Laser cutting:

Group assignment:

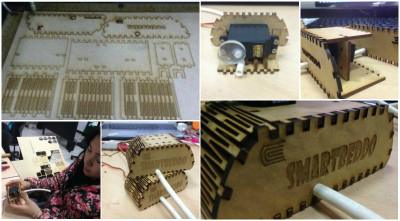

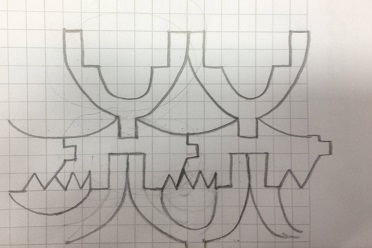

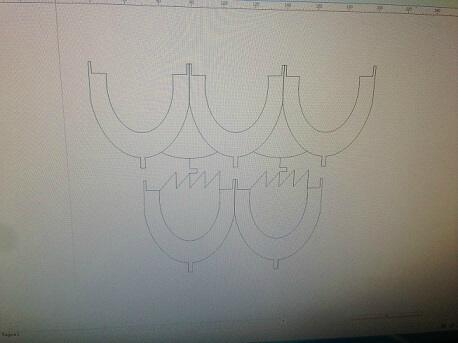

In order to carry out this assignment, we met after class and began to propose ideas for the design of the joints tester.

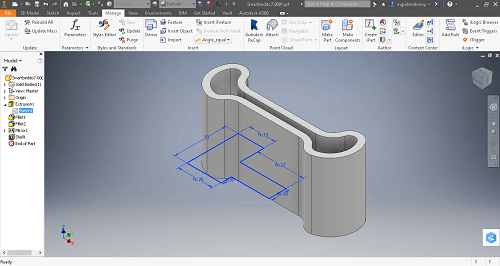

There is my "Hand Tester", we call it so for design purposes.

As you can see, we have different kind of joints there: on the fingers, between the fingers and on the palm.

This is a creative way to try if the joint will be the best choice for making the idea you have in mind.

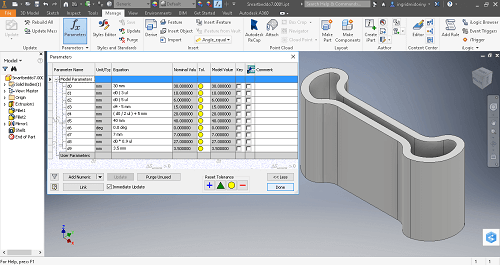

In my case, I tried the following measures: 2.8, 2.85, 2.90, 2.95, 3.00, 3.05, 3.10, 3.15, 3.20. All in millimeters. At the beginning, I had some troubles understanding why should we play with different measures but I got it finally when I started designing.

The best joint for me was 3.00 with 2.95, I worked with MDF of 3.00 mm thick.

If you try 3.00 with 3.00, the fit will be loose.

Individual assignment:

To do: to cut something on the vinyl cutter

To design, make, and document a parametric press-fit construction kit, accounting for the lasercutter kerf, which can be assembled in multiple ways

Vinyl cutting:

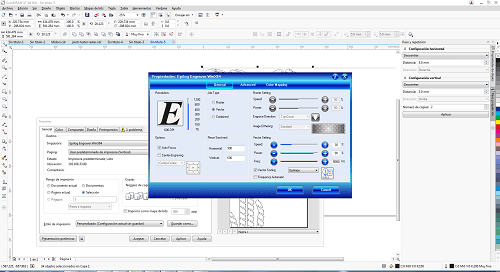

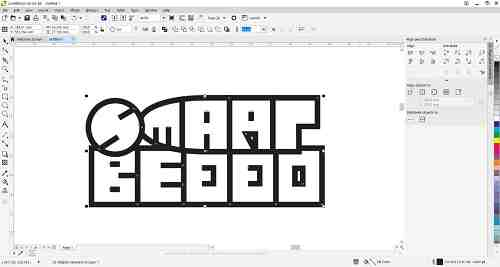

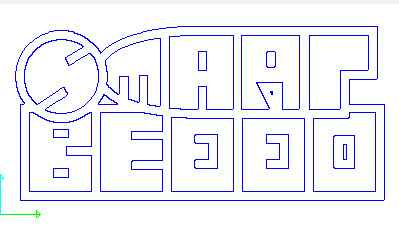

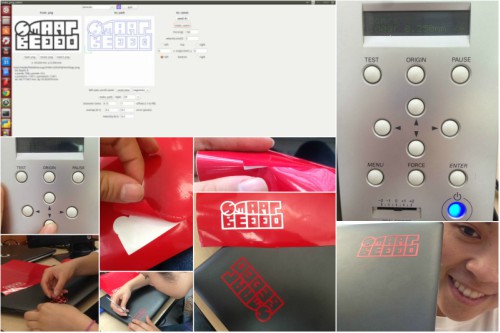

I opened CorelDrawX7 and drew my final project logo, with it I will make a sticker for my lap top.

For this challenge I use the Roland CAMM-1Servo machine.

Let's see how can we do it

First we have to export the design as .png format

The design have 4 px of contour width and 6cm*3cm of size.

