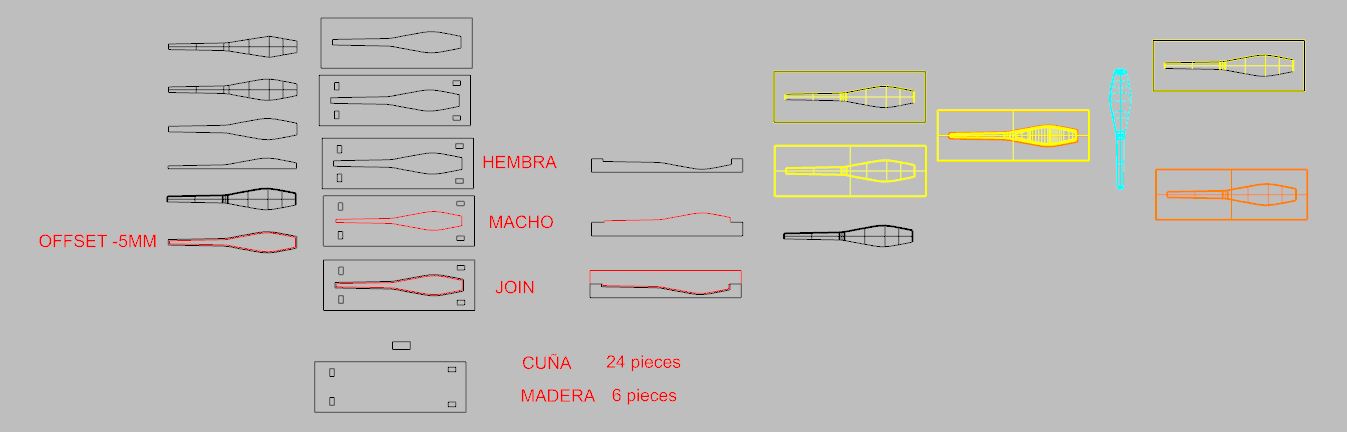

I used Rhinoceros to design my juggling club. First, I replicate my notes in Rhinoceros windows. To do lines, could use top toolbar, where digitalize a command to ejecute. I write "Line", press enter and enter the length. There are a lot of commands, so it is necessary to inquire inside Rhino to learn. Start doing circles, squares, basic forms, playing with each left-hand icon, just take time to interact with software.

Now, it is possible to add layers, change color and name of them . For example, measurements (cota) are in yellow color. It helps to recognize easily each part of your work. It allows to work orderly.

Once time I did lines, using commands I have the shape of my juggling club. One whole and other cut in half. Shape cut in half is to do my juggling club in 3D.

