Until 31 May 2017

applications and implications

Contents

- what will it do?

- who's done what beforehand?

- what materials and components will be required?

what parts and systems will be made?

what processes will be used?

- where will they come from?

how much will it cost?

- what tasks need to be completed?

what questions need to be answered?

what is the schedule?

what will it do?

Wearable device that tracks body(shoulder, thigh or calf) movements data from bouldering, boxing and other activities. Advance climber every move is calculated, rhythmic, minimizing energy expenditure. The tilt sensor data will get collected and shown through the LEDs attached on the device. I will make this wearable sensors mostly using 3D printing, laser cutting, molding and casted silicone. After careful observation in the bouldering gym, I realized that bands and body tapping is often used. It will be enough structure to hold my device.

who's done what beforehand?

- MoMoB Modular Body Sensors_ by Citlali in 2016 Fab Academy.

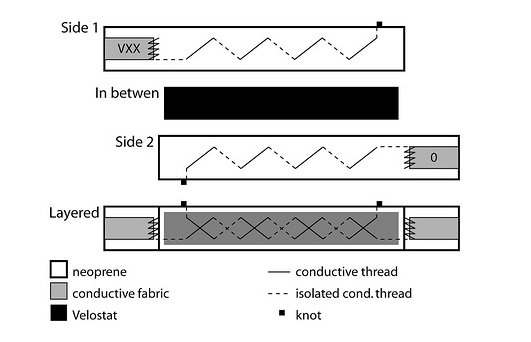

- Dangerous Tilt_ by Hannah Perner-Wilson

<

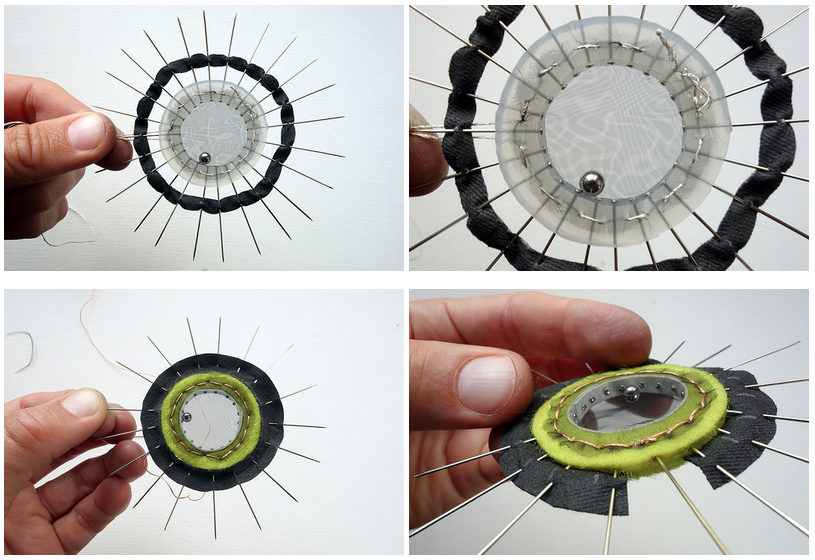

- Pin Tilt Sensor_ by Plusea

- Mi.mu_Creating music through movements with wearing gloves.

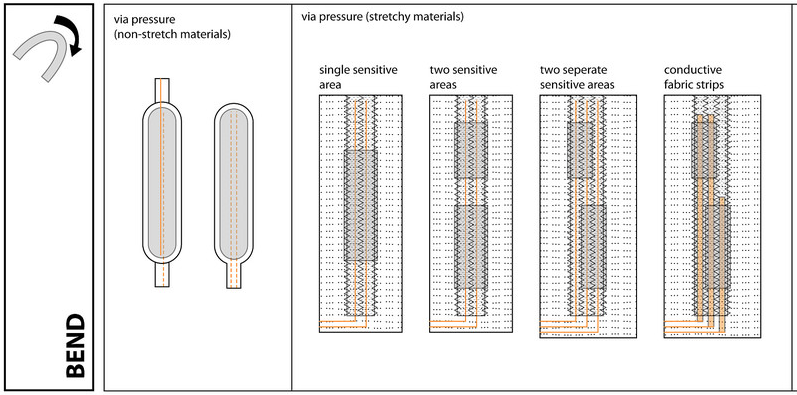

- Neoprene Bend Sensor_by Kobakant.

- Resistive sensor_ by Kobakant.

what materials and components will be required?

what parts and systems will be made?

what processes will be used?

Device

Materials: Smooth-on Mold Star 16 Fast Platinum Silicone., PLA 3D Printed, Acrylic.

Technique: Molding and castering(CNC & silicone), Laser cutting(Fabric), 3D Print and Electronic Production(PCB)

Tilt Sensor

Materials: Pins, conductive thread, regular thread, felt(thick fabric/leather?), conductive ball, Acrylic

Tools: Laser cutting acrylic first then sew everything together.

