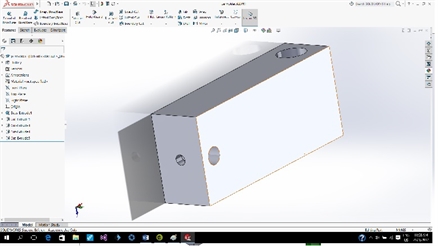

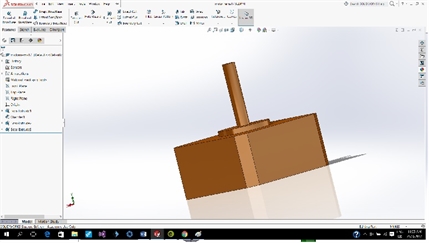

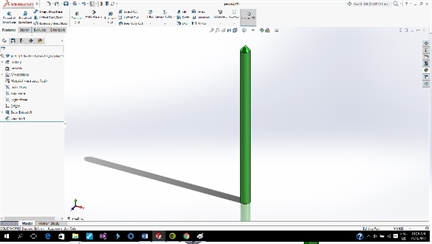

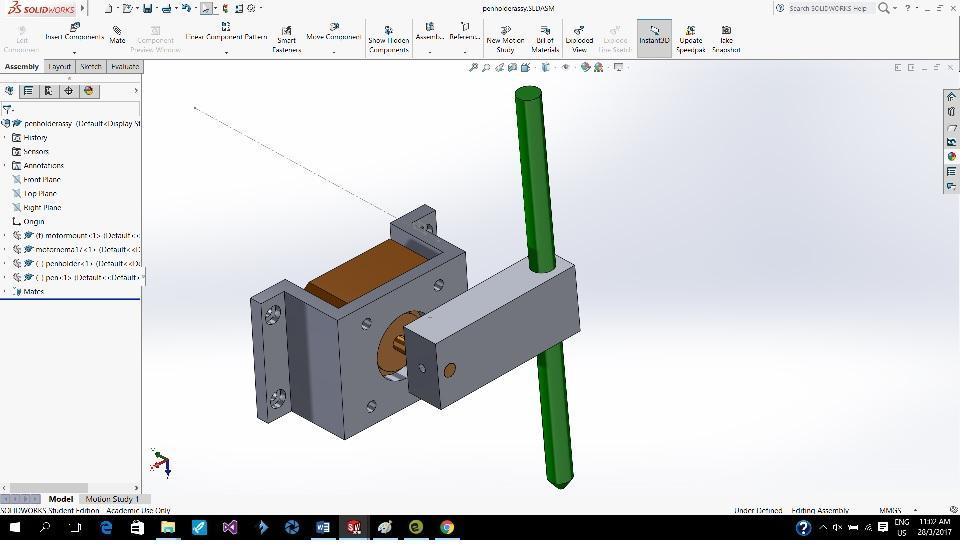

Mechanical design

Group assignment

Design a machine (mechanism+automation), including the end effector

