Output Device

Assignment

Add an output device to a microcontroller board you've designed and program it to do something

Add an output device to a microcontroller board you've designed and program it to do something

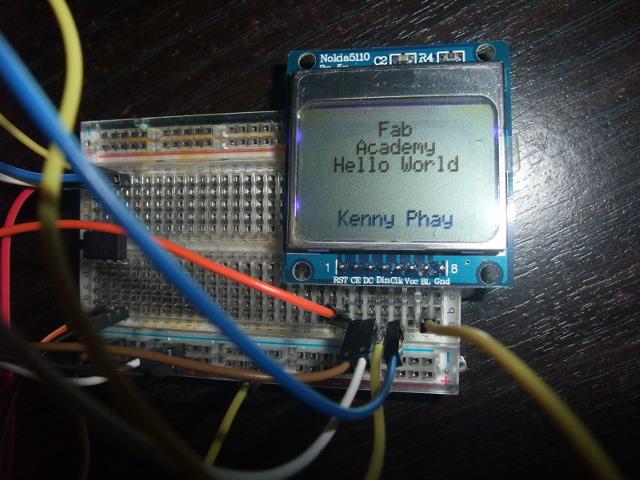

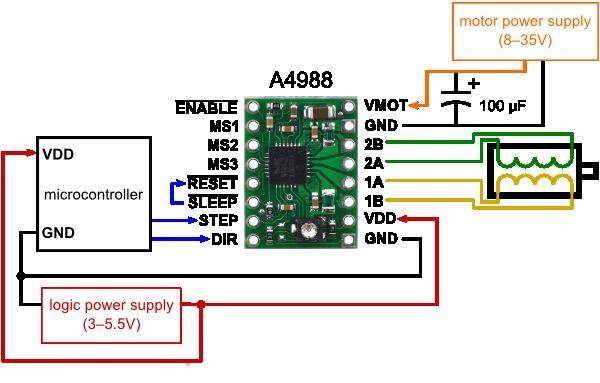

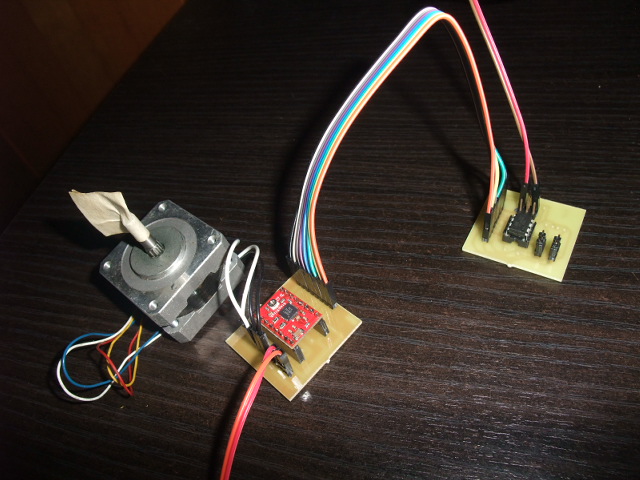

For this week assignment, I am starting to have this idea of using the weekly assignments to build up the final project, a robotic arm. For output device, I would like to have a LCD display and a stepper driver. And on input device, perhaps a keyboard or limit switch monitor board. Maybe it would be a good idea to links these devices with a RS485 or I2C during the network and communication assignment.