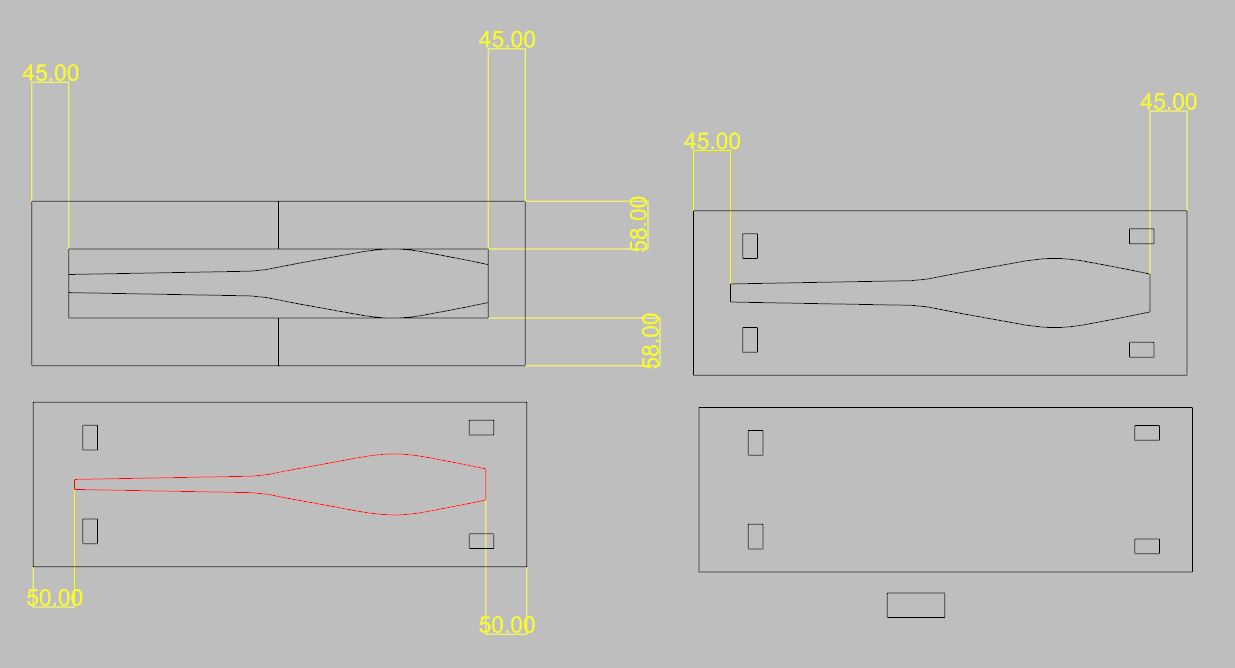

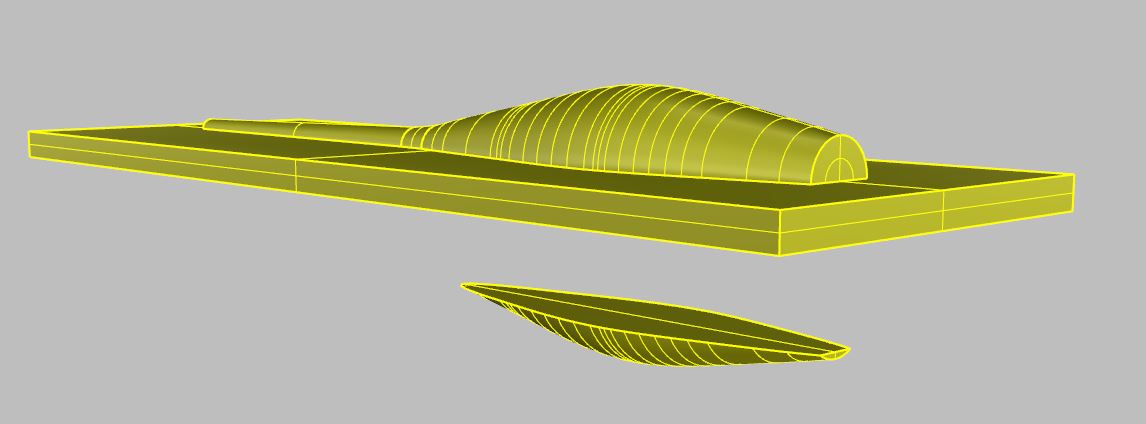

Whole shape is to do the rectangle. Which I am going to cut in plywood to obtain a wooden block (putting together three pieces of 18mm plywood). Also a little block, it is important to hold wooden block to base using screw obviously.