Build the passive parts and operate it manually

document the group project and your individual contribution

Design a machine (mechanism+automation), including the end effector

Build the passive parts and operate it manually

document the group project and your individual contribution

Our Group

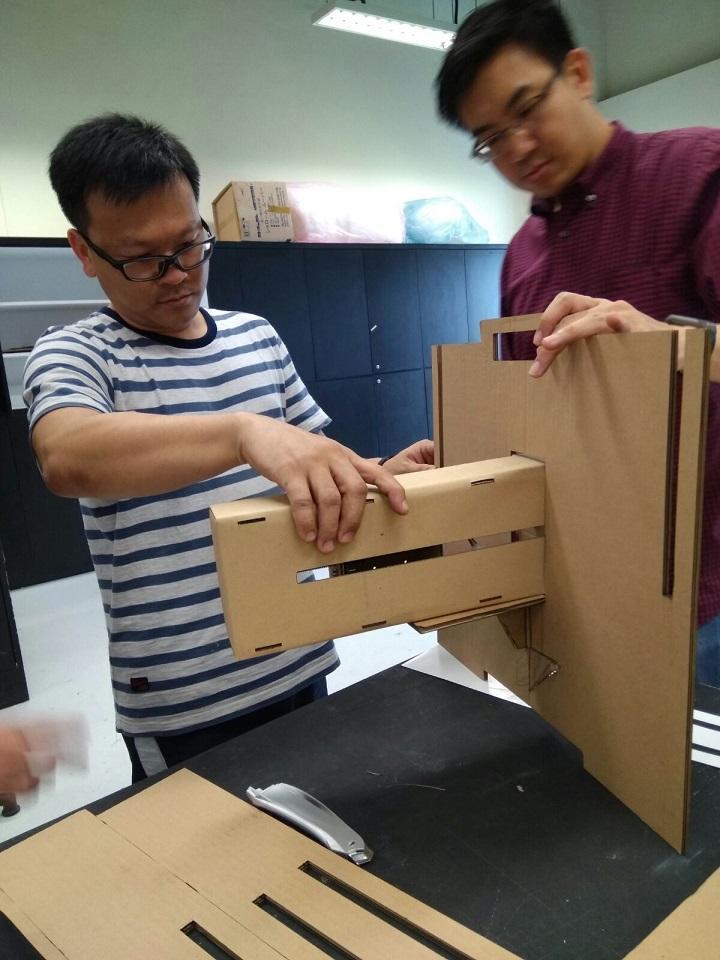

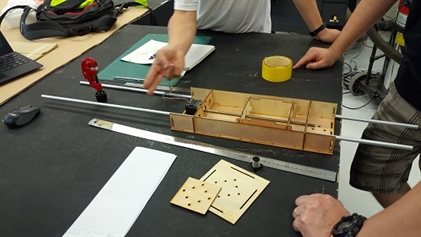

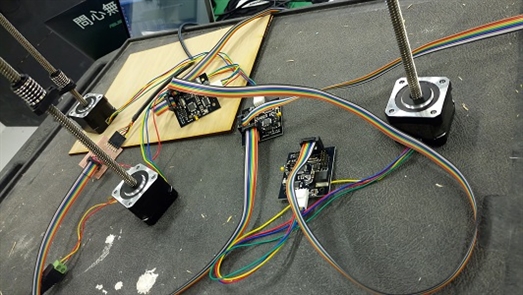

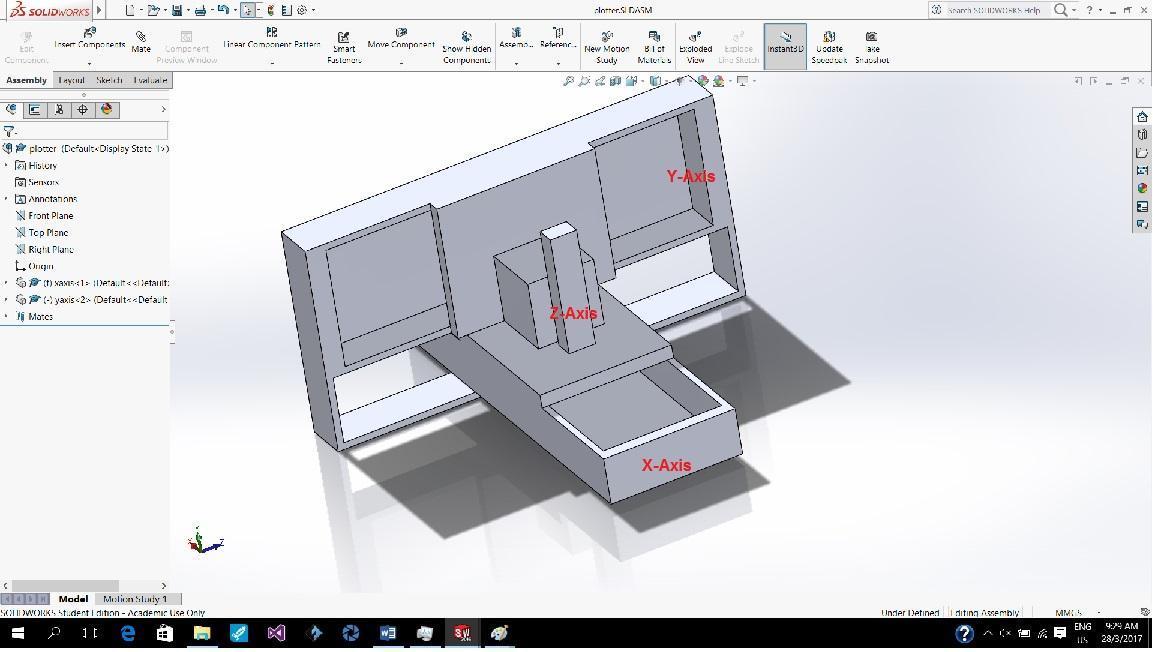

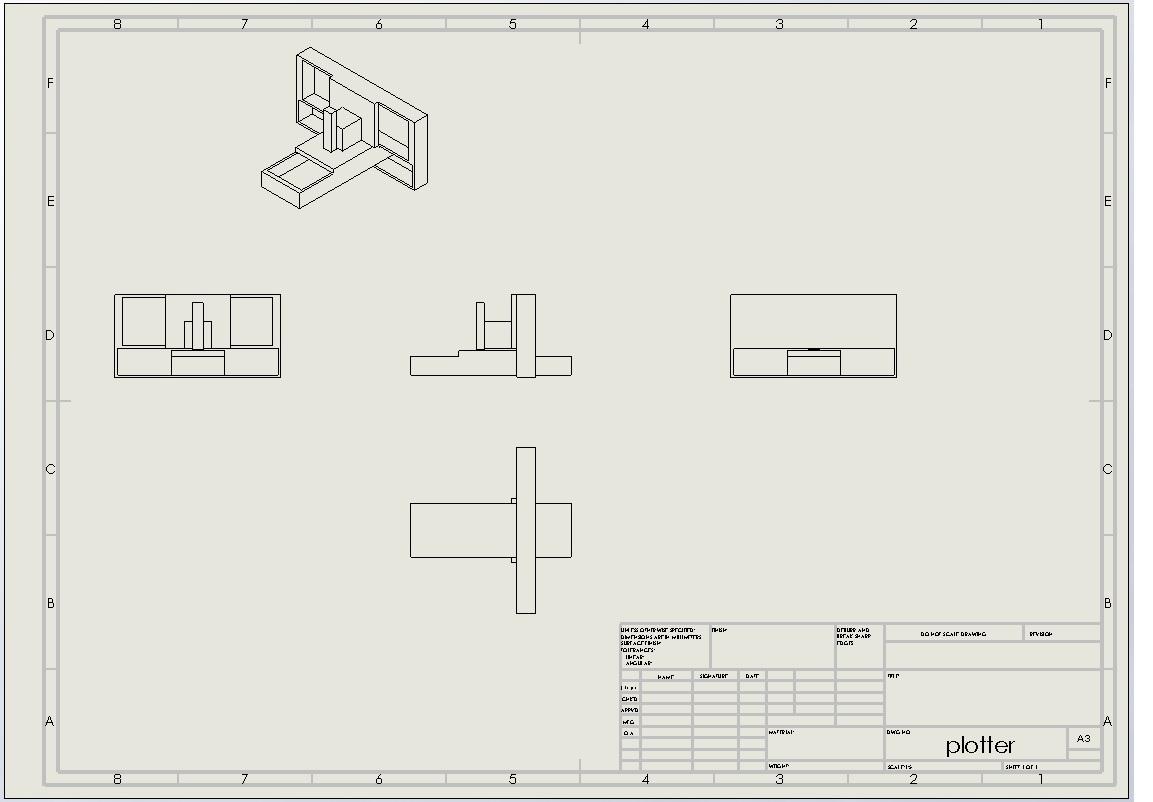

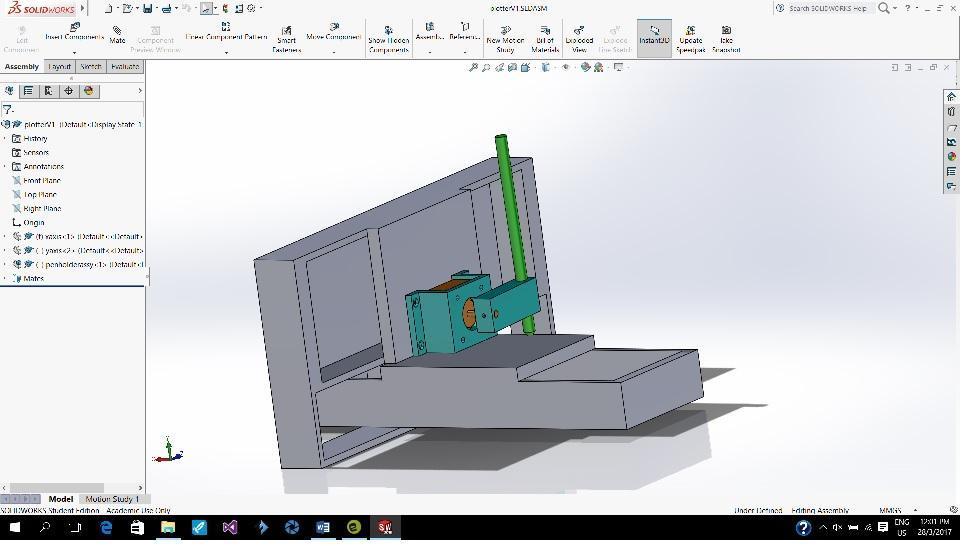