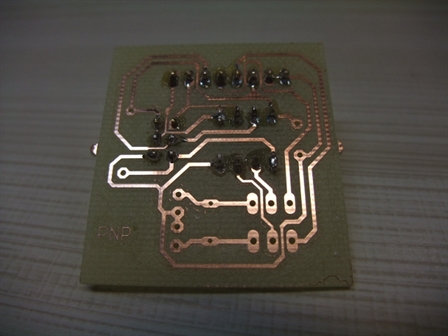

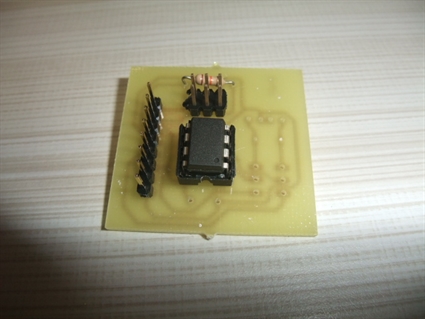

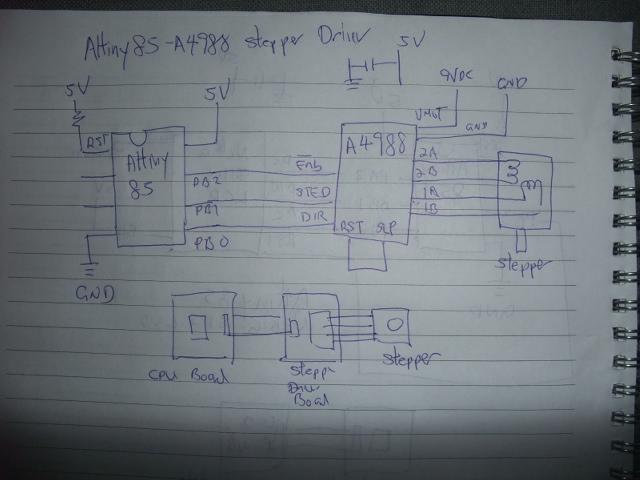

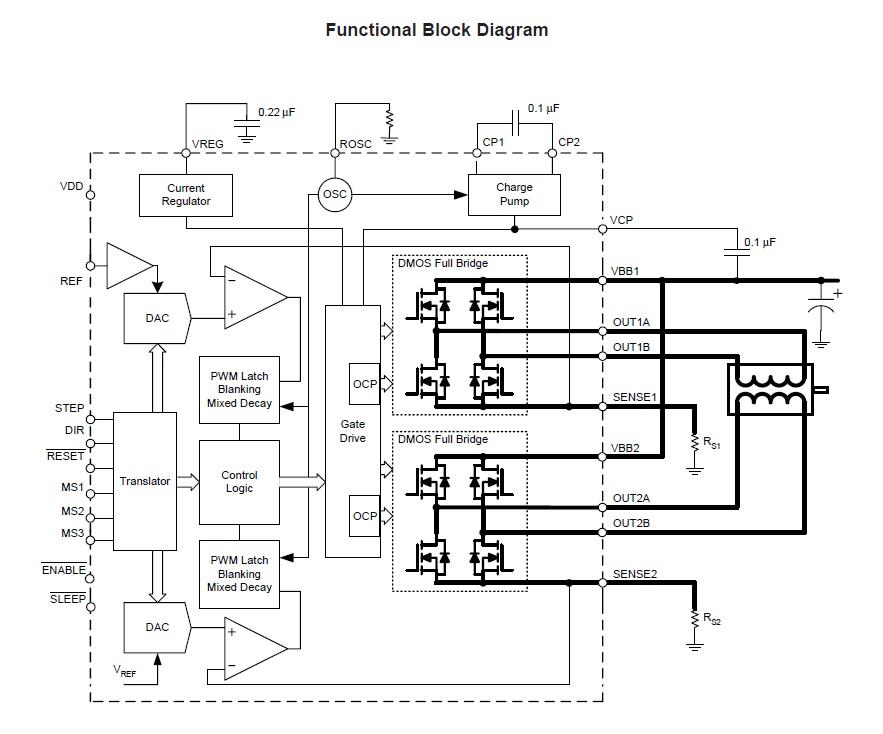

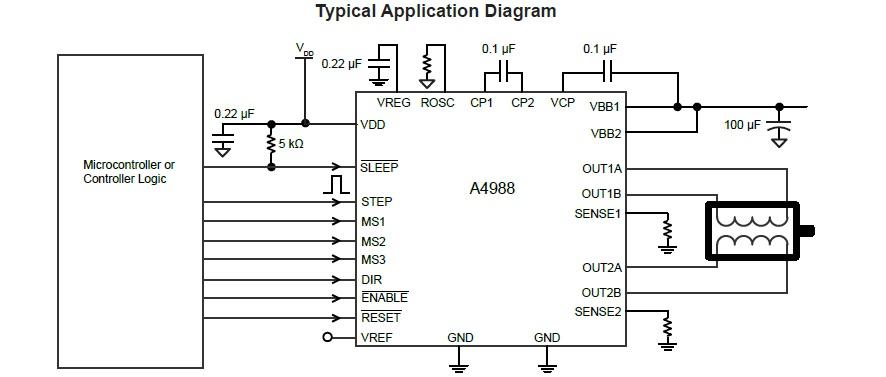

I will start with output device to make a microcontroller board based on Attiny 85, connect a graphic LCD to it as output device, program the microcontroller to display something. Next I will make a microcontroller based A4988 stepper driver board.