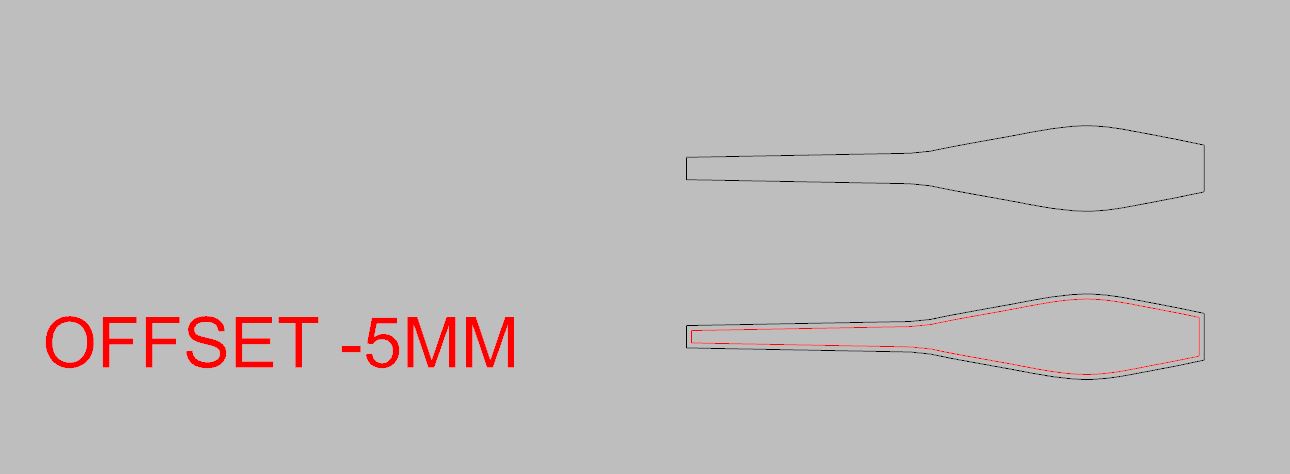

Also, I did an offset of 5mm, because beetween mold and mold there will be a space of 5mm to make composite, in this way I am going to manufacture my club. Shape normal is for mold "hembra" (this will have a gap) and offset shape is for mold "macho" (this enter into mold "hembra").

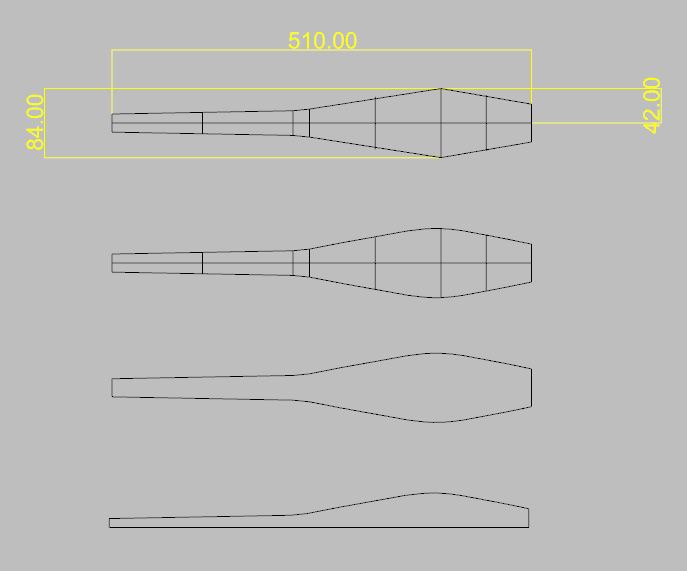

Designing 3D

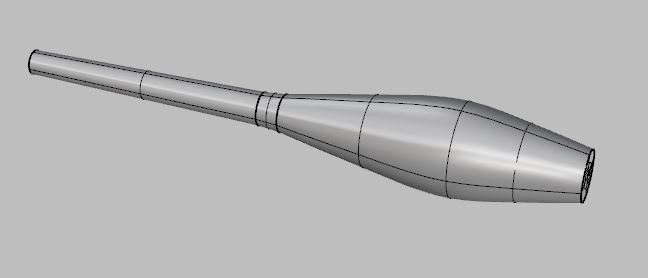

Using 2D design. I am going to design my wooden molds. First, use shape cut in half to get club solid. Using revolutionize command.

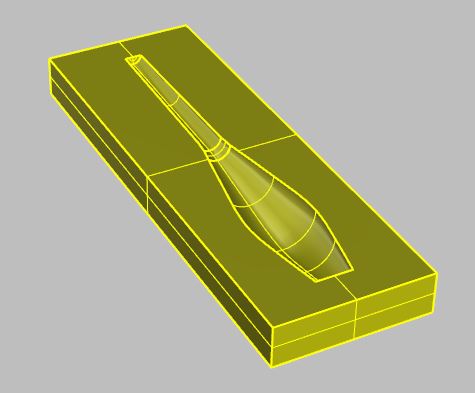

Well, I created a box to simulate 3 pieces of 18mm plywood glued. This box and club are centered and aligned. Using "boolean split" and boolean tools in general obtain our first mold, "macho part". Do the same for "hembra part". To verify If there is a space of 5mm when both molds are joined, assembly both parts to measure the space.

Files

Here my files: -Moldehembra.stl -Moldemacho.stl -Design clava.3dm [Rhinoceros]

Result

I could see even the smallest detail during my 2D design and 3D design. Because, Rhino allowed me do a lot of scrawls until to have my final version. I could copy, move, trim, split, explode, etc, etc using command toolbar and a big space to work.

As final result I have my designs and files, ready to manufacture in next assignment.