Electronic Design, Production Embedded & Programming

Software: Eagle

Materials: PCB

Tools: Roland SRM-20

Software: Arduino IDE

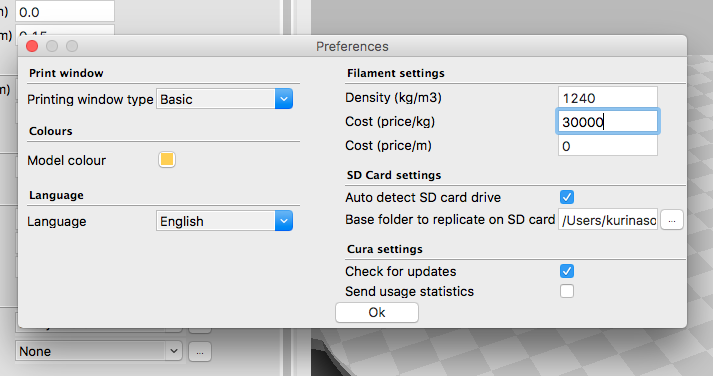

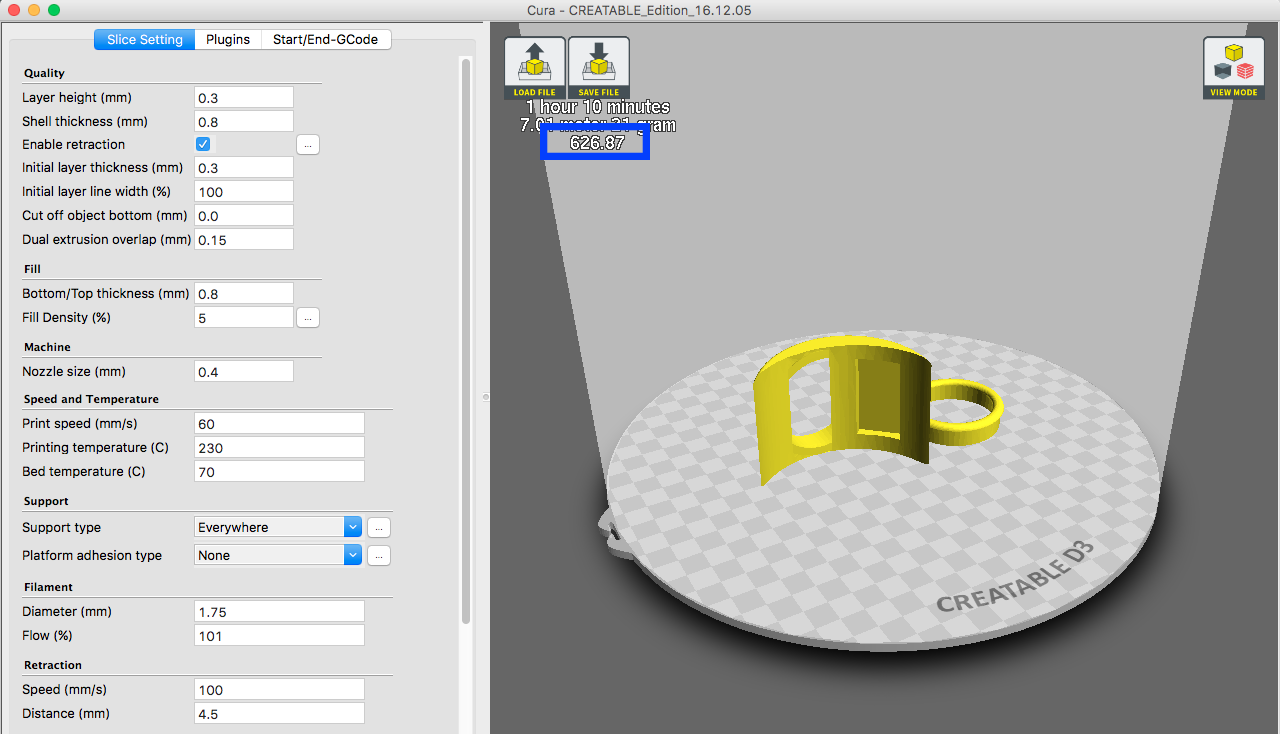

Side-note: getting cost from Cura Software.

Total of 626.87 won, so about 60 cents.

where will they come from?

how much will it cost?

- 3D Print: 60cents ~ a dollar.

- Smooth-on Silicone 5L is 300 dollars, but I only used about 10 dollar worth.

- Construction Foam(local store), around 2 dollar.

- Full copper board is around 4 dollars so 1/6 PCB board would be 67 cents.

- Clear acrylic(local store) is 1.5mm is 8 dollars, so around 1 dollar or less.

- Bearing balls(local store) one ball is less than 50 cents.

- Attiny 44(digikey) is 40 cents, other components about one dollar.

Total of more or less 17 dollars.

what tasks need to be completed?

what questions need to be answered?

what is the schedule?

So much work left to do. I have completed in testing soft potentiometer and tilt sensor. Made Eagle file and cut PCB, bootload, and code. I still need to make mold and 3D Print the device.

How will it be evaluated?

- Hopefully evaluated by the improvements in my skills

- the ideas

- the trials and failures