I will make the LCD display first to full fill the assignment requirement, the completion of the stepper driver is optional depends on how much time is left (Although I like to spend a lot of time doing this, but I still have a day job and need to keep the boss happy :])

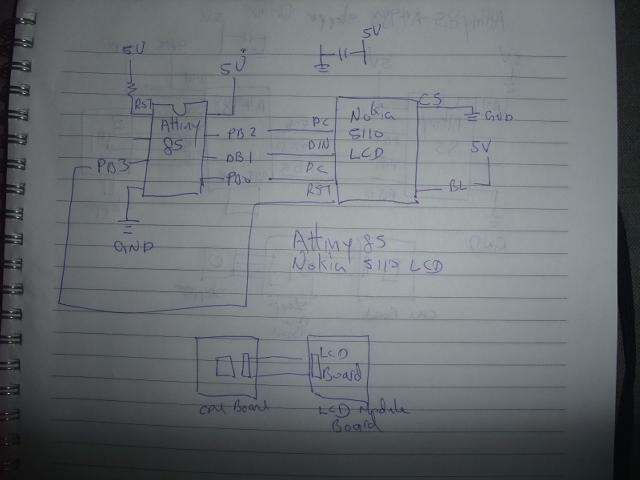

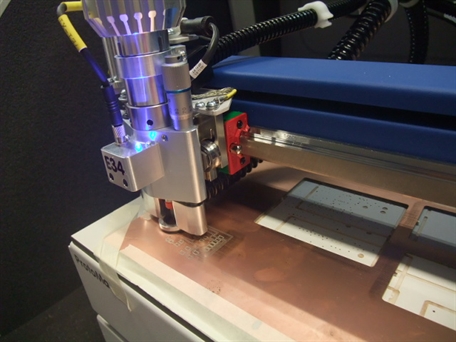

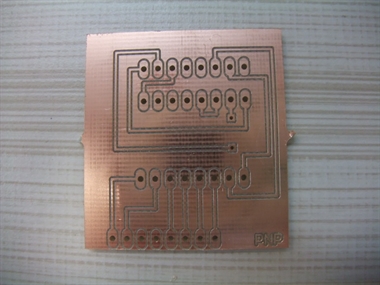

As a habit, I always start my design on paper, make sure that there is enough though given to the design and it can be turned into a real working item. Like anybody, I would look around the internet to see if there is something closely resembled what I want to do that I can modify for my purpose.(Life is too short to reinvent the wheel everytimes : ). Then I will build a test piece using breadboard to make sure that all the hardware and software are working as planned before going to the CAD station to design the PCB. This way I know that if the final product is not working, it would just be the PCB assembly process.