Here you can download the .png format

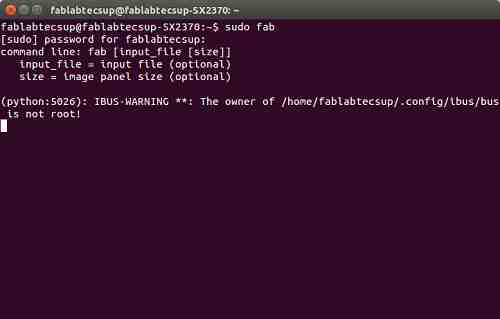

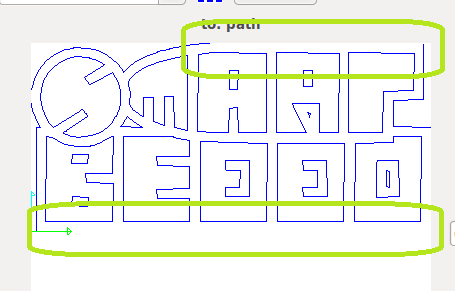

Then I had to open in Ubuntu, the software that we use for work with the Roland Viinylcutter machine

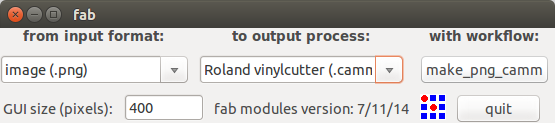

As you can see at the picture, those are the steps:

from input format: image(.png)

to output process: Roland vinylcutter (.camm)

with workflow: make_png_camm (Clicked it)

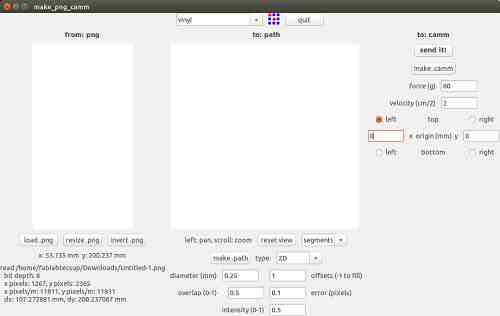

Now we have the main screen, as you can see in this part, I had to choose vinyl as material and all the options change by default.

I had to change the offsets option, wrote 1, it means that only one stroke will be made with the blade.

Change the error option, wrote 0.1, to get a better result, detail and quality. And clicked on "make .path"

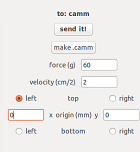

Finally, in this part before I clicked on "make.camm", I had to change the force,wrote 60, and velocity, wrote 2.

I selected "left" as origin where it will start to cut

Left "0" in "x" and "0" in "y"

I clicked on "make.camm" and after 5 min. I got my sticker.

As you can see there is a mistake, I can't got my sticker! :( so, I will try again!

First, I will analize why it happens.

My design is not correct for this format, I had to made a contour and improve it to get a best result. Also I will change the force and velocity before "make.camm"

Looks different with contour.

Parameters

Force (g): 100

Velocity (cm/Z): 5

Left

Clicked on "make.camm"

Now I will sen it !

That is how I got my Smartbeddo sticker

Press-fit construction kit:

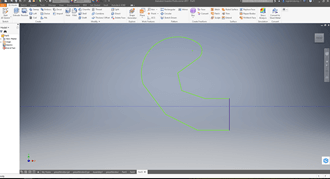

Sketch:

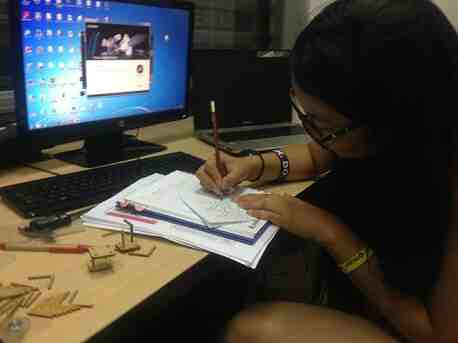

I started drawing some ideas

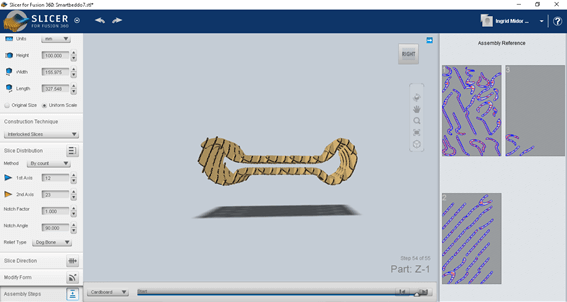

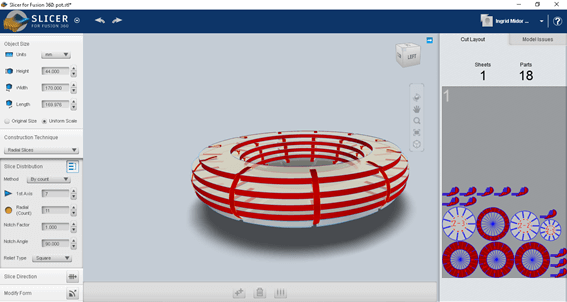

After hours, I decided to make a press fit construction kit's bag

Design:

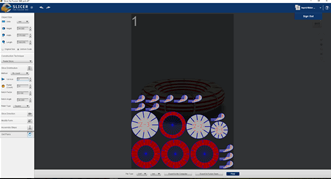

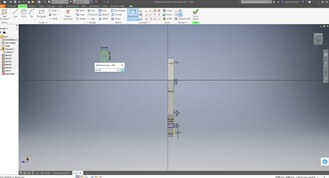

I started designing using Corel Draw. That's how I got the pieces for my bag.

Cutting:

I worked in MDF of 3mm thick. As you can see on the GIF, I planned to use these two pieces for the "weave" of the bag, with a tribal design. Then I cut them with "Epilog Legend 36 Ext" using the following parameters: Speed: 30%, Power: 80% and Frequency: 100%

I got the pieces and just cut some to try. I luckily did that. When I started to build my bag, I discovered that I did not have so much success. I learned a lot, but now I will have to re-test the changes for the observations I made.

What did not work was:

When you join A and B to fit into G, it becomes loose and does not support the pieces.

When F and E join, it is loose.

The design will not allow you to fold it to a bag unless you opt for a square style. That's an idea that does not excite me so much.