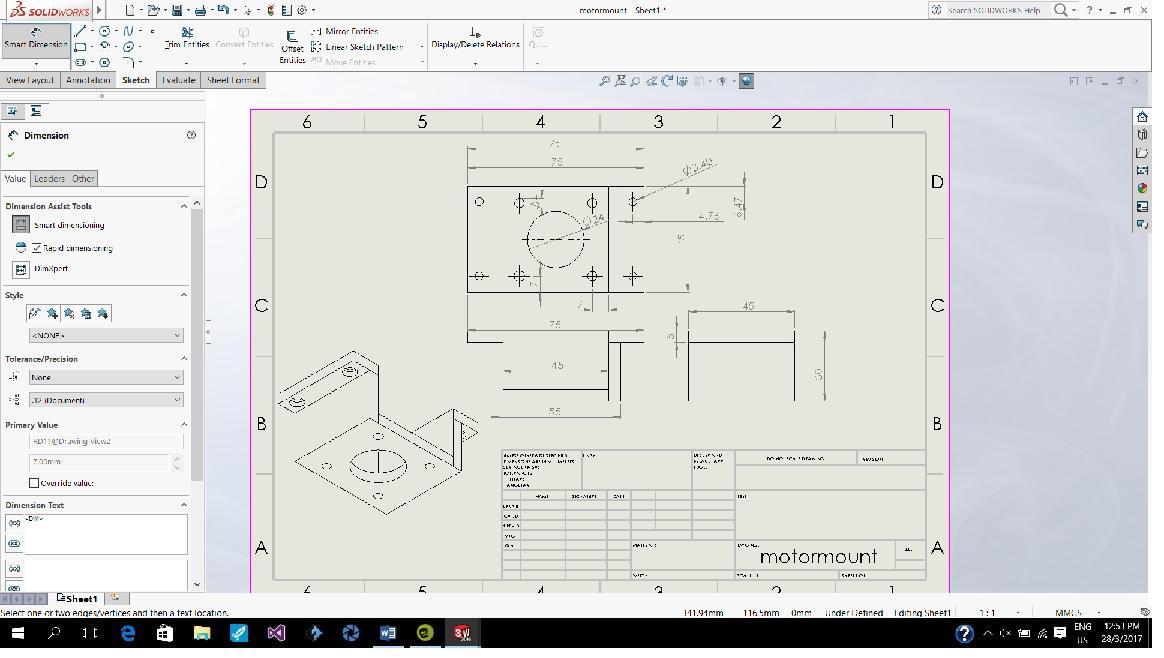

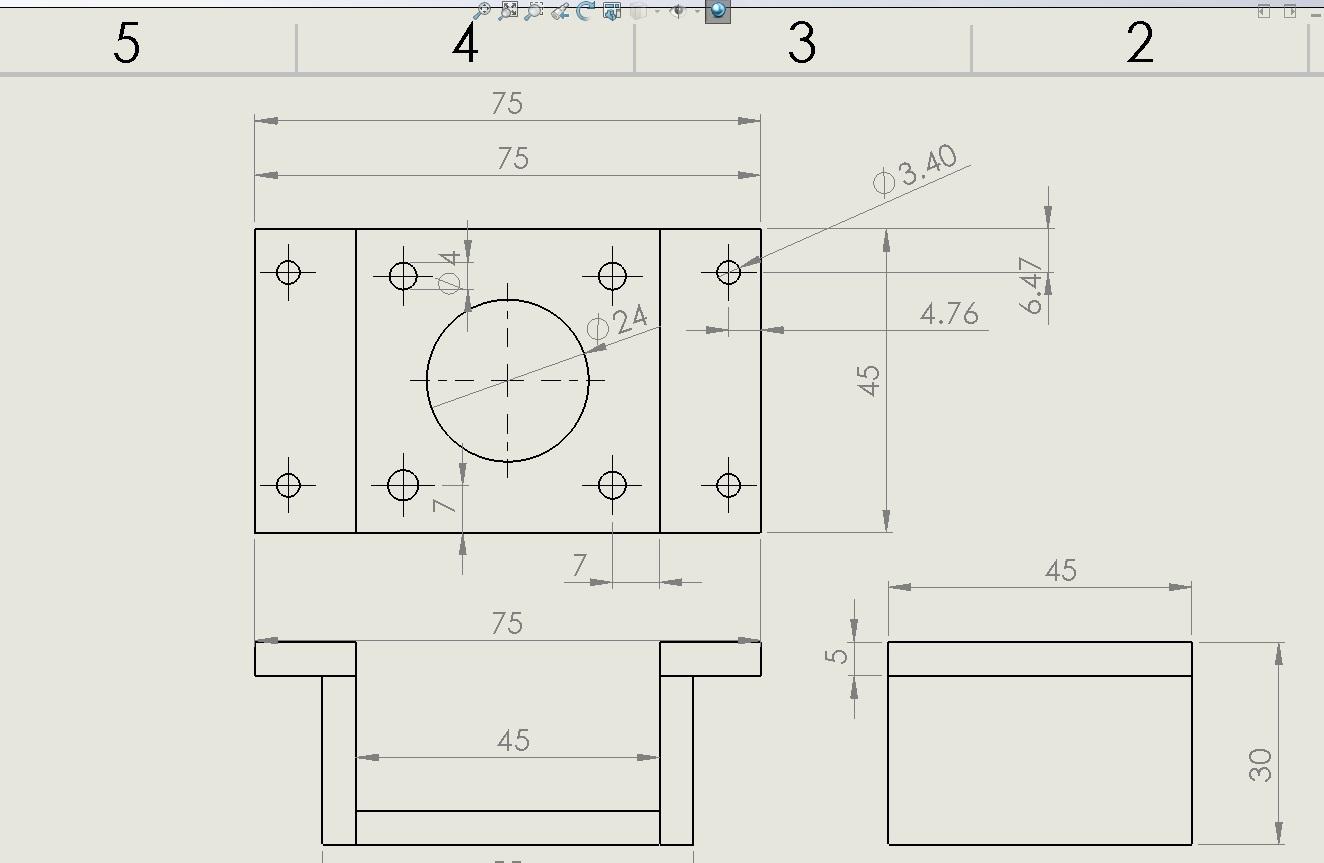

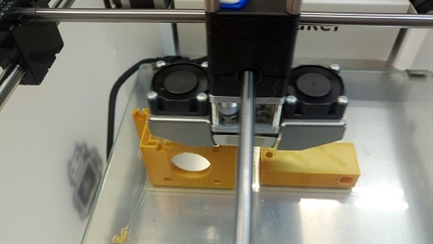

For this week’s assignment, we have form a team to design and build a 3 axis gantry type CNC pen plotter, the members of the group include:

Teo Cher Kok

Hong Guan Soh

Foo Tian Seih

Louis Goh Chong Hao

Phay Ngiap Peng Kenny

For this week’s assignment, we have form a team to design and build a 3 axis gantry type CNC pen plotter, the members of the group include:

Teo Cher Kok

Hong Guan Soh

Foo Tian Seih

Louis Goh Chong Hao

Phay Ngiap Peng Kenny