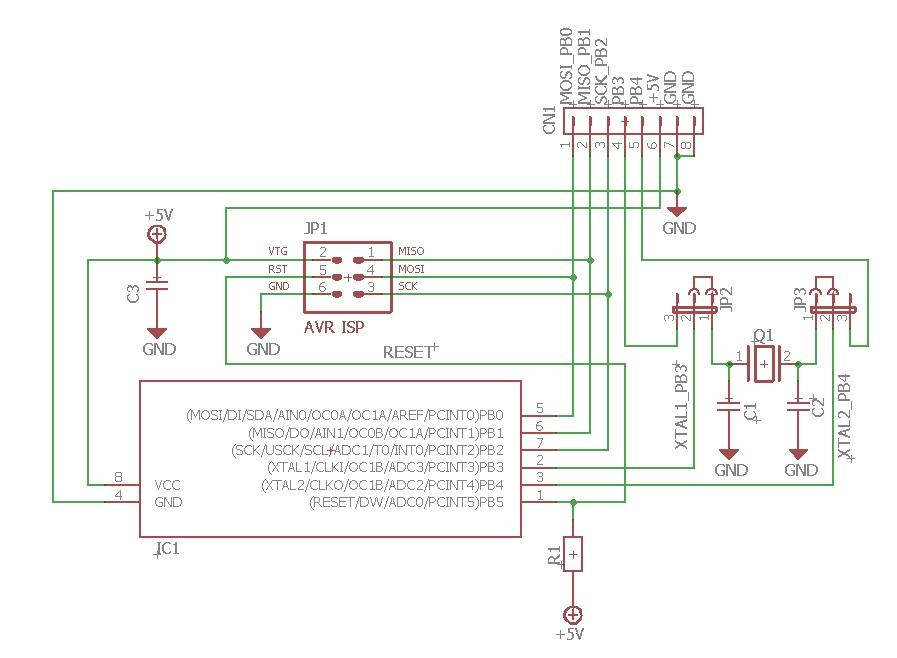

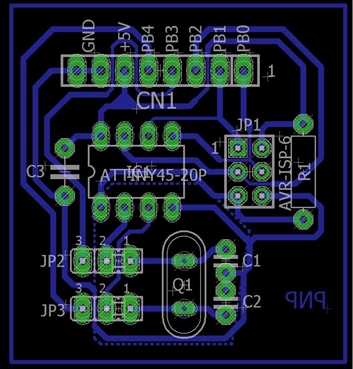

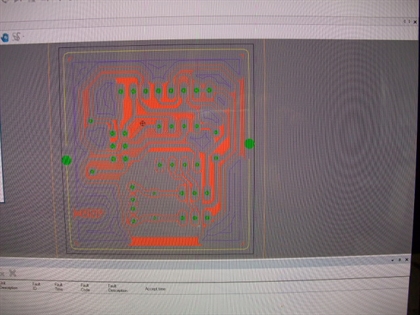

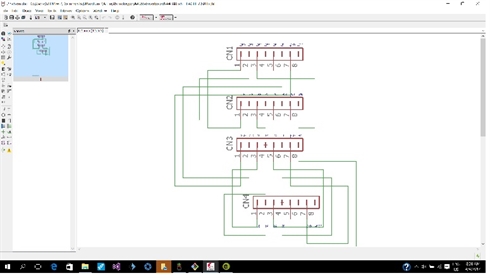

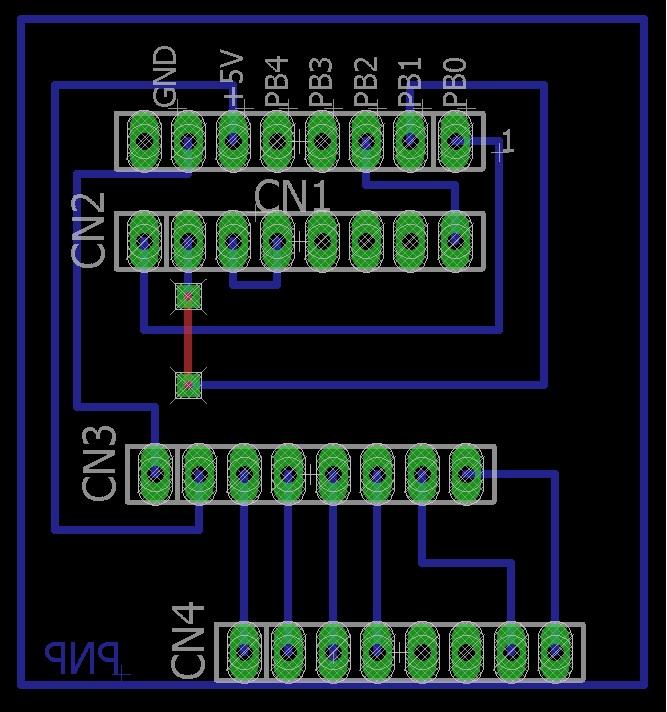

The conceptual design of the microcontroller LCD system is as shown below.

I will start with output device to make a microcontroller board based on Attiny 85, connect a graphic LCD to it as output device, program the microcontroller to display something. Next I will make a microcontroller based A4988 stepper driver board.

I will make the LCD display first to full fill the assignment requirement, the completion of the stepper driver is optional depends on how much time is left (Although I like to spend a lot of time doing this, but I still have a day job and need to keep the boss happy :])

As a habit, I always start my design on paper, make sure that there is enough though given to the design and it can be turned into a real working item. Like anybody, I would look around the internet to see if there is something closely resembled what I want to do that I can modify for my purpose.(Life is too short to reinvent the wheel everytimes : ). Then I will build a test piece using breadboard to make sure that all the hardware and software are working as planned before going to the CAD station to design the PCB. This way I know that if the final product is not working, it would just be the PCB assembly process.

The conceptual design of the microcontroller LCD system is as